SCREW PLUG and Screws for Diesel and Gas Engines

Screws are critical fastening and sealing components in every combustion engine. From securing covers and brackets to sealing pressurized oil and coolant galleries, this article category covers a wide spectrum of threaded hardware, including highly specialized SCREW PLUG variants. In large diesel engine rooms and compact gas gensets alike, screws transform torque into reliable clamping force and leak-tight closures—fundamental to performance, efficiency, and safe operation. Whether applied on a marine engine running heavy fuel or a high-speed industrial diesel engine, correctly specified screws ensure structural integrity, controlled preload, and fluid containment under heat, pressure, and vibration.

Technical function of Screws and SCREW PLUG in marine engine and diesel engine applications

In engines, screws serve two main functions: structural fastening and fluid sealing. Structural screws (for example, cap screws, flange screws, and set screws) generate defined preload that holds components in precise alignment. This preload resists cyclic loads, vibration, and thermal expansion, preventing micro-movement that causes fretting, wear, and noise. Correct thread engagement, material strength class (e.g., 8.8, 10.9, 12.9), and surface finish are vital to achieve predictable torque–tension relationships.

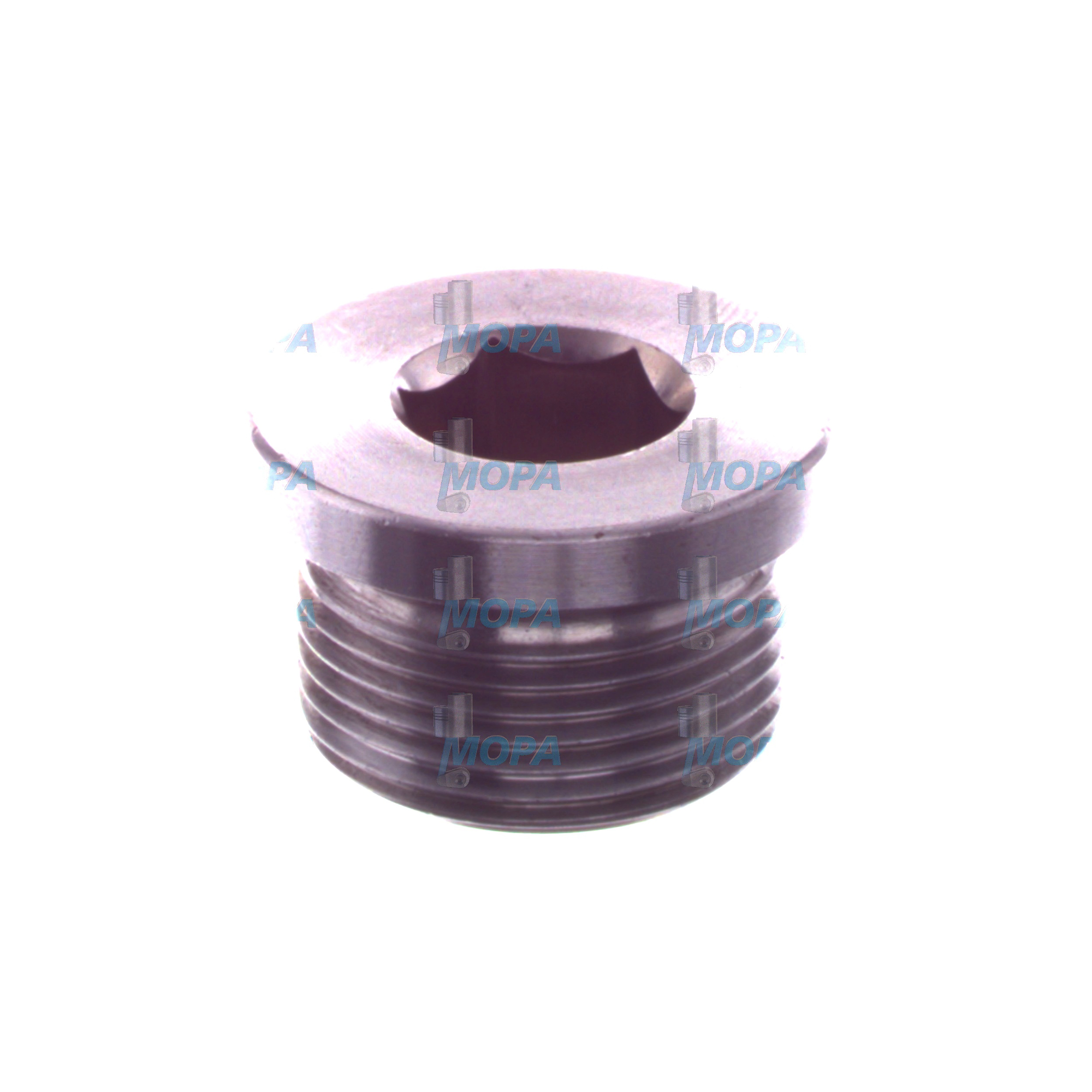

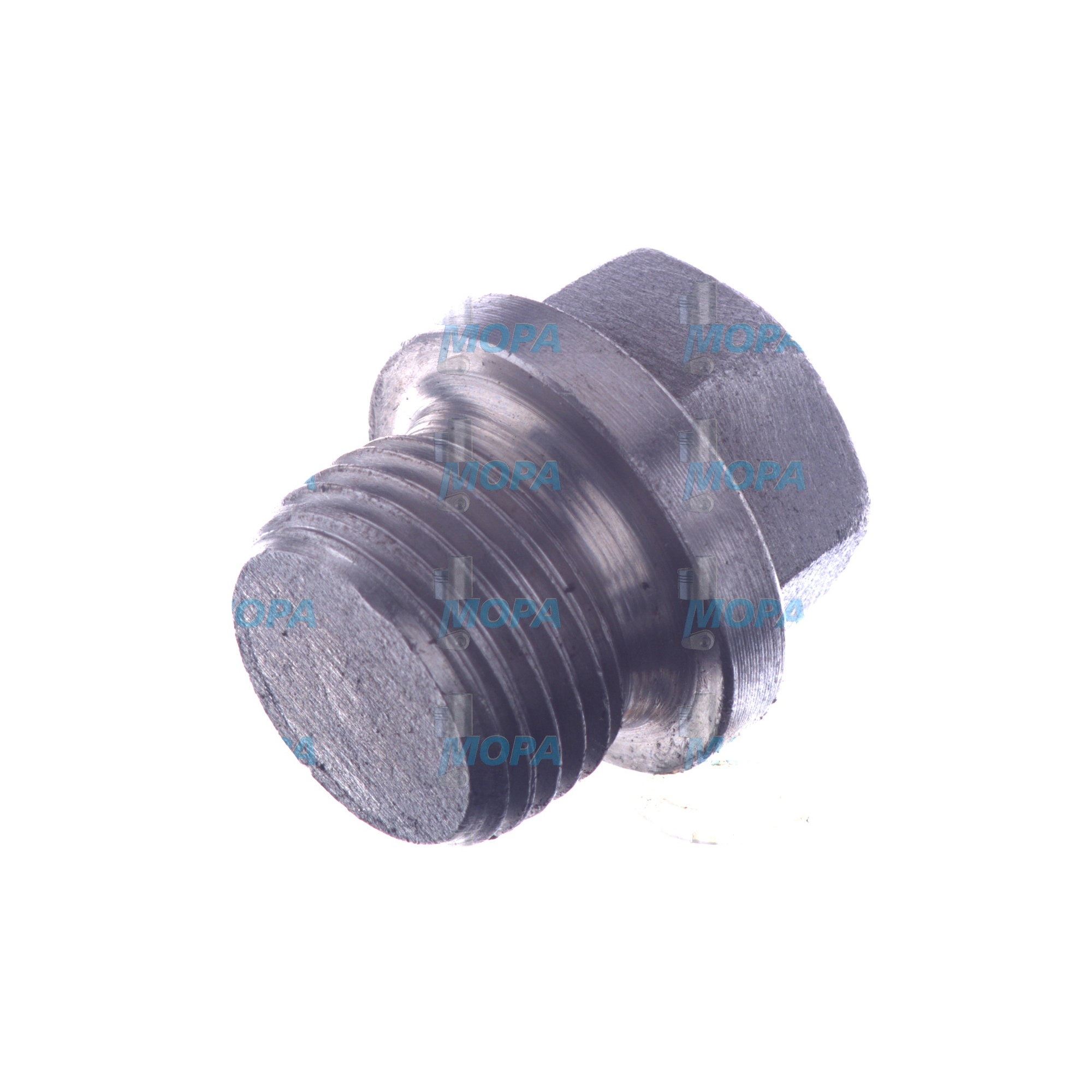

Sealing screws—commonly referred to as a SCREW PLUG—close off oil, fuel, and coolant passages in blocks, heads, and housings. A SCREW PLUG for a marine engine may use tapered threads (NPT/BSPT) for metal-to-metal sealing, or parallel threads combined with a copper, aluminum, or elastomeric sealing ring. In a diesel engine, a SCREW PLUG prevents pressure loss in the lubrication system, stabilizing oil film thickness at bearings and turbochargers. Specified clearances, thread tolerances, and coatings protect against galling and enable correct tightening even in confined, hot environments.

