ROCKER ARM SHAFT Valve train components for diesel and marine engines

Valve train components form the precision link between the camshaft and the combustion chamber, controlling when and how inlet and exhaust valves open and close. This category includes the ROCKER ARM SHAFT, rocker arms, bridges, pushrods or cam followers, valves, guides, springs, retainers, and related hardware. In heavy-duty diesel and marine engine applications, these parts must deliver repeatable timing accuracy under high loads, varying temperatures, and continuous operation. When specified and maintained correctly, they safeguard power density, fuel efficiency, emissions compliance, and overall engine availability.

For purchasers and technical decision-makers, choosing the right valve train components is about more than replacement; it is about protecting the engine’s kinematics. Surface finish, hardness profiles, lubrication pathways, and dimensional tolerances are decisive. A properly engineered ROCKER ARM SHAFT establishes stable pivot geometry for the rocker set, ensuring precise valve lift and duration across thousands of operating hours.

Technical function of valve train components and ROCKER ARM SHAFT in a diesel engine

The valve train converts cam lobe profiles into linear valve motion. In a typical four-stroke diesel engine or gas engine, the camshaft rotates in sync with the crankshaft, transferring force via followers or tappets. The ROCKER ARM SHAFT supports the rocker arms as they pivot, translating cam-driven motion to the valves (directly or via bridges). Its concentricity, stiffness, and surface integrity govern how consistently valve lash is maintained, which directly influences cylinder filling, scavenging efficiency, and combustion stability.

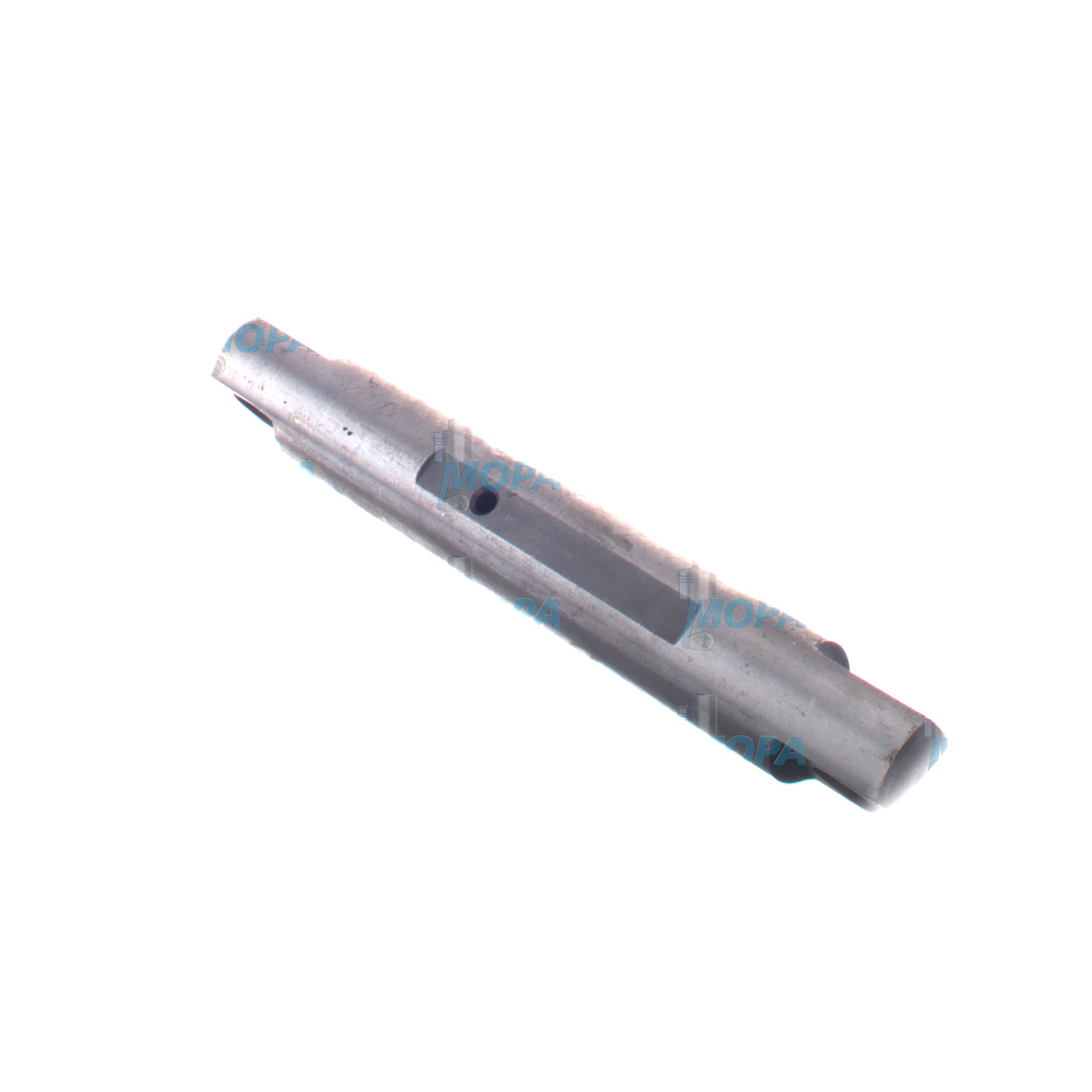

In a marine engine with long duty cycles and high mean effective pressures, the ROCKER ARM SHAFT must resist bending, fretting, and wear at the bearing interfaces. High-quality shafts are often manufactured from alloy steels such as 42CrMo4, heat-treated and induction hardened or nitrided to achieve a wear-resistant surface (commonly 58–62 HRC) with a tough core to absorb cyclic loads. Cross-drilled oil galleries distribute pressurized oil to the rocker bushings and valve tips, forming hydrodynamic films that minimize friction and reduce temperature rise at contact points.

