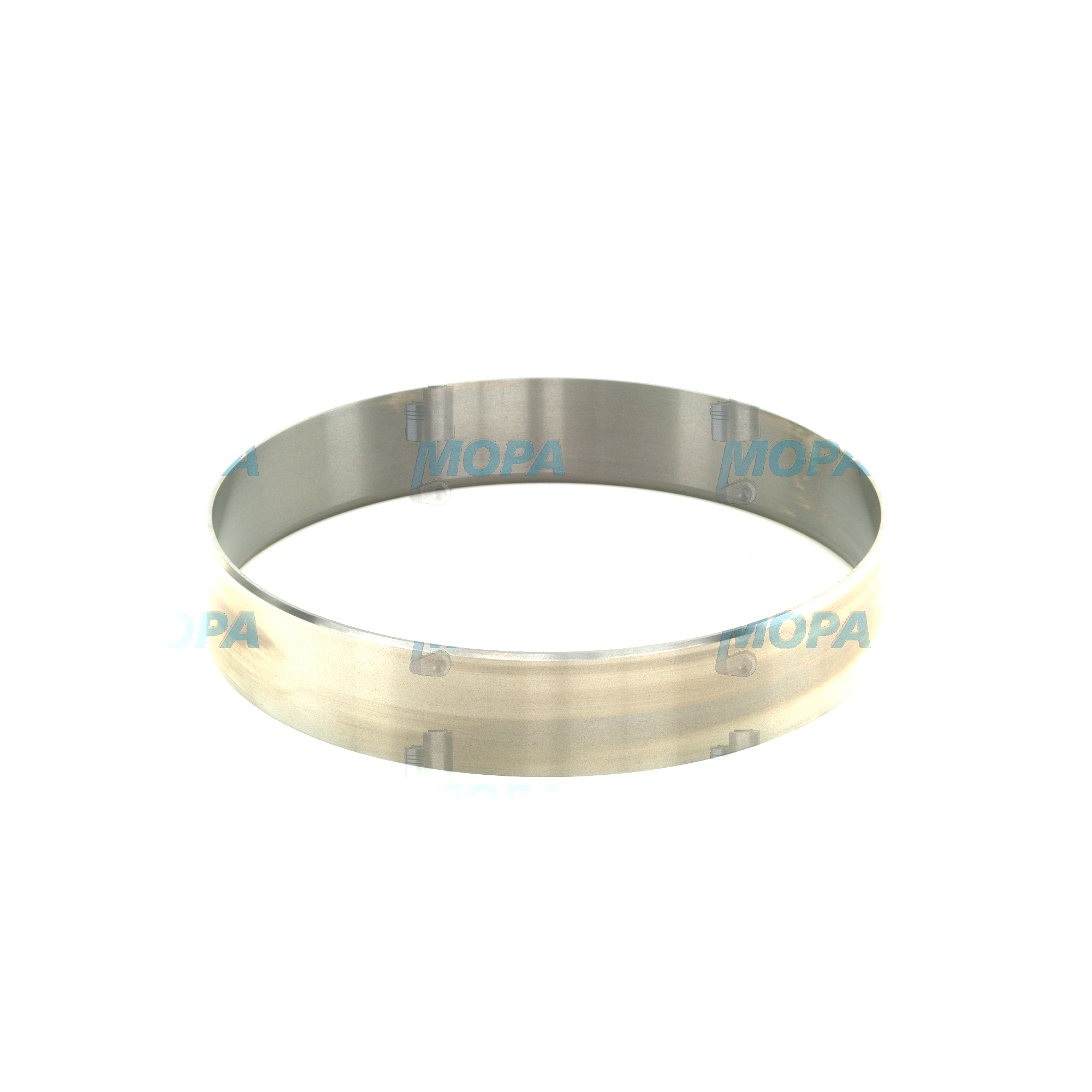

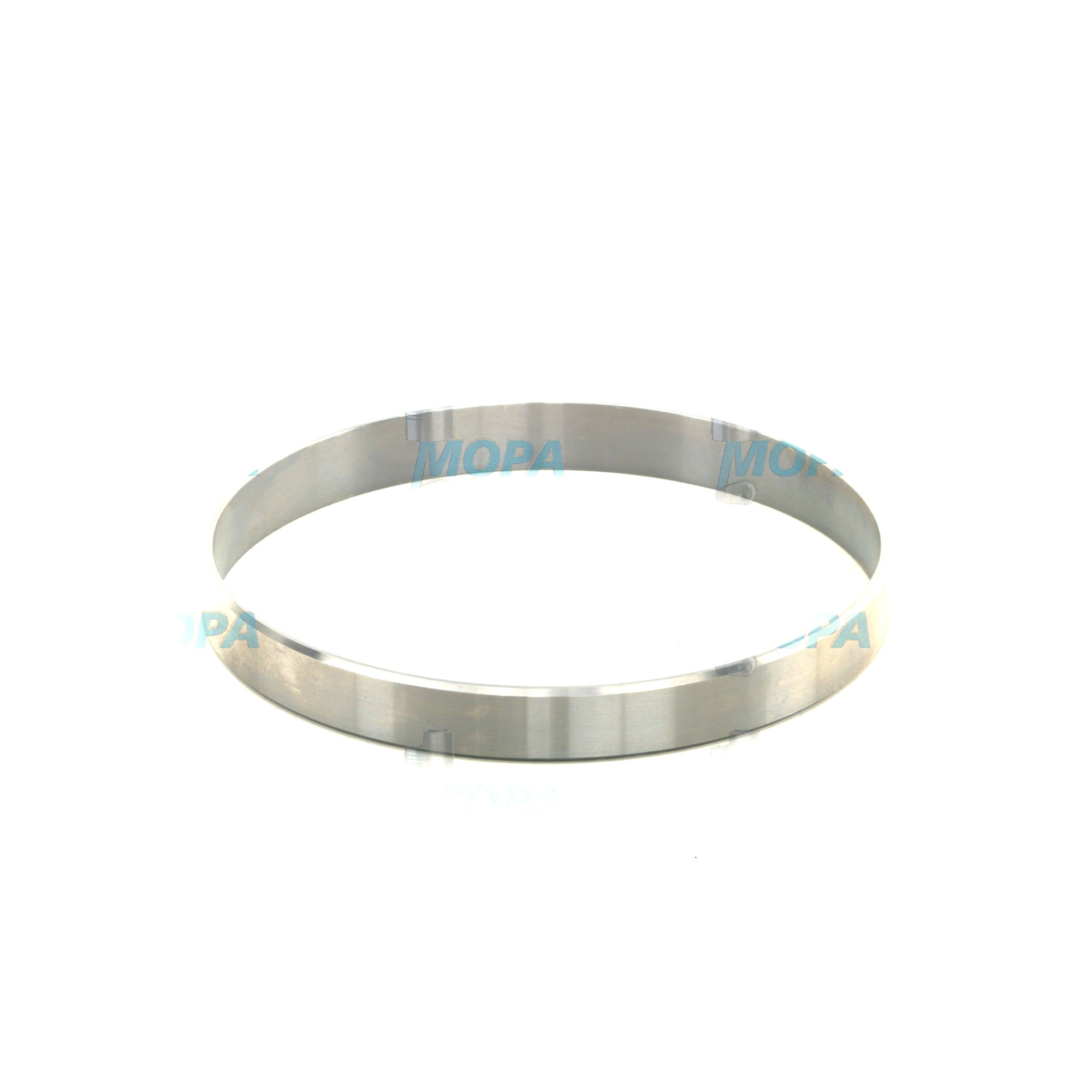

COKE SCRAPER RING

COKE SCRAPER RING Tools for marine and diesel engines

Tools are the backbone of reliable engine service. In heavy-duty diesel and gas applications—especially in marine engine environments—precision tools enable safe, accurate installation, removal, measurement, and inspection of critical components. Within this category, specialized equipment for handling the COKE SCRAPER RING and associated assemblies plays a decisive role in protecting cylinder liners, maintaining compression, and preserving lubrication control. Without the right tools, even experienced technicians risk damaging high-value parts and compromising engine performance.