SCREW PLUG OEM parts and engine-matched screws are often supplied with pre-applied sealants or thread lockers to speed service and guarantee consistent sealing performance without over-application of liquid compounds. Coatings such as phosphate, zinc flake, or nickel plating combat corrosion, especially in salt-laden marine atmospheres, while high-temperature alloys maintain strength near exhaust manifolds and turbocharger casings.

- · Engineered preload for dimensional stability under load.

- · Thread forms matched to engine drawings (metric, UNC/UNF, NPT, BSPT).

- · Material classes and heat treatment for tensile strength and ductility.

- · Sealing options: tapered threads, bonded seals, or crush washers.

- · Coatings to reduce corrosion, galling, and seizure.

- · Pre-applied thread lockers and sealants for consistent assembly.

- · Defined torque values for repeatable clamp force.

- · Traceability and batch consistency for critical applications.

Importance of Screws and SCREW PLUG for engine reliability and service life

Fastener integrity is foundational to engine uptime. If screws lose preload or a SCREW PLUG weeps under pressure, cascading faults can follow: oil pressure drop, coolant loss, overheating, contamination of fluids, or even bearing damage. Under-torqued screws allow joint separation and gasket extrusion; over-torqued screws risk thread stripping in aluminum housings or fastener yielding. Corroded or mismatched threads introduce stress risers that lead to fatigue cracks, especially in high-vibration diesel engine installations.

In marine engine environments, pervasive humidity and salt accelerate corrosion on exposed fasteners and sealing plugs. Selecting corrosion-resistant materials and correct surface treatments extends the interval between overhauls. For fuel systems, maintaining leak-tight SCREW PLUG closures prevents air ingress that would impair injection timing and combustion quality. Across the engine, from rocker covers to auxiliary pump housings, properly specified screws safeguard alignment, sealing, and calibration—directly influencing efficiency, emissions, and the longevity of major components.

Advantages of OEM spare parts suitable for Screws and SCREW PLUG

Choosing OEM spare parts suitable for this category ensures that every screw and SCREW PLUG matches the engine maker’s drawings, materials, and process windows. That precision matters: a small deviation in thread tolerance or sealing face geometry can compromise clamp load or leak-tightness. With OEM spare parts, you gain controlled metallurgy, validated coatings, and approved sealant patches—delivering predictable torque–tension behavior and reliable pressure retention in diesel and gas engines.

For purchasers and technical managers, the gains are practical and measurable: lower rework rates during overhauls, shorter installation time thanks to pre-applied compounds, and fewer unplanned stoppages due to seepage or fastener loosening. Compatibility across engine families streamlines inventory while sustaining performance and safety margins designed into the equipment.

- · Exact fit to engine specifications and thread standards.

- · Consistent mechanical properties for repeatable preload.

- · Durable coatings tailored to marine and industrial conditions.

- · Pre-applied sealing/locking features that save time on board or in the shop.

- · Lower lifecycle costs through extended service intervals and reduced leaks.

- · Reliable SCREW PLUG sealing in high-pressure oil and coolant circuits.

MOPA as a partner for OEM parts Screws and SCREW PLUG

MOPA supplies OEM spare parts for Screws and SCREW PLUG across a broad range of diesel and gas engines. Customers value our speed in sourcing, consistent quality, and transaction security—from inquiry to delivery. We identify the correct item by engine model, serial number, and BOM references, ensuring the right thread form, length, material class, and coating for each application.

With established logistics for marine engine operators and power plants, MOPA shortens downtime and minimizes procurement risk. We support projects with technical documentation on request and provide packaging that protects threads, sealing faces, and pre-applied compounds during transport. For shipowners and maintenance providers, this means dependable availability and parts that assemble right the first time.

Typical engine applications for Screws and SCREW PLUG

Applications include oil gallery closures in blocks and heads, coolant jacket plugs, fuel rail and filter head plugs, rocker cover screws, accessory bracket fasteners, turbocharger heat shield screws, and instrumentation ports sealed with a SCREW PLUG for diesel engine monitoring. In marine engine service, deck-side corrosion resistance and vibration stability are paramount—areas where correctly specified fasteners make a measurable difference.

Conclusion

Screws—and especially the SCREW PLUG variants used to seal pressurized passages—are indispensable to engine performance and safety. Selecting OEM spare parts suitable for Screws and SCREW PLUG preserves clamp load, prevents leaks, and supports long service life. With MOPA as your partner, you secure fast, reliable access to OEM parts that keep diesel and gas engines running at their best.