BARRING DEVICE context for Valve train components

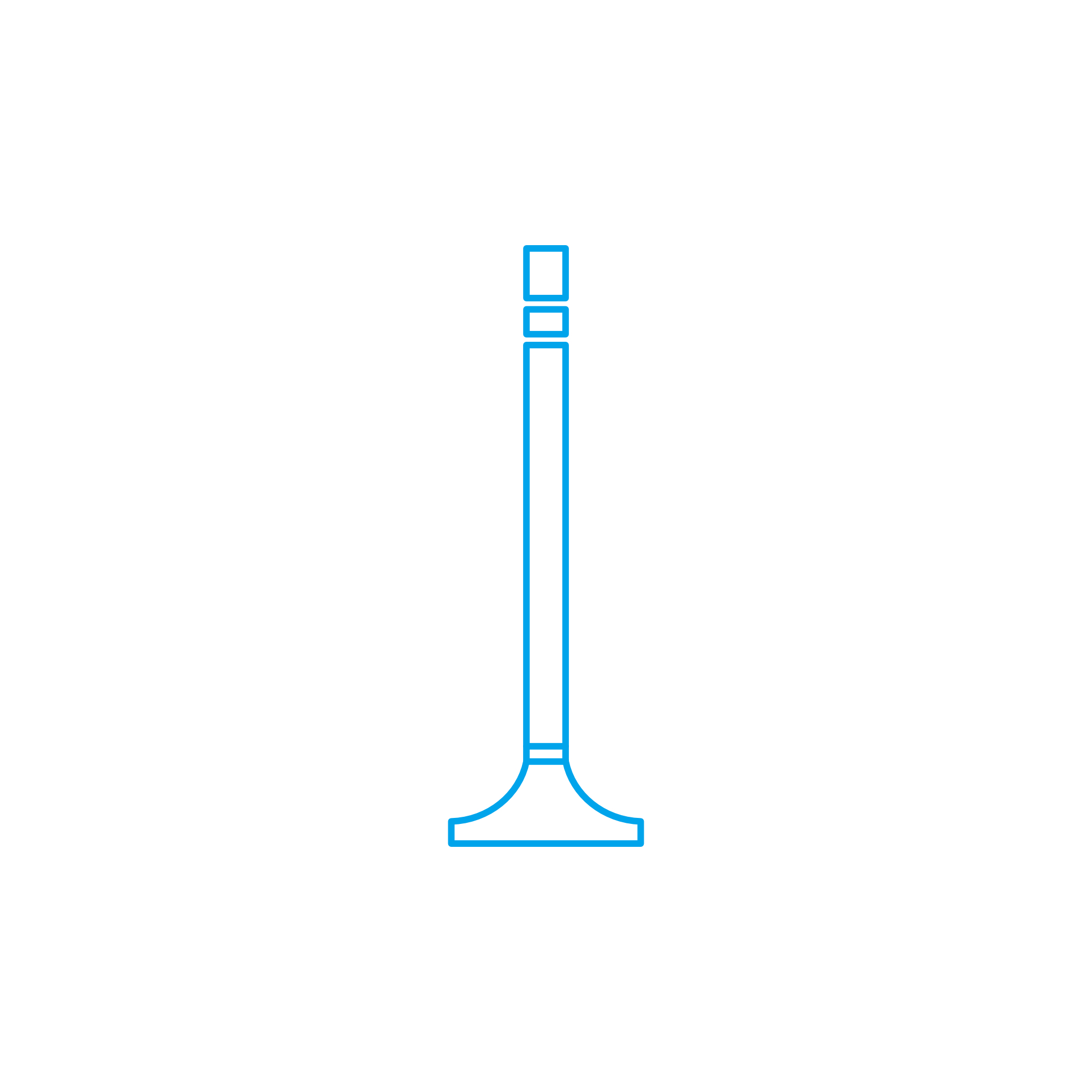

Valve train components are the precision parts that open and close intake and exhaust valves in exact synchrony with piston movement. In heavy-duty diesel and gas engines—especially in marine propulsion and power generation—the valve train converts rotational motion from the camshaft into accurately timed linear valve lift. This system includes camshafts, cam followers/tappets, pushrods, rocker arms, valve bridges, valves, springs, retainers, collets, guides, seats, and lash adjusters. Together, they control airflow, protect pistons, manage combustion temperatures, and underpin the engine’s performance, efficiency, and emissions profile.

In practice, the valve train is the “breathing system” of the engine. Its geometry, materials, and surface finishes determine how fast and how cleanly an engine can run across the load range. From start-up to full load, stable valve timing prevents backflow, misfire, valve float, and damaging valve-to-piston contact. On large marine engines, valve train components are built to withstand extreme contact stresses and hydrodynamic lubrication regimes, making material integrity and dimensional accuracy absolutely critical.

During inspection and adjustment work, technicians frequently use a BARRING DEVICE on a diesel engine to index cylinders to firing order and to set precise valve lash. Safe, incremental rotation with a BARRING DEVICE on a marine engine enables accurate measurements, ensures repeatability, and protects the valve train from accidental overtravel while the engine is offline.

