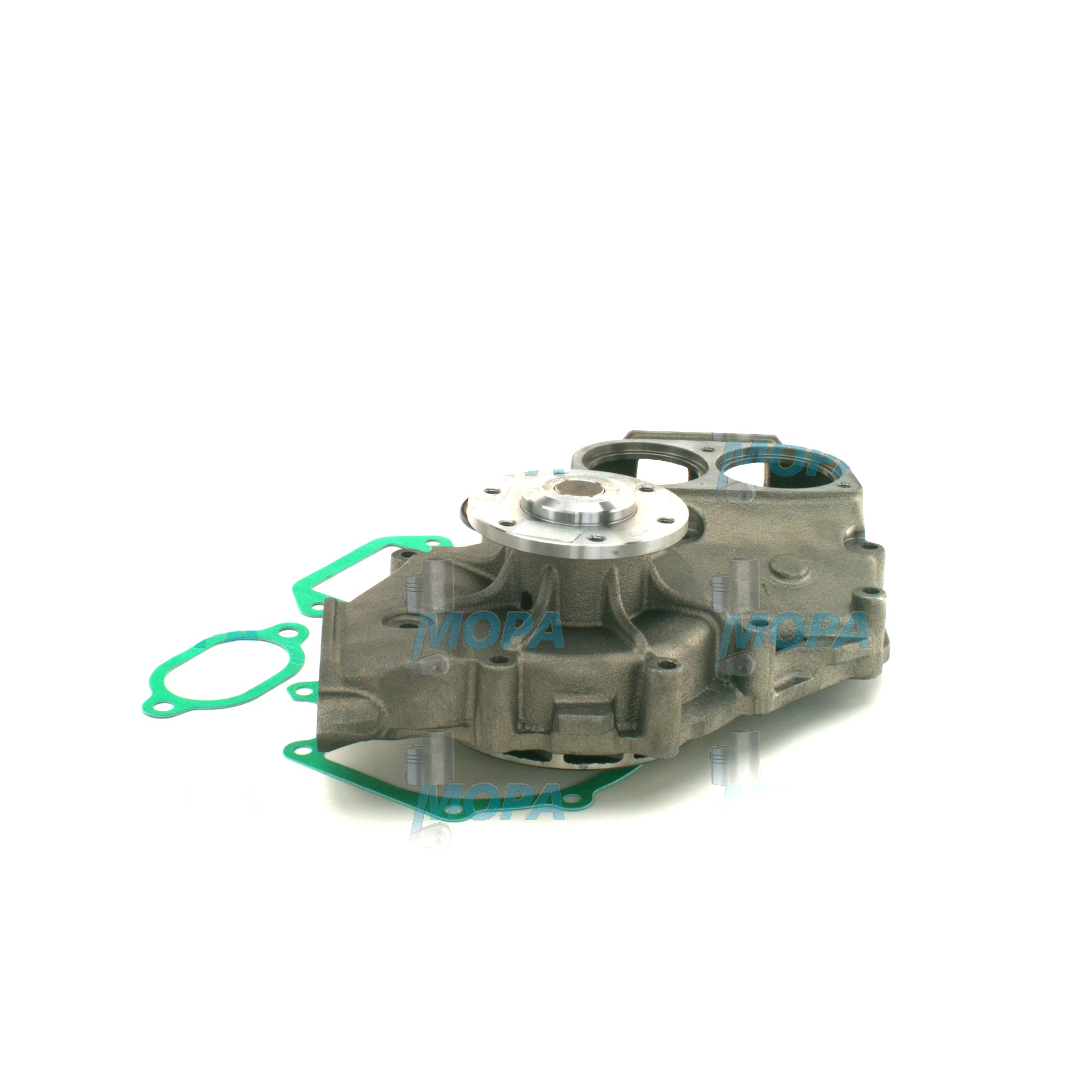

COOLING WATER PUMP – Pumps, parts and accessories for demanding engine applications

Pumps, parts and accessories form a critical component group in every propulsion and power-generation system. In marine and stationary contexts, they move coolant, seawater, fuel, lube oil and other media reliably through the engine and its auxiliaries. Within this category, the COOLING WATER PUMP is central to temperature control, while complementary accessories such as impellers, wear rings, mechanical seals, bearings, housings, gaskets and couplings ensure stable, efficient operation. For purchasers, shipowners and technical teams, choosing the right pumps and precisely matched spare parts is essential to prevent downtime, safeguard the asset and maintain predictable operating costs.

Whether specified for a marine engine or a land-based diesel engine, the right combination of pump hydraulics, materials, sealing technology and drive configuration determines how well an engine holds its design temperatures and maintains efficiency. Pumps, parts and accessories are therefore not just consumables; they are performance components that directly influence fuel burn, emissions, and the longevity of major engine parts.

Technical function: how a COOLING WATER PUMP and related pumps keep a marine or diesel engine in balance

A COOLING WATER PUMP circulates jacket water through the engine block, cylinder heads and heat exchangers, maintaining the designed temperature gradient between hot and cold circuits. In a marine engine, two circuits are often present: a closed jacket-water loop handled by a centrifugal pump, and a seawater loop managed by a raw-water pump feeding plate or shell-and-tube exchangers. In diesel engine power plants, the same principle applies, with closed-loop coolant running through radiators or cooling towers. The pump’s duty point (flow and head) is matched to engine displacement, heat rejection and permissible delta-T, ensuring sufficient coolant velocity to prevent hot spots and reduce scale deposition.

