TAPPET valve train components for marine and diesel engines

Valve train components are the precision parts that open and close the intake and exhaust valves in synchrony with the crankshaft. They translate rotational motion from the camshaft into linear valve motion, controlling gas exchange, combustion stability, and emissions in every four-stroke diesel or gas engine. In marine engines and power generation sets, the valve train must perform flawlessly under continuous load, high temperatures, and demanding lubrication conditions. From the TAPPET (lifter) to the camshaft, pushrod, rocker arm, guide, spring, and retainer, each component plays a defined role in timing accuracy and mechanical efficiency.

As a category, valve train components combine metallurgy, micro-geometry, and surface engineering to minimize friction and wear while maintaining precise valve lift, duration, and overlap. Correctly matched parts preserve compression, protect the turbocharger and aftertreatment, and reduce specific fuel oil consumption—key goals for shipowners and operators focused on uptime and lifecycle cost.

Technical function of valve train components with TAPPET in a diesel engine

In a typical pushrod diesel engine, the cam lobe acts on the TAPPET, which converts the cam’s profile into vertical motion. That motion travels through the pushrod to the rocker arm, multiplying or translating lift to the valve stem. The valve spring and retainer ensure fast, controlled closure, while guides maintain alignment and prevent side-loading. In overhead-cam layouts, the principle is the same, though the driveline may route motion through finger followers or buckets rather than long pushrods.

