FIXTURE

FIXTURE Tools for professional engine maintenance and overhaul

Tools are the backbone of precise engine service. In heavy-duty diesel, gas, and marine applications, they are engineered instruments that enable safe disassembly, accurate measurement, controlled installation, and reliable quality checks. Whether you are aligning a crankcase on a container vessel or reseating injectors on a standby power unit, the right Tools translate engineering tolerances into repeatable results and keep propulsion and power generation assets performing to specification.

This article category covers specialized Tools such as timing locks, alignment gauges, lifting beams, pullers, press sleeves, dial indicators, and calibration devices. Their purpose is to control force, position, and sequence during service so components enter the engine exactly as designed. By protecting surfaces, setting torque consistently, and verifying geometry, professional Tools reduce downtime, protect investments, and directly influence safety at sea and on land.

Technical function: how Tools and a FIXTURE support diesel and marine engine performance

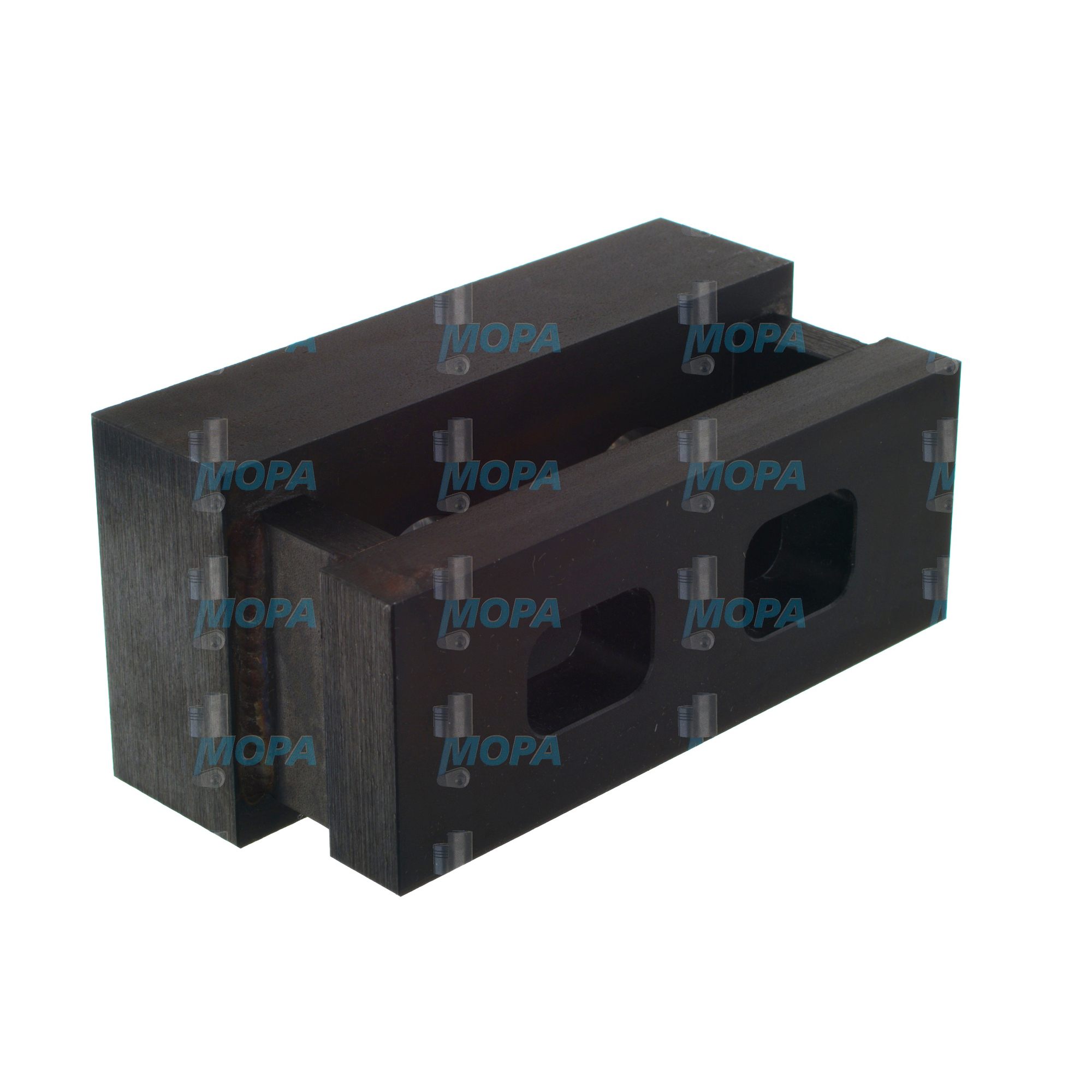

A FIXTURE is a purpose-built device that holds or locates parts during service. In a marine engine overhaul, a camshaft timing FIXTURE aligns the cam gear relative to the crank when the block is at TDC, ensuring valve events match design timing. In a diesel engine top-end service, an injector sleeve FIXTURE centers the sleeve during press-fit to prevent ovality and coolant leaks. During main bearing work, a bearing cap FIXTURE supports the cap while bolts are tensioned, distributing load to prevent fretting and distortion.

Beyond fixtures, Tools manage force and measurement. Liner pullers extract sleeves without scoring the bore. Seal installers press elastomers squarely to stop spiral-wind failures. Dial bore gauges confirm liner ID taper; alignment bars check concentricity across housings; torque and angle tools achieve specified clamp load. When these steps are performed with the correct Tooling, the engine’s compression, lubrication, and timing systems remain stable—improving efficiency, reducing vibration, and enhancing safety. Using a FIXTURE for marine engine cylinder head handling or a timing FIXTURE for diesel engine synchronization is not optional; it is a prerequisite for dependable outcomes with new OEM parts.

- · Precise alignment of rotating and reciprocating groups.

- · Repeatable torque, angle, and preload application.

- · Controlled force for safe removal and installation.

- · Protection of critical sealing and bearing surfaces.

- · Measurement traceability for quality documentation.

- · Direct compatibility with OEM parts tolerances.

- · Reduced risk of leaks, vibration, and early wear.

- · Faster turnaround with fewer rework cycles.

Importance for engine operation: why Tools determine reliability and service life

