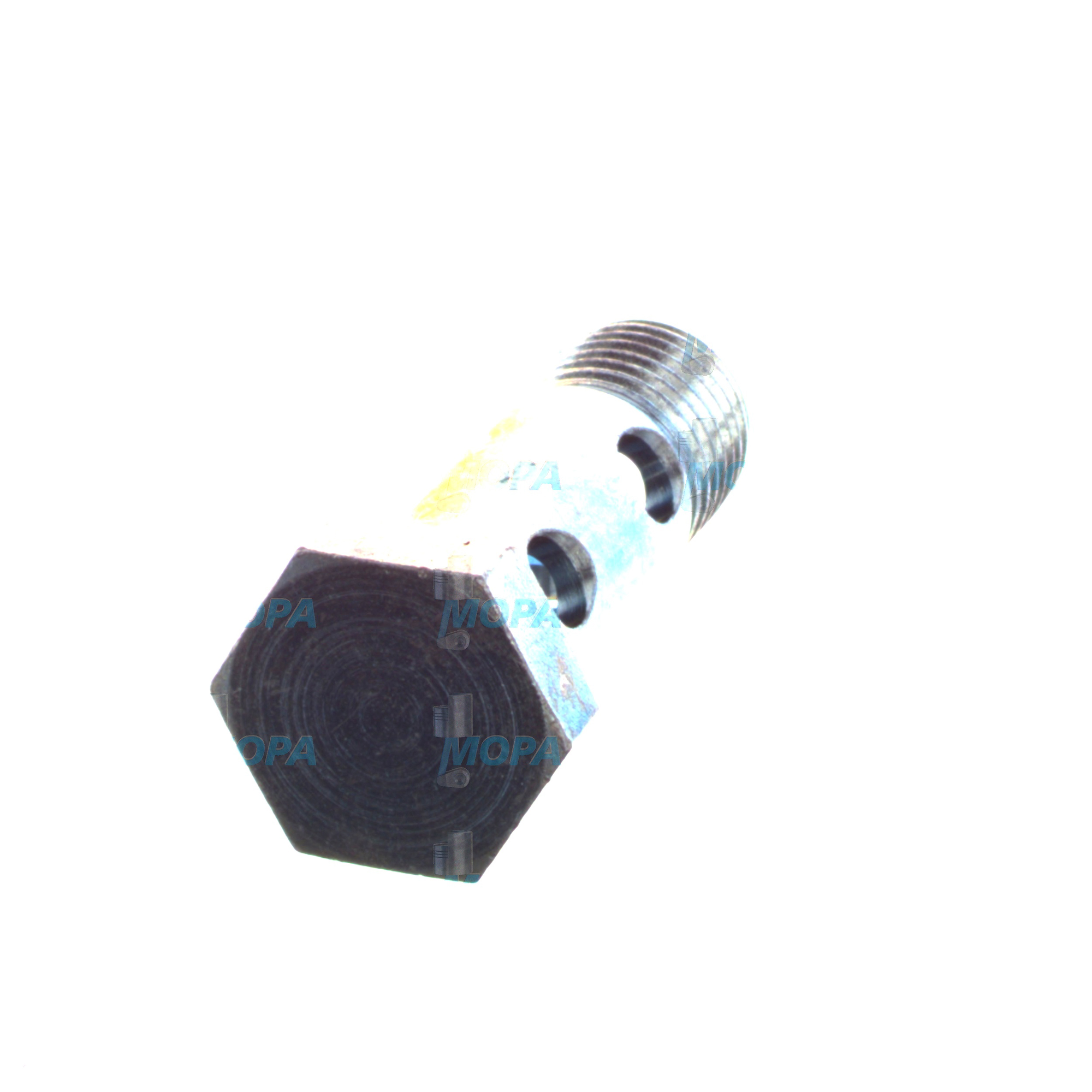

BANJO BOLT Screws for high‑performance marine and diesel engines

Screws are precision fasteners that hold critical engine assemblies together, seal fluid systems, and maintain stable alignment under load. In large marine engines, industrial diesel engines, and gas engines, the category includes standard hex screws, flange screws, stud/bolt combinations, and specialized designs such as the BANJO BOLT used in fuel, lube oil, and coolant lines. Without the right screws in the right specification, engines cannot sustain the clamping forces, sealing integrity, and vibration resistance required for safe and efficient operation.

