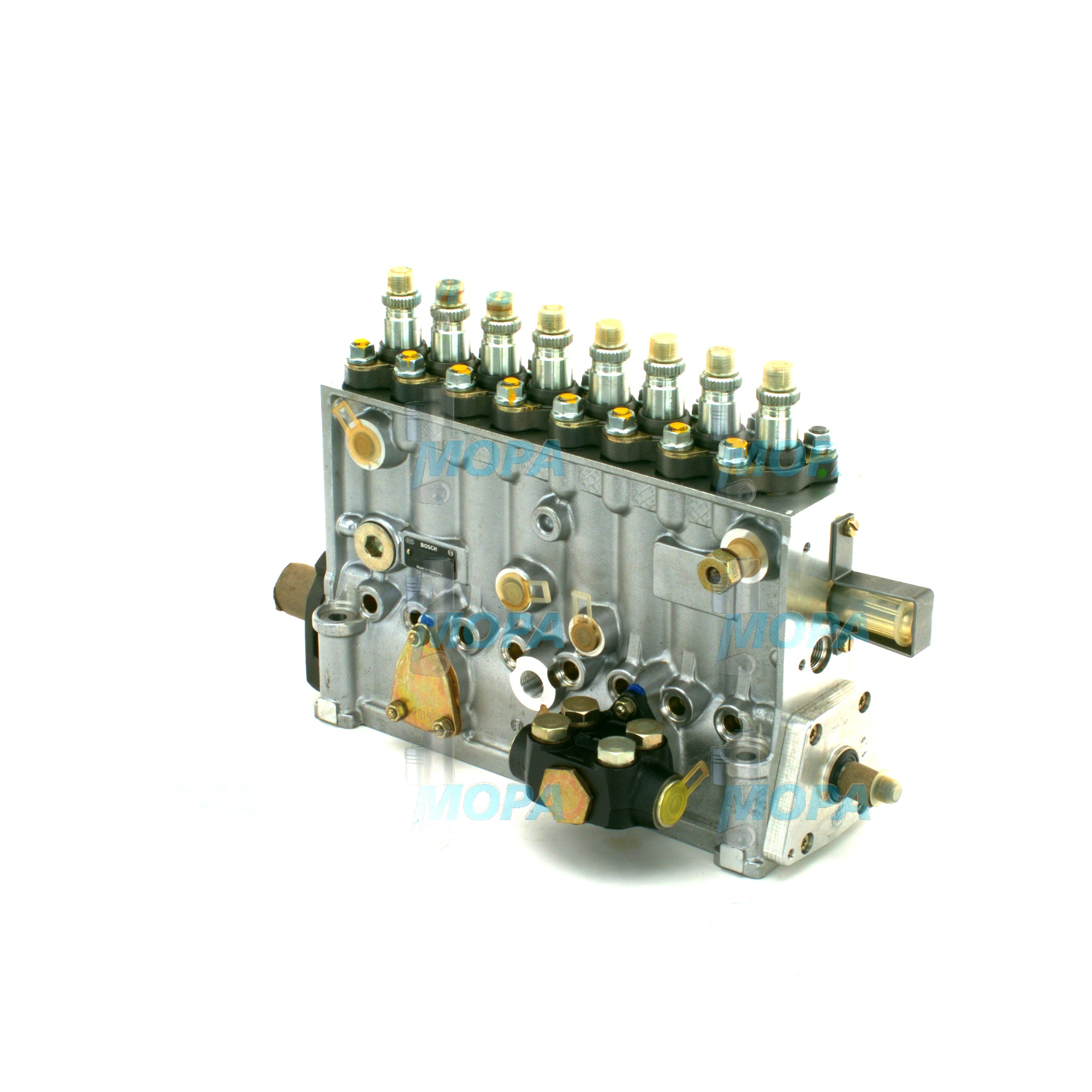

FUEL INJECTION PUMP recondit. – Pumps, parts and accessories

Pumps, parts and accessories form the fluid-handling backbone of any engine installation. In marine, power generation, and industrial applications, this article category includes fuel injection pumps, feed/transfer pumps, lube oil pumps, coolant and seawater pumps, as well as precision parts and accessories such as seals, gaskets, bushings, wear rings, shafts, couplings, filters, and calibration hardware. Together, these components meter, pressurize, circulate, cool, and lubricate—functions that directly determine engine performance, efficiency, and uptime. Without reliable pumps and correctly matched accessories, even a high-spec diesel engine cannot achieve stable combustion, proper thermal balance, or long service life.

Technical function and FUEL INJECTION PUMP recondit. in diesel engine and marine engine systems

In any diesel engine, pumps convert rotational energy into controlled fluid flow and pressure. Fuel transfer pumps move fuel from tanks to conditioning modules; booster or supply pumps stabilize inlet pressure. The lube oil pump creates a protective film on bearings and cams, while coolant and seawater pumps manage heat rejection through jacket water and heat exchangers. Among these, the fuel injection pump is the metering heart: it builds high pressure and times delivery precisely to each cylinder for efficient atomization and clean combustion.