In practice, engine tools encompass purpose-built fixtures, gauges, mandrels, pullers, ring expanders, torque tools, and calibration instruments. For operations that work with a COKE SCRAPER RING (often associated with anti-polishing functionality in large-bore engines), the right tool set ensures correct positioning, alignment, and dimensional control—key to achieving consistent running conditions, reduced blow-by, and longer intervals between overhauls.

Technical function of COKE SCRAPER RING tools in a diesel engine

The COKE SCRAPER RING is engineered to control carbon and lacquer build-up on the upper cylinder area, protecting the liner surface and piston top land from polishing and abrasive wear. In a marine engine, its function is especially critical due to long operating hours, variable loads, and heavy fuel use. When combined with the correct tools, technicians can install and service this part to the exact tolerances defined by the engine maker, ensuring that carbon deposits are consistently removed and that oil film integrity is preserved.

Specialized tools support three essential tasks: precise measurement, controlled handling, and clean installation. Measurement tools—such as ring groove gauges, bore gauges, micrometers, and feeler gauges—verify the ring groove width, side clearance, and end-gap against specification. Handling tools—like ring expanders, installation sleeves, and dedicated mandrels—prevent overstressing or twisting the COKE SCRAPER RING during fitting. Clean installation tools—such as deburring tools, surface cleaners, and torque-controlled fasteners—ensure the seating faces are pristine and clamping forces are uniform. Together, they enable repeatability and reduce human error, which translates into stable compression ratios and predictable wear patterns.

In overhaul routines, COKE SCRAPER RING tools for OEM parts help maintain alignment between the ring and liner top edge, minimizing the risk of step formation, micro-welding, or scuffing. Properly executed, the result is lower oil consumption, fewer cold-corrosion hotspots, and improved exhaust cleanliness—benefits that accumulate across the lifecycle of the diesel engine.

- · Precision handling prevents ring deformation and micro-cracks.

- · Accurate measurement protects clearances and ring tension.

- · Clean seating reduces blow-by and oil carryover.

- · Faster overhauls shorten off-hire and dock time.

- · Consistent results across units and sister vessels.

- · Lower risk of liner scoring, scuffing, and polishing.

- · Better combustion stability and fuel efficiency.

Importance for engine operation: why COKE SCRAPER RING tools matter

For operators and technical managers, the condition of assembly and inspection tools directly influences reliability. A COKE SCRAPER RING that is installed without the appropriate fixtures can seat incorrectly, chip at the edges, or run out of round. Misalignment or incorrect clearances allow carbon to accumulate at the liner top, raising local temperatures and eroding the protective oil film. Over time, this leads to liner glazing, piston ring sticking, elevated blow-by, and rising specific lube oil consumption. In severe cases, it can trigger scuffing events that force unscheduled downtime.

By contrast, using dedicated engine tools preserves the geometry intended by the designer. The ring remains square to the bore, the groove side clearance is controlled, and end-gap is set to the defined limits for the operating profile. The net effect is safer operation, predictable maintenance intervals, and a longer service life for pistons, liners, and rings. For marine engine fleets, this consistency simplifies class compliance and planned maintenance scheduling across multiple vessels.

Advantages of OEM spare parts suitable for Tools and the COKE SCRAPER RING

Pairing precision tools with OEM parts delivers the best outcome for performance, reliability, budget, and service life. Engineered-to-drawing components match the tool interfaces exactly—whether it’s the chamfer angle on an installation sleeve or the diameter steps on a mandrel—so technicians can work quickly without improvisation. Material quality and heat treatment are consistent, which keeps elastic properties and wear resistance within the ranges the diesel engine was designed around.

