VALVE CAP and Valve Train Components for Heavy-Duty Engines

Valve train components are the precision parts that open and close the intake and exhaust valves with exact timing and controlled motion. In medium- and high-speed diesel and gas engines, as well as in every marine engine, they convert the rotational movement of the camshaft into linear valve travel, sealing the combustion chamber and ensuring efficient charge exchange. This category includes valves, valve guides, seats, springs, retainers, collets, rocker arms, pushrods, tappets/rollers, camshafts, and the critical VALVE CAP (also known as lash cap). Together, these components define combustion stability, fuel economy, emissions, and engine longevity.

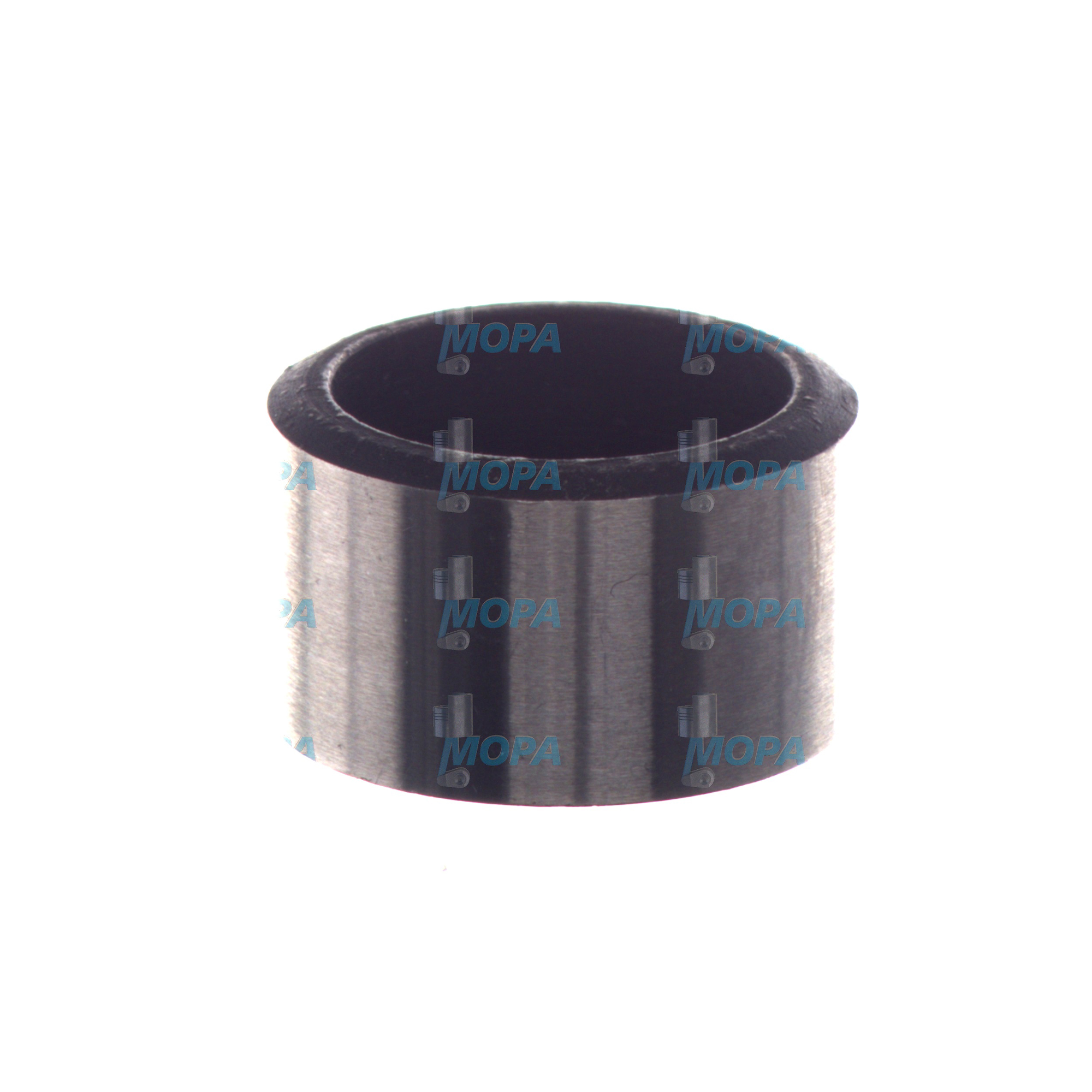

The VALVE CAP sits on the valve stem tip and provides a hardened interface for the rocker arm or cam follower. In large-bore diesel engine applications, where valve loads are high and duty cycles are continuous, the cap protects the stem tip from brinelling, spreads contact stress, and enables fine adjustment of lash to maintain correct valve timing. As part of the broader valve train, this seemingly small component plays an outsized role in reliability and performance.

Technical function: valve train components and the role of a VALVE CAP in diesel and marine engines

In operation, the cam lobe lifts a follower or rocker, compressing the valve spring and moving the valve off its seat. The geometry between cam/follower/rocker and the valve stem must be precisely maintained to avoid edge loading, scuffing, or valve rotation loss. The VALVE CAP in a diesel engine provides a sacrificial, wear-resistant surface with controlled thickness, which sets the contact height and lash. In a marine engine running at constant load, maintaining this lash is essential for stable seating velocity, reduced impact, and consistent heat transfer from the valve to the seat.

Materials and finishes matter. Caps are typically manufactured from through-hardened or case-hardened alloy steel with a high surface hardness (often 58–62 HRC) and fine surface finish (e.g., Ra ≤ 0.2–0.4 µm), sometimes with nitriding for improved wear and scuff resistance. Correct cap thickness compensates for stem wear or valve recession and helps keep rocker sweep centered on the stem. When paired with properly matched retainers, keepers, springs, tappets, and guides, the valve train maintains accurate timing, prevents valve float, and protects the cam/follower interface from boundary lubrication failure.

