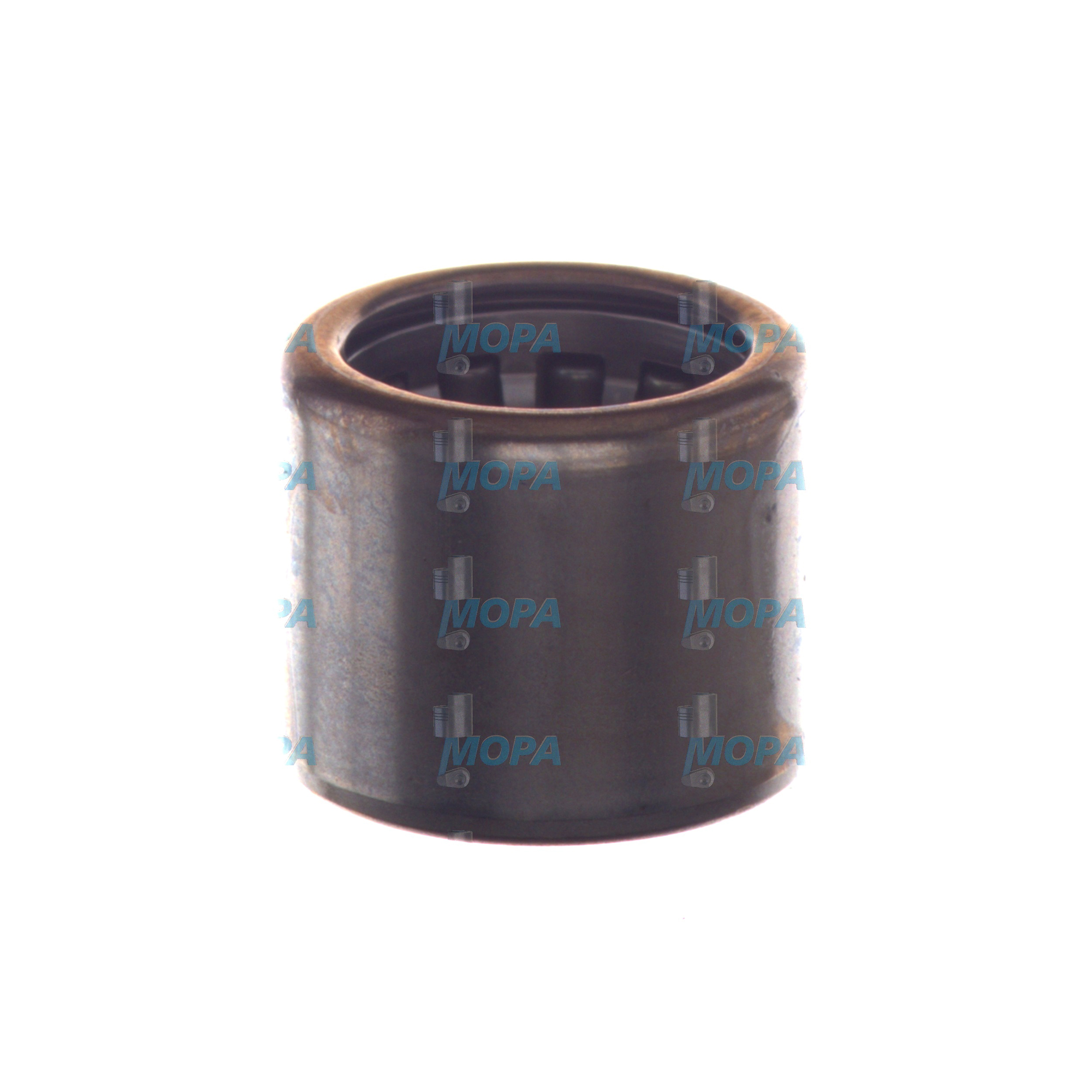

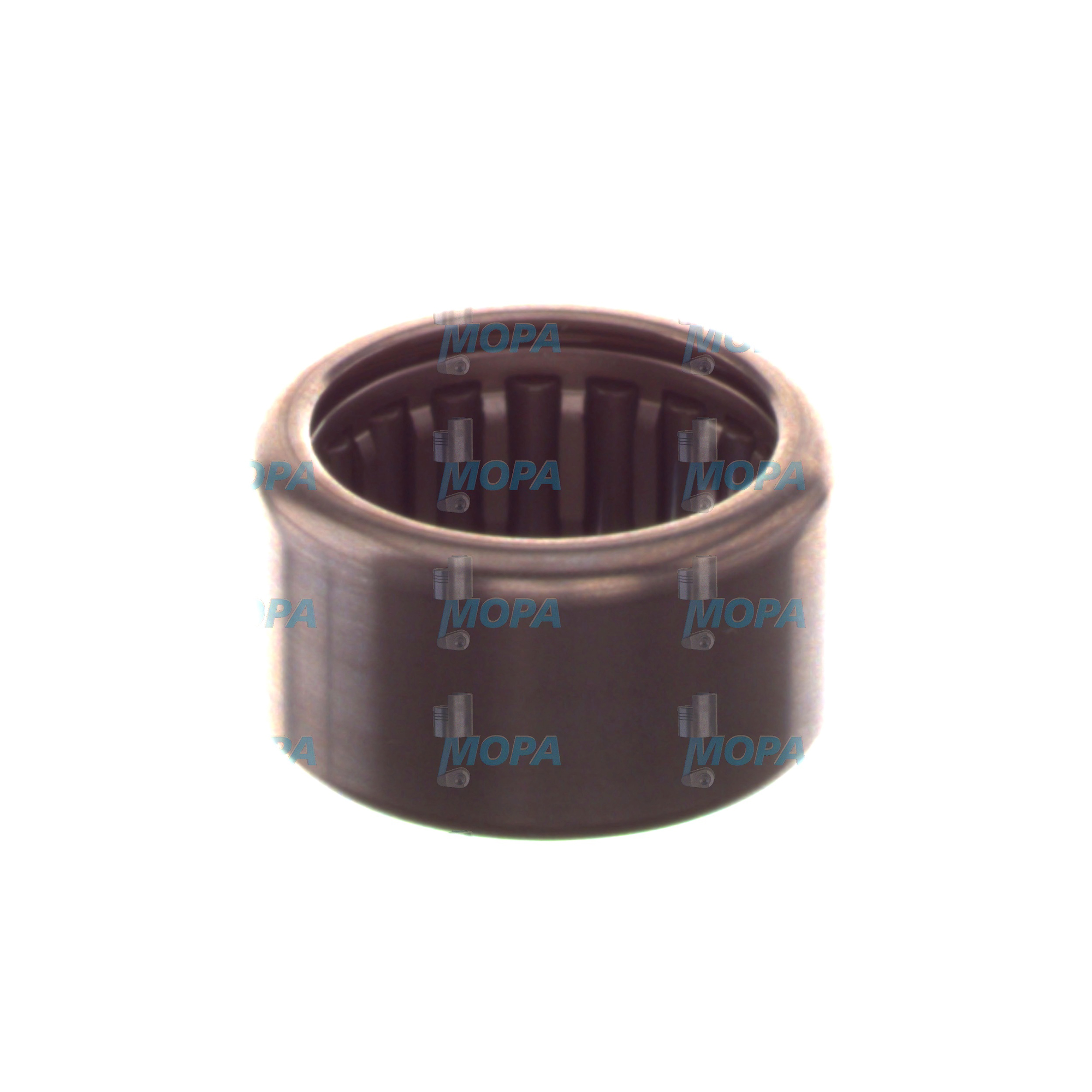

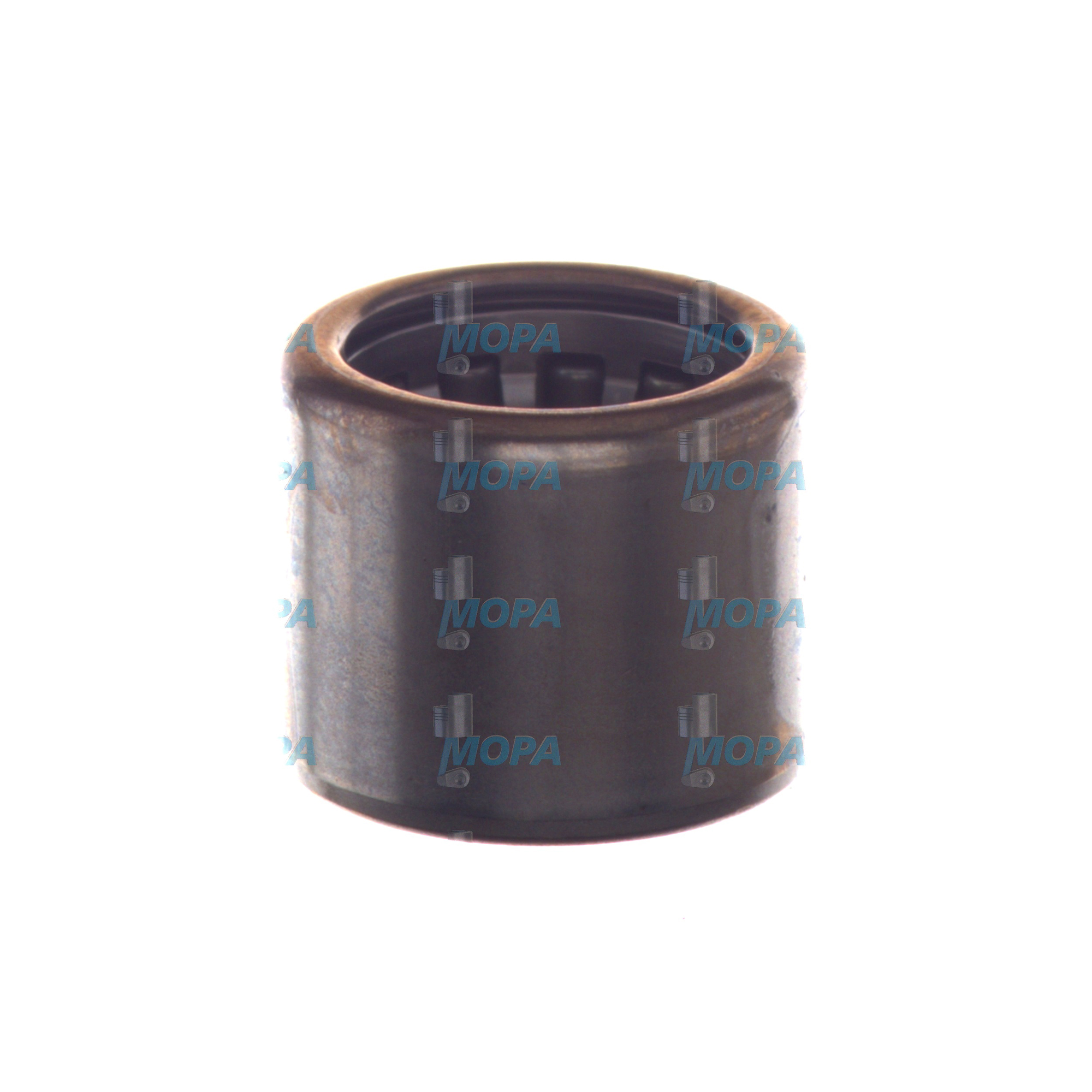

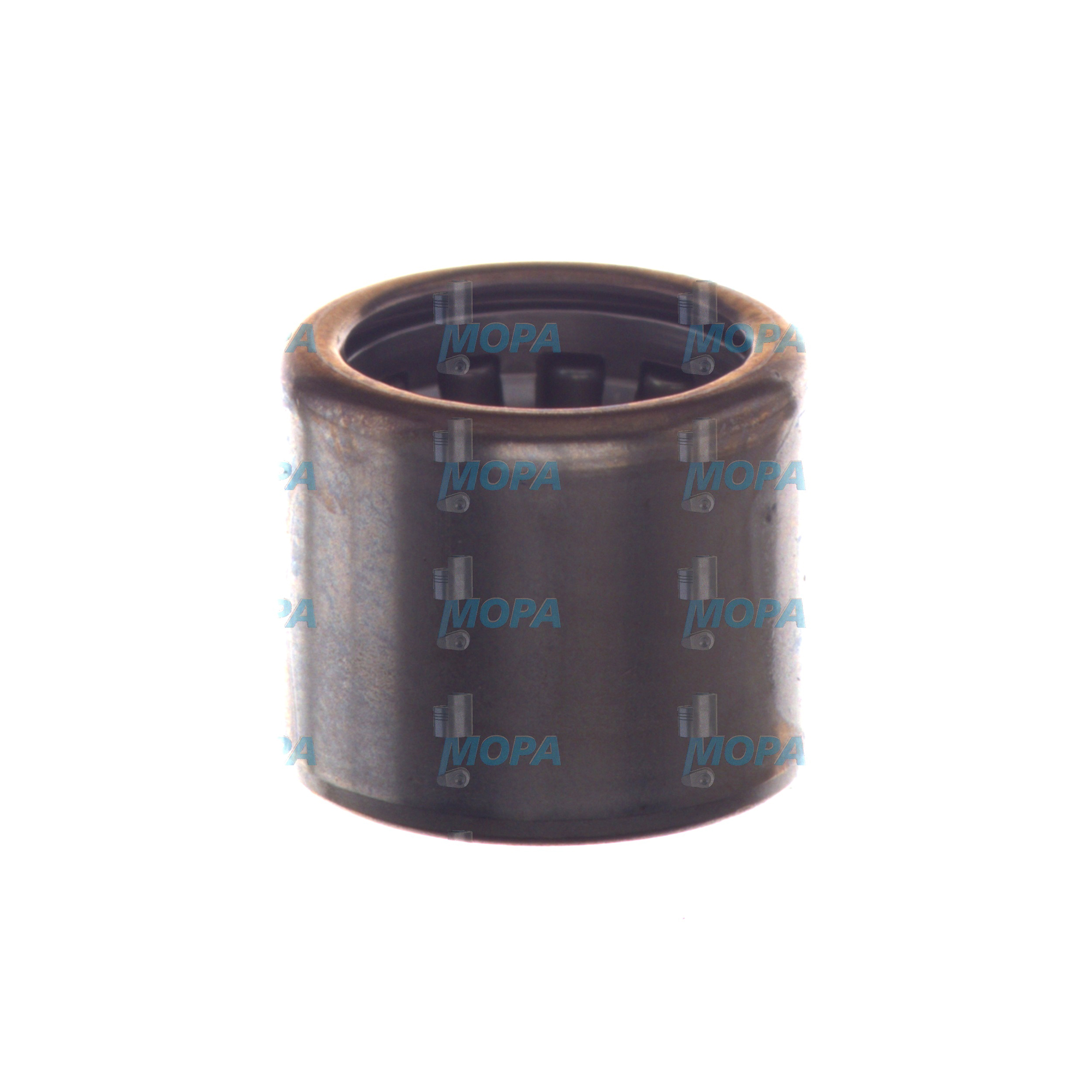

NEEDLE SLEEVE Sleeves for diesel and marine engines

Sleeves are precision-engineered inserts and bushings that protect, guide, and seal critical moving parts inside engines. In heavy-duty diesel and marine engines, they appear in several forms—injector needle sleeves, cylinder liners, valve guide sleeves, and pump bushings—each tailored to withstand high pressure, high