HOLLOW SCREW and Screws for Marine, Diesel and Gas Engines

Screws are precision fasteners engineered to clamp engine components with predictable preload and long-term stability under heat, vibration, and pressure. Within the article category “Screws,” you’ll find everything from high-strength cylinder head and main bearing screws to specialized banjo-style components known as the HOLLOW SCREW. In marine engine, diesel engine, and gas engine environments, these fasteners secure housings, guide fluid flow, and preserve sealing integrity—functions that directly impact performance, emissions, and safety.

Engine builders design screw joints as structural elements: when properly torqued, they maintain controlled clamping force that keeps gaskets sealed, rotating assemblies in alignment, and accessories anchored. Whether used on turbochargers, fuel rails, oil galleries, or exhaust manifolds, screws must withstand cyclical loading, thermal expansion, and corrosive atmospheres without loosening or fatiguing. Selecting the right specification—and keeping these parts in top condition—is therefore essential to uptime and lifecycle cost.

Technical function of Screws and HOLLOW SCREW in a diesel engine

In any diesel engine, screws convert tightening torque into clamping force to hold joint faces together. The link between torque and preload depends on material grade, thread geometry, lubrication, and surface finish. Property classes such as 10.9 and 12.9 are common for high-load joints; many critical locations specify torque-angle tightening or hydraulic tensioning to deliver repeatable preload. Correct clamping force prevents gasket blow-by on cylinder heads and exhausts, sustains bearing crush at main caps, and stops fretting between mating faces.

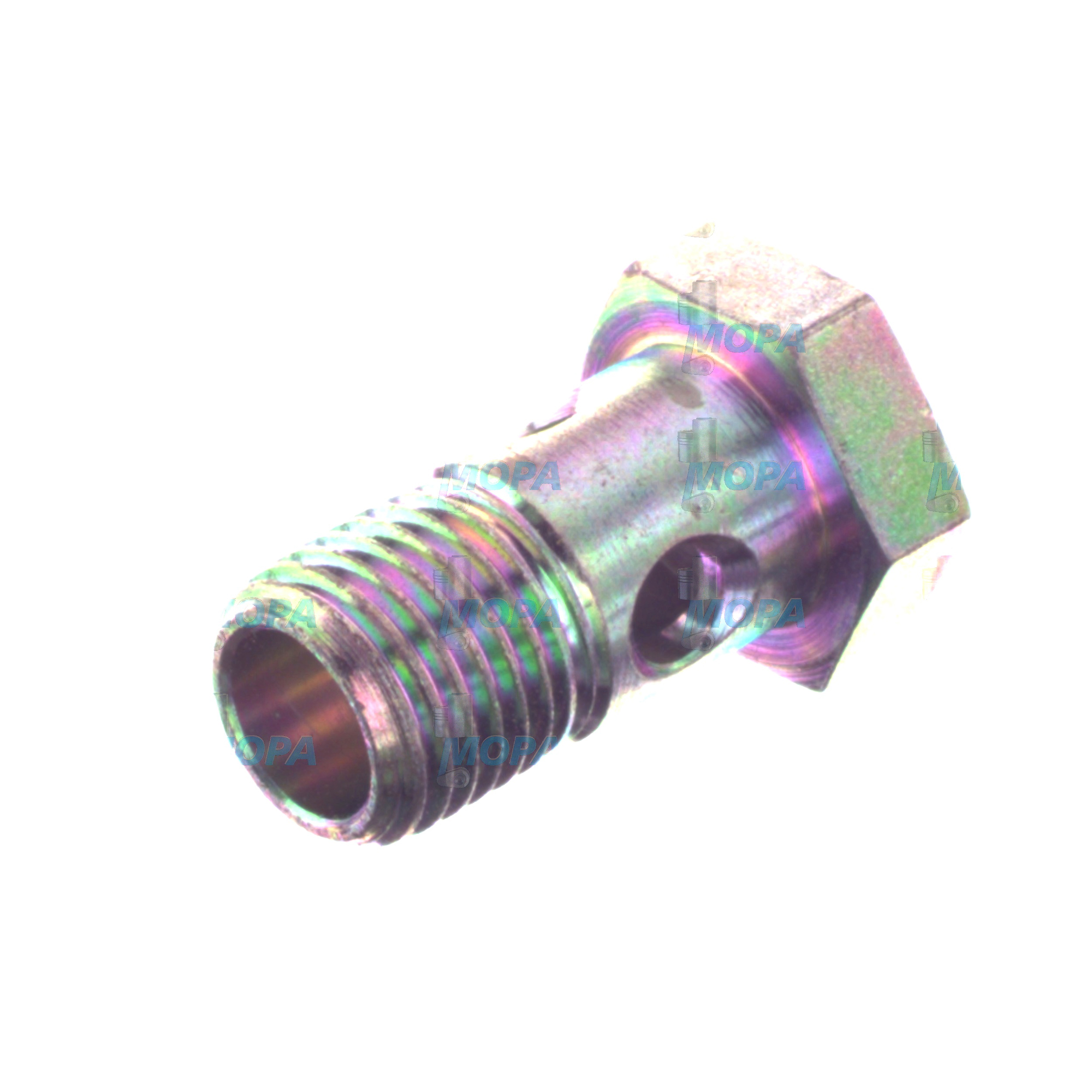

The HOLLOW SCREW is a specialized screw—commonly called a banjo screw—designed with an axial bore and radial ports to allow fluid transfer through the fastener body. In a diesel engine or marine engine, a HOLLOW SCREW typically secures banjo fittings for oil supply lines, fuel return lines, or coolant bypasses. When tightened, the screw clamps the banjo eye and sealing washers while simultaneously providing a controlled fluid passage. The precision of the bore, port geometry, and thread fit governs both flow capacity and sealing behavior under pulsating pressures. HOLLOW SCREW OEM parts are engineered so the flow path, hardness, and coating are aligned with engine-maker specifications, ensuring stable torque-to-seal performance over thousands of service hours.

