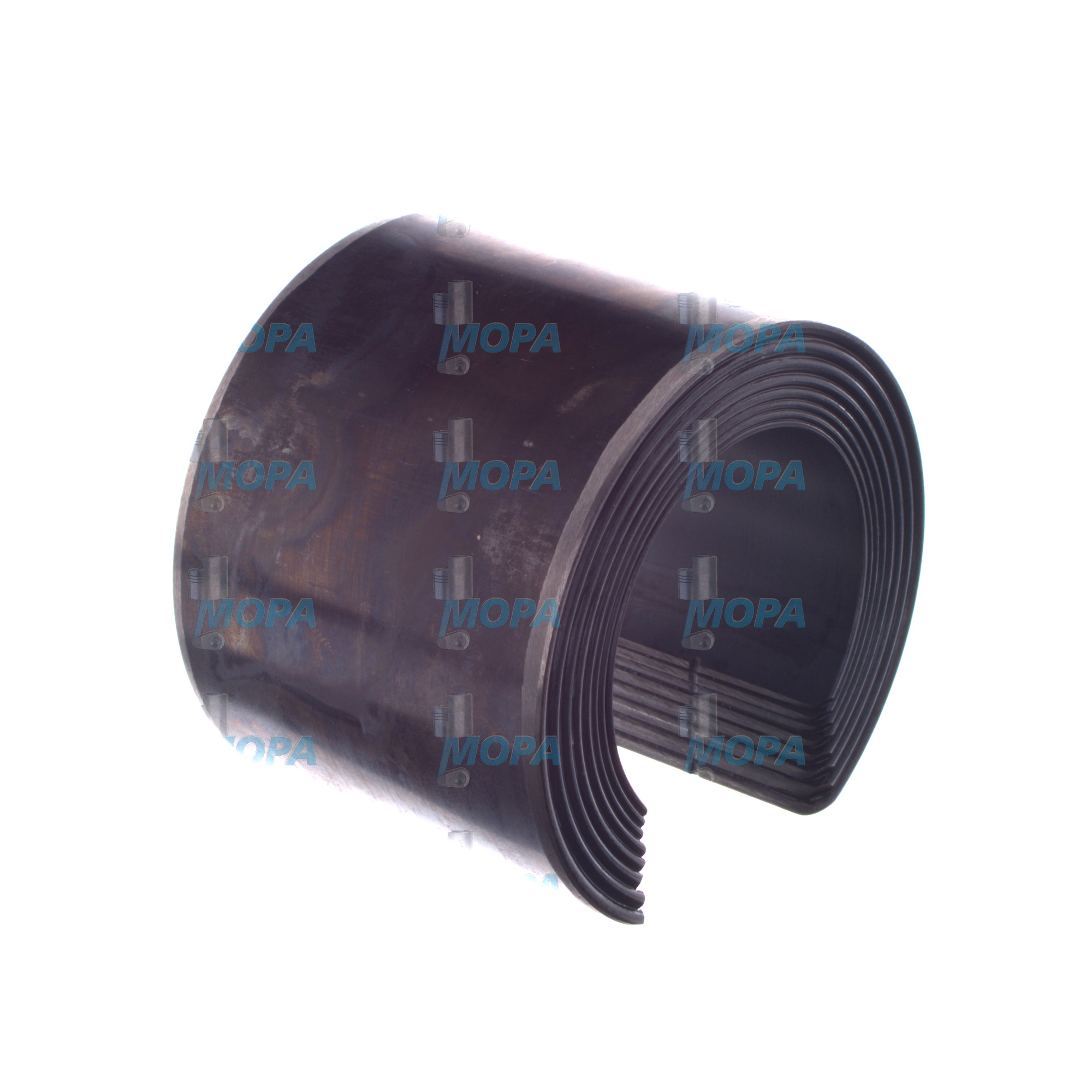

SLEEVE SPRING Springs for diesel and marine engines

Springs are precision elastic components that store and release energy to control motion, preload assemblies, seal interfaces, and protect critical parts inside engines. In high-duty diesel and gas engines, Springs ensure valves seat reliably, injector needles close cleanly, governors remain stable, and control sleeves return to a defined position. Across propulsion, power generation, and auxiliary drives, the right spring design directly influences output, emissions, and uptime—making Springs a small part with major impact.

Within this category, the SLEEVE SPRING is particularly relevant where a sliding sleeve must be positioned against hydraulic or mechanical forces—common in fuel systems and control mechanisms on large-bore and medium-speed engines. Engineered to exact rates and free lengths, these Springs maintain consistent forces over millions of cycles, even at elevated temperatures and under contaminated lubrication environments typical of marine and industrial applications.