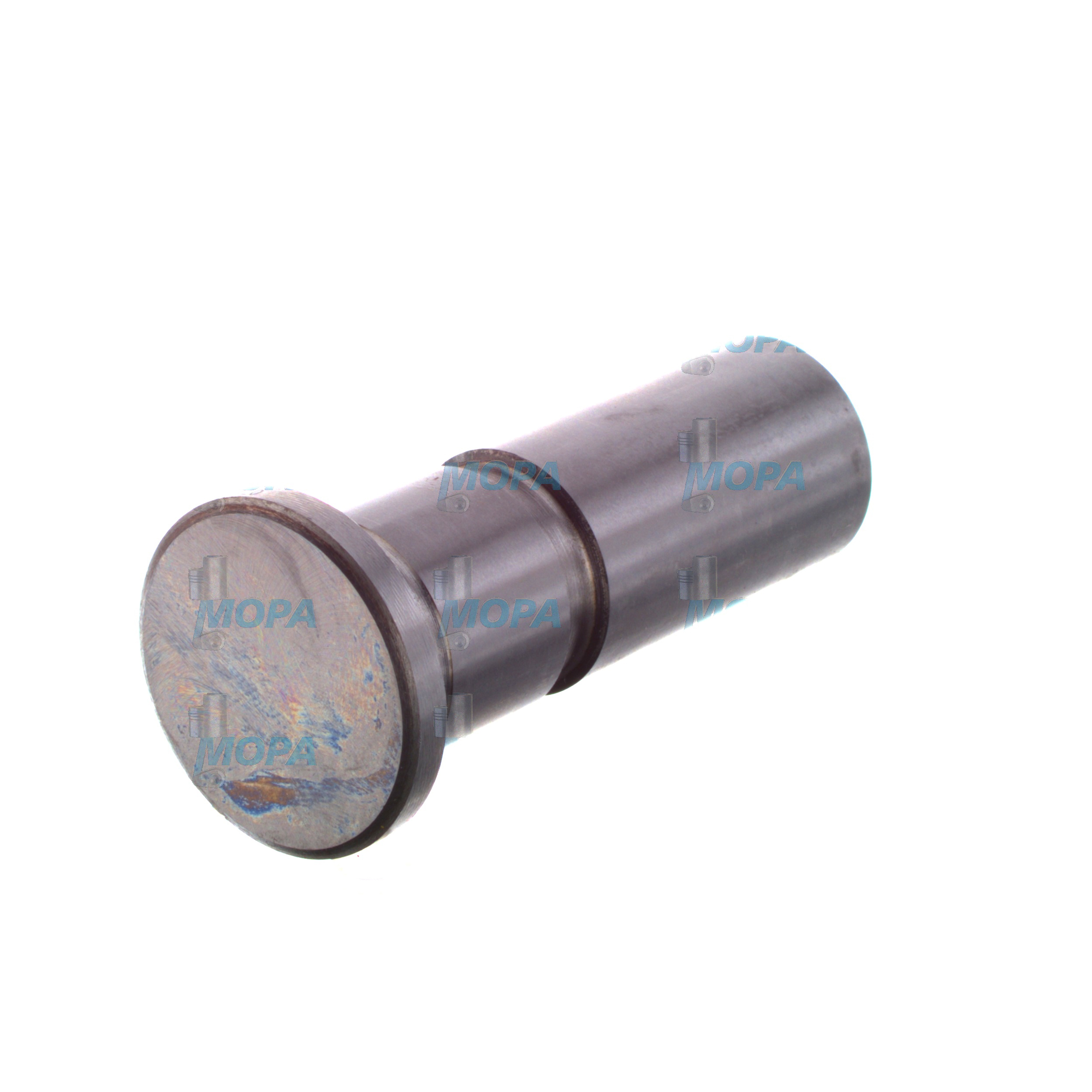

The TAPPET in a marine engine can be flat (slightly crowned) or roller type. Flat tappets rely on a controlled rotation across the cam lobe to distribute wear; roller tappets reduce sliding friction and contact stress. Hydraulic TAPPET designs maintain zero lash via internal oil pressure, improving noise and reducing maintenance, whereas solid lifters require periodic adjustment and are often chosen for high-temperature stability. Material choices—such as chilled cast iron, carburized steel, or DLC- and nitrided surfaces—are selected for hardness (often HRC 58–62 on contact zones), scuff resistance, and oil film compatibility. Proper oil supply and ZDDP additive chemistry are critical; boundary lubrication frequently occurs at start-up and low-speed operation, making surface finish and taper geometry decisive for cam and lifter life. For supply chain assurance and fit, TAPPET OEM parts are engineered and tested to match the cam profile, seat angle, and follower radius specified by the engine maker.

Key characteristics of valve train components and TAPPET performance

- · Precise valve timing preserves combustion efficiency and power.

- · Optimized contact geometry reduces wear on cam lobes and lifters.

- · Hydraulic lash control stabilizes valve lift across temperature ranges.

- · Roller interfaces cut friction and lower oil temperatures.

- · High-surface hardness and advanced coatings resist scuffing.

- · Corrosion-resistant materials suit marine engine environments.

- · Tight tolerances maintain sealing, emissions, and fuel economy.

- · Balanced spring loads prevent valve float at high RPM.

- · Reliable oil flow paths protect bearings and follower needles.

- · Consistent part matching ensures predictable service intervals.

Importance for engine operation and service life

Valve train components directly determine engine breathing. When tappets, rocker arms, or guides wear, the valve event deviates from the intended cam map, causing hard starting, misfire under load, rising exhaust temperatures, and increased soot. Excess lash hammers seats and stems, while insufficient lash can hold a valve off its seat, reducing compression and risking hot gas blow-back that burns valves. On medium-speed marine engines, poor follower-to-lobe contact can generate metal debris, contaminate lubrication circuits, and accelerate bearing damage. In extreme cases, spring failure or rocker fracture can lead to piston-to-valve contact and catastrophic downtime at sea.

Routine inspection of the TAPPET in a diesel engine—checking crown wear, roller smoothness, lash adjuster leak-down, and needle bearing integrity—is vital. Correct surface finish, geometry, and hardness across the entire valve train preserve camshafts, keep NVH low, and extend overhaul intervals. For gas engines, precise valve motion is equally critical to detonation avoidance and emissions control, since mixture quality and burn rate depend on consistent valve opening profiles.

Advantages of OEM spare parts suitable for valve train components

Choosing OEM spare parts suitable for valve train components is a practical way to protect performance, reliability, budget, and service life. These parts are manufactured to the dimensional targets, heat treatments, and surface specs that the cam design requires. Matched cam–TAPPET pairs, correct follower radii, and specified spring rates make break-in predictable and keep contact stress within design limits. Coatings and metallurgy are validated for the lubricant chemistry approved for your engine, ensuring proper film formation and wear control in slow-speed maneuvering, harbor cycles, or base-load power generation.

From a cost perspective, tight tolerance control means fewer reworks and faster overhauls. Parts traceability and documented test regimes reduce operational risk and help maintain class compliance and audit readiness for fleet operators. When you order a TAPPET for a marine engine as OEM parts, you get the intended oil metering, leak-down rate (for hydraulic types), and needle bearing specification for the duty cycle—details that directly influence valve event stability and fuel consumption over thousands of hours.

MOPA as a partner for OEM parts for valve train components

MOPA supplies OEM spare parts suitable for valve train components with a focus on speed, quality, and security in international trade. Whether you need a TAPPET set for a medium-speed diesel engine or complete rocker assemblies for a gas engine, MOPA provides fast quotations, short lead times, and reliable logistics. Our team aligns parts selection with engine model, cam profile, and operating profile, helping purchasers and shipowners avoid mismatch risks that drive unplanned downtime.

With strong supplier networks, controlled storage conditions, and careful packing, MOPA supports on-time delivery to shipyards, vessels, and power plants. Documentation, batch traceability, and material certificates are available on request, and our specialists can assist with kitting for scheduled overhauls—minimizing idle time and ensuring components integrate seamlessly with related systems such as timing drives and lubrication circuits.

Conclusion

Valve train components are central to engine breathing, efficiency, and durability, and the TAPPET is a decisive link between the camshaft and the valves. Selecting OEM spare parts suitable for valve train components preserves timing accuracy, reduces wear, and stabilizes performance in demanding marine and diesel applications. With MOPA, technical decision-makers gain a fast, secure source for the right parts, extending service life while controlling operating costs.