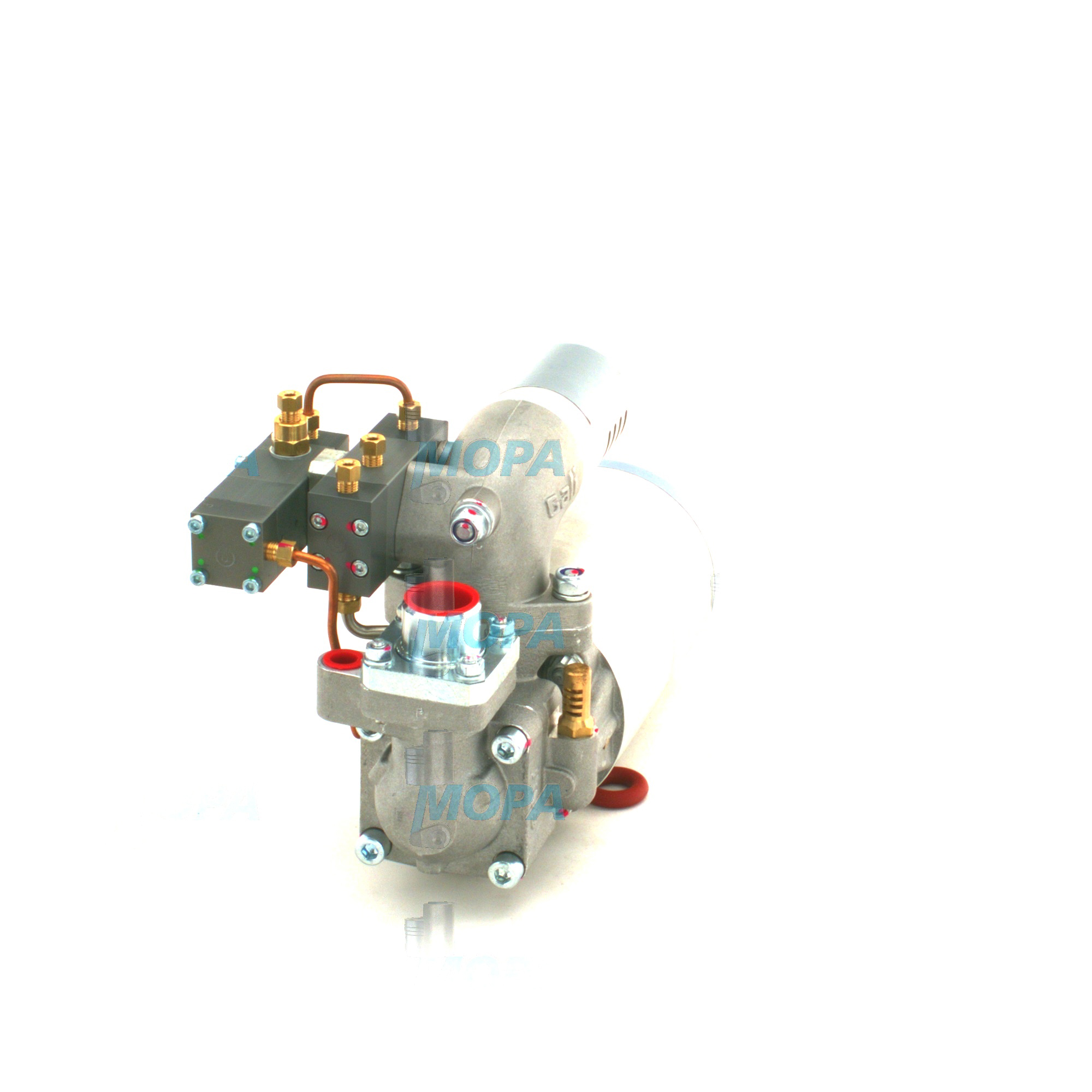

AIR STARTER for marine and diesel engines

The article category Starter covers all components that initiate crankshaft rotation to bring an engine from standstill to firing speed. In heavy-duty applications such as propulsion sets, gensets, and compressor drives, the AIR STARTER is a proven solution that uses compressed air to deliver reliable cranking without electrical ignition sources. For shipowners, plant operators, and maintenance teams, a well-specified Starter is fundamental: it governs whether a diesel or gas engine can be brought online quickly, safely, and repeatedly under demanding conditions.

While electric starters dominate in light-duty engines, the AIR STARTER excels in large-bore diesel engines and marine engine environments thanks to high torque density, robustness, and suitability for hazardous areas. Its mechanical simplicity, coupled with engineered pneumatics, offers consistent performance across a wide range of ambient temperatures and load scenarios.

