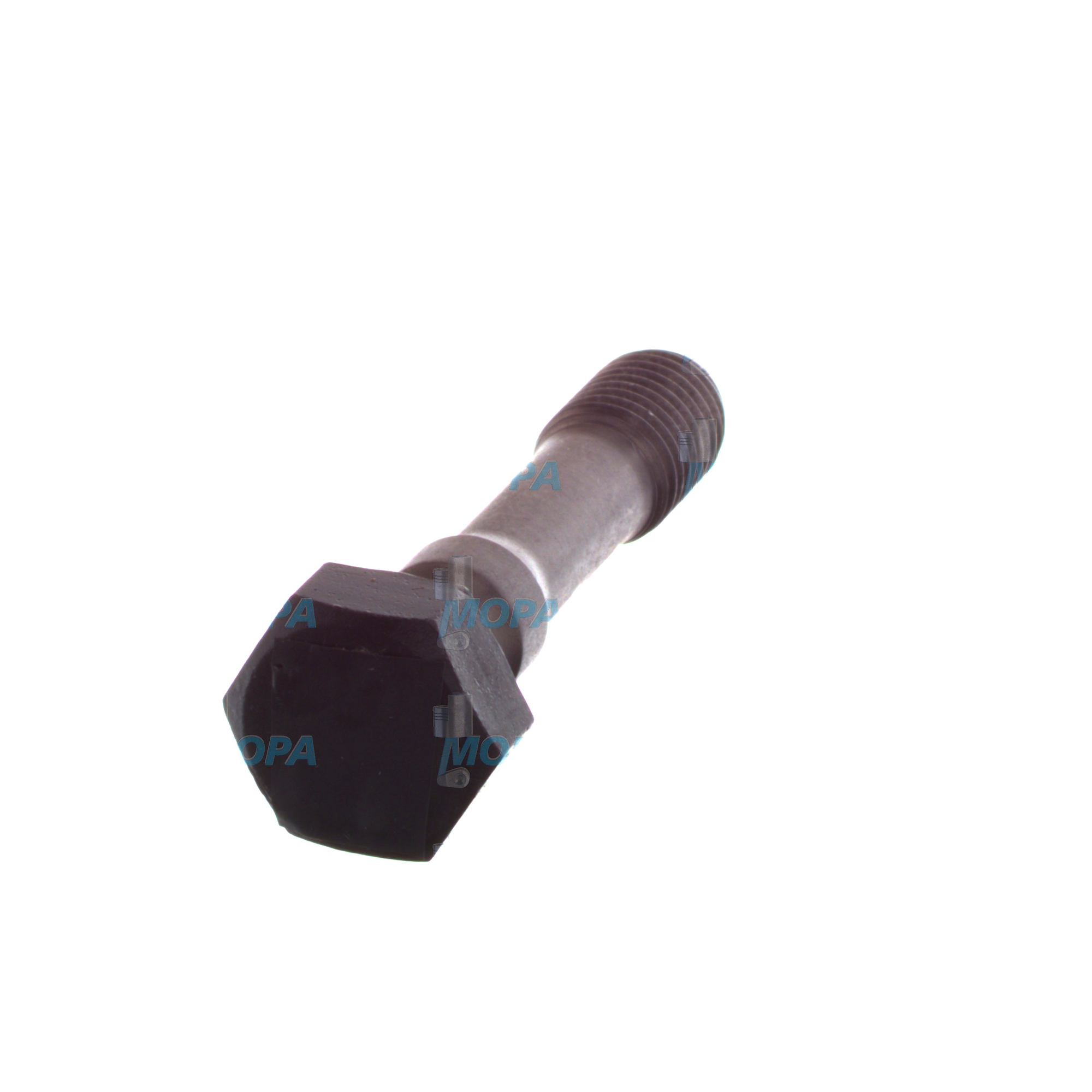

BIG END BOLT Screws: Critical Fasteners for Marine and Diesel Engines

Screws are precision-engineered fasteners that convert tightening torque into reliable clamping force. In engines, they secure the structural core: cylinder heads, main bearing caps, camshaft carriers, accessories, and—most critically for the connecting rod—the BIG END BOLT. As a category, screws in powertrains are not mere commodities; they are safety-relevant components that influence bearing alignment, gasket sealing, vibration behavior, and ultimately the service life of marine and diesel engines. Selecting and maintaining the right screws, and installing them with process control, directly affect uptime and total cost of ownership.

Technical Function of Screws in Engines – BIG END BOLT Role in Performance and Safety

Every engine screw is a calibrated spring. During tightening, it is elastically stretched to produce a defined preload that keeps joint members compressed under operating loads. For a connecting rod, the BIG END BOLT creates the clamp that holds the cap and rod together, maintaining bearing crush and concentricity around the crankpin. In a diesel engine, this bolt is subjected to extreme cyclic tension from gas pressure and inertia loads; in a marine engine running long duty cycles, fatigue resistance and stable preload are critical for round-the-clock reliability.

