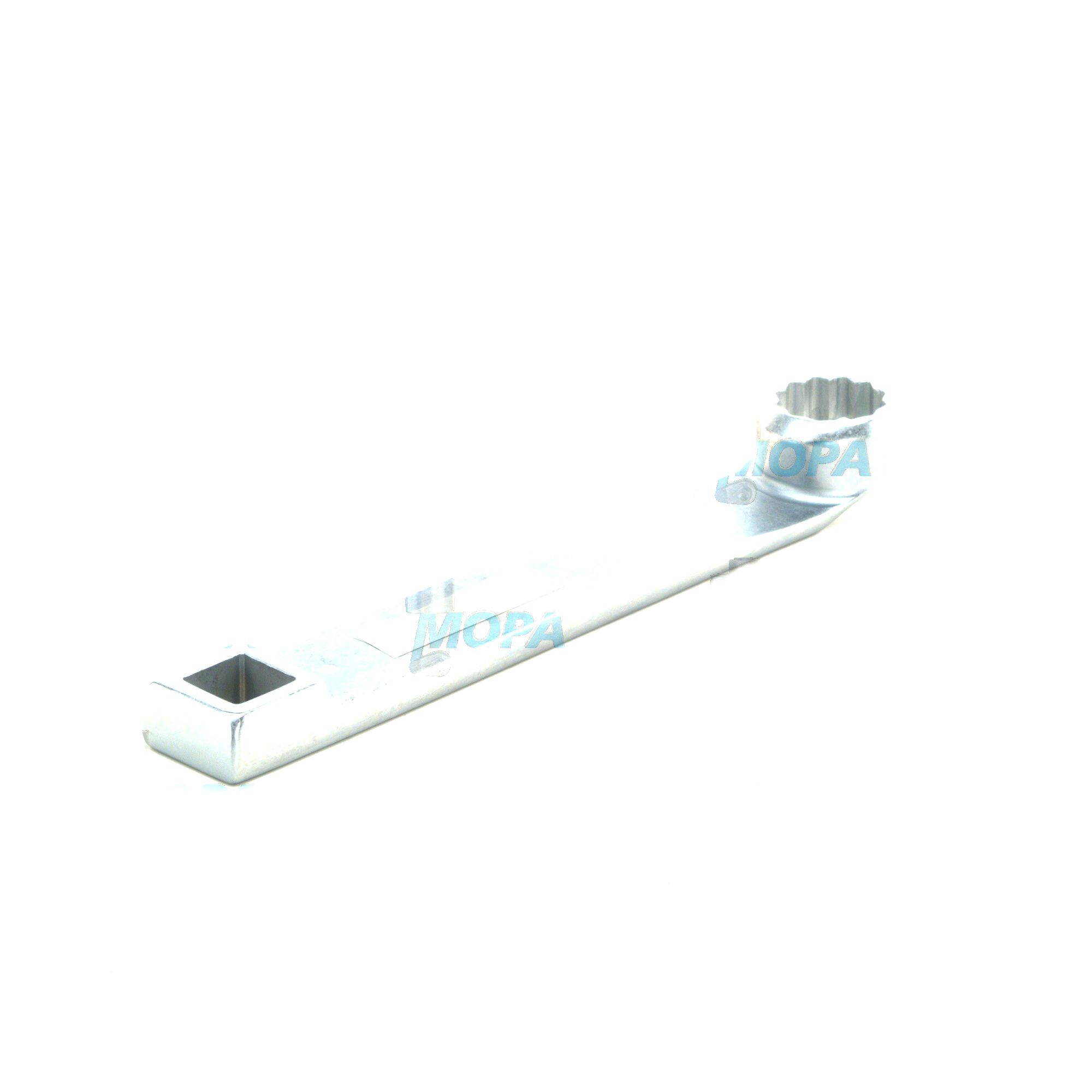

COMBINATION WRENCH Tools for professional engine maintenance

Tools are the backbone of precise engine assembly, overhaul, and daily service. In marine engines, power plant diesel engines, and high-duty gas engines, correct fitting, alignment, and controlled tightening of fasteners depend on high‑quality hand tools and measuring instruments. From a COMBINATION WRENCH to torque equipment, pullers, and gauges, the right tool selection safeguards performance, uptime, and safety across the full maintenance cycle.

As a category, Tools include hand tools, torque and measurement devices, and special service equipment tailored to the confined spaces and heavy-duty components found on propulsion systems and gensets. When engine components are serviced—cylinder heads, fuel systems, turbochargers, pumps, couplings, and ancillary systems—proper Tools ensure parts are installed to specification and operate reliably under thermal, mechanical, and vibrational load.

