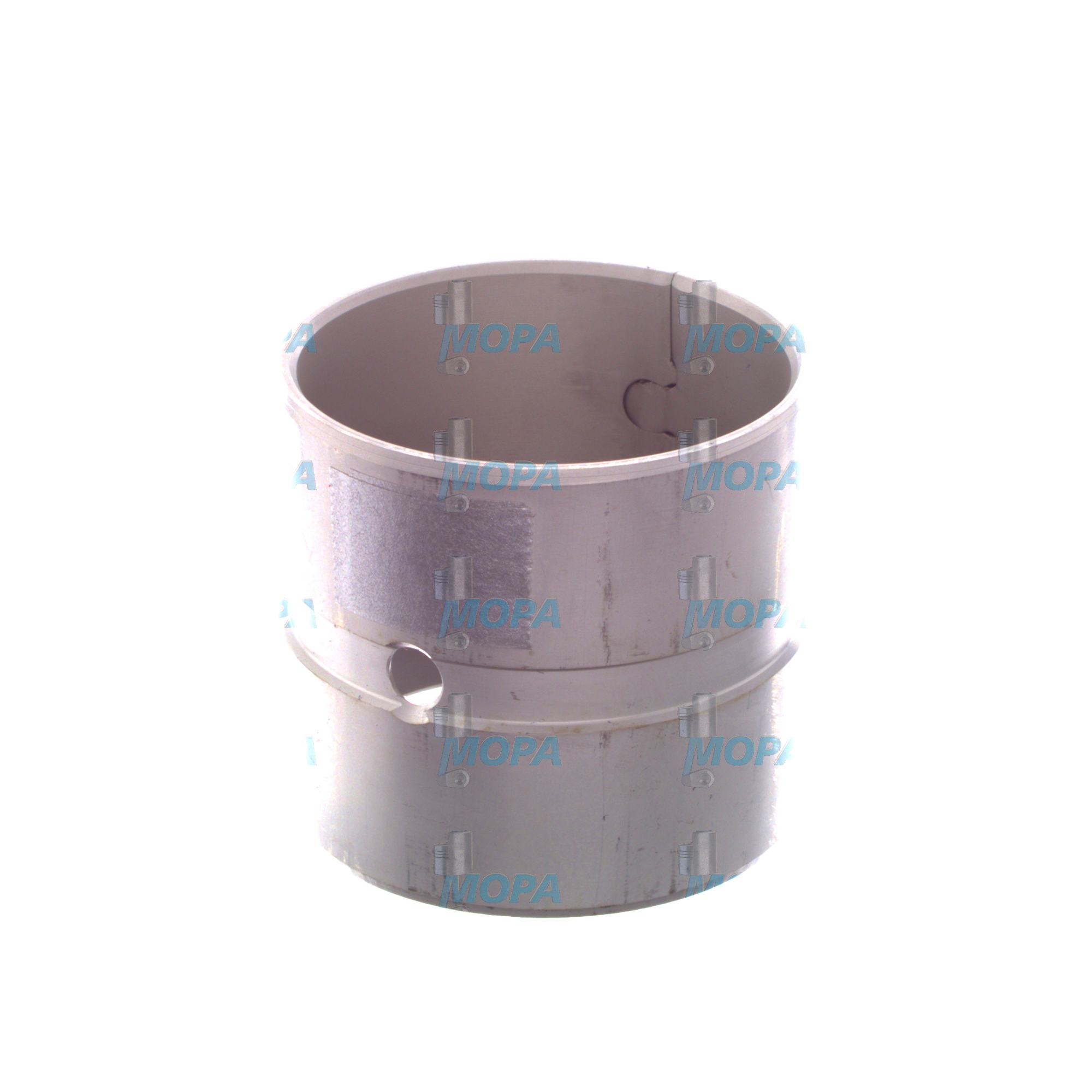

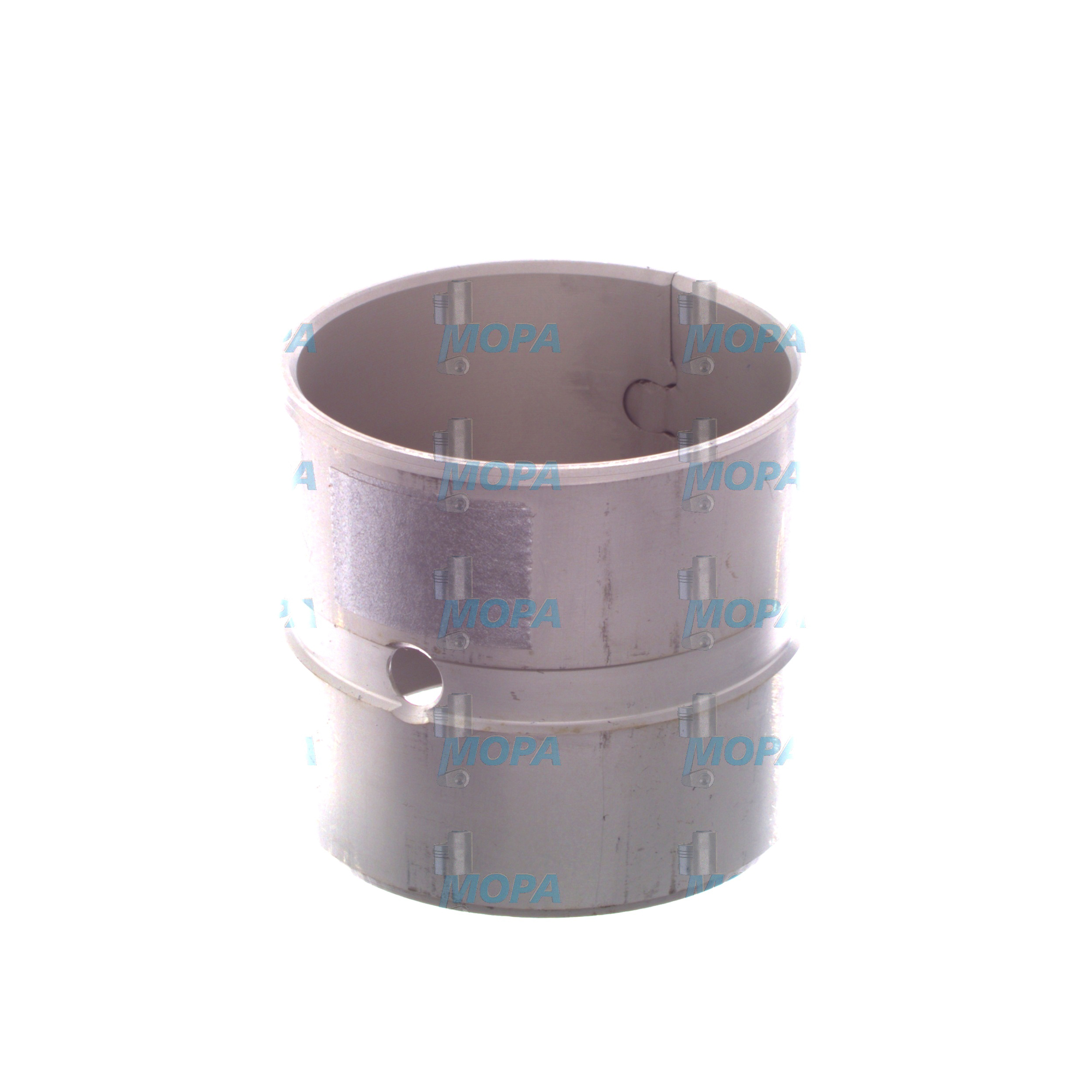

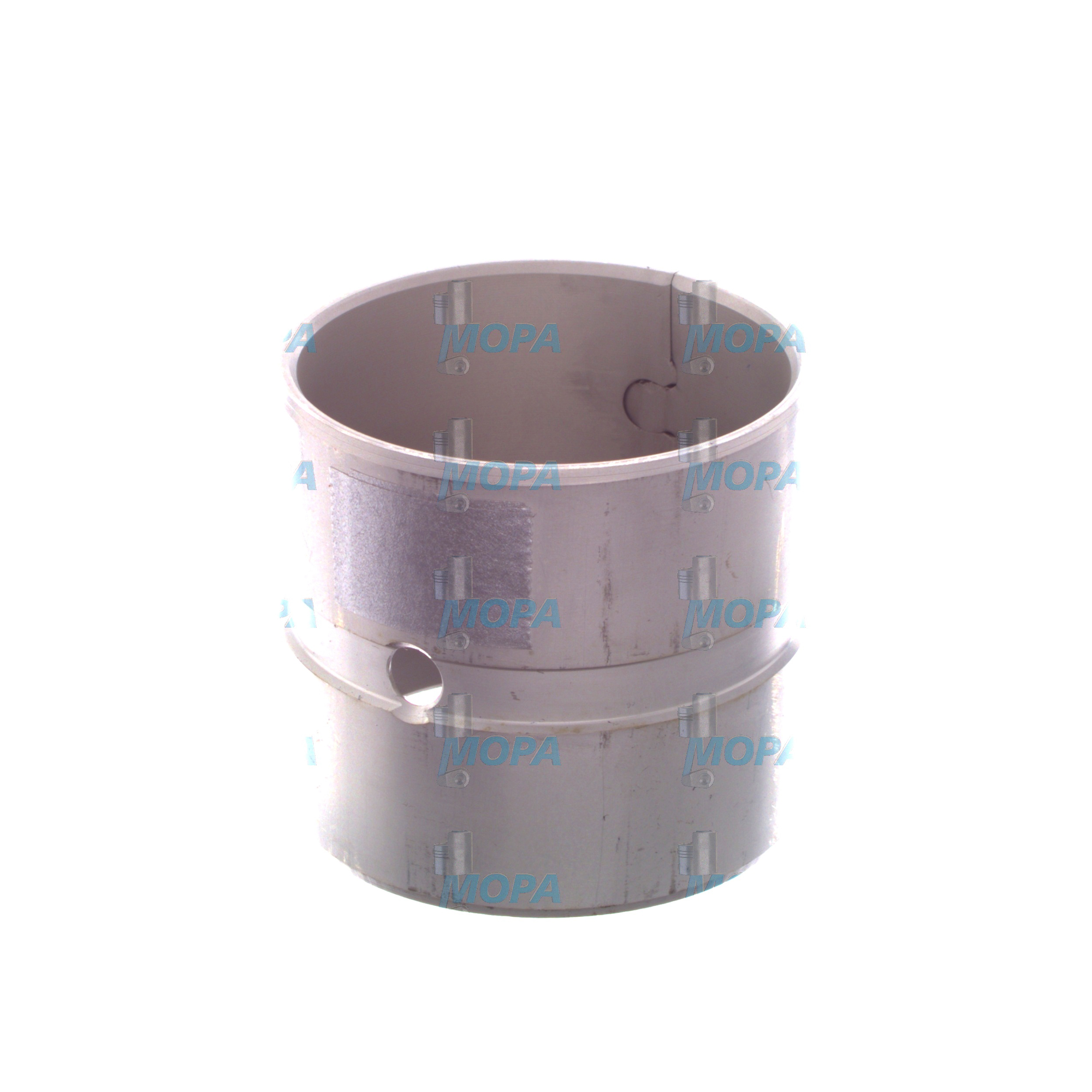

ROCKER ARM BUSH in Valve Train Components for Diesel and Marine Engines

Valve train components form the mechanical system that controls intake and exhaust events in combustion engines. From the camshaft through lifters and pushrods to rocker arms, bridges, valves, springs, and guides, each element must work in precise harmony to open and close the valves at exactly the right time. Central in this kinematic chain is the bearing interface at the rocker pivot — the ROCKER ARM BUSH — which allows smooth, low-friction motion under high load. In large-bore diesel and gas engines, including marine engine applications, robust valve train components are essential for power density, fuel efficiency, emissions control, and dependable uptime.

Technical function of valve train components and the ROCKER ARM BUSH

The valve train converts the rotating profile of the camshaft into linear valve lift. In overhead-valve and many overhead-cam designs, the rocker arm acts as a lever, transmitting motion to the valve stem while amplifying or modifying lift according to its ratio. The ROCKER ARM BUSH provides the hydrodynamic or mixed-lubrication bearing surface between the rocker and its shaft or pin. In a diesel engine cylinder head, this bush is typically manufactured from high-strength bronze or bimetal materials with controlled porosity and oil grooves that stabilize the oil film at start-up and operating temperature. Its job is to minimize friction, dissipate heat, and distribute load to protect both the rocker and the shaft from scuffing and fretting.