Additional benefits include assured dimensional accuracy, traceable production batches, and documentation that supports quality audits. Over the life of a vessel, this reduces rework, repeat inspections, and collateral damage costs. Fewer fitment issues mean shorter layovers and better predictability for spare parts planning. For purchasing teams, a stable specification also simplifies cross-referencing, ensuring that COKE SCRAPER RING replacements and companion tools align across engine marks and revisions.

How COKE SCRAPER RING tools enhance marine engine efficiency

When COKE SCRAPER RING tools interface correctly with OEM parts, they maintain ring seating pressure and scraping efficiency, keeping the upper liner zone clean. This supports a steady thermal profile, reduces soot accumulation in the exhaust path, and helps sustain target fuel rates. The incremental gains in combustion stability and oil control compound across many running hours, strengthening the business case for standardized toolkits and controlled part sourcing.

MOPA: your partner for COKE SCRAPER RING OEM parts and engine tools

MOPA is an experienced and reliable partner for OEM spare parts in the Tools category, including specialized equipment and matched components for the COKE SCRAPER RING. Procurement teams value MOPA for speed, quality, and security in the trade of OEM parts for diesel and gas engines. From rapid availability and global logistics to rigorous supplier vetting and documentation, MOPA simplifies the path from RFQ to delivery. Technical support helps you select the right tool sets, verify compatibility by engine model, and avoid costly fitment errors.

Whether you manage a single vessel or a fleet, MOPA’s focus on lead time, traceability, and consistent quality reduces downtime risk and protects lifecycle economics. The result is efficient overhauls, robust parts performance, and confidence that your maintenance standard remains consistently high.

Conclusion: COKE SCRAPER RING tools and OEM parts for dependable operation

COKE SCRAPER RING tools are essential to protect liners, stabilize compression, and maintain the cleanliness that marine and diesel engines need for efficient operation. Paired with OEM spare parts, they deliver repeatable installations, fewer failures, and lower total maintenance cost. Choose proven tooling and parts to keep your engines running safely and efficiently—voyage after voyage.

Reliable and Efficient with Comparison Number X59301300035 Discover our product, the Coke scraper ring, with the comparison number X59301300035. This spare part belongs to the category Tools and ensures that your engines operate optimally.

Effective Maintenance with Coke Scraper RingDiscover the Coke scraper ring with the comparison number 12344823 – a premium product designed for engine maintenance. This OEM replacement part leads you to optimal engine performance. Weighing only 0.098 kg and with compact dimensions of 13.7 cm in length and width and a height of 1.3 cm, the Coke scraper ring offers practical application and easy handling.

Coke scraper ring with comparison number 12343418Discover our coke scraper ring with the comparison number 12343418, an essential product compatible with MWM & Deutz engines. This OEM replacement part offers outstanding quality, ensuring your engines operate reliably at all times. Weighing just 0.1 kg, you can easily integrate the coke scraper ring into your maintenance routine.

COKE SCRAPER RING/TOP LAND RING with the comparison number Z=002 548 suitable for MTU engines

Optimal Performance with the Scraper RingThe Scraper Ring with the reference number 5240110259 is an essential OEM replacement part specifically designed for your engines. With this product, you ensure outstanding performance and efficiency of your engines – ideal for applications in marine and stationary use. The Scraper Ring weighs only 0.205 kg, allowing for easy handling during installation in running systems.Compatibility with MTU EnginesThis OEM replacement part is suitable for a range of MTU engines, including the Series 4000 as well as the specific engine types 12V4000, 16V4000R43L, and 20V4000M73L. The Scraper Ring ensures effective sealing, extending the lifespan of your engines. Rely on the efficiency and compatibility – the Scraper Ring is designed to meet all demands in these challenging applications.

