VALVE BRIDGE and valve train components for demanding diesel and gas engines

Valve train components form the mechanical chain that transfers motion from the camshaft to the intake and exhaust valves. This category includes the camshaft followers (tappets), pushrods, rocker arms, VALVE BRIDGE assemblies, valve springs, retainers, collets, valve guides, and valve seats. Together, these precision parts control timing, lift, and duration of valve events, directly shaping combustion quality, fuel efficiency, emissions, and engine durability. In large-bore diesel and gas engines used in marine propulsion, power generation, and industry, the integrity of every element in the valve train is decisive for reliable operation and predictable maintenance cycles.

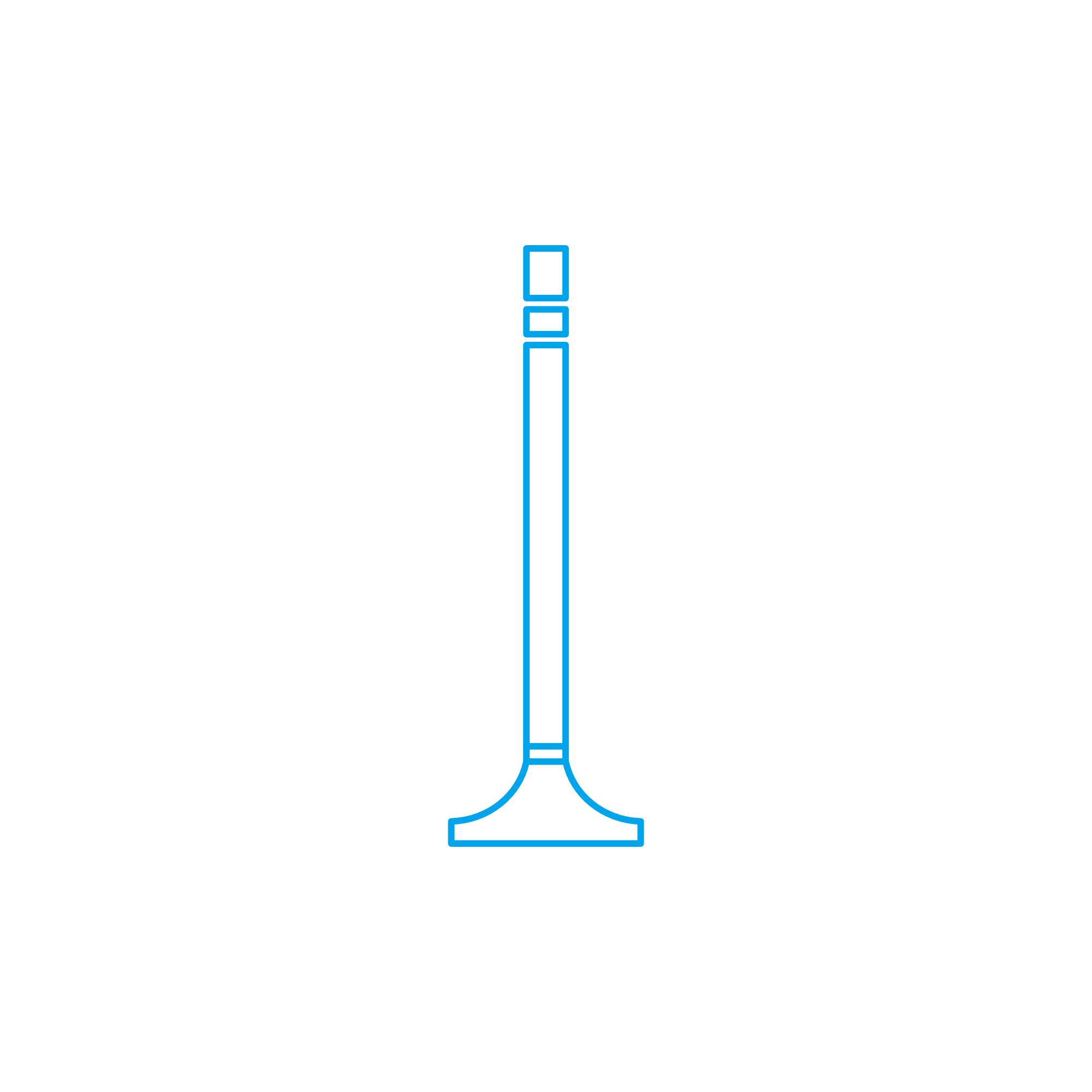

Within this system, the VALVE BRIDGE is a critical load-distribution component—especially in engines with paired valves per cylinder. It equalizes force from a single rocker arm onto two valve stems, ensuring synchronous opening, consistent lift, and balanced thermal loading. The result is stable airflow, even exhaust scavenging, and reduced mechanical stress throughout the cylinder head.

