MUSHROOM TAPPET valve train components for diesel and marine engines

Valve train components form the mechanical chain that times the breathing of an engine. From camshaft and MUSHROOM TAPPET to pushrods, rocker arms, valves, springs, guides, and seats, each element translates cam rotation into precise valve lift. In high-output diesel and marine engine applications, this system must endure extreme contact loads, high oil temperatures, and long service intervals, while maintaining stable timing and minimal friction. Robust valve train engineering protects power density, fuel economy, and emissions compliance across thousands of operating hours.

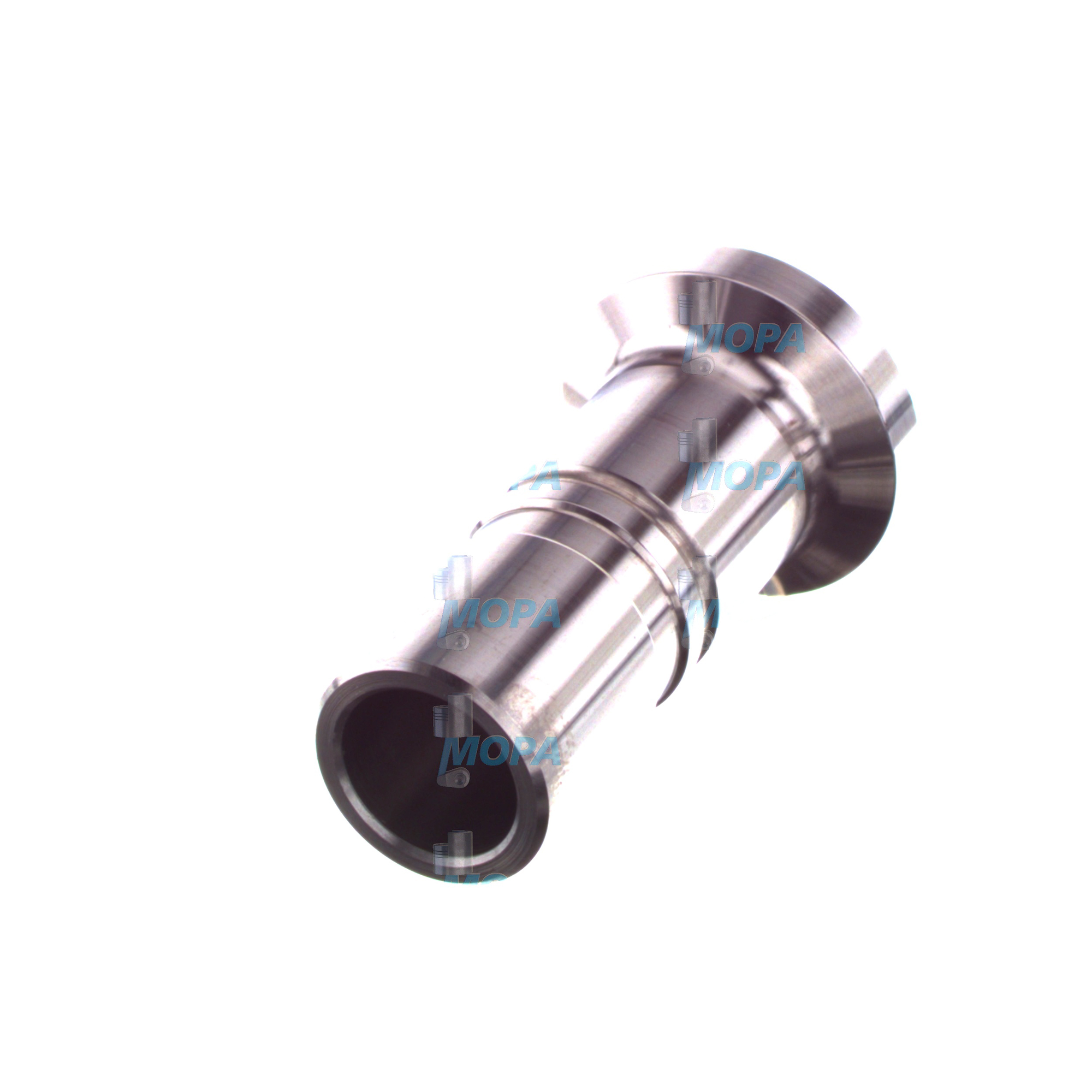

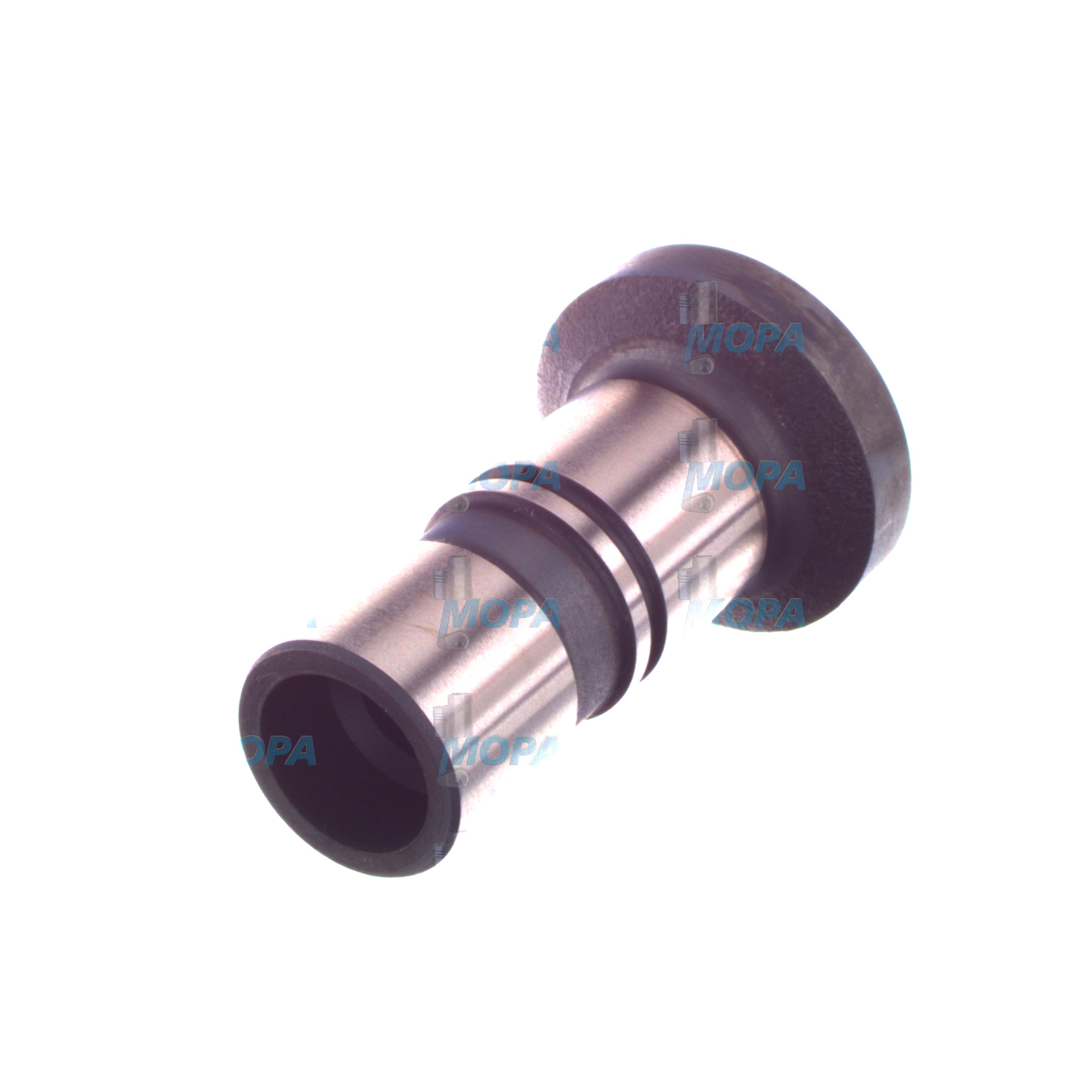

Within this system, the MUSHROOM TAPPET is the critical cam follower that transfers the cam lobe profile into controlled, repeatable movement. Its larger “mushroom” head spreads contact stress, maintains stable Hertzian loading, and supports aggressive cam ramps without scuffing—attributes especially valuable in slow- and medium-speed marine engine platforms and stationary gas engines. When the tappet, pushrod, rocker, and valve act in perfect synchrony, combustion is clean, cylinder pressure is optimized, and the engine delivers predictable performance even under heavy cyclic loads.

Technical function: how valve train components and the MUSHROOM TAPPET drive engine performance

The camshaft defines valve timing events—opening, lift, duration, and closing. The MUSHROOM TAPPET rides on the cam lobe, converting rotational motion into linear motion, while distributing contact over a broader face. In a diesel engine, contact surfaces are typically case-hardened and precision-ground to achieve the microfinish needed for a stable oil film. Proper lubrication is vital: pressurized oil and directed galleries feed the tappet face and bore, preventing scuffing and micro-welding under boundary conditions.

