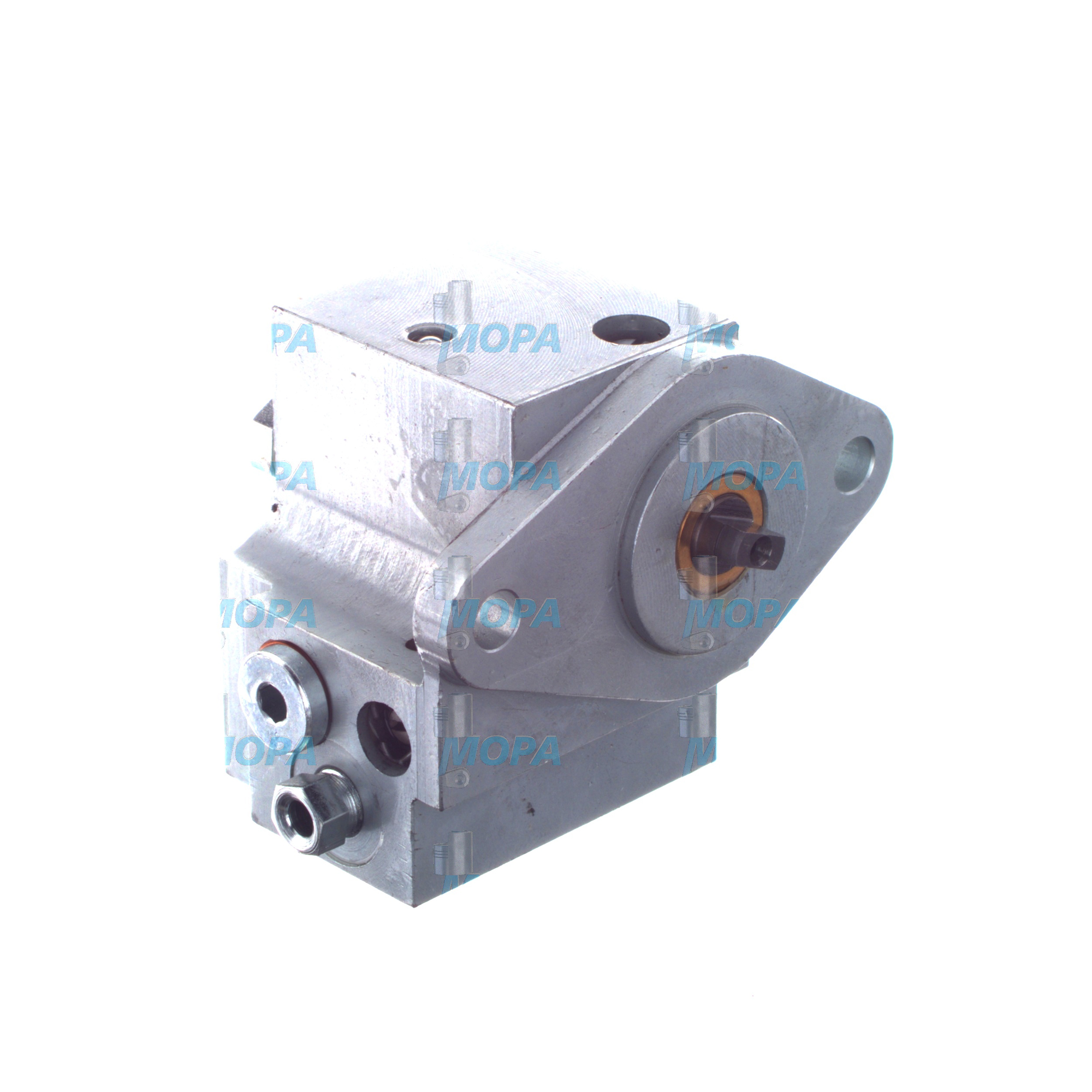

LUBRICAT. OIL PUMP – Pumps, parts and accessories

Pumps, parts and accessories cover the complete set of fluid-handling components that keep engines supplied with lubrication oil, fuel, and coolant. From the primary LUBRICAT. OIL PUMP to jacket-water and fuel transfer pumps, plus precision components such as gears, rotors, shafts, seals, bearings, strainers, and relief valves, this category is fundamental to engine health. Without reliable pumping systems and the right accessories, even the best-designed marine engine or diesel engine cannot develop safe oil pressure, maintain temperature control, or deliver the fuel stability needed for efficient combustion.

In daily operation, these components create, control, and monitor the flow and pressure of vital media. They protect high-value parts—bearings, camshafts, turbochargers, and pistons—from friction and thermal stress. Selecting, maintaining, and sourcing pumps, parts and accessories to the correct specification is therefore a strategic decision for purchasers, shipowners, and technical managers who aim to maximize availability and minimize life-cycle cost.