BARRING DEVICE and the technical function of valve train components

The valve train’s core task is to translate the cam lobe profile into controlled valve lift, duration, and timing. Cam lobes push on followers (flat, roller, or hydraulic), transferring force through pushrods and rocker arms to the valve stem. Valve springs close the valve with calibrated force, preventing float at high RPM/load. Guides and seats keep the valve centered and sealed; lash adjusters maintain the correct running clearance as temperatures and wear change. Oil supply galleries lubricate sliding or rolling interfaces to avoid scuffing and pitting.

This motion control determines cylinder filling and scavenging. Correct intake timing improves volumetric efficiency and torque; precise exhaust timing regulates turbine energy for turbochargers and keeps exhaust temperatures within limits. On two-stroke crosshead designs with exhaust valves, the mechanism is equally vital—any deviation in timing or lift can upset scavenge pressure balance and thermal loading. Reliable seating prevents hot gas leakage that can burn valves and seats, while optimized spring rates avoid resonance and reduce fatigue.

Service teams rely on a BARRING DEVICE OEM parts setup to position crankshaft and camshaft at known reference points, enabling accurate dial-indicator checks of cam lift, pushrod travel, and rocker ratios. With the engine barred to TDC or specific degrees BTDC/ATDC, valve lash can be set consistently, ensuring that the designed cam profile is translated into real valve motion.

- · Precise timing transfer from cam to valve for efficient breathing.

- · Wear-resistant contact pairs (cam/follower) for long service intervals.

- · Calibrated spring rates to prevent valve float and bounce.

- · Accurate valve guidance and sealing to maintain compression.

- · Optimized surface hardness and coatings to resist scuffing and pitting.

- · Stable lash control for consistent lift and duration across temperatures.

- · Robust lubrication paths to protect sliding and rolling interfaces.

- · Thermal and mechanical integrity to handle continuous high load.

BARRING DEVICE relevance: why valve train components are critical to engine operation

Valve train components are central to reliability and service life. Minor deviations—such as excessive lash, worn guides, or a fatigued spring—cascade into major effects: increased valve seat leakage, rising exhaust temperatures, misfire under load, turbocharger instability, and elevated emissions. If contact surfaces degrade (spalling on tappets, lobe wear, or rocker pad scuffing), lift and duration drop, reducing cylinder filling and power density. In severe cases, spring failure or incorrect timing can cause valve-to-piston interference, leading to catastrophic damage.

Operational symptoms include rough running, hard starting, elevated fuel consumption, smoke, and high exhaust temperature spreads. Regular condition monitoring—lash checks, borescope inspection of valve faces, cam lift measurement—paired with safe rotation using a BARRING DEVICE on the diesel engine helps detect trends early. Keeping the valve train within specification ensures stable combustion, consistent power output, and predictable overhaul schedules.

BARRING DEVICE + OEM parts: advantages of OEM spare parts suitable for valve train components

OEM spare parts suitable for valve train components deliver the dimensional accuracy, metallurgy, and heat treatment the engine was engineered around. Cam lobes and followers must match in hardness and surface finish to maintain the designed lubrication regime. Springs require tightly controlled wire quality, shot peening, and load characteristics to prevent early fatigue. Guides and seats must retain geometry under thermal cycling to keep sealing pressure uniform across thousands of hours.

Using OEM parts preserves the kinematic chain from camshaft to valve tip and maintains the intended timing map. The result is stable efficiency, lower wear rates, and reduced risk of secondary damage to pistons, cylinder heads, or turbochargers. Traceable specifications and consistent tolerances shorten installation time, as shimming and rework are minimized. Over the lifecycle, this translates into lower fuel penalties, fewer unplanned stops, and predictable maintenance windows.

When technicians pair a BARRING DEVICE on a marine engine with OEM parts in the valve train, setup tasks—lash, rocker geometry checks, and cam timing verification—become faster and more repeatable, supporting safe return to service with documented measurements.

MOPA and the BARRING DEVICE context: your partner for OEM spare parts Valve train components

MOPA is an experienced, reliable partner for OEM spare parts Valve train components. We source and deliver camshafts, followers/tappets, pushrods, rocker arms, valve bridges, valves, springs, retainers, guides, seats, and associated hardware for diesel and gas engines, including marine applications. Our processes emphasize speed—rapid quotations and dispatch—quality through rigorous incoming inspections and documentation, and security with traceable supply chains and compliant export handling.

Whether you are overhauling a main propulsion unit, a genset, or conducting cylinder-top maintenance with a BARRING DEVICE on a diesel engine, MOPA supports you with technically correct cross-references, clear lead times, and packaging that protects critical surfaces. The result: reduced downtime, dependable fit, and confidence in every installed component.

Conclusion – BARRING DEVICE alignment with Valve train components

Valve train components dictate how effectively an engine breathes, performs, and endures. Precise parts, installed and adjusted with the help of a BARRING DEVICE on a marine engine, safeguard timing, sealing, and long-term reliability.

Choosing OEM spare parts suitable for Valve train components preserves designed performance, stabilizes operating costs, and extends service life—benefits that MOPA delivers with speed, quality, and security across diesel and gas engine fleets.