Technical function of Springs and SLEEVE SPRING in a marine engine and diesel engine

Springs convert deflection into force. In engines, this function is used to maintain contact, create defined preloads, and provide fail-safe returns. Valve springs counter inertial forces to prevent valve float at high RPMs, injector springs ensure rapid needle closure to avoid dribble, relief-valve springs define cracking pressures, and torsion or compression Springs hold governors and actuators at set points. A SLEEVE SPRING applies axial force to a control sleeve or sliding bushing so that timing, metering, or bypass functions remain repeatable despite vibration, thermal expansion, and oil-film variations. In unit injectors or pump-line-nozzle systems, the SLEEVE SPRING helps the sleeve track cam-driven motion precisely, improving injection timing stability and cylinder-to-cylinder balance.

When specified correctly, a SLEEVE SPRING in OEM parts tolerances delivers a stable spring rate (N/mm), minimal relaxation over time, and predictable behavior across the full stroke. Metallurgy (e.g., Si-Cr or Cr-V steels), wire geometry, shot peening, and heat treatment jointly determine fatigue resistance and set loss. Surface coatings resist corrosion from fuel or crankcase vapors, while tight tolerances on roundness and free length ensure even contact pressures and low wear of the sleeve and mating surfaces.

Key characteristics and advantages of Springs

· Precisely defined spring rate for consistent force across stroke.

· High-cycle fatigue strength for millions of load reversals.

· Low relaxation and set under continuous high temperature.

· Corrosion- and wear-resistant surfaces for long service intervals.

· Tight dimensional tolerances to protect sleeves, guides, and seats.

· Materials matched to diesel engine thermal and chemical environments.

· Stable behavior under vibration and shock loads in marine service.

· Repeatable performance supporting emissions and fuel efficiency targets.

Why Springs and SLEEVE SPRING are critical for engine reliability and service life

Reliability depends on keeping forces and timing within design limits. If a valve spring weakens, valve float and seat hammering accelerate wear, raising exhaust temperatures and risking turbocharger damage. If an injector or SLEEVE SPRING loses rate, the control sleeve may not return fully, causing late or uneven fuel delivery, smoke, increased specific fuel consumption, and rough running. Weak relief-valve Springs allow oil pressure drift; over-strong ones elevate pressure and aeration, both harmful to bearings and cam lobes.

Consequences of worn or mismatched Springs include higher emissions, poor cold start, loss of peak power, piston crown overheating, liner scuffing due to fuel wash, and unplanned stoppages. Because Springs work in concert—valvetrain, fuel injection, governors, and safety valves—a single degraded element can propagate faults across the system.

Advantages of OEM spare parts suitable for Springs and SLEEVE SPRING OEM parts

Choosing OEM spare parts suitable for Springs ensures the specified steel grades, wire diameters, heat treatment curves, and shot-peening intensities are consistently met. That precision safeguards the engineered spring rate, fatigue life, and set characteristics demanded by the engine designer. It also preserves the micro-geometry of mating sleeves, guides, and retainers, preventing costly collateral wear.

From a performance and lifecycle perspective, OEM spare parts suitable for SLEEVE SPRING deliver predictable timing and metering, which translates into stable cylinder pressures, lower fuel burn, and cleaner exhaust. For budgets, the lower risk of repeat jobs, secondary damage, or detuned operation typically outweighs any short-term savings from unspecified components. Traceable OEM production lots, dimensional inspection, and test certificates provide the technical transparency purchasing and classification stakeholders expect.

In practical terms, that means faster installation with correct fit, fewer setup adjustments, and confidence that the spring will perform across the full maintenance interval under real engine loads—whether the duty is harbor maneuvering, base-load power generation, or variable hotel loads at sea.

MOPA—experienced partner for OEM spare parts Springs and SLEEVE SPRING

MOPA supplies OEM spare parts suitable for Springs and SLEEVE SPRING across a wide range of diesel and gas engines used in marine propulsion and power applications. Customers rely on our speed in quoting and delivery, our consistent quality standards, and the security of working with a partner focused on compliant, traceable trade in OEM parts.

Our team cross-references part numbers, drawings, and engine build lists to propose the correct spring variant—free length, rate, material spec, and seating hardware—so your maintenance window is kept tight and predictable. We coordinate logistics worldwide, arrange urgent shipments, and provide documentation that supports class and safety audits. With MOPA, purchasers, shipowners, and technical decision-makers gain a single, reliable source for critical spring components that protect performance and uptime.

Maintenance insights for SLEEVE SPRING and other engine Springs

Inspect Springs during overhauls for free length loss, surface cracking, corrosion pitting, and squareness. Measure spring rate where procedures allow; any deviation from spec indicates impending failure. Replace SLEEVE SPRING sets as pairs or full sets per engine-side guidance to maintain balance. Avoid over-compressing during assembly, keep components clean, and verify sleeve travel and return during function checks to ensure correct actuation after installation.

Conclusion: SLEEVE SPRING and Springs underpin efficient engine operation

Springs—especially the SLEEVE SPRING in control and fuel metering assemblies—are essential to stable performance, efficiency, and safe running in diesel and marine engines. Specifying and installing OEM spare parts suitable for Springs sustains designed forces, timing accuracy, and long service life while protecting budgets through reduced downtime and repeat work.