HOLLOW SCREW marine engine applications and safety

On marine engines, HOLLOW SCREW fasteners are often used in tight spaces where a compact combined fastener-and-connector simplifies routing of oil or fuel lines. Seal integrity relies on flatness of the banjo faces, washer material (often copper or coated steel), and the surface treatment of the screw itself. A correct part prevents micro-leaks, air ingress on suction lines, and oil starvation events at turbochargers—each a major safety and cost concern in vessel operations.

- · High-strength clamping for structural joints

- · HOLLOW SCREW enables integrated oil, fuel, or coolant passages

- · Engineered thread geometry for repeatable torque–tension correlation

- · Heat- and corrosion-resistant materials and coatings

- · Sealing compatibility with copper or composite washers

- · Vibration resistance to prevent loosening and leakage

- · Dimensional accuracy for alignment and flow control

- · Traceability and documentation for critical engine locations

Importance of Screws for engine operation and service life

Screws are fundamental to engine reliability. Loss of preload due to incorrect torque, thermal relaxation, or thread damage can lead to gasket failures, misalignment of rotating parts, and fatigue cracking. For example, insufficient clamping on a cylinder head joint increases blow-by, raises local temperatures, and accelerates head warpage. In the fuel system, a damaged HOLLOW SCREW may cause pressure drops or micro-bubbles that destabilize injection, reduce efficiency, and raise emissions. On oil supply lines, any leak at a banjo joint can starve a turbocharger bearing within seconds, leading to catastrophic failure.

Wear mechanisms include thread galling, corrosion pitting, hydrogen embrittlement (if coatings or processes are incorrect), and fretting at joint interfaces. In high-hour diesel engine operation, even small deviations in hardness or plating thickness can magnify into loosening or leakage. That is why condition, specification fidelity, and proper replacement intervals are essential for the entire screw category—especially for fluid-carrying fasteners like the HOLLOW SCREW.

Advantages of OEM spare parts suitable for Screws and HOLLOW SCREW

For critical applications, OEM spare parts suitable for screws deliver the dimensional control, metallurgy, and surface treatments that the engine design requires. Materials and heat treatment are calibrated for toughness and fatigue resistance; threads and under-head geometries are cut to precise tolerances for consistent torque–tension behavior; and coatings are selected for corrosion performance, thread friction stability, and compatibility with sealing washers. The result is predictable clamp load and durable sealing—key to protecting performance, budgets, and service life.

Choosing OEM spare parts suitable for the HOLLOW SCREW is equally important. The axial bore diameter, radial port placement, and concentricity determine real flow rates and pressure losses. Inconsistent drilling or burrs inside the passage can trigger cavitation, restrict fuel return, or shed particles into sensitive systems. With HOLLOW SCREW OEM parts, you maintain the intended flow profile, prevent leakage at the banjo interface, and safeguard downstream components like injectors and turbo bearings.

Why technical buyers prefer OEM spare parts for Screws

Procurement teams value repeatability, traceability, and lifecycle savings. OEM spare parts suitable for screws reduce rework and unplanned downtime because torque specifications, stretch characteristics (where applicable), and sealing behavior match the engine documentation. This minimizes installation risk, aligns with class and compliance requirements in marine service, and lowers total cost of ownership by preventing failures that can dwarf any short-term savings from non-specified fasteners.

MOPA as your partner for OEM parts: Screws and HOLLOW SCREW

MOPA is an experienced, reliable partner for OEM spare parts suitable for Screws, including HOLLOW SCREW variants for oil, fuel, and coolant applications. We focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines, serving shipowners, fleet managers, and industrial operators worldwide. Our network ensures rapid sourcing, consistent documentation, and careful handling—from property-class engine screws to fluid-transfer HOLLOW SCREW components—so your maintenance team can install with confidence and keep assets running.

With MOPA, you benefit from knowledgeable support on torque procedures, sealing washer selection, and material compatibility, as well as efficient logistics that reduce downtime. Whether you need a single critical screw for a turbo oil feed or a full set for a major overhaul, we align parts and lead times with your operational priorities.

Conclusion: HOLLOW SCREW and Screws keep engines tight, safe, and efficient

Screws—especially the HOLLOW SCREW used in fluid connections—are vital to the structural integrity and fluid management of marine, diesel, and gas engines. Accurate preload, correct materials, and proven sealing protect performance and extend service life. By selecting OEM spare parts suitable for Screws and HOLLOW SCREW, and by partnering with MOPA, operators secure consistent quality, reliable delivery, and long-term operational confidence.