Dimensional accuracy is critical. Typical production targets include tight roundness and straightness on the shaft, fine surface roughness on bearing tracks, and exact center distances to maintain rocker geometry. Even small deviations can alter effective valve lift or introduce side-loads that accelerate guide and stem wear. By keeping the pivot axis true, the ROCKER ARM SHAFT in a diesel engine sustains optimal valve timing, which helps lower specific fuel oil consumption and reduces the risk of valve bounce at higher speeds.

For procurement contexts where traceability and repeatability matter, ROCKER ARM SHAFT OEM parts provide consistent metallurgy, controlled heat treatment, and validated lubrication hole orientation—crucial for engines operating in harsh marine environments.

- · Stable pivot for precise valve lift and timing.

- · Hardened bearing surfaces for long service life.

- · Internal oil galleries for reliable lubrication.

- · Tight tolerances preserve valve lash and geometry.

- · Corrosion-resistant finishes for marine engine duty.

- · Compatibility with diesel and gas engine layouts.

- · Reduced friction and heat at contact interfaces.

ROCKER ARM SHAFT marine engine dynamics and safety

On propulsion and auxiliary sets, reliability hinges on stable valve events. The ROCKER ARM SHAFT marine engine configuration must endure torsional vibration, hull-induced motions, and thermal gradients. Proper oil supply through the shaft, combined with bushings matched for clearance (typically in the low tens of microns depending on design), prevents boundary lubrication and reduces the risk of scuffing. The result is safer operation, fewer unplanned stops, and predictable maintenance windows.

Importance for engine operation and service life

Valve train components directly affect compression integrity, combustion efficiency, and emissions. As parts wear, valve timing drifts and valve lash grows unstable. Symptoms include hard starting, elevated fuel consumption, smokier exhaust, and abnormal valvetrain noise. In severe cases, valve float can occur, followed by contact between valve and piston, bent pushrods, or broken springs—events that can escalate to catastrophic engine damage and extended downtime.

Specific failure modes to watch include brinelling or pitting on the ROCKER ARM SHAFT bearing tracks, bushing wear leading to rocker tilt, oil starvation from clogged drillings, and corrosion pitting in marine atmospheres. Preventive measures include oil cleanliness control, scheduled lash checks, condition-based inspections of contact patterns, and adherence to torque and alignment specifications during overhaul.

Advantages of OEM spare parts suitable for Valve train components

Selecting OEM spare parts for valve train components, including the ROCKER ARM SHAFT, safeguards performance and lifecycle economics. These components are produced to the engine maker’s validated drawings and process controls, ensuring material consistency, correct heat treatment depth, and exact lubrication channel geometry. This precision preserves cam-to-valve kinematics, maintains emissions conformity, and supports predictable overhaul intervals.

From a budget perspective, the value lies in repeatable fit, reduced installation time, and fewer early-life issues. Correct hardness gradients and surface finishes mitigate wear-in, while dimensional fidelity protects adjacent parts—valves, guides, bridges, and cams—lowering total cost of ownership. For high-load diesel engine fleets and marine engine operations, using ROCKER ARM SHAFT OEM parts is a practical way to minimize operational risk and keep SFOC and emissions on target.

MOPA as a partner for ROCKER ARM SHAFT OEM parts and valve train components

MOPA is an experienced, reliable partner for OEM spare parts in the category of Valve train components. We focus on speed, quality, and security across sourcing and delivery, supporting operators of diesel and gas engines in maritime and industrial settings. Our team understands the technical sensitivities of the valve train—surface hardness windows, bushing clearances, oiling schemes—and helps you match the right parts to your engine specification and service profile.

With fast lead times, rigorous documentation, and a network oriented to critical spares, MOPA reduces downtime exposure while maintaining the integrity of your engine’s valve actuation system. Whether you require a ROCKER ARM SHAFT for a medium-speed marine engine or a complete set of coordinated components, we deliver solutions aligned with OEM criteria.

Conclusion on ROCKER ARM SHAFT valve train components

Valve train components, and especially the ROCKER ARM SHAFT, are central to precise valve timing, stable combustion, and long engine life in diesel and marine applications. Specifying and maintaining the correct parts protects performance, efficiency, and safety.

Choosing OEM spare parts suitable for Valve train components ensures the dimensional accuracy, materials, and lubrication geometry needed to keep your engines reliable and cost-effective over the full service interval—on land and at sea.