For buyers and technical decision-makers, the choice of screws is not just about size and thread. It is about material grade, property class, surface treatment, and the exact geometry that ensures compatibility with gaskets, fittings, and housings. The BANJO BOLT is a prime example: a drilled screw that enables fluid flow through a banjo fitting while simultaneously providing the preload needed to seal under pressure—vital in both a marine engine environment and a hard-working diesel engine on land.

Technical function of Screws and BANJO BOLT in engine systems

Engine screws perform three fundamental functions: clamping, sealing, and alignment. Clamping creates the preload that keeps joint surfaces in contact, distributing loads and preventing fretting. Sealing, often achieved with washers and precise surface finishes, keeps fuel, oil, and coolant inside their circuits. Alignment is maintained through consistent thread engagement and head geometry that matches the mating part, ensuring repeatable service and safe reassembly.

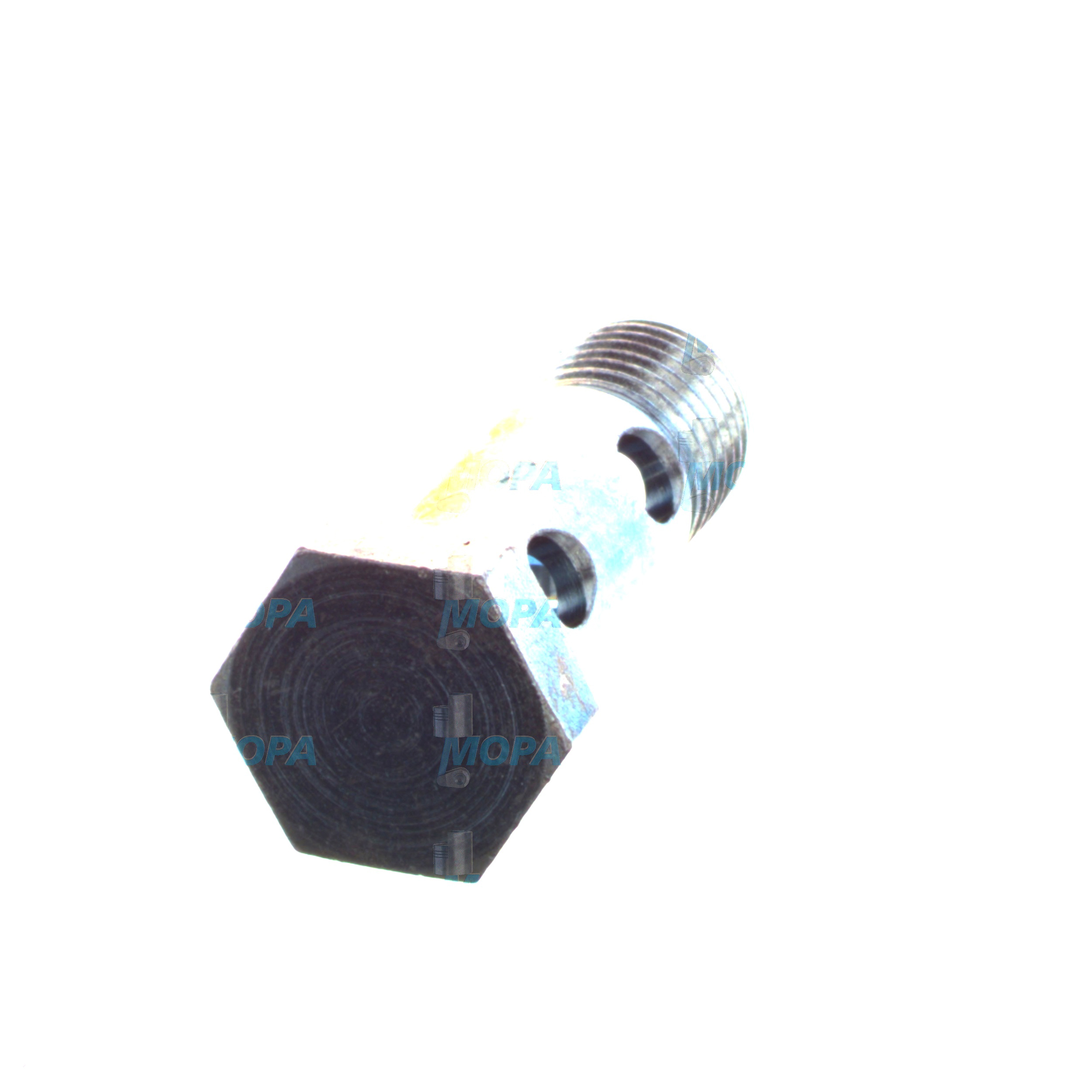

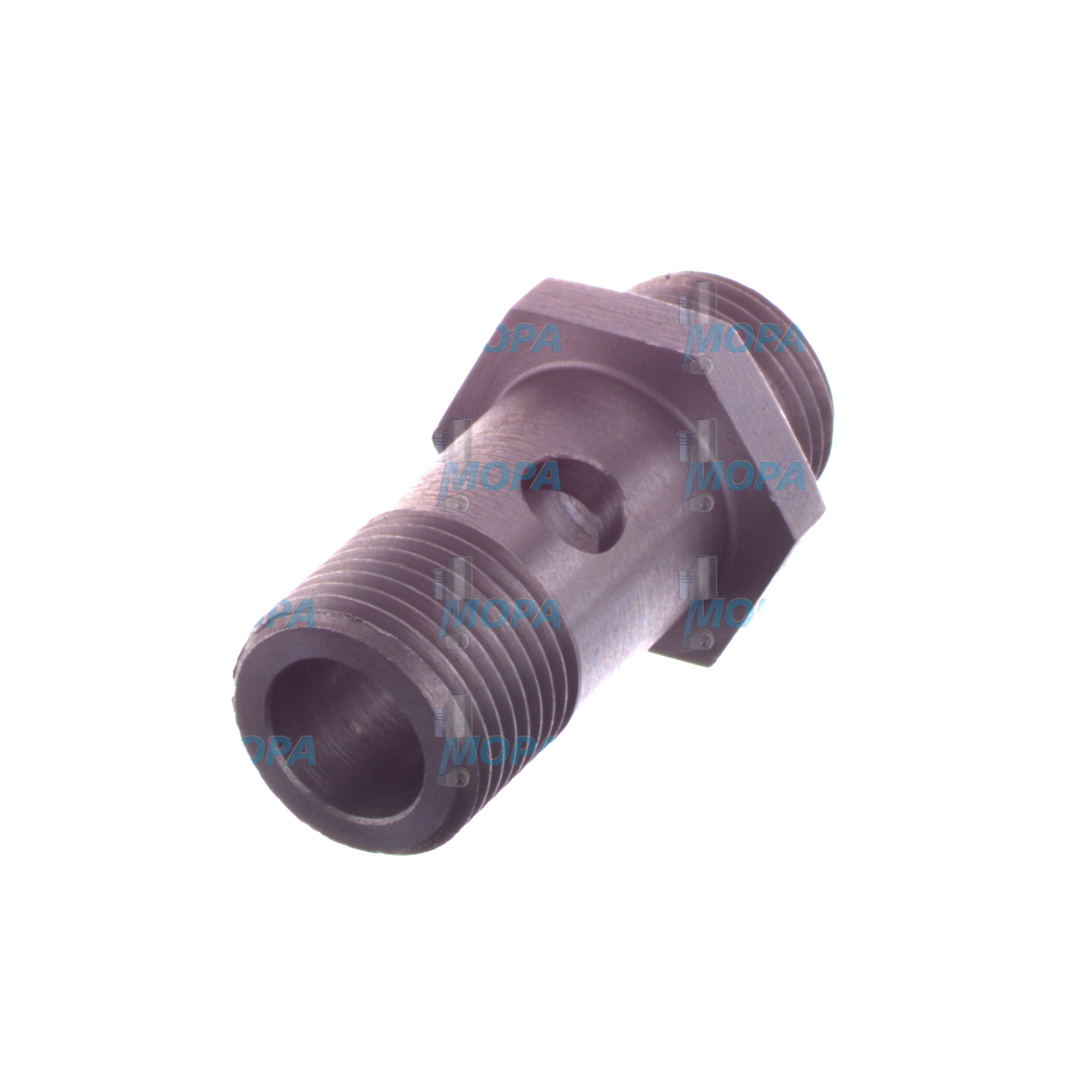

BANJO BOLT in fuel, lube oil, and coolant circuits

A BANJO BOLT is a hollow, cross-drilled screw used with a banjo fitting to route fluids through a compact 360°-orientable connection. In a diesel engine fuel system, a BANJO BOLT provides a low-profile, serviceable joint at injection pumps or filter heads. In a marine engine lube oil circuit, it supports reliable lubrication of turbochargers or auxiliary drives. The bolt’s internal passage and radial ports allow controlled flow while the head and shank deliver the required clamping force to compress sealing washers—commonly copper or bonded seals—against the fitting faces. In OEM parts configurations, geometry and hole diameters are engineered to match target flow rates, pressure limits, and vibration conditions typical for diesel and gas engines.