Engines rely on exact clearances and geometries. Tools maintain those conditions during service. If a timing FIXTURE is not used, cam-crank phasing can drift, leading to hard starts, elevated EGTs, and piston-to-valve contact in extreme cases. Without a proper puller, liner flanges can be nicked, causing coolant loss or combustion blow-by. Inaccurate torque from worn Tools results in uneven clamp load; main bearings may misalign, oil films can collapse under load, and shafts run out of center, amplifying wear.

Misapplied force and poor alignment also shorten the life of seals and gaskets, increasing the frequency of maintenance interventions and risk of unplanned stops. For shipowners, that means missed schedules and higher fuel per kWh. For power plant operators, it means reduced availability. Proper Tools—especially dedicated FIXTURE solutions—eliminate variables that degrade reliability, preserving the engine’s designed service interval and protecting major components like liners, pistons, and bearings.

Advantages of OEM spare parts suitable for Tools and FIXTURE-based procedures

Combining the correct Tools with OEM spare parts is the most dependable path to stable performance. An installation FIXTURE matched to OEM spare parts dimensions ensures seats, guides, and seals are driven squarely to the engineered depth. The result is consistent compression, optimized combustion, and lower friction losses. In fuel systems, OEM spare parts paired with calibration Tools maintain injector flow balance and spray pattern integrity, which directly affects emissions and specific fuel consumption.

From a budget perspective, precision fit reduces rework, scrap, and collateral damage. Downtime shortens because parts mate as intended and measurements quickly confirm compliance. For long-term service life, the combination of OEM spare parts and the appropriate FIXTURE protects mating faces, avoids stress risers, and preserves surface finishes that would otherwise deteriorate under misaligned load paths. This is particularly critical in high-BMEP diesel engine applications and large-bore marine engine platforms where component masses and loads magnify any installation error.

Operational benefits of pairing Tools, a FIXTURE, and OEM parts

• Higher first-time-right rates and predictable overhaul durations. • Stable clearances that protect oil films and sealing integrity. • Compliance with class and maker procedures, simplifying audits and documentation. • Safer workflows thanks to controlled handling and proven interfaces.

MOPA as a partner for OEM spare parts and FIXTURE Tools

MOPA supports purchasers, shipowners, and technical decision-makers with fast, secure sourcing of OEM spare parts for diesel and gas engines—and with guidance on the Tools and FIXTURE solutions required for correct installation. Our team focuses on speed of delivery, consistent quality, and transactional security, helping you keep assets online while maintaining technical standards.