temperature, and abrasive environments. By providing a replaceable, dimensionally stable interface, sleeves preserve the integrity of expensive housings and components while stabilizing performance. Whether installed in fuel systems or the power cylinder group, the right sleeve specification directly influences combustion quality, efficiency, and service life.

Technical function: NEEDLE SLEEVE in the diesel engine fuel system

Within an injector, the NEEDLE SLEEVE serves as the precision guide and hydraulic sealing surface for the injector needle. In a modern diesel engine or marine engine, injection pressures can exceed 2,000 bar, placing extreme demands on concentricity, surface hardness, and finish. The sleeve maintains micrometer-level clearance to keep the needle centered on the nozzle seat, minimizing leakage, ensuring crisp opening and closing, and protecting spray quality. When the sleeve is manufactured to the correct geometry and roughness, it reduces stick-slip, stabilizes needle dynamics, and supports accurate injection timing across the entire load range.

Material selection is equally important. NEEDLE SLEEVE OEM parts typically use through-hardened alloy or stainless tool steels with controlled microstructure, often combined with nitriding or advanced coatings for scuff resistance. Honed and lapped surfaces (Ra often below 0.1 μm) reduce boundary friction and fuel erosion, especially in low-sulfur fuels common in marine applications. Proper sleeve design also manages fuel film control and micro-leakage to cool and lubricate the needle without compromising injection pressure integrity.

