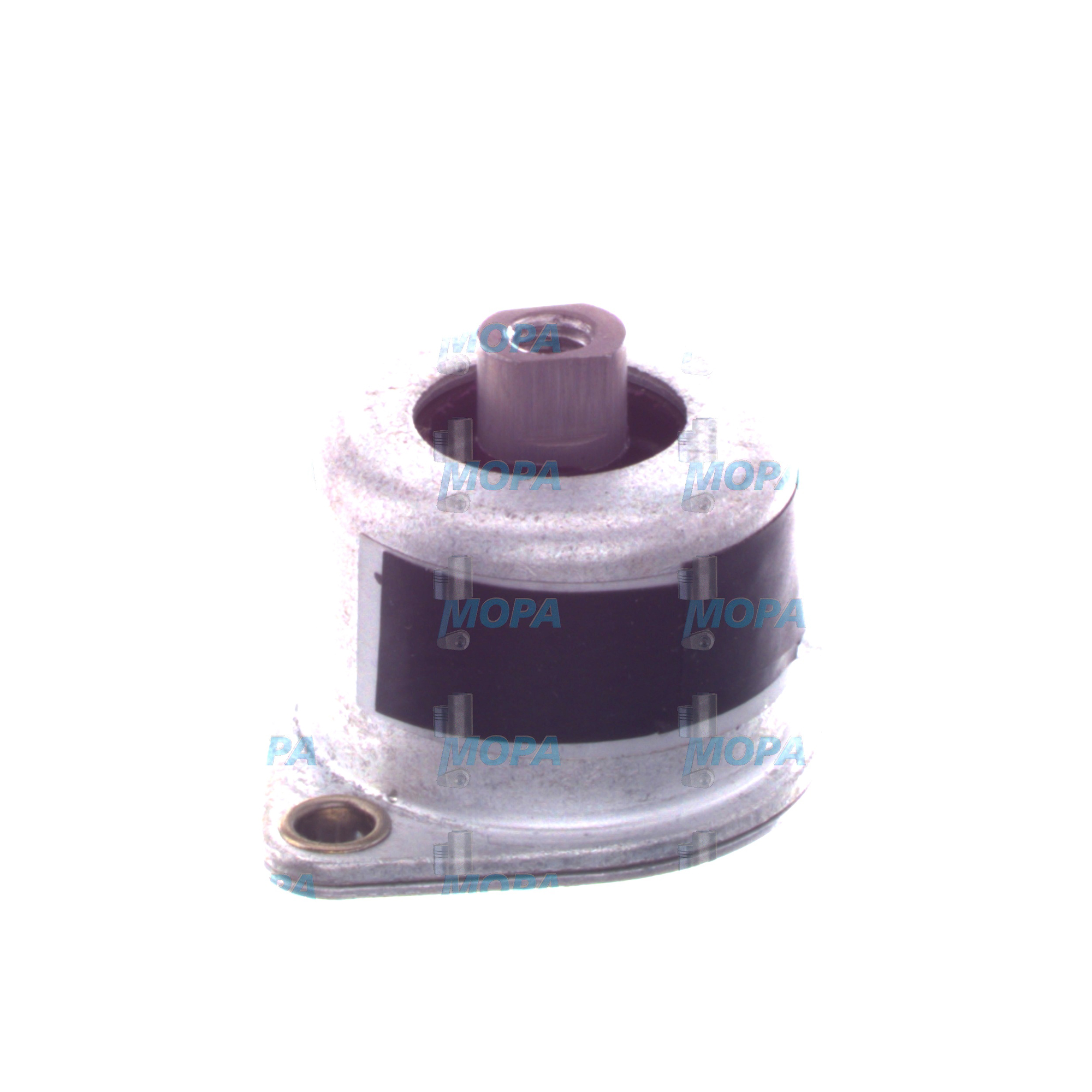

RESILIENT ELEMENT Springs for Diesel and Marine Engines

Springs are precision-engineered resilient elements that store and release mechanical energy to control motion, force, and vibration across critical subsystems of diesel and gas engines. In a marine engine or power plant prime mover, springs appear in the valve train, fuel injection equipment, governors, pressure relief valves, torsional couplings, and safety devices. As compact, highly stressed components, they influence timing accuracy, sealing forces, vibration behavior, and protection functions—making them indispensable for reliable operation, fuel efficiency, and compliance with class and emission standards.

Technical function: Springs as a RESILIENT ELEMENT in marine engine and diesel engine assemblies

In an engine, a spring acts as a controlled force provider that follows a defined load–deflection characteristic. Valve springs deliver the seat and open load required to keep valves sealed under combustion pressure, then rapidly close them at high speed without valve float. Injector and pump springs stabilize injection timing and needle lift, ensuring repeatable fuel delivery. Governor springs counterbalance centrifugal forces to regulate fuel rack position and engine speed. In couplings and dampers, spring packs work as a RESILIENT ELEMENT to tune torsional stiffness and mitigate crankshaft vibration harmonics.