Technical function of pumps and the LUBRICAT. OIL PUMP in a diesel engine

The LUBRICAT. OIL PUMP is the heart of the lubrication circuit in a diesel engine or marine engine. Drawing oil from the sump through a strainer, it pressurizes the lube circuit and delivers flow to filters, coolers, and distribution galleries. A relief valve limits maximum pressure, while calibrated orifices and piston-cooling nozzles meter delivery to bearings and other friction pairs. Typical pump designs include external gear, internal gear, and screw pumps; each is chosen for viscosity range, desired pulsation level, and speed-torque characteristics. In large-bore engines, robust gear or screw pumps provide stable delivery across the load profile, supporting continuous operation at variable RPM.

Beyond the LUBRICAT. OIL PUMP, this category includes coolant pumps that circulate jacket water and raw water through heat exchangers, as well as fuel feed and transfer pumps that stabilize supply pressure to injection systems. Accessories—pressure switches, temperature sensors, non-return valves, strainers, flexible couplings, and mounting kits—complete the system, ensuring controlled start-up, clean media, and vibration-safe operation. Precisely machined parts such as rotors, bushings, thrust plates, and seals maintain tight clearances, minimizing internal leakage and preserving volumetric efficiency. When sourced as LUBRICAT. OIL PUMP OEM parts, matched tolerances and surface finishes secure the design performance envelope intended by the engine builder.

Key characteristics and advantages of pumps, parts and accessories

· Stable flow and pressure across the engine’s operating range.

· Materials and coatings selected for high temperature and oil/fuel compatibility.

· Tight clearances reduce slip and protect efficiency at low RPM.

· Integrated relief and bypass functions protect circuits and filters.

· Serviceable wear items: rotors, gears, bearings, seals, and gaskets.

· Robust shafts and couplings transmit torque with minimal vibration.

· Instrumentation accessories enable real-time pressure and temperature monitoring.

· Configurations for diesel and gas engines in marine, power-gen, and industrial duty.

Why pumps, parts and accessories — including the LUBRICAT. OIL PUMP for marine engine duty — are critical

Reliability and service life depend on maintaining correct flow, pressure, and cleanliness. A worn LUBRICAT. OIL PUMP can cause low oil pressure at idle and during load transients, accelerating bearing wear, cam lobe scuffing, and turbocharger distress. Excessive internal leakage reduces film thickness, raising metal-to-metal contact risk and elevating oil temperatures. Defective seals or warped end plates lead to aeration and cavitation, further degrading lubrication performance.

In coolant circuits, diminished pump head or eroded impellers compromise heat rejection, triggering high-temperature alarms and post-combustion deposits. On the fuel side, unstable transfer pressure invites injection irregularities, rough running, and higher specific fuel consumption. Accessories matter just as much: clogged strainers, sticking relief valves, or mis-specified couplings can propagate vibration, pressure spikes, and unplanned shutdowns. Keeping pumps, parts and accessories in specification is therefore central to predictable maintenance intervals and safe operation in harsh marine environments.

Advantages of OEM spare parts suitable for pumps, parts and accessories

When replacing wear components or complete assemblies, OEM spare parts suitable for pumps, parts and accessories preserve design intent. For a LUBRICAT. OIL PUMP in a diesel engine, correct gear geometry, tooth profile, and heat treatment determine hydrodynamic sealing and noise behavior. Proper metallurgy and surface finish on rotors and thrust plates stabilize clearances as temperatures change. Elastomers matched to oil chemistry and temperature prevent swelling and leakage over long service periods.

Using LUBRICAT. OIL PUMP OEM parts safeguards performance metrics—start-up pressure build, steady-state pressure stability, and volumetric efficiency at low RPM—while reducing the risk of misalignment, premature wear, and unbalanced loads on couplings and drives. For buyers focused on total cost of ownership, predictable fit and performance reduces troubleshooting time, shortens maintenance windows, and supports planned dry-dock schedules. Documentation and traceable specifications help technical teams uphold class and internal standards across fleets operating both diesel and gas engines.

MOPA: your partner for OEM parts for LUBRICAT. OIL PUMP and pumps, parts and accessories

MOPA is an experienced and reliable partner for OEM spare parts for Pumps, parts and accessories. We supply LUBRICAT. OIL PUMP components and complete assemblies for diesel and gas engines with a focus on speed, quality, and security in every transaction. Our team supports urgent requisitions, consolidates multi-brand requirements, and provides parts that align with the engine maker’s specifications to maintain flow, pressure, and durability targets.

From seals, gears, and shafts to fully built pumps and monitoring accessories, MOPA helps technical decision-makers reduce downtime risk through fast response, proven quality, and careful handling. Secure packaging, clear documentation, and efficient logistics ensure parts arrive ready to install—whether for a single marine engine or a fleet-wide maintenance program.

Conclusion: LUBRICAT. OIL PUMP and the value of OEM parts

Pumps, parts and accessories are vital to safe lubrication, cooling, and fuel delivery, with the LUBRICAT. OIL PUMP at the core of engine protection and efficiency. Selecting OEM spare parts suitable for this category preserves performance, extends service life, and supports reliable operation across marine and land-based power applications.

Partnering with MOPA combines fast sourcing, dependable quality, and secure trade for OEM parts that keep diesel and gas engines running at their best.