With a broad network, traceable documentation, and kitting options tailored to specific overhaul scopes, MOPA streamlines procurement and reduces administrative load. Whether you are planning a dry-dock main bearing replacement, a cylinder liner campaign, or a fuel system refresh, MOPA helps align OEM spare parts with the right Tools and FIXTURE support so your team can execute the job efficiently and safely.

Conclusion: FIXTURE Tools sustain performance and protect assets

Professional Tools—and especially the correct FIXTURE for each task—are essential to control force, geometry, and quality during engine service. They safeguard reliability, extend service life, and keep diesel, gas, and marine engines operating at their designed efficiency.

When paired with OEM spare parts suitable for these procedures, Tools deliver consistent results, fewer disruptions, and better budget control. MOPA provides the speed, quality, and security you need to implement this standard across your fleet or facility.

Reliable Product Solution: FixtureDiscover the robust fixture with the comparison number 8205890235/00, suitable for MTU engines. This product has been designed as an OEM replacement part and offers you the highest precision for your engine maintenance. Rely on our many years of experience and benefit from equipment that stands out for its top-notch quality.Efficient Tool Solution for Your EnginesOur fixture belongs to the tool category and is specifically designed to provide you with effortless installation and maintenance of engines. Suitable for MTU engines, it ensures that you get the highest efficiency from your machine. Trust in the reliability of our OEM replacement parts and experience the advantages of smooth operation.

Top-quality product suitable for MAN D enginesDiscover the fixture with the reference number 80996066220, an excellent product for engine maintenance. This fixture is suitable for MAN D engines and ensures optimal performance and safety.Rely on our OEM replacement partsThanks to our vast inventory of OEM replacement parts, we ensure that you find exactly the part you need. With the reference number 80996066220, we offer you solutions specifically for brands such as MWM, Mercedes-Benz, Deutz, and many more.

Precise Fixture for Your ProjectDiscover our Fixture with the reference number 8385890159/00, which offers specially developed benefits for your MTU engines. This product is an essential tool, providing you with future-proof solutions for technologically advanced applications. As a compatible component, it supports the efficiency of your machines.Items Suitable for Various RequirementsOur reference number 8385890159/00 refers to a modern Fixture that is suitable for various manufacturers of engines, particularly in the field of marine and stationary installations. The OEM tools deliver quality and stability at attractive prices.

FIXTURE with the comparison number 8385890459 suitable for MTU engines

Ideally tuned for MAN D enginesThe fixture is the ideal replacement part, compatible with MAN D engines. With the comparison number 80996066196, this product offers high compatibility and performance of major OEM replacement parts.Features and ApplicationsThis fixture has been specifically designed to meet the demands of engines in marine and stationary applications. The replacement part is characterized by precision and durability to optimize your operational processes.

Professional Fixture for EnginesDiscover our fixture, comparison number 8375891361/00, specially designed for requirements in professional applications. This product is an essential OEM spare part, compatible with MTU engines. Rely on the strength and efficiency of our OEM spare parts, manufactured to the highest standards.Optimally Compatible and Efficient PerformanceThis important component is perfectly compatible with your MTU engines and impresses with its combination of precision and quality. Our extensive experience in the distribution of engine spare parts ensures availability and performance. We have a large stock that provides you with an excellent selection of OEM spare parts for various manufacturers such as MWM, Mercedes-Benz, and Deutz.

Precise Fixture for Your NeedsDiscover the flexible fixture that is optimal for your technical challenges. With the comparison number 80996066197, this product offers outstanding quality and reliability when handling a variety of engines.Suitable for MAN D Engines: Maximum EfficiencyThis fixture is suitable for MAN D engines and ensures precise fastening and handling. Due to its excellent workmanship, the product is an ideal choice for application professionals who place great importance on effectiveness.

FIXTURE with the comparison number 8375891361 suitable for MTU engines

Versatile Fixture for Reliable EnginesThe fixture with the reference number 80996066228 is an essential product specifically designed for use in MAN D engines compatible with. These OEM replacement parts offer excellent performance and longevity, which are crucial for diesel and gas engines.Quality and Experience in a Family BusinessAs a second-generation family business, we emphasize tradition and expertise. Our OEM replacement parts are highly qualified to meet the specific requirements of our B2B customers. Trust in over 25 years of experience in engine technology to optimally support MAN D engines compatible with.

Reliable Fixture for MAN D EnginesDiscover the Fixture with the comparison number 80996040595. This OEM spare part is precisely designed for MAN D engines and offers the performance you need for diesel and gas engines.Perfect Fit for MAN D EnginesThe product, the Fixture, is specifically designed to be suitable for MAN D engines. With our many years of experience, we provide you with first-class OEM spare parts, so you can rely on the functionality of your engines.

