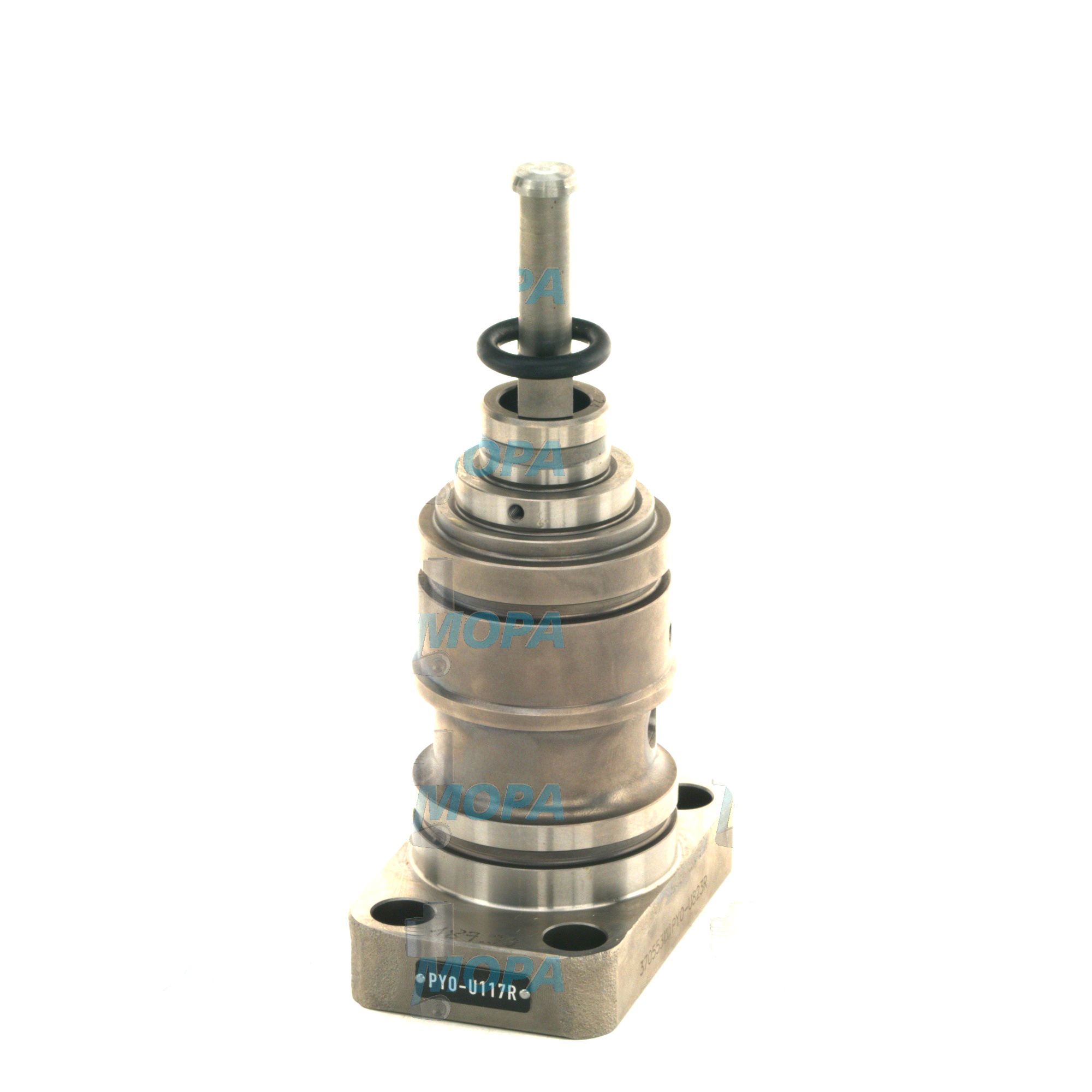

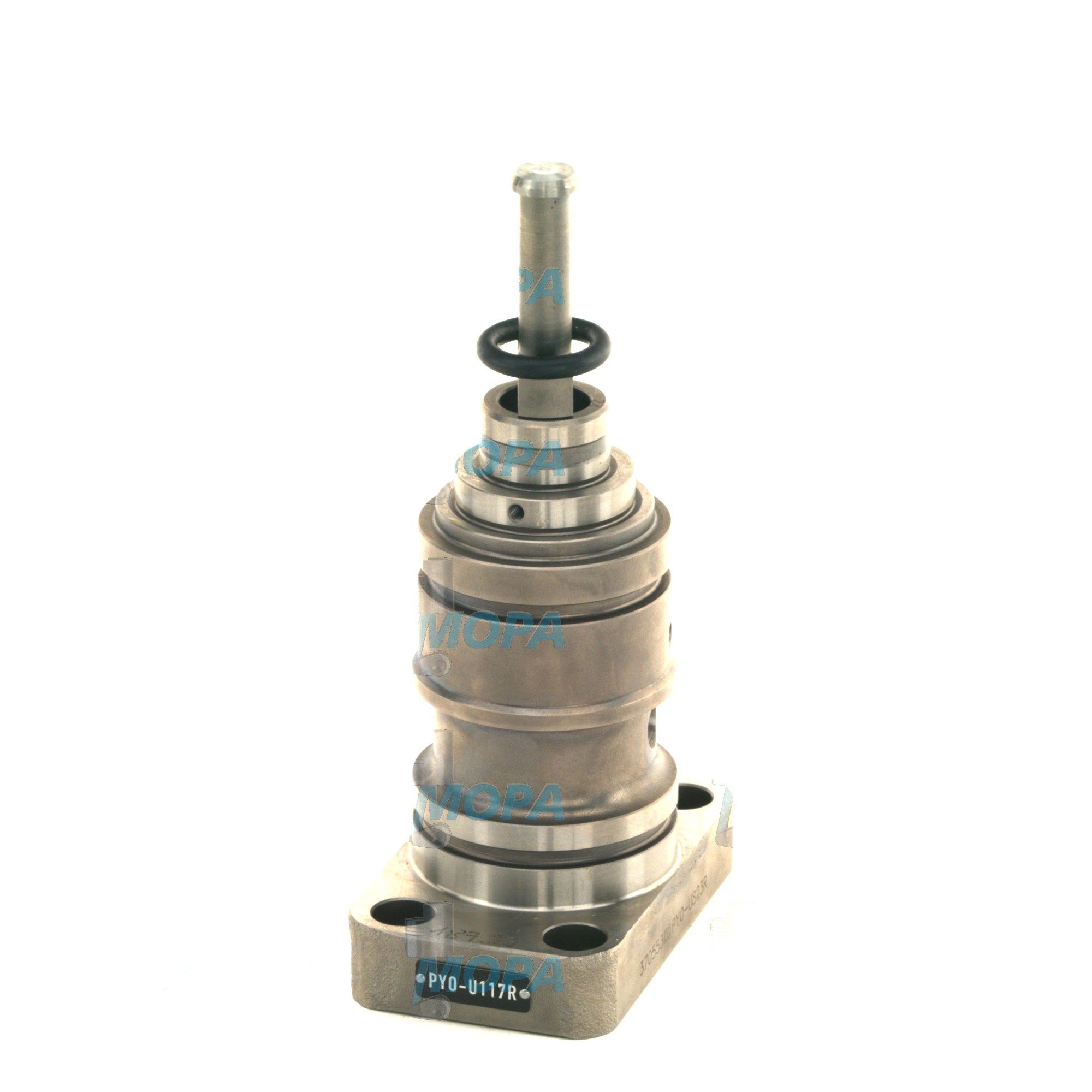

PLUG-IN PUMP Pumps, parts and accessories for high-performance diesel and marine engines

Pumps, parts and accessories form the fluid-handling backbone of every engine room. From precisely metered fuel delivery to stable lubrication and effective thermal management, this category covers everything that moves, meters, seals, and safeguards liquids inside a power unit. In large diesel engine and marine engine applications, components such as the PLUG-IN PUMP for injection, lube oil pumps, jacket-water and seawater pumps, as well as the associated shafts, impellers, seals, valves, housings, and couplings, work together to keep the engine running cleanly and efficiently under all loads. Selecting the right assemblies and matching accessories is essential to maintain performance, reduce lifecycle costs, and protect critical engine assets.

Technical function of Pumps, parts and accessories with PLUG-IN PUMP in diesel and marine engine systems

Within the fuel circuit, a PLUG-IN PUMP in a diesel engine acts as a compact, replaceable unit that generates the injection pressure and meters the exact fuel quantity for each cycle. In marine engine configurations, this unitized design helps simplify maintenance while delivering the high, repeatable pressures necessary for clean combustion and responsive torque. The pump’s cam-driven plunger, delivery valve, and precision-matched barrel convert mechanical input into a stable, high-pressure pulse, synchronized with timing gear. Correct calibration of the PLUG-IN PUMP—often supplied as OEM parts to match the engine’s specification—ensures optimal injection timing, atomization, and load response, which directly influences fuel burn, emissions, and starting behavior.