Technical function of Tools and COMBINATION WRENCH sets in marine and diesel engine service

Every critical joint on an engine—flanges, bearing caps, injector clamps, manifold studs—requires the correct tool to achieve design clamping force without damaging fasteners or mating surfaces. A COMBINATION WRENCH enables quick access in tight spaces using the open end, while the ring end applies higher load without slipping, essential for pipe unions, alternator brackets, and pump housings on a marine engine. In combination with torque procedures, Tools deliver consistent preload so that gaskets seal, alignments hold, and vibration is controlled.

For diesel engine overhauls, Tools extend beyond wrenches: calibrated torque devices for head bolts and big-end bolts; dial indicators for liner protrusion; micrometers and plastigauge for bearing clearances; pullers for gears and couplings; and thread repair sets for restoring damaged studs. The synergy of correct Tool use with OEM parts prevents micro-movements that cause fretting, leaking, or loosening under load.

- · High-strength materials for heavy-duty use

- · Precise sizing in metric and imperial standards

- · Anti-slip geometry to protect fasteners

- · Corrosion resistance for marine environments

- · Calibrated instruments for OEM parts specifications

- · Slim profiles for confined engine rooms

- · Heat-treated jaws and rings for long service life

- · Consistent results that support safety and uptime

When servicing pipework or fuel equipment, a COMBINATION WRENCH with correct jaw geometry reduces rounding on hex fittings, preserving torque accuracy on subsequent service intervals. For rotating assemblies, proper pullers and alignment Tools prevent shaft scoring and bearing damage, directly protecting performance and efficiency.

Why Tools and COMBINATION WRENCH usage are critical for engine reliability and service life

Engines rely on the integrity of each mechanical joint. If Tools are worn, incorrectly sized, or misapplied, fasteners can round off, threads can gall, and seals can be crushed or distorted. The result is loss of compression, coolant or lube oil leaks, exhaust gas leakage at manifolds, and progressive misalignment that cascades into vibration and bearing distress. In extreme cases, improper tightening compromises safety devices and leads to unplanned shutdowns.

Correctly maintained Tools preserve specification torque and alignment, which stabilizes temperatures, reduces fuel consumption, and protects emission performance. On a diesel engine working under load, these effects translate into fewer corrective interventions, longer intervals between overhauls, and predictable availability—key metrics for shipowners and plant operators.

Advantages of OEM spare parts suitable for Tools in engine service

Using OEM spare parts together with the right Tools delivers repeatable, specification-level fits that stand up to duty cycles and classification requirements. Tolerances and surface finishes on fasteners, gaskets, and assemblies are engineered to work with standard Tool geometries and defined torque ranges, so procedures execute smoothly and without rework. For example, tightening a cylinder head with a calibrated device and final checks using a COMBINATION WRENCH on OEM parts hardware ensures even load distribution and secure sealing.

Performance, reliability, budget, and service life

Choosing OEM spare parts suitable for Tools provides tangible operational benefits:

- · Predictable fit and torque response reduce installation time.

- · Verified materials resist creep, corrosion, and thermal cycling.

- · Lower risk of rework protects budgets and schedules.

- · Stable interfaces extend the service life of both parts and Tools.

- · Documentation and traceability support audits and class compliance.

- · Consistent dimensions safeguard sealing integrity and alignment.

In practical terms, injectors clamp correctly, turbocharger casings align without stress, and flange joints retain preload across temperature swings. This consistency is only achievable when Tools work with parts built to the intended specifications.

MOPA: fast, high-quality, and secure supply of OEM parts and Tools for diesel and gas engines

MOPA is a reliable partner for OEM spare parts and Tools supporting COMBINATION WRENCH workflows on diesel and gas engines. Purchasers and technical teams value our speed in sourcing, quality-focused selection, and transactional security across international projects. From fasteners and sealing kits to specialist service Tools, we help crews execute maintenance to specification, on time and on budget.

Whether you manage a merchant vessel, offshore asset, or power plant, MOPA streamlines the supply of OEM parts that interface seamlessly with your Tools—helping you maintain torque procedures, preserve safety margins, and sustain engine efficiency throughout the life cycle.

Conclusion: Tools and COMBINATION WRENCH solutions that protect engine performance

Tools are essential to the integrity of every marine engine and diesel engine. When combined with a properly sized COMBINATION WRENCH and precision instruments, maintenance achieves the designed preload, alignment, and sealing that keep engines reliable and efficient.

OEM spare parts suitable for Tools ensure consistent fits, protect budgets with fewer reworks, and extend service life. With MOPA as your partner, you secure fast, quality, and safe access to the components and Tools needed to keep your engines at peak performance.