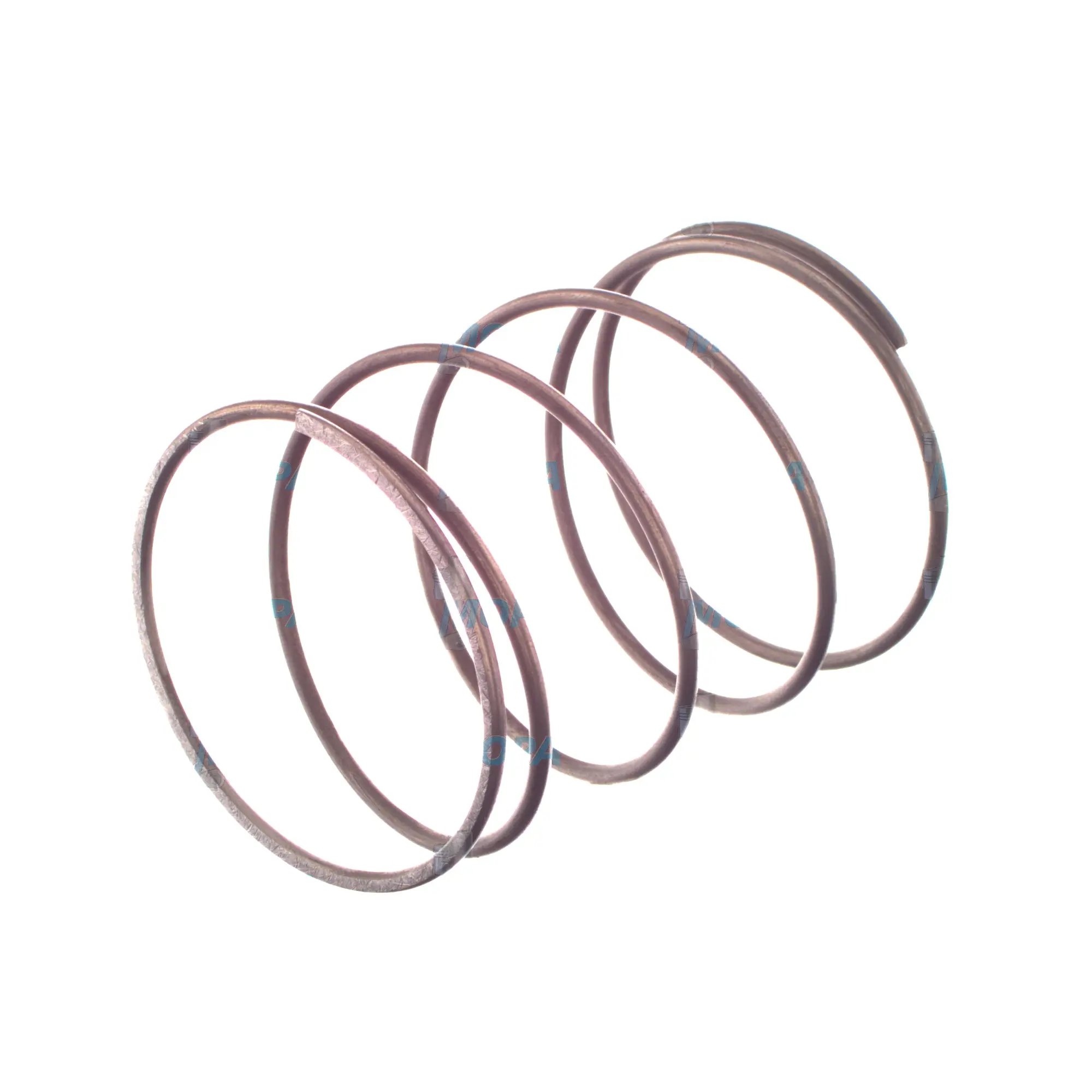

COMPRESSION SPRING Springs for marine and diesel engines

Springs are precision mechanical components that store and release energy to create force, maintain position, or enable controlled movement. In large marine and stationary diesel and gas engines, Springs are found throughout the valve train, fuel injection equipment, safety and relief valves, governors, couplings, and sealing systems. Correctly specified Springs keep timing accurate, pressures stable, and vibration within safe limits—making them indispensable for reliability and performance.

Within this category, the COMPRESSION SPRING is the most prevalent form used in engines. It delivers force when compressed, translating linear deflection into repeatable load according to its spring rate. Whether stabilizing a valve at high RPM or resetting a high-pressure fuel plunger, a COMPRESSION SPRING for marine engine duty must withstand heat, corrosion, cyclic stress, and long service intervals without loss of load.