In heavy-duty cycles, such as a ROCKER ARM BUSH for marine engine service, the component must tolerate continuous high contact stress, micro-motions from valve lash adjustments, and corrosive blow-by contaminants. Properly engineered oil feed holes and surface finishes maintain a stable lubricant wedge at varying speeds and viscosities. When paired with matched geometry and hardness in the rocker and shaft, a ROCKER ARM BUSH OEM parts specification secures long service intervals, consistent valve timing, and quiet operation. The result is reduced parasitic loss, lower component temperatures, and sustained power delivery across the load range.

Key characteristics and advantages of valve train components

· High precision geometry for accurate valve timing.

· Wear-resistant materials for long life in continuous duty.

· Optimized lubrication paths to prevent scuffing.

· Controlled clearances for stable oil film formation.

· Heat-treated contact surfaces for load distribution.

· Low friction to reduce fuel consumption and noise.

· Compatibility across diesel and gas engine platforms.

· Serviceable designs that simplify maintenance windows.

Importance for reliable engine operation

Valve train components are a primary determinant of engine reliability and lifecycle cost. If the ROCKER ARM BUSH or related parts wear beyond tolerance, the oil film collapses and metal-to-metal contact accelerates damage. Consequences include rapidly increasing valve lash, erratic valve events, elevated vibration, and localized overheating. The engine may exhibit loss of compression, reduced cylinder balance, higher fuel consumption, and non-compliance with emissions limits. In severe cases, seized bushes can score the rocker shaft, crack the rocker body, or transfer load to the cam profile, causing cam lobe pitting. On marine engines that run long hours at steady load, such deterioration can lead to unplanned off-hire, expensive in-port repairs, and secondary damage to valves, guides, and springs.

Maintaining the integrity of the entire valve train — rocker arms, bushes, bridges, pushrods, tappets, springs, retainers, and shafts — preserves timing accuracy and protects the combustion chamber. Correct clearances and material pairings also prevent valve float at high speed and safeguard against valve seat erosion, especially in gas engines with hotter exhaust environments.

Advantages of OEM spare parts suitable for valve train components

Selecting OEM spare parts that are suitable for valve train components ensures the dimensional accuracy, metallurgy, and surface finishes the design requires. A ROCKER ARM BUSH diesel engine specification is not merely a sleeve; it is a precision bearing engineered with exact internal diameter, wall thickness, oil groove geometry, and hardness profile to match the rocker and shaft. Using OEM parts that meet the engine maker’s drawings helps achieve:

· Consistent performance through verified tolerances and fit.

· Predictable service life thanks to proven materials and heat treatment.

· Lower fuel and lube oil consumption due to reduced friction and leakage.

· Protection of adjacent components (rocker shafts, cams, valves) from accelerated wear.

· Faster maintenance, because parts fit without rework or adaptation.

· Reduced downtime and total cost of ownership across overhaul cycles.

· Compliance with engine performance and emissions specifications.

· Clear traceability and documentation for audits and class approvals.

For fleets and power plants, these factors translate into stable operating budgets, reliable overhaul planning, and minimized risk of unscheduled stops.

MOPA as your partner for OEM parts in valve train components

MOPA is an experienced, reliable partner for OEM spare parts suitable for valve train components, including every critical ROCKER ARM BUSH required in modern diesel and gas engines. Procurement with MOPA emphasizes speed in quotation and delivery, consistent quality through stringent supplier selection, and security in the trade of OEM parts via full documentation and traceability. Whether you operate a coastal vessel, deep-sea ship, or stationary power unit, MOPA supports tight maintenance windows with expert cross-referencing, ready stock on commonly used items, and global logistics that keep assets running.

Conclusion

Valve train components — with the ROCKER ARM BUSH as a key bearing interface — are vital to precise valve timing, efficiency, and long-term reliability in diesel and marine engines. Choosing OEM spare parts suitable for this category protects performance, extends service life, and safeguards your maintenance budget. Partnering with MOPA provides fast, secure access to the right OEM parts when it matters most.