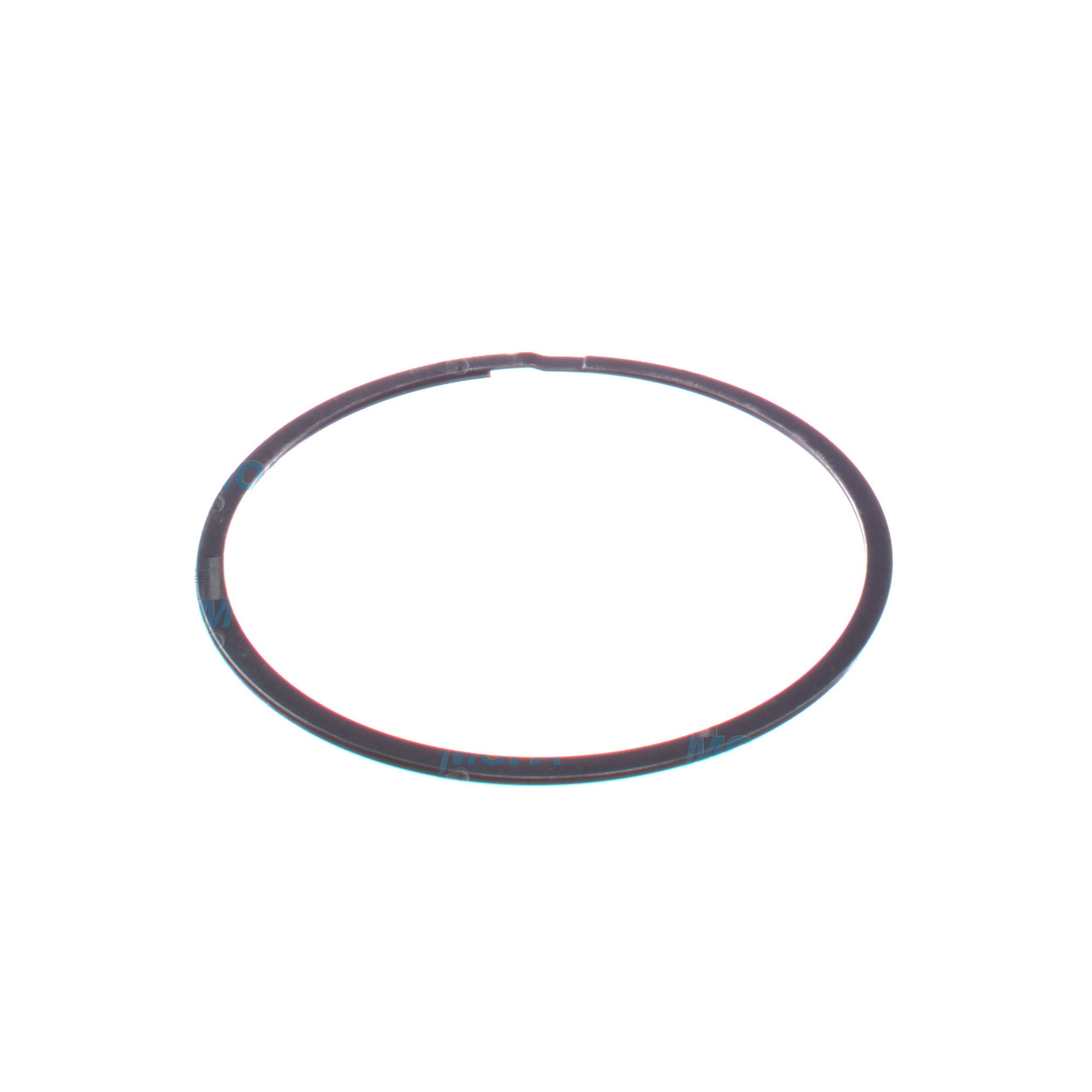

MULTIPIECE OIL RING Piston Rings for Diesel and Marine Engines

Piston rings are precision-engineered sealing and oil-control components that sit in the grooves of the piston and interface with the cylinder liner. In every diesel or gas engine—whether a compact generator set or a large-bore marine engine—piston rings protect compression, manage lubrication, and transfer heat away from the piston crown. As a result, they are fundamental to fuel efficiency, emissions control, and the long-term reliability of the power unit.

Within the ring pack, the MULTIPIECE OIL RING works alongside the compression and scraper rings to stabilize the oil film and prevent oil from entering the combustion chamber. When properly selected and maintained, a high-quality piston ring set ensures clean combustion, low oil consumption, and consistent performance across the entire duty cycle, including frequent load changes and high thermal loads.