Technical function of valve train components and the VALVE BRIDGE in a diesel engine or marine engine

The camshaft transforms rotary motion into a precisely defined linear displacement via the follower and pushrod (or through an overhead cam arrangement). The rocker arm pivots to convert this motion into valve lift. When an engine employs dual intake or dual exhaust valves, the VALVE BRIDGE sits across both stems so a single rocker tip actuates both valves simultaneously. In a marine engine with high cylinder pressures and long duty cycles, the VALVE BRIDGE stabilizes load paths, maintains valve synchronization, and prevents uneven seat contact that would otherwise accelerate wear.

Key engineering aspects include material hardness, surface finish, flatness, and parallelism. A VALVE BRIDGE typically uses high-strength alloy steels with controlled heat treatment (e.g., case hardening or nitriding) for wear resistance. Critical surfaces—contact pads, stem pockets, and the rocker interface—require tight tolerances to prevent tilting, fretting, or galling. Proper oil supply to contact zones minimizes friction and dissipates heat, preserving both the bridge and the valve tips. In modern applications, VALVE BRIDGE OEM parts are dimensionally matched to the cam profile and rocker geometry to achieve the specified lift curve and valve lash.

For large-bore diesel engine platforms, stricter demands apply: bridges must withstand alternating loads, resist bending under high valve spring forces, and maintain dimensional stability across the service temperature range. In addition, bridge mass is optimized to control valve train inertia and reduce the risk of valve float at higher speeds. When correctly specified and installed, the bridge helps keep exhaust gas temperatures uniform, protects the turbocharger from load imbalance, and supports emission compliance by securing consistent gas exchange per cycle.

VALVE BRIDGE load distribution and contact integrity

Because two valves rarely share exactly identical conditions, the VALVE BRIDGE compensates for minor differences in stem length, seat wear, and thermal expansion. Its geometry and lash-adjustment strategy ensure both valves reach the same lift within microns. This prevents one valve from shouldering excessive load, which would risk seat recession, stem mushrooming, or micro-pitting at the contact surfaces.

Key characteristics of valve train components and the VALVE BRIDGE

· Precise valve timing and lift for stable combustion.

· Even load distribution across dual valves via the VALVE BRIDGE.

· High-strength materials and engineered heat treatment.

· Tight tolerances for flatness, hardness, and surface finish.

· Optimized lubrication paths at all contact interfaces.

· Dimensional consistency for drop-in alignment with OEM parts.

· Resistance to fretting, pitting, and thermal fatigue.

· Support for emissions control and fuel efficiency targets.

Importance for engine operation, reliability, and service life

Healthy valve train components protect the entire combustion process. If the VALVE BRIDGE or related parts wear out of specification, a cascade of problems can follow: drifting valve lash, uneven valve seating, hot spots on the valve head, rising exhaust gas temperatures, and accelerated turbocharger and manifold stress. Persistent misalignment can lead to seat recession, tip deformation, rocker foot damage, and ultimately valve failure—an event with severe implications for pistons, cylinder heads, and uptime.

In continuous-duty marine and power generation service, these risks translate into higher fuel burn, unstable load acceptance, increased emissions, and unplanned off-hire. Consistent inspections—measuring valve lash, checking contact patterns, and monitoring wear on bridge pads and valve tips—are essential. When measurements deviate from the engine maker’s specifications, timely replacement of the relevant valve train components, including the VALVE BRIDGE, preserves cylinder balance and extends overhaul intervals.

Advantages of OEM spare parts suitable for valve train components and the VALVE BRIDGE

Choosing OEM spare parts for valve train components ensures that material grades, heat treatment, and geometry match the intended kinematics of the engine. Dimensional fidelity—across pad thickness, stem pocket depth, and contact surface parallelism—reduces setup time during maintenance, shortens commissioning after rebuilds, and stabilizes valve lash from the first hours of operation. Traceability and process control help keep performance consistent across replacement cycles, which is critical for fleets with standardized maintenance regimes.

For procurement and technical teams, the benefits are practical as well as economic: predictable fit, reduced risk of rework, and lower exposure to follow-on damage from misaligned or soft components. Correctly specified OEM spare parts support long-term budget planning by minimizing unscheduled downtime and preserving cylinder head components such as guides and seats. In short, the right VALVE BRIDGE and associated parts sustain performance, reliability, and total cost of ownership across the engine’s service life.

MOPA as your partner for OEM parts: VALVE BRIDGE and valve train components

MOPA is an experienced and reliable partner for sourcing OEM spare parts for valve train components—including the VALVE BRIDGE—for diesel and gas engines. Our team focuses on speed, quality, and security in every transaction: rapid identification by part number or engine type, efficient logistics to minimize vessel or plant downtime, and documentation that supports safe installation and operation. Whether you operate a marine engine or a land-based genset, MOPA helps you secure the correct components on time, aligned with the specifications required for consistent engine performance.

Conclusion: VALVE BRIDGE and valve train components secure efficient combustion

Valve train components, with the VALVE BRIDGE at their core in dual-valve layouts, are fundamental to stable gas exchange, efficiency, and long-term engine health. Using OEM spare parts suitable for valve train components maintains precise kinematics, reduces wear, and protects your investment by supporting predictable maintenance and dependable uptime.