COMPRESSION SPRING function in a marine engine and diesel engine

In the valve train, compression Springs (valve Springs) keep valves seated against their seats, follow the cam profile precisely, and prevent valve float at high speed. The engineered spring rate (N/mm), free length, and installed preload ensure the valve stays closed under combustion pressure yet opens with the correct dynamics to minimize wear. Ground ends, shot peening, and stress relief treatments improve fatigue strength and reduce relaxation, ensuring stability across thousands of operating hours.

In fuel systems, a COMPRESSION SPRING in a diesel engine returns the pump plunger, controls delivery-valve closing, and stabilizes injector needles against nozzle seat chatter. Accurate load characteristics preserve injection timing, reduce hydraulic hammer, and contribute to clean combustion and lower specific fuel consumption. Relief and safety valves use calibrated compression Springs to set opening pressure; small deviations can shift the protection point, so tight tolerances are critical for safe operation of charge-air, lube-oil, and cooling circuits.

Sealing systems and mechanical couplings rely on compression Springs to maintain face contact or engage/disengage mechanisms consistently under thermal expansion and vibration. Across these use cases, selecting COMPRESSION SPRING OEM parts with documented metallurgy, heat treatment, and dimensional control preserves the intended dynamic behavior of the assembly.

Key characteristics and advantages of Springs in engine applications

- · Consistent spring rate and preload across temperature range.

- · High fatigue strength for long life under cyclic loading.

- · Materials matched to duty: SiCr, Cr-V, or high-temperature alloys.

- · Shot-peened and set-removed for stability and reduced relaxation.

- · Precision on free length, wire diameter, coil count, solid height.

- · Corrosion and scale resistance for marine environments.

- · Traceability and batch testing for dependable quality control.

Why Springs are critical for reliable engine operation

Springs directly influence engine timing, efficiency, and safety margins. Valve Springs that lose load due to creep or corrosion can cause valve float, seat leakage, or—under worst conditions—valve-to-piston contact. The outcome ranges from rough running and elevated exhaust temperatures to catastrophic damage. In fuel equipment, weakened Springs shift injector opening pressures, degrading atomization and increasing smoke, fuel consumption, and thermal stress on pistons and turbochargers. In safety valves, drifted set points erode the protective envelope of the system.

Typical warning signs include increased tappet noise, unstable idle, hard starting, misfires under load, and recurring relief-valve lifts. Preventive measures include measuring free length versus specification, verifying rate on a spring tester, inspecting for surface cracks, pitting, or coil wear marks, and replacing Springs at recommended intervals—especially before major overhauls. Using a correctly rated COMPRESSION SPRING for marine engine service keeps dynamic components aligned with design intent and avoids secondary failures that drive unplanned downtime.

Advantages of OEM spare parts suitable for Springs

OEM spare parts suitable for Springs maintain the exact load-deflection curve the engine designer specified, securing component interactions across the camshaft, rocker gear, retainers, seats, and fuel equipment. That precision matters: a few newtons per millimeter can be the difference between stable operation and resonance or surge. COMPRESSION SPRING OEM parts also preserve clearances and heights (installed and at coil bind), protecting retainers and preventing spring surge at operating speed.

For purchasers and technical managers, the benefits are practical and measurable:

- · Performance: Correct rates sustain valve control and injection timing.

- · Reliability: Proven metallurgy and heat treatment resist relaxation.

- · Budget: Longer service life reduces overhaul frequency and labor.

- · Service life: Predictable fatigue behavior supports planned maintenance.

- · Safety: Calibrated loads keep relief and safety valves on-spec.

- · Compatibility: Exact fit with seats, retainers, and adjoining OEM parts.

MOPA as your partner for OEM parts Springs

MOPA supplies OEM spare parts suitable for Springs across leading diesel and gas engine platforms, combining speed, quality, and transaction security. Our network and stock depth enable short lead times for COMPRESSION SPRING OEM parts, valve Spring sets, injector Springs, and safety-valve Spring kits tailored to marine and power generation requirements.

Purchasers and superintendents value fast quotations, reliable documentation, and shipment coordination to shipyards and ports worldwide. Each delivery emphasizes quality control, correct specification matching, and safe packing—so components arrive ready to install and perform. With MOPA, you gain a responsive partner focused on uptime and lifecycle cost in demanding engine environments.

Conclusion: Springs and COMPRESSION SPRING benefits

Springs are small components with a decisive impact on engine timing, efficiency, and protection. Specifying and replacing with OEM spare parts suitable for Springs—especially the COMPRESSION SPRING used in valve trains, fuel systems, and safety equipment—preserves performance and extends overhaul intervals.

With MOPA as a supplier for OEM parts, technical buyers secure the right Spring, on time, with the quality and consistency required for modern marine and diesel engines.