COKE SCRAPER RING/TOP LAND RING with the comparison number 85200013587 suitable for MAN D engines

Product Description Coke Scraper Ring with Comparison Number 12454446Discover the Coke scraper ring with comparison number 12454446, a precise OEM replacement part that is perfectly suitable for the demands in industrial and maritime applications. This product is ideally compatible with MWM & Deutz engines. Weighing only 0.17 kg, it is both lightweight and functional, ensuring you enjoy the highest precision in your application.Reliable Solutions for MWM & Deutz EnginesThe Coke scraper ring is designed as an OEM replacement part, ensuring smooth operation of engines, particularly suitable for MWM & Deutz engines. The component is developed specifically for MWM & Deutz to ensure optimal operational processes.

COKE SCRAPER RING/TOP LAND RING with the comparison number 85200013715 suitable for MAN D engines

Excellent Replacement Part for Your EnginesDiscover our OEM replacement part, the Coke scraper ring with the reference number 12452795. This product has been specifically designed for use in your MWM & Deutz engines. With this essential component, you ensure the performance of your engines and increase their longevity.Suitable for MWM & Deutz EnginesThe Coke scraper ring is suitable for MWM & Deutz and optimizes the efficiency of your engine. Weighing only 0.13 kg, this OEM replacement part is easy to handle. It ensures that the operation of your engines remains continuously efficient and minimizes maintenance costs.

Coke Scraper Ring for Demanding Engines Experience efficiency with our Coke scraper ring, characterized by the comparison number 12453580. This product is equipped with a thoughtful design, perfectly suited for applications in diesel and gas engines. With a length and width of 17.5 cm and a height of just 0.8 cm, this Coke scraper ring fits optimally into your system.Ideal Fit for MWM & Deutz Engines This OEM replacement part is perfectly compatible with MWM & Deutz engines, particularly for the series 2020 GAS and the engine types TCG2020-V16. With its special construction, the Coke scraper ring helps to minimize deposits during the combustion process. In this way, overall engine performance is improved, ensuring consistent efficiency and supporting the longevity of the engines.

Coke Scraper Ring Comparison Number 12285659Discover our Coke scraper ring, comparison number 12285659, as an indispensable product suitable for your MWM & Deutz engines. This OEM replacement part delivers a precisely fitting quality that you can expect from reputable manufacturers. With a weight of 0.7 kg, this tool is optimally designed to be used in various applications related to diesel and gas engines.Suitable for MWM & Deutz EnginesOur Coke scraper ring is ideally suited for use with MWM & Deutz engines. As an OEM replacement part, it ensures precise fit and functionality. This minimizes mechanical wear and extends the lifespan of your engines.

Robust Coke Scraper Ring – Comparison Number 5840110059Discover the Coke scraper ring with the comparison number 5840110059, specifically designed to provide top performance in engines. This OEM replacement part is excellently suited to maximize the efficiency and reliability of your drive system. The Coke scraper ring is engineered to meet industrial requirements and prevent performance bottlenecks.

Precise Coke Scraper Ring from First-Class ManufacturingThe Coke scraper ring with the comparison number 12282827 is an essential product for your engines. With this reliable spare part, you can significantly enhance the maintenance and upkeep of your equipment. Thanks to the highest quality standards, the Coke scraper ring meets all requirements to ensure ideal operating temperatures in production machines.

COKE SCRAPER RING/TOP LAND RING with the comparison number 85600011674 suitable for MAN D engines

Quality Spare Part: Coke Scraper Ring with Comparison Number 5240110159Discover the Coke scraper ring, which plays an essential role in maintaining the performance of your engine. With the comparison number 5240110159, this product is an OEM spare part, specifically designed to support the efficiency and performance of your engines. Precision and high quality are inherent in every aspect of this spare part.Optimal Fit for MTU EnginesThis Coke scraper ring is compatible with several MTU engine types, including 12V4000, 12V4000M70, and 20V4000G62. Weighing 0.225 kg and with compact dimensions of 16.8 cm in length and width and 1.9 cm in height, it optimizes space in your engine design. Powerful performance is a crucial factor in both marine and stationary applications.