From the tappet, motion passes through pushrods and rocker arms (or via direct-acting configurations) to the valve stem. Springs, retainers, and seats control valve dynamics—preventing bounce and float at higher speeds. Guides maintain alignment, minimizing side load and wear. Together, these valve train components safeguard the cam profile’s intended airflow characteristics, improving volumetric efficiency, start-up reliability, and steady-state fuel burn. In a marine engine, the system’s stability directly influences exhaust temperature balance between cylinders, turbocharger health, and overall uptime.

Because the tappet is the first mechanical interface with the cam, its material pairing, crown geometry, and surface finish are pivotal. A MUSHROOM TAPPET for OEM parts programs is typically produced with tight roundness and taper tolerances to maintain correct rotation and avoid edge loading. The result is consistent lift, reduced NVH, and controlled lash across the maintenance interval—even under heavy fuel and lubricant contamination typical of harsh operating environments.

Key characteristics and advantages of valve train components

· Precision timing of intake and exhaust events.

· Stable combustion, power density, and fuel efficiency.

· Low friction through optimized materials and surface finishes.

· Controlled valve dynamics to prevent float and bounce.

· Accurate lash control for quieter, cleaner operation.

· Long service life under high loads and high temperatures.

· Compatibility with marine engine and diesel engine duty cycles.

· Predictable performance across extended maintenance intervals.

Why valve train components are critical for reliability and service life

Reliability starts with consistent cam-to-valve motion. Wear or deformation in tappets, guides, or rocker pivots changes lift and timing, causing poor cylinder filling and uneven exhaust temperatures. If a MUSHROOM TAPPET loses its surface integrity, contact stress rises, leading to scuffing, pitting, or spalling. The consequences include accelerated cam lobe wear, metal debris in the oil circuit, and rising friction losses.

Misaligned guides or ovalized tappet bores increase side loads and oil film breakdown. Excessive lash produces noise, impact loading, and valve seat erosion. Insufficient spring pressure or fatigued springs allow valve float, which risks piston-to-valve contact—a catastrophic failure in any diesel engine. In marine operations, such events compromise voyage schedules, raise operating costs, and threaten safety. Keeping valve train components in tolerance is therefore essential for uptime, predictable maintenance planning, and long-term asset value.

Advantages of OEM spare parts suitable for valve train components

For tappets, rockers, valves, and springs, dimensional and metallurgical fidelity matters. OEM spare parts suitable for valve train components are engineered to the cam profile’s intended contact geometry, heat treatment, and finish. This matters most at the cam-tappet interface, where microfinish and hardness gradients sustain hydrodynamic lubrication and minimize wear-in. Selecting OEM spare parts for a MUSHROOM TAPPET in a marine engine or diesel engine helps preserve designed lift curves and reduces the risk of early surface distress.

Benefits that directly impact technical performance and budgets include:

· Exact fit and contact geometry that protect cam profiles.

· Controlled hardness and case depth for durable surfaces.

· Consistent microfinish for stable oil film formation.

· Verified material specs for high fatigue resistance.

· Repeatable tolerances to maintain correct lash and valve timing.

· Lower life-cycle cost through longer service intervals and fewer unplanned stops.

· Maintained emissions and fuel efficiency by preserving valve events.

· Simplified risk management with traceable, spec-compliant components.

OEM parts for MUSHROOM TAPPET and related components

Using OEM parts for the MUSHROOM TAPPET, pushrods, rockers, and springs aligns the whole valve train around the intended cam dynamics. That coherence reduces contact stress spikes, stabilizes wear patterns, and keeps lubrication in the safe regime. For operators of diesel and gas engines—especially in marine propulsion, auxiliary gensets, and industrial power—this translates into fewer interventions, predictable overhauls, and reliable performance under continuous load.

MOPA: your partner for OEM spare parts for valve train components

MOPA supplies OEM spare parts suitable for valve train components— including MUSHROOM TAPPET solutions—across a wide range of diesel and gas engines. Customers value our speed in sourcing, our focus on quality, and our secure, transparent trade processes. Whether supporting a single-unit overhaul or fleet-wide procurement, we deliver the parts, documentation, and technical clarity purchasers and shipowners require.

With deep experience in marine engine and power generation applications, MOPA helps match component specifications to engine models and operating profiles. Our team prioritizes rapid lead times, consistent part quality, and supply chain security so your maintenance windows stay on schedule and your assets remain productive.

Conclusion

Valve train components—anchored by a robust MUSHROOM TAPPET—are fundamental to timing accuracy, combustion quality, and long engine life. Selecting OEM spare parts suitable for valve train components preserves cam-following geometry, reduces wear, and supports dependable performance in diesel and marine engines. Partner with MOPA to secure fast, high-quality, and secure delivery of OEM parts that keep your engines running efficiently.