TURNING GEAR/ROTOCAP Valve Train Components for Marine and Diesel Engines

Valve train components form the precise mechanical chain that opens and closes intake and exhaust valves in synchronization with crankshaft rotation. In medium-speed and low-speed marine engines as well as high-output diesel engines, the valve train governs breathing, combustion stability, and emissions. From camshafts and followers to rocker arms, bridges, valve springs, guides, rotators (rotocaps), keepers, and seats, each part is engineered to handle extreme loads, high temperatures, and continuous duty. The result is predictable timing, minimal friction, and reliable sealing—critical parameters for shipowners, power plant operators, and industrial fleets aiming for maximum uptime and fuel efficiency.

TURNING GEAR/ROTOCAP in the valve train: technical function

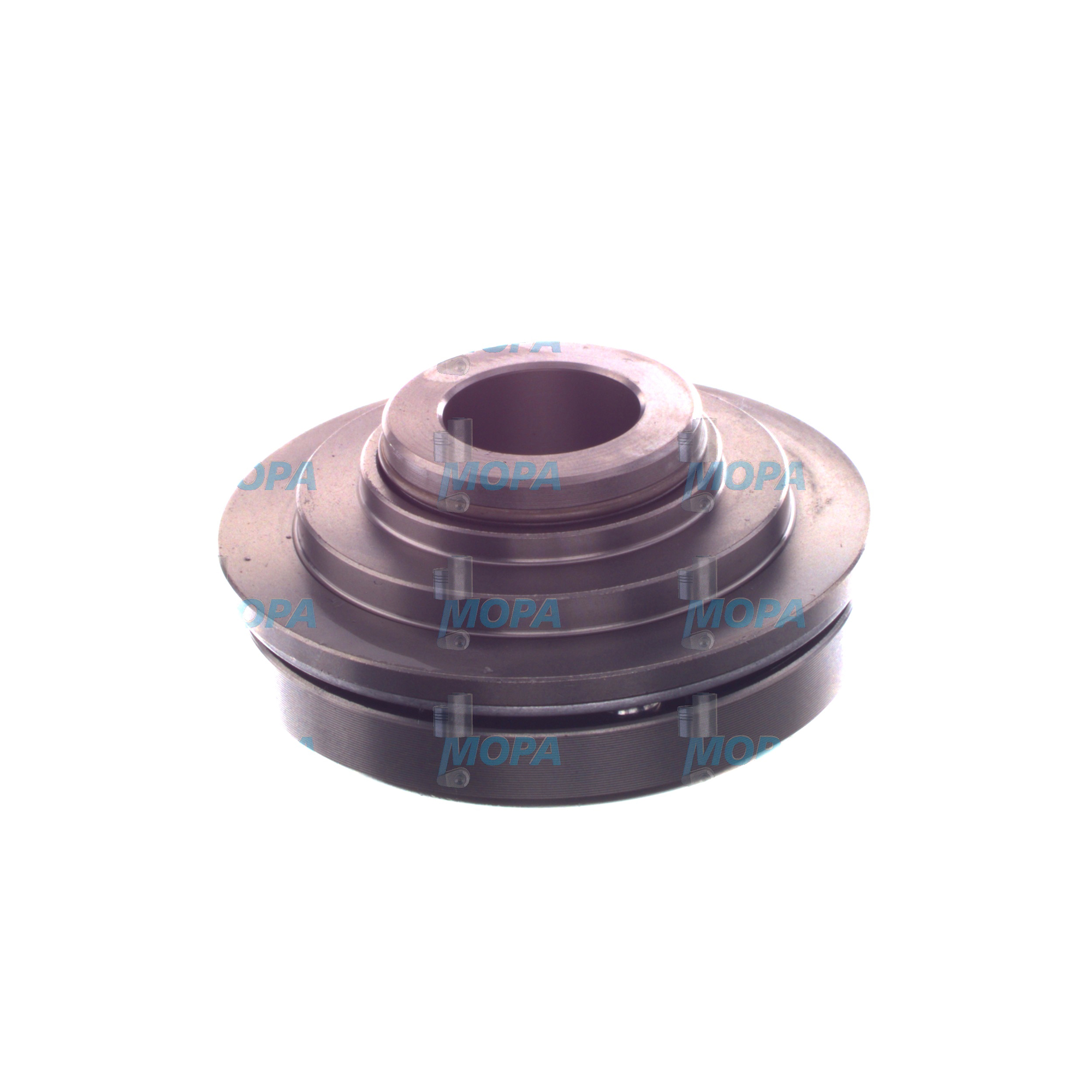

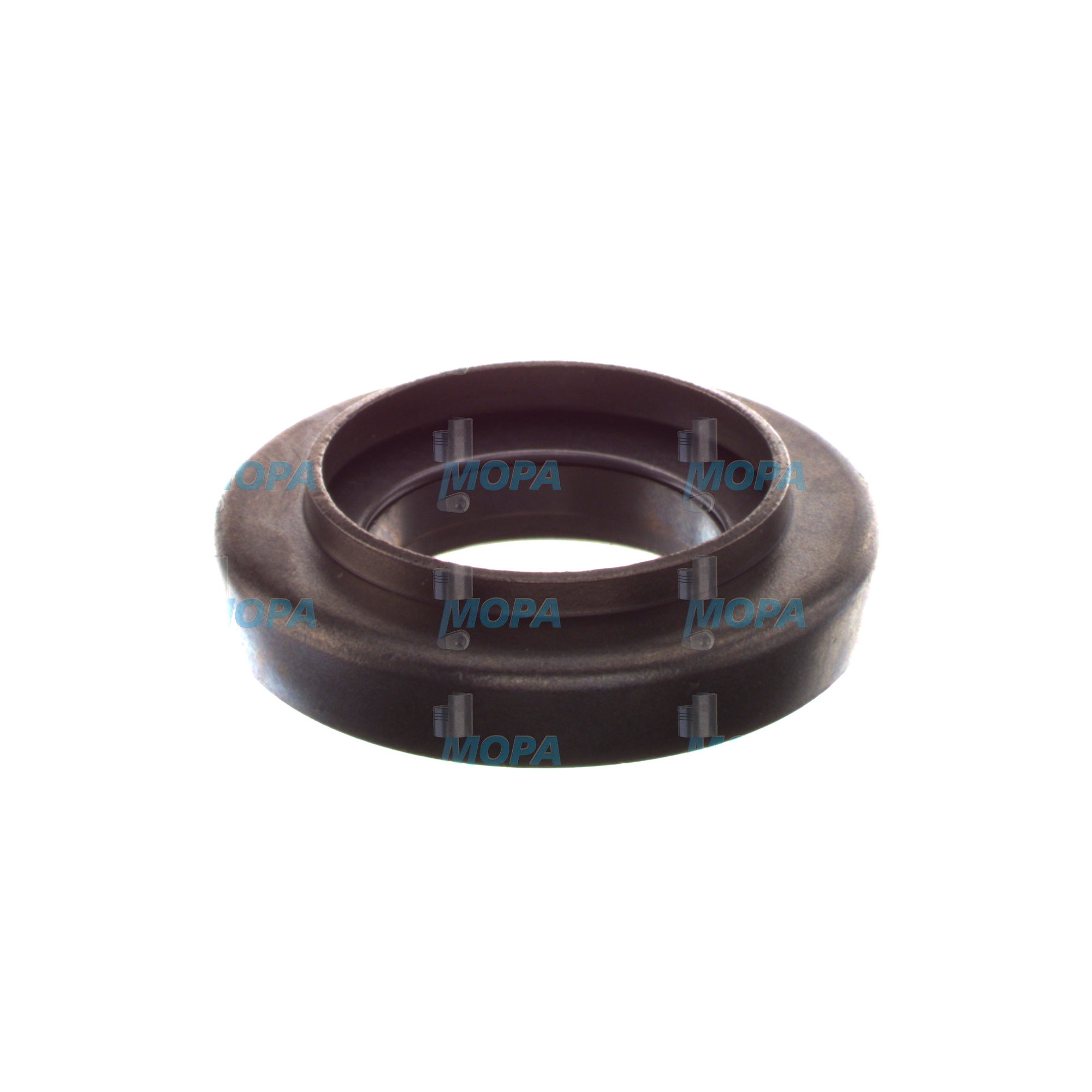

In a four‑stroke diesel engine, the camshaft’s lobe profiles define valve lift, duration, and acceleration. Followers or tappets transfer this motion through pushrods (if applicable) to rocker arms, which deliver the exact lift to the valve stem. Valve springs ensure rapid, controlled closing and maintain seat pressure to prevent blow‑by. The rotocap (valve rotator) is a specialized component in this chain: it incrementally rotates the valve at each opening event to disperse heat, reduce seat groove wear, and prevent hot‑spotting and tuliping. In large bore engines, robust rotocaps are indispensable for exhaust valves exposed to extreme thermal cycles.