Beyond the injection circuit, Pumps, parts and accessories span vital auxiliaries. Lube oil pumps maintain film strength across bearings and cam surfaces; coolant and seawater pumps stabilize thermal gradients through jackets and heat exchangers; booster and transfer pumps condition fuel and feed day tanks; and bilge or sludge pumps maintain a safe, clean bilge. Accessories such as mechanical seals, O-rings (e.g., FKM/NBR suited to fuel or oil), impellers (bronze or composite for seawater service), wear rings, and couplings preserve efficiency by minimizing leakage and vibration. Proper net positive suction head (NPSH) margins, cavitation-resistant materials, and correct clearances are critical design features that keep pumps quiet, efficient, and long-lived in tough marine environments.

- · Precise fuel metering and timing with PLUG-IN PUMP unit design.

- · Stable lubrication and cooling through dedicated oil and water pumps.

- · Cavitation control via optimized suction, materials, and clearances.

- · Corrosion resistance with marine-grade metals and elastomers.

- · Reduced vibration and noise through balanced rotors and couplings.

- · Easy serviceability with modular pumps, parts and accessories.

- · Compliance support through calibrated components and documentation.

Importance for engine operation and service life

Reliable Pumps, parts and accessories are fundamental to engine uptime. If a PLUG-IN PUMP drifts out of calibration, injection quantity errors and poor spray quality can cause hard starting, higher specific fuel oil consumption, smokiness, and increased thermal loading on pistons and exhaust valves. In the lube circuit, a worn gear set or degraded seal can drop oil pressure, accelerating bearing wear and risking journal damage. Cooling pumps with eroded impellers or scaled flow paths reduce heat rejection, leading to hotspots, liner polishing, and gasket stress. In the seawater circuit, incorrect materials or neglected anodes accelerate corrosion, causing leaks and unplanned off-hire.

Typical failure modes include cavitation pitting, seal lip hardening from incompatible media, shaft fretting due to misalignment, and reduced pump efficiency from increased internal leakage. Monitoring differential pressure across filters, observing suction vacuum, trending discharge pressure, and following the maker’s flow/pressure map are practical steps that extend service life. Using precisely matched components and accessories restores design clearances and maintains hydraulic balance, preventing a cascade of secondary damage.

Advantages of OEM spare parts suitable for Pumps, parts and accessories

Choosing OEM spare parts suitable for Pumps, parts and accessories safeguards the engineered performance of the fuel, lube, and cooling circuits. Dimensional accuracy, calibrated springs and plungers in a PLUG-IN PUMP, and material specifications for seals and impellers are all validated at the source to meet the engine maker’s duty points. This preserves injection timing, minimizes leakage, and sustains efficiency under high thermal and mechanical loads in both diesel and marine engine environments.

With OEM spare parts, purchasers benefit from consistent fit-up and predictable lead times, enabling planned maintenance windows and reducing the total cost of operation. Traceable manufacturing, documentation packages, and conformity with class requirements help technical decision-makers manage risk. In a PLUG-IN PUMP assembly, matched barrels and plungers, correct delivery valves, and the specified return springs ensure that each replacement maintains the same hydraulic signature as the engine’s baseline, protecting performance, emissions profiles, and component longevity.

MOPA as a partner for OEM parts for Pumps, parts and accessories

MOPA is an experienced and reliable partner for OEM spare parts Pumps, parts and accessories across diesel and gas engines. Our team sources and supplies PLUG-IN PUMP units, lube and coolant pumps, and the associated accessories with speed, quality, and security. We focus on technical clarity—matching part codes, revision levels, and engine serials—so buyers receive exactly what the equipment requires.

Fast, secure supply of PLUG-IN PUMP OEM parts for marine engine and diesel engine fleets

MOPA combines a vetted supplier network with stringent QA checks and robust packing, ensuring components arrive ready for installation. From urgent AOG-style dispatches to coordinated dry-dock deliveries, we provide dependable logistics, full traceability, and export documentation on request, reducing downtime risk and simplifying compliance. Whether you need a single PLUG-IN PUMP for an inline diesel engine or a complete set of pumps, parts and accessories for a multi-engine vessel, MOPA streamlines the process from inquiry to installation.

Conclusion: PLUG-IN PUMP and Pumps, parts and accessories

Pumps, parts and accessories—anchored by the precision of a PLUG-IN PUMP in the fuel circuit—are essential to engine efficiency, reliability, and safety. Selecting OEM spare parts suitable for this category preserves calibrated performance, extends service life, and protects budgets by preventing avoidable failures and downtime.