Beyond injectors: sleeves across the engine

In parallel to the injector’s NEEDLE SLEEVE, sleeves elsewhere handle distinct duties. Cylinder sleeves (liners) form the working surface of the combustion chamber while transferring heat to the coolant and resisting wear from rings and combustion byproducts. Valve guide sleeves keep valves aligned and prevent oil migration into the exhaust path. Pump sleeves in fuel and lube circuits stabilize shafts and rotors, maintaining clearances that are vital for volumetric efficiency. Across all these locations, sleeves act as sacrificial, high-precision interfaces that preserve expensive housings, keep clearances within design windows, and protect rotating or reciprocating components from accelerated wear.

- · Precise guidance for injector needles at ultra-high pressure.

- · Stable clearances for consistent spray pattern and timing.

- · Hardened, wear-resistant surfaces for long service life.

- · Enhanced sealing to minimize leakage and dribbling.

- · Heat transfer and scuff protection in cylinder applications.

- · Alignment control for valves, pumps, and rotating assemblies.

- · Replaceable interfaces that safeguard major engine castings.

Importance for engine operation and reliability

When a sleeve wears or loses geometry, the effects ripple through the entire engine. A worn injector NEEDLE SLEEVE allows excessive needle side clearance, creating leakage that lowers effective injection pressure, delays start of injection, and degrades atomization. The result is higher specific fuel consumption, increased smoke and NOx, rough running at low load, and more frequent filter and exhaust treatment interventions. Needle sticking caused by poor sleeve finish or contamination can lead to over-fueling in one cylinder, thermal hotspots, piston crown damage, and bearing washdown—events that compromise both performance and safety.

In the power cylinder, out-of-round or scored cylinder sleeves escalate blow-by, oil consumption, and ring wear, while weak heat transfer drives localized overheating. Valve guide sleeve wear causes valve misalignment, seat erosion, and potential valve failure. Across marine engine duty cycles—slow steaming, maneuvering, and load changes—robust sleeves ensure stable clearances, clean combustion, and predictable maintenance intervals. In short, sleeves are a small cost item with a large impact on uptime and lifecycle efficiency.

Advantages of OEM spare parts suitable for Sleeves

Choosing OEM spare parts suitable for Sleeves secures the dimensional accuracy, metallurgy, and surface engineering that high-load applications demand. Tight tolerances and validated heat treatments preserve the design clearances that underpin injection precision and cylinder sealing. Traceable processes ensure repeatable hardness profiles, residual stress control, and coating adhesion—critical for resisting cavitation, fuel erosion, and abrasive particles.

From a budget and lifecycle perspective, the right sleeve specification reduces unplanned downtime and avoids collateral damage to injectors, pistons, valves, or pump housings. Consistent geometry enables straightforward installation, quicker commissioning, and immediate performance stability after overhaul. For operators balancing compliance and costs, OEM spare parts suitable for Sleeves support emissions consistency and fuel efficiency across diverse duty profiles, protecting asset value over long service intervals.

MOPA: your partner for NEEDLE SLEEVE and Sleeves OEM parts

MOPA is an experienced, reliable partner for OEM spare parts Sleeves, including the NEEDLE SLEEVE used in diesel engine and gas engine applications. We focus on speed, quality, and security in the trade of OEM parts, ensuring that purchasers and technical teams receive the right specification fast—supported by documentation, traceability, and careful packaging for global logistics. Our team assists with cross-references, dimensional checks, and application guidance for marine engine fleets and stationary power, helping you plan overhauls confidently and keep downtime to a minimum.

Whether you need injector needle sleeves, cylinder sleeves, valve guide sleeves, or pump bushings, MOPA aligns delivery times with dry-dock schedules and maintenance windows. With responsive sourcing and a quality-driven approach, we help you safeguard performance, control fuel costs, and extend service life across your engine portfolio.

Conclusion: NEEDLE SLEEVE relevance in diesel and marine engines

Precise, durable Sleeves—and especially the injector NEEDLE SLEEVE—are central to clean combustion, reliable starting, and stable power across diesel and marine engine operations. Selecting OEM spare parts suitable for Sleeves secures the materials, tolerances, and finishes that protect efficiency, reliability, and budget through the full lifecycle of your assets.