Performance hinges on repeatable preload. Techniques such as torque-plus-angle or direct bolt stretch measurement limit the influence of friction so the designated clamping force is achieved. Materials and geometry are engineered accordingly: micro-alloyed steels in property classes like 10.9 or 12.9, rolled threads with optimized root radii for fatigue resistance, controlled underhead fillets, and coatings or lubricants that stabilize the friction coefficient. On BIG END BOLT marine engine applications, washers or serrated flanges may be specified to preserve clamp under vibration. Heat treatment and shot peening further enhance high-cycle fatigue life. The result is a joint that stays tight, preserves alignment, and protects bearings and seals at full load.

- · High-strength steels (e.g., 10.9/12.9) for durable preload.

- · Rolled threads and optimized underhead geometry for fatigue life.

- · Torque-angle or stretch methods for precise clamping force.

- · Coatings/lubricants to stabilize friction and prevent galling.

- · Materials suited to temperature and corrosion in marine service.

- · Dimensional accuracy to meet engine-maker specifications.

For BIG END BOLT diesel engine service, installation quality is as important as the part itself: clean threads, correct lubricant, calibrated tools, and adherence to the specified tightening sequence ensure that the intended preload is achieved across all screws in the assembly.

Installation Controls – BIG END BOLT in diesel engine and marine engine service

Optimal practice includes verifying bolt and rod cap seating surfaces, measuring elongation for critical BIG END BOLT joints, and using torque-angle methods where specified. Replace torque-to-yield variants during overhauls, record applied angles/elongations for traceability, and confirm bearing crush after tightening. These steps mitigate loosening, fretting, or cap shift—events that can quickly escalate into severe damage.

Why Screws Matter for Engine Reliability – BIG END BOLT Focus

Engine reliability depends on joints that never relax below the dynamic loads they face. If screws lose preload due to wear, corrosion, thread damage, or improper lubrication during assembly, several failure modes can appear:

Loss of clamping in a BIG END BOLT joint can allow the connecting rod cap to micro-move, leading to fretting corrosion, reduced bearing crush, spun bearings, and ultimately connecting rod failure. On cylinder heads, insufficient screw preload compromises sealing, causing coolant or combustion leaks and thermal hotspots. On brackets and housings, movement increases vibration and misalignment, accelerating wear on adjacent components. In diesel and gas engines that operate for thousands of hours, even small deviations in preload or material quality compound into large reliability risks.

Advantages of OEM spare parts suitable for Screws – BIG END BOLT OEM parts Perspective

Selecting OEM spare parts suitable for screws—and especially for critical BIG END BOLT assemblies—ensures that metallurgy, heat treatment, thread profile, and underhead geometry match the engine specification. This precision matters because preload accuracy and fatigue life are highly sensitive to material properties and surface condition. OEM parts also come with consistent coatings or lubricants to achieve the specified friction coefficient, leading to repeatable torque-tension behavior and safeguarded performance.

From a budget standpoint, correct screws minimize rework, reduce the risk of catastrophic failures, and extend maintenance intervals. For performance and service life, the right BIG END BOLT OEM parts preserve bearing geometry, maintain sealing, and sustain alignment under continuous high load. For reliability, documented production processes and batch testing provide the traceability that procurement and class societies expect in marine engine overhauls.

MOPA – Fast, Quality-Assured Supply of OEM Parts for Screws and BIG END BOLT Applications

MOPA is an experienced partner for OEM spare parts suitable for screws, including BIG END BOLT requirements across diesel and gas engines. Purchasers and technical teams rely on our speed, quality, and security in parts supply: accurate part-number matching, documentation support, and logistics tailored to yard schedules and vessel itineraries. Whether you need a single set of BIG END BOLT marine engine fasteners or a complete screw kit for a major overhaul, we streamline sourcing with responsive quotations, short lead times, and proven QA processes. Our team understands torque-angle specifications, surface treatments, and material classes, helping you procure the correct configuration the first time—reducing downtime and installation risk.

BIG END BOLT OEM parts for marine and diesel engines – Procurement with confidence

MOPA supports cross-references, batch traceability, and packaging that protects threads and seating surfaces. We coordinate global shipments to shipyards and offshore locations, enabling maintenance windows to be kept without compromising on engineering standards.

Conclusion – Screws and BIG END BOLT Significance

Screws are foundational to engine integrity, with the BIG END BOLT as one of the most critical fasteners for maintaining bearing geometry and resisting cyclic loads. Choosing OEM spare parts suitable for screws provides the dimensional accuracy, metallurgy, and friction control needed for performance, reliability, and long service life.

With MOPA as your partner for OEM parts in diesel and gas engines, you gain speed, quality, and security in supply—so every screw, from head bolts to the BIG END BOLT, delivers the clamping force your engine depends on.