FUEL INJECTION PUMP recondit. units for diesel engine and marine engine applications are meticulously reworked and calibrated to meet the targeted injection profile. The plunger-barrel clearance, cam profile contact, delivery valve response, and governor synchronization are set so that pressure rise, injection timing, and quantity match the engine map. When paired with the right OEM parts—nozzles, delivery valves, control racks, and seals—FUEL INJECTION PUMP recondit. solutions help stabilize ignition delay, reduce unburned hydrocarbons, and optimize specific fuel consumption. In fleets, this precision translates into consistent cylinder balance, lower thermal stress, and predictable maintenance intervals.

Accessories matter just as much: correctly specified elastomers withstand fuel blend variations; corrosion-resistant alloys extend pump housing life in marine environments; and dimensionally accurate keys, couplings, and gaskets maintain alignment and sealing integrity. On cooling and lubrication circuits, the right impeller geometry, shaft hardness, and bearing specification keep volumetric efficiency high while minimizing friction and cavitation risk.

· Broad scope: fuel, lube oil, coolant, and seawater pumps plus matching accessories

· Precision metering: FUEL INJECTION PUMP recondit. calibrated for diesel engine duty

· Stable operation: controlled pressure, timing, and flow across load ranges

· Durability: wear-resistant materials and correct clearances for long service life

· Safety: reliable cooling and lubrication prevent overheating and bearing damage

· Efficiency: accurate injection and minimal leakage reduce fuel consumption

Why Pumps, parts and accessories are decisive for reliability and service life

Reliable engines depend on pumps that maintain design pressure and flow under varying viscosity, temperature, and load. When a fuel pump loses volumetric efficiency or timing accuracy, the engine can suffer misfiring, higher smoke number, injector coking, and rising exhaust temperatures. Inadequate lube oil pressure accelerates bearing and cam wear; inefficient coolant or seawater pumps lead to hotspots, liner cavitation, and shortened overhaul intervals. Small deviations—worn bushings, tired springs, eroded impellers—cause ripple effects in performance and emissions. Keeping pumps, parts and accessories within specification is therefore essential to minimize unplanned downtime, safeguard major components, and preserve the planned TBO (time between overhauls).

OEM spare parts suitable for Pumps, parts and accessories: performance, reliability, budget, service life

OEM spare parts keep the pump set and its accessories aligned with the engine designer’s intent. Dimensional accuracy, surface finish, metallurgy, and elastomer chemistry ensure that clearances, spring rates, and sealing loads match the calibration values used by the fuel system and cooling/lube circuits. For a FUEL INJECTION PUMP recondit., OEM components preserve injection timing windows and pressure rise rates; for coolant and lube oil pumps, they protect shaft integrity, bearing life, and impeller efficiency.

Choosing OEM spare parts suitable for this article category supports:

· Performance: consistent injection quantity, correct spray characteristics, and stable pressure

· Reliability: materials and treatments engineered for thermal, chemical, and mechanical loads

· Budget: predictable maintenance cycles, fewer reworks, and reduced collateral damage

· Service life: parts that maintain clearances and minimize wear over long operating hours

· Compliance: easier alignment with engine maker specifications and class/flag expectations

· Traceability: documentation that supports calibration records and quality audits

FUEL INJECTION PUMP recondit. OEM parts for marine engine and diesel engine fleets

For shipowners and power plant operators, aligning a FUEL INJECTION PUMP recondit. with the correct OEM parts helps retain the injection curve and governor behavior intended for heavy fuel oil or distillate operation. Matching delivery valves, plungers, racks, and seals as a system reduces uneven cylinder loading, lowers SFOC, and stabilizes start/stop and low-load response. The same system approach applies to transfer, lube, and coolant pumps: OEM impellers, bearings, and seal kits keep hydraulic efficiency high and leakage low, extending the interval to the next planned service.

MOPA – your partner for OEM parts: Pumps, parts and accessories and FUEL INJECTION PUMP recondit.

MOPA is an experienced, reliable partner for OEM spare parts across Pumps, parts and accessories, including FUEL INJECTION PUMP recondit. solutions for diesel and gas engines. Customers value our speed in sourcing and deliveries, quality-focused selection, and security in the trade of OEM parts. We support marine engine and stationary diesel engine operators with calibrated components, documentation, and expert guidance—helping you cut downtime, reduce risk, and keep fleets on schedule.

Conclusion: Pumps, parts and accessories with FUEL INJECTION PUMP recondit.

Pumps, parts and accessories are central to engine performance, efficiency, and longevity. A well-matched FUEL INJECTION PUMP recondit., combined with the right OEM spare parts, keeps injection, lubrication, and cooling precisely within design. Partnering with MOPA adds speed, quality, and security—so your diesel and gas engines deliver reliable power with predictable lifecycle costs.