Coke Scraper Ring: Quality for Professional ApplicationsExperience the quality of our Coke scraper ring, which perfectly fits into the category of OEM spare parts. With the reference number 12454445, this item is a reliable product for diesel and gas-powered MWM & Deutz engines. The Coke scraper ring measures 17.7 cm in length and width and 0.9 cm in height. Weighing only 0.125 kg, it is characterized by easy and efficient handling.Ideally Compatible with MWM & Deutz EnginesThis Coke scraper ring is suitable for MWM & Deutz and particularly supports the series CG170 as well as the engine types CG170-20 and TCG2020-V20. Under increasingly demanding operating conditions, the Coke scraper ring minimizes deposits and contributes to the longer lifespan of your engines. With the reference number 12454445, you are well-equipped to enhance the performance of your MWM & Deutz engines.

COKE SCRAPER RING/TOP LAND RING with the comparison number 85200013570 suitable for MAN D engines

The Coke Scraper Ring: Powerful and ReliableThe Coke scraper ring with the comparison number 12285658 is an essential OEM spare part specifically designed for use in compatible with MWM & Deutz engines. With a weight of 0.48 kg, it is ideal for various operating conditions and contributes to the reliability of engines used in extensive applications such as marine and locomotive technology.Optimal Fit for Best Engine PerformanceThe Coke scraper ring with comparison number 12285658 minimizes deposits, ensuring smooth operation of your compatible with MWM & Deutz engines. Its precise adaptation makes this product compatible with the series 2032 GAS and ensures full performance capability for engine-driven applications.

COKE SCRAPER RING/TOP LAND RING with the comparison number 84965100001 suitable for MAN D engines

Coke Scraper Ring: Your Solution for MTU EnginesDiscover the Coke scraper ring with the comparison number 5320110059, an essential product for the maintenance of MTU engines. This OEM spare part significantly contributes to the efficiency and longevity of your engines by helping to minimize coke deposits. We offer only top-quality OEM spare parts, whose quality is reflected in their high functionality.Suitable for All Major MTU Engine TypesThe Coke scraper ring is suitable for a variety of types, including the 10V2000M72, 10V2000M93, and 12V2000M93, all part of the renowned series 2000. Weighing only 0.092 kg and with compact dimensions of 13.9 cm in length and width, and 1.5 cm in height, this Coke scraper ring is easy to handle and fits perfectly into your maintenance strategy.

Reliable Performance of the Coke Scraper Ring Discover the Coke scraper ring, comparison number 5840110059/N20, an essential OEM spare part for your engine applications. This product offers optimal functionality for your engines and impresses with a perfect fit.Suitable for MTU Engines with Precision The Coke scraper ring is suitable for MTU engines and stands out due to its authenticity. As an OEM spare part, it ensures long life and optimal efficiency in your propulsion system. Choose quality that comes directly from the manufacturer instead of questionable aftermarket products.

Robust Coke Scraper Ring for Demanding Engine TechnologyThe Coke scraper ring with the comparative number 5360110359 is an essential OEM replacement part that ensures smooth operation in marine and stationary applications. Over many years, this ring has proven to be a reliable companion, specifically designed to fit MTU engines, particularly for the series 2000 and the engine type 16V2000M90. Weighing only 0.089 kg and with compact dimensions of 13.4 cm x 13.4 cm x 1.4 cm, it fully realizes its functionality and allows for effortless installation in existing engine systems.

COKE SCRAPER RING/TOP LAND RING with the comparison number 85600011679 suitable for MAN D engines

Premium Coke Scraper Ring - Efficiency for Your EnginesDiscover the Coke scraper ring with the comparison number 12284827 – the ideal product for your engines. This item is perfectly suited as a replacement for engines developed for MWM & Deutz. Weighing 0.53 kg, this Coke scraper ring provides the necessary durability and reliability for precise applications in marine and stationary use.Features of the Coke Scraper RingThe Coke scraper ring is an OEM replacement part that meets high standards. By using OEM replacement parts, you ensure the efficiency of your machines and extend their lifespan. This replacement part, which is excellently compatible according to comparison number 12284827, helps significantly reduce downtime and optimize the performance of your machines.