Beyond the core COOLING WATER PUMP, this category includes fuel transfer and booster pumps, lube oil pumps, bilge and ballast pumps, and all associated accessories. Properly engineered impellers, wear rings and volutes achieve high hydraulic efficiency, while mechanical seals and packing sets prevent leakage at the shaft. Bearings and couplings stabilize the rotating assembly, and corrosion-resistant materials—such as bronze, duplex stainless or coated cast iron—combat seawater attack and cavitation erosion. Correct Net Positive Suction Head (NPSH) margins, priming provisions, and alignment practices further reduce the risk of cavitation, vibration and premature wear.

- · High-efficiency hydraulics for stable flow and head.

- · Corrosion- and erosion-resistant metallurgy for marine duty.

- · Precision-balanced impellers to minimize vibration.

- · Robust mechanical seals and bearings for leak-tight operation.

- · Tight dimensional tolerances for reliable fit and alignment.

- · Accessory kits (gaskets, O-rings, wear rings) for complete service jobs.

- · Configurations for marine engine and diesel engine installations.

Correct operation depends on the interaction of hydraulics and control elements. Thermostats modulate coolant routing, and the COOLING WATER PUMP must respond with sufficient flow at varying engine loads. On vessels, raw-water strainers and anti-fouling measures protect the seawater side; on land, glycol mix, additive packages and filtration protect the jacket-water loop. When specified as COOLING WATER PUMP OEM parts, tolerances, seal faces (e.g., SiC/SiC or carbon/ceramic), elastomer compatibility (EPDM, FKM) and shaft hardness are aligned with engine-maker requirements for predictable performance.

Why pumps, parts and accessories are critical for engine reliability and life

Temperature control is directly linked to engine health. If a COOLING WATER PUMP loses efficiency due to impeller wear or cavitation, coolant velocity falls and local boiling can occur in high-heat zones, leading to liner scuffing, warped heads or cracked exhaust valves. Seal degradation can introduce air into the loop, causing flow instability and oxidation of coolant additives. On the seawater side, leakage risks saltwater ingress to machinery spaces and corrosion. In fuel and lube circuits, pump wear manifests as pressure dips, inadequate hydrodynamic film formation and accelerated bearing wear.

Common failure modes include misalignment causing bearing failure, scaling and biofouling reducing exchanger efficiency, elastomer incompatibility with coolant chemistry, and stray-current or galvanic corrosion on seawater pumps. Any of these can elevate engine outlet temperatures, enlarge delta-T beyond specification and drive up fuel consumption. Unplanned stops, class non-conformities and emergency repairs are the costly outcome when pumps and accessories are not maintained or correctly matched.

Advantages of OEM spare parts suitable for pumps, parts and accessories

Selecting OEM spare parts suitable for this category safeguards the engineered balance between hydraulics, materials and tolerances. These components are produced to the same specifications applied to serial production, which protects pump efficiency and shaft-seal integrity throughout the service interval. The result is stable coolant temperatures, consistent lube oil pressure and dependable fuel delivery—factors that directly influence fuel economy and emissions.

From a budget perspective, properly matched OEM spare parts suitable for a COOLING WATER PUMP reduce lifecycle cost by minimizing repeat interventions, preventing collateral damage and shortening refit times. Seal kits that include the correct face materials and springs, wear rings machined to the correct clearance, and bearings with the right load ratings avoid rework and help crews complete a service job in one attempt. For safety and compliance, traceable materials and documented specifications support audits and help fleets meet internal and regulatory standards.

COOLING WATER PUMP OEM parts for diesel engine and gas engine fleets

Whether you operate a coastal vessel, an ocean-going ship or a land-based power module, COOLING WATER PUMP OEM parts tuned for your diesel engine or gas engine application provide predictable fit and performance. Correct geometry restores pump curves to design values, while certified elastomers ensure compatibility with glycol blends and inhibitor packages. This precision translates into fewer hot-spot alarms, better heat-exchanger performance and extended service intervals.

MOPA – your partner for OEM spare parts: pumps, parts and accessories

MOPA is an experienced and reliable partner for OEM spare parts across the full range of pumps, parts and accessories. Customers value our speed in sourcing and logistics, the consistent quality of supplied components, and the security of a professional trading process for OEM parts supporting diesel and gas engines. We coordinate multi-brand deliveries, provide technical cross-references, and streamline shipments to minimize downtime on board and on site.

From COOLING WATER PUMP assemblies to mechanical seal kits, wear components and complete service packs, MOPA supports planned maintenance and urgent needs alike with responsive handling, accurate documentation and safe packaging. Our team helps you match part numbers to engine-maker specifications, reducing risk and accelerating the return to service.

Conclusion

Pumps, parts and accessories—especially the COOLING WATER PUMP—are pivotal to engine performance, efficiency and operational safety. By selecting OEM spare parts suitable for this category, operators protect temperature control, reduce unplanned downtime and extend the service life of major components.

With MOPA as a partner, fleets gain fast, secure access to quality OEM parts for diesel and gas engines, keeping assets in spec and operations on schedule.