The performance of these components depends on material selection (e.g., Cr-Si spring steel or high-temperature alloys), heat treatment, surface finishing (shot peening), and precise grinding of ends. The result is a well-defined spring rate (k), high fatigue strength, and controlled stress distribution that stands up to millions of cycles. Because diesel engines run with strong pressure pulses and high thermal load, a correctly specified RESILIENT ELEMENT ensures consistent valve events, stable injection, and smooth driveline behavior. When sourced as RESILIENT ELEMENT OEM parts, the dimensional tolerances, coil geometry, and surface integrity align with the engine maker’s specifications, supporting safe operation at rated speed and load.

- · Stable spring rate for precise timing and control.

- · High fatigue strength for long service intervals.

- · Shot-peened surfaces to delay crack initiation.

- · Corrosion protection suited to marine atmospheres.

- · Tight tolerances for fit, preload, and free length.

- · Material traceability and process consistency.

- · Compatibility with diesel and gas engine duty cycles.

RESILIENT ELEMENT dynamics that protect performance and safety

Springs must avoid surge and resonance within the operating speed range. Proper damping and seat pressure prevent valve float and bounce, safeguarding pistons and exhaust components. In safety devices—such as pressure relief valves and overspeed trips—the spring’s calibrated force is the RESILIENT ELEMENT that determines activation thresholds. In torsional systems, spring stiffness and preload are tuned to shift critical frequencies, protecting gear trains, couplings, and generator windings from damaging oscillations.

Importance for engine operation: Why Springs are mission-critical

Even small deviations in spring characteristics can cascade into costly issues. Loss of preload, relaxation, or micro-cracking causes:

• Valve leakage, hot-gas erosion, and seat recession. • Valve float at high RPM, leading to impact damage and power loss. • Unstable injection needle motion, poor atomization, and increased fuel consumption. • Erratic governor behavior, speed hunting, or late overspeed response. • Amplified torsional vibration, damaging couplings and bearings.

Routine inspections should measure free length, spring force at defined heights, and visual surface condition. If fatigue marks, corrosion pits, or heat tinting appear, replacement is recommended. Keeping these RESILIENT ELEMENT components within spec preserves combustion quality, emissions performance, and component life across the entire engine system.

Advantages of OEM spare parts suitable for Springs and RESILIENT ELEMENT functions

Choosing OEM spare parts suitable for Springs ensures that load–deflection curves, metallurgy, and surface treatments match the engine’s design intent. This precision translates into predictable dynamics and longer life under marine duty cycles and high sulfur or humid environments.

Key reasons to select OEM spare parts suitable for Springs:

- · Performance: Correct seat and open loads maintain valve control and injection accuracy.

- · Reliability: Proven fatigue resistance and controlled residual stresses reduce unexpected failures.

- · Budget: Longer service life and fewer unplanned stoppages lower total operating costs.

- · Service life: Proper materials and coatings resist relaxation, corrosion, and fretting.

- · Compliance: The right RESILIENT ELEMENT OEM parts help engines meet class and emission requirements in service.

- · Fit and function: Dimensional consistency prevents coil bind, misalignment, and uneven loading.

With OEM specification alignment, you protect precision-engineered interfaces—retainers, seats, guides, spring pockets—and maintain the designed stress margins through overhaul intervals.

MOPA as a partner for OEM parts: RESILIENT ELEMENT Springs for diesel and gas engines

MOPA is an experienced and reliable partner for OEM spare parts Springs across major diesel and gas engine platforms. We focus on speed, quality, and security in the supply chain—sourcing from audited manufacturers, providing documentation where required, and delivering on tight dry-dock and outage schedules. Whether you operate a marine engine on deep-sea routes or a land-based power unit, MOPA streamlines procurement of RESILIENT ELEMENT OEM parts: valve springs, injector springs, governor springs, and torsional spring packs included.

Our team supports identification by part number, engine model, and build list, helping purchasers and superintendents match the right specification at the first attempt. With responsive logistics and careful packaging, we reduce the risk of corrosion or damage during transit, so springs arrive ready for installation during your maintenance window.

Conclusion: RESILIENT ELEMENT Springs that secure uptime and efficiency

Springs are the compact RESILIENT ELEMENT behind stable timing, clean combustion, and safe protection functions in every diesel or marine engine. Selecting OEM spare parts suitable for Springs preserves designed performance, keeps operating costs predictable, and extends component life under real-world conditions.

MOPA delivers fast, dependable access to the correct RESILIENT ELEMENT OEM parts, helping you protect your assets and keep your engines running at peak efficiency.