Fixture with Comparison Number VM72720/0Discover the reliable fixture with the comparison number VM72720/0, suitable for MTU engines. This product offers efficient performance and is ideal for use in marine and stationary applications. Our OEM replacement parts ensure perfect fit and longevity.Extensive Range of Replacement PartsMOPA Motorparts offers over 1 million replacement parts that have been designed to fit your engines perfectly. The comparison number VM72720/0 refers to our fixture, which is perfectly suited to meet the highest demands. Trust our extensive selection of OEM replacement parts!

First-Class Fixture for Professional ApplicationsThe fixture with the comparison number XPG0299100067 is an essential OEM spare part specifically designed to meet the demands of engines. This product impresses with its perfect fit and quality. As a tool in the category, the fixture offers an outstanding solution for your technical needs.Quality and Control for MTU EnginesThe internal controls at MOPA Motorparts ensure that the quality of all OEM spare parts meets the highest standards. Our fixture is suitable for MTU engines and ensures that your machines perform reliably. You receive a product that is optimally coordinated.

Coffee Machine for Unforgettable EnjoymentDiscover the fixture with comparison number 80996226017, which offers an optimal solution for your requirements. This spare part provides you with the signal quality you need, ideal for the marine and off-highway segment.Perfect Solution Suitable for MAN D EnginesThis fixture is suitable for MAN D engines and meets the specific requirements of the manufacturer. As a spare part of exceptional quality, it ensures reliable functionality of your engines and provides a long-term solution.

FIXTURE with the comparison number F6097061 suitable for MTU engines

Exclusive Fixture for MTU EnginesDiscover the fixture with the comparison number 8385890359/00, an essential OEM spare part designed specifically for MTU engines. This product ensures precision and durability in use, optimally supporting engine performance.Suitable for MTU: Effective SolutionsOur OEM spare part, the fixture, is suitable for MTU engines. With an exact fit, it ensures that repairs or maintenance can be carried out smoothly.

FIXTURE with the comparison number 85900015587 suitable for MAN D engines

Precise Fixture for Versatile EnginesDiscover our fixture with the comparison number 80996060312, specifically designed to meet various requirements. This product is compatible with MAN D engines and is thus a valuable addition to any workshop. You benefit from state-of-the-art technology and ISO standards that ensure this OEM replacement part exceeds your expectations.

Qualitative Fixture with Comparison Number 80996170217 The fixture with the comparison number 80996170217 is an essential OEM spare part that is perfectly suited for your needs. This precise product significantly contributes to the stability and performance of your equipment.

Powerful Fixture OverviewThe fixture with the comparative number 999857030400 is a valuable OEM spare part specifically designed to efficiently support engines from MTU. Its durability and excellent workmanship ensure smooth operation of your machine.

Robust Tools: Fixture for MAN D EnginesDiscover the functional fixture that has been specially designed for MAN D engines. Weighing 6.7 kg, this product combines stability and efficiency to provide optimal handling and performance. Trust in the quality of OEM replacement parts that meet your requirements.

Precise OEM Replacement Part: Fixture XPG0299100068 The fixture, identified by the comparison number XPG0299100068, meets the highest standards as an OEM replacement part for engines. This valuable component is ideal when you need reliable tools.Component Suitable for MTU Engines Designed as a significant component, the fixture is perfectly suitable for MTU engines. Take advantage of this opportunity to improve the efficiency and performance of your entire engine fleet.

Precise OEM Replacement Part: Fixture The fixture with the comparison number 8395892731/00 is an essential tool that meets the demanding requirements of your engines. This product provides reliable support for maintenance and upkeep.

Precise Fixture in Top QualityDiscover the fixture with the comparison number 80996066178. This product belongs to the categories of high-quality OEM replacement parts and is particularly suitable for MAN D engines. With its precise manufacturing, it offers an optimal solution for your engine needs.The Benefits of OEM Replacement PartsOur OEM replacement parts, such as the fixture, provide you with the quality that only manufacturers can offer. Compared to aftermarket products, you avoid compromises in performance and reliability with us. Rely on our offerings to operate your MAN D engines efficiently.

Quality of the FixtureThe fixture with the comparison number XPG0299100065 is a precise OEM spare part, suitable for MTU engines. This product supports the efficient operation of your diesel and gas engines used in marine applications, stationary operations, and locomotives. Rely on the reliability associated with this comparison number.