While a turning gear is not part of the valve train itself, its role is closely tied to valve train setup and inspection. Using the TURNING GEAR/ROTOCAP marine engine combination during service allows safe barring of the crankshaft at very low speed, enabling accurate valve clearance checks, cam timing verification, and inspection of rotocap function. In commissioning or overhaul, a TURNING GEAR/ROTOCAP diesel engine workflow ensures correct lash, valve bridge alignment, and spring installed heights before the unit returns to load.

- · Precise timing via cam–follower–rocker geometry

- · Controlled valve lift curves for airflow and efficiency

- · Rotocap rotation prevents local overheating and seat grooving

- · High‑strength alloys and surface treatments for wear resistance

- · Correct valve spring rates for high‑speed stability

- · Consistent valve seating for compression and emissions control

- · TURNING GEAR/ROTOCAP OEM parts enable safe setup and inspection

How valve train components contribute to performance, efficiency, and safety

Valve train accuracy translates directly into power density and specific fuel consumption. Optimized lobe profiles manage valve velocity and jerk to maintain air charge, reduce pumping losses, and stabilize combustion. Tight tolerances on guides, stem diameters, and seat concentricity preserve sealing under load, while correct seat contact width (typically 2–3 mm on exhaust, application‑dependent) manages heat rejection. Surface‑hardened cam lobes (e.g., nitrided or induction‑hardened) and DLC‑coated followers combat scuffing and micropitting, extending inspection intervals. The rotocap’s incremental rotation mechanism—often a spring‑loaded roller or ramp stack—spreads wear evenly around the seat, keeping face temperatures uniform and extending valve life. Safe slow rotation using the turning gear before start mitigates oil starvation and minimizes thermal bow, protecting bearings and enabling reliable pre‑start checks of valve motion.

Importance for engine operation and service life

When valve train components drift out of specification, reliability deteriorates. Excessive lash leads to impact loads, noise, and accelerated cam/follower wear; insufficient lash can hold valves off the seat, causing hot burning, compression loss, and power imbalance. Weak or fatigued valve springs cause valve float at speed, risking piston‑to‑valve contact. Worn guides increase oil consumption and coking, while eroded seats compromise sealing and heat transfer. A failed rotocap stops valve rotation, creating hot spots on the valve head and rapid seat recession. Skipped or unsafe barring—rather than controlled turning gear use—can mask timing issues and contribute to catastrophic failures during start. Consistent, high‑quality valve train components, together with disciplined TURNING GEAR/ROTOCAP OEM parts procedures, sustain stable timing, lower maintenance costs, and longer overhaul intervals.

Advantages of OEM spare parts suitable for valve train components

Choosing OEM spare parts suitable for valve train components protects both performance and lifecycle cost. These parts are manufactured to the exact metallurgy, heat treatment, and surface finish the engine design requires. That precision translates to predictable load paths and fatigue life, ensuring components perform as modeled.

- · Dimensional accuracy for drop‑in fit and correct valve geometry

- · Proven materials and heat treatment for cam lobes, followers, and rotocaps

- · Consistent spring rates and coil‑bind margins for high‑speed stability

- · Surface finishes that reduce friction and prevent scuffing

- · Traceability and quality records for safety‑critical components

- · Lower total cost through longer service life and reduced downtime

- · Compatibility with TURNING GEAR/ROTOCAP OEM parts and maintenance procedures

For purchasers balancing budgets with risk, OEM spare parts suitable for valve train components minimize rework, shorten dock time, and secure predictable performance across diesel and gas engines. The result is dependable operation with maintained efficiency and emissions compliance.

MOPA: your partner for OEM spare parts Valve Train Components

MOPA supports fleets and power operators with fast, secure supply of OEM spare parts for valve train components—camshafts, rocker arms, bridges, valve springs, guides, seats, retainers, and rotocaps. Our focus is speed, quality, and transaction security in the trade of OEM parts for diesel and gas engines. Whether you need a rotocap set for a two‑stroke exhaust valve or assistance aligning procedures around a TURNING GEAR/ROTOCAP marine engine service, MOPA provides technical clarity, reliable lead times, and parts you can deploy with confidence. We help you standardize across engine types, streamline overhauls, and keep your asset availability high.

Conclusion: Valve train components and TURNING GEAR/ROTOCAP

Valve train components are the backbone of combustion control, directly influencing reliability, efficiency, and safety. Matched with disciplined use of the turning gear and robust rotocaps, they keep marine and diesel engines performing at design levels. Selecting OEM spare parts suitable for valve train components—and partnering with MOPA—ensures long service life, predictable costs, and confidence in every operating hour.