Correct screw selection spans property class (e.g., 8.8, 10.9, 12.9 per ISO 898-1), thread form and tolerance (e.g., metric coarse or fine, class 6g), and materials (alloy steel, stainless grades for corrosion exposure, or coated steels). Surface treatments such as zinc-nickel, phosphate, or specialized anti-corrosion finishes protect against salt-laden air in marine environments. For BANJO BOLT connections, pairing the correct washer type and torque method (torque or torque-angle as specified by the engine maker) is essential to achieve preload without restricting flow or damaging the fitting.

- · High preload capacity for stable joints under vibration.

- · Precise threads and head geometry for repeatable assembly.

- · Engineered materials and coatings for corrosion resistance.

- · BANJO BOLT passages optimized for target fuel or oil flow.

- · Compatibility with copper or bonded sealing washers.

- · Proven performance in marine engine and diesel engine duty cycles.

Importance of Screws for reliable engine operation

Engine uptime depends on fasteners that maintain clamping force over thousands of thermal and load cycles. Under-tightened screws can loosen, leading to leaks, gasket blow-by, or misalignment that accelerates wear on bearings and rotating parts. Over-tightening risks thread damage, permanent joint deformation, or flow restriction in a BANJO BOLT connection. Corroded or fatigued screws lose preload and can fail unexpectedly, particularly in high-vibration locations like turbocharger brackets or pipe supports.

In fluid systems, BANJO BOLT degradation shows up as fuel seepage, oil misting, or pressure fluctuations. A partially obstructed BANJO BOLT passage can starve components of fuel or lubrication, causing power loss, overheating, or early component failure. On marine engines, even minor leaks can create safety hazards and trigger environmental incidents, raising cost and operational risk. Using the right screws—maintained to specification—directly protects performance, efficiency, and safety.

Advantages of OEM spare parts suitable for Screws and BANJO BOLT

Precision and consistency are critical when replacing screws in demanding engines. OEM spare parts suitable for Screws and BANJO BOLT deliver repeatable dimensions, material traceability, and finishing quality that match the engine maker’s specifications. That means correct shank lengths, under-head radii, drilled-port geometry, and thread tolerances that ensure both preload and flow are achieved as designed.

For purchasers managing fleets and budgets, the advantages are tangible:

- · Performance: Correct preload, stable sealing, and specified flow through each BANJO BOLT.

- · Reliability: Consistent metallurgy, heat treatment, and coatings for long service intervals.

- · Budget control: Lower total cost of ownership through fewer reworks, leaks, and unplanned stops.

- · Service life: Fasteners that resist fatigue and corrosion in diesel and marine engine environments.

- · Compliance: Documentation and markings aligned with engine and class requirements.

Choosing OEM parts for Screws means the fasteners align with the clamp load calculations and joint designs validated during engine development. For BANJO BOLT connections, this safeguards the intended flow characteristics and pressure retention across the full operating envelope.

MOPA — your partner for OEM parts Screws and BANJO BOLT

MOPA supplies OEM spare parts suitable for Screws—including the BANJO BOLT—for leading diesel and gas engines used at sea and on land. Customers rely on MOPA for speed, quality, and security in the trade of OEM parts: short lead times from stock or fast-track sourcing, rigorous supplier qualification with full traceability, and careful packing that protects critical threads and sealing faces.

Whether you need a BANJO BOLT for a marine engine fuel manifold, high-strength screws for cylinder covers, or corrosion-resistant fasteners for auxiliary systems, MOPA streamlines procurement and reduces risk. Technical support helps match thread forms, property classes, and washer types to the engine’s requirements, ensuring trouble-free installation and operation.

Conclusion

Screws—including the specialized BANJO BOLT—are foundational to engine safety, efficiency, and longevity. The right fastener keeps joints tight, fluids contained, and flow precisely controlled in marine engine and diesel engine applications. OEM spare parts suitable for Screws protect performance and service life while keeping budgets predictable across the fleet.