Technical function of piston rings with MULTIPIECE OIL RING in a diesel engine or marine engine

Piston rings perform three core tasks: gas sealing, oil control, and heat transfer. The top ring provides the primary gas seal and is often barrel-faced or keystone-shaped to manage ring twist and conform to the liner. The second ring supports sealing and scrape-back, reducing blow-by and stabilizing ring dynamics at mid-stroke. The MULTIPIECE OIL RING, typically built from two thin steel rails and a central expander, maintains an optimal oil film on the liner while returning excess oil to the crankcase. In a diesel engine, this prevents oil carry-over that would otherwise increase particulate emissions and foul the turbocharger and exhaust passages. In a marine engine, stable oil control is equally important to protect the liner surface during slow steaming and at high continuous loads.

Gas pressure behind the compression rings enhances radial contact, while precisely calibrated tangential force keeps each ring seated against the liner. Correct side clearance in the grooves prevents sticking, and an engineered free gap ensures that thermal expansion at operating temperature does not cause ring ends to butt. The MULTIPIECE OIL RING OEM parts design provides reliable conformability in worn or thermally distorted bores, leveraging expander force and rail flexibility to maintain effective scraping without damaging the oil film needed for hydrodynamic lubrication.

Material and surface technology further shape performance. Alloyed cast iron and steel rings with coatings such as chromium, molybdenum, or PVD/nitride resist scuffing and micro-welding. Profiled ring faces manage contact pressure distribution, limiting liner wear and ring flutter at high RPM. In heavy-duty service, these features translate into stable compression, lower specific fuel consumption, and safer operation under high cylinder pressures.

- · Robust gas sealing for stable compression.

- · Precise oil control via MULTIPIECE OIL RING rails and expander.

- · Efficient heat transfer from piston to cylinder liner.

- · Optimized ring profiles to reduce wear and ring flutter.

- · Coating technologies that resist scuffing and corrosion.

- · Calibrated tangential force for consistent liner contact.

- · Dimensional accuracy for proper groove fit and end gap.

Importance for engine operation and service life

Healthy piston rings are critical to engine uptime and lifecycle cost. When rings wear or lose tension, blow-by rises, crankcase pressure increases, and compression drops—leading to poor starting, reduced power, and higher fuel consumption. Insufficient oil control causes elevated lube oil make-up, blue smoke, and deposit formation on pistons, valves, and turbocharger components. Persistent oil carry-over accelerates aftertreatment fouling and raises emissions. If ring side clearance is out of spec or deposits cause ring sticking, hot spots and boundary contact can trigger scuffing of the liner—an expensive failure with long downtime. In large marine engines, compromised sealing can also destabilize combustion across cylinders, adding mechanical stress to bearings and increasing the risk of unplanned off-hire.

Regular inspection of ring end gap, groove side clearance, ring height, and liner wear pattern—combined with timely replacement—protects the engine’s core assets: pistons, liners, and turbocharger. The relatively low cost of a correctly matched ring set prevents disproportionately high costs arising from excessive oil consumption, overhauls, and fuel penalties.

Advantages of OEM spare parts suitable for Piston Rings

Choosing OEM spare parts suitable for piston rings aligns ring geometry, materials, and surface finishes with the engine’s design intent. This alignment ensures the correct interaction between ring face profile, tangential load, and liner honing pattern, which is essential for fast, controlled bedding-in after overhaul and for long intervals between services. Precision in groove fit, back clearance, and free gap minimizes the risk of ring sticking or end-gap butting under thermal load.

With OEM spare parts suitable for piston rings, purchasers and superintendents gain predictable performance and stable operating costs. Dimensional consistency across batches supports fleet standardization, simplifies inventory, and reduces installation time. Traceable production and documented specifications help technical decision-makers comply with class and audit requirements, while consistent oil control helps maintain clean exhaust paths and protect turbocharger efficiency. In practice, this means higher reliability, longer service life of liners and pistons, and better budget control across maintenance cycles.

MOPA: experienced partner for OEM parts and MULTIPIECE OIL RING piston rings

MOPA is a reliable partner for OEM spare parts suitable for piston rings, including MULTIPIECE OIL RING solutions for diesel and gas engines. Our focus on speed, quality, and security in the trade of OEM parts helps operators minimize downtime and maintain stable engine performance. We support marine engine and power plant customers with rapid sourcing, careful packaging that protects ring ends and coatings, and documentation aligned with technical and logistical requirements.

From advisory support on ring selection and clearances to swift deliveries from strategically positioned inventories, MOPA enables maintenance teams to execute overhauls on schedule and with confidence. The outcome is a cleaner combustion process, reliable oil control, and the performance consistency that fleets and plants expect from their engines.

Conclusion: MULTIPIECE OIL RING piston rings remain essential

Piston rings—and especially a well-matched MULTIPIECE OIL RING—are decisive for sealing, oil control, and the overall efficiency of diesel and marine engines. OEM spare parts suitable for piston rings secure the intended performance, extend service life, and protect budgets through predictable, reliable operation.