Technical function: how an AIR STARTER drives a diesel engine

An AIR STARTER converts compressed air energy into rotational torque via a compact vane or turbine motor. When the operator initiates the start command, a pilot valve and main air valve admit regulated pressure to the starter motor. Through a reduction gear train and an overrunning clutch, the pinion engages the flywheel ring gear, accelerating the crankshaft to firing speed. Once the engine fires, the clutch automatically disengages and the pinion retracts to prevent back-drive. In a marine engine, this sequence is integrated with interlocks (e.g., turning gear out, lube oil pressure ready) to ensure safe engagement.

Two design principles are common. Vane-motor AIR STARTER units deliver strong low-speed torque and predictable cranking profiles. Turbine-motor variants offer low mass, quick spool-up, and tolerance to intermittent lubrication. Both rely on clean, dry, and properly filtered air, typically fed via an FRL (filter–regulator–lubricator) set and controlled by a solenoid or pneumatic pilot. Correct line sizing and valve capacity ensure sufficient mass flow so the diesel engine reaches target cranking rpm within the specified time, minimizing fuel enrichment and thermal stress during light-off.

In performance terms, the AIR STARTER contributes to efficient, repeatable engine starts by delivering high torque at low speed, maximizing cylinder charge motion and ignition stability. From a safety perspective, it removes electrical sparking risks and reduces the complexity of high-current cabling in wet or classified spaces. For operators who rely on OEM parts, the ability to match the AIR STARTER to the engine’s flywheel data, gear module, and required torque curve is central to reliable service.

- · High cranking torque at low rpm.

- · Spark-free operation for hazardous environments.

- · Robust gear train with overrunning clutch protection.

- · Vane or turbine motor options to suit duty profile.

- · Integrated control via pilot and main air valves.

- · Works in cold starts and repeated start cycles.

- · Compatible with marine engine interlock systems.

Importance of the Starter for reliable engine operation

The Starter is decisive for availability. If cranking torque is insufficient or engagement is erratic, the engine may fail to start, start slowly, or suffer repeated aborts that waste fuel and stress components. Worn pinions, fatigued overrunning clutches, or leaking air valves can produce slow roll, gear chatter, or incomplete engagement that damages the flywheel ring gear—leading to unplanned outages and costly dry-dock or shutdowns. Moisture or contamination in the air supply can score vane surfaces, erode turbine blades, and degrade seals, reducing delivered torque and increasing air consumption.

Keeping the AIR STARTER in proper condition preserves start quality, protects the flywheel interface, and minimizes cranking time—key to emissions control during start-up and to overall engine health. For fleet operators, consistent Starter performance also standardizes procedures and reduces training complexity across vessels or plants.

Advantages of OEM spare parts suitable for Starter

Using OEM spare parts suitable for Starter assemblies ensures that each element—pinion geometry, clutch rollers, bearing sets, springs, seals, and housings—matches the engine builder’s interface and the starter maker’s torque map. Precision in tooth profile and heat treatment preserves the flywheel, while correct elastomer compounds resist oil mists, saline humidity, and temperature cycling. The result is predictable cranking torque, stable engagement timing, and a longer service interval for the entire starting system.

Beyond fit and function, component traceability and consistent manufacturing processes translate into fewer re-starts, less compressed air consumption, and lower lifetime cost. Purchasers benefit from standard lead times and clear documentation, and maintenance crews gain from drop-in compatibility that shortens change-out windows during port calls or planned shutdowns.

- · Exact fit to flywheel ring gear and housing interfaces.

- · Stable torque output across the designed pressure range.

- · Durable materials and surface treatments for long service life.

- · Sealing systems that resist oil, heat, and saline air.

- · Lower downtime thanks to predictable, repeatable performance.

- · Optimized air consumption for efficient starts.

- · Documentation and traceability that support compliance.

MOPA: your partner for AIR STARTER OEM parts

MOPA supports shipowners, power producers, and industrial operators with OEM spare parts for Starter systems used on diesel and gas engines. As a seasoned trading partner, MOPA focuses on speed, quality, and security—from item identification and technical cross-reference to packing, certification, and worldwide logistics. Our team sources AIR STARTER OEM parts that align with engine-maker specifications, ensuring that pinions, clutches, motors, and valve kits integrate seamlessly with your equipment.

Whether you operate a single marine engine or a multi-site fleet, MOPA streamlines procurement with responsive quotes, reliable lead times, and careful documentation. The result is reduced risk in your supply chain and dependable availability of the components that keep engines start-ready.

Conclusion: why the AIR STARTER category matters

The Starter is pivotal to engine availability, and the AIR STARTER variant provides the torque, safety, and repeatability needed in marine and industrial diesel applications. By selecting OEM spare parts suitable for Starter assemblies, you safeguard performance, control costs, and extend service life. MOPA delivers the expertise and supply reliability to keep your starting systems operating at their best.