For engines using rotators or valve rotation devices, the cap’s flatness and hardness enable reliable micro-rotation that cleans the seating surface and distributes thermal loads. In high-boost applications, correct spring pressures, retainer angles, and installed heights work in concert with the cap to avoid lofting and surge. Sourcing a VALVE CAP OEM parts set that matches the engine manufacturer’s specification ensures correct metallurgy, contact geometry, and dimensional tolerances across the entire valve train stack.

- · Hardened contact surface protects valve stem tips.

- · Controlled thickness helps set precise valve lash.

- · Optimized geometry improves rocker/follower contact pattern.

- · Supports valve rotation for cleaner seating and heat dissipation.

- · Integrates with springs, retainers, and guides for stable timing.

- · Critical for heavy-load marine engine and diesel engine durability.

Why valve train components are crucial for engine reliability and service life

Valve train components determine how accurately an engine breathes and how efficiently heat leaves the combustion chamber. If a VALVE CAP wears or the lash drifts out of spec, the valve may seat too harshly or too softly. Excess impact accelerates seat recession, damages guides, and can lead to bent pushrods or cracked rocker arms. Insufficient seating force causes hot gas blow-by, valve face burning, loss of compression, and reduced turbocharger efficiency. Incorrect contact geometry increases side loading and oil film collapse at the follower interface, leading to scuffing and pitting on tappets and cam lobes.

Other failure modes linked to degraded valve train components include valve float at high RPM/load, broken springs from surge, dropped valves due to keeper/retainer mismatch, and elevated fuel consumption from mistimed charge exchange. In marine propulsion and auxiliary gensets, such failures risk unscheduled downtime, costly dry-docking, and collateral damage to pistons and cylinder heads. Robust, precisely matched components preserve timing accuracy, emissions compliance, and power output across long maintenance intervals.

Advantages of OEM spare parts suitable for valve train components

Choosing OEM spare parts suitable for valve train components—valves, guides, seats, springs, retainers, tappets, rocker arms, and the VALVE CAP—delivers consistent metallurgy, heat treatment, and dimensional control that field-proven engines depend on. The result is repeatable valve lash, predictable wear patterns, and tight control of seating velocity and spring dynamics.

- · Performance: Consistent timing, proper seating, stable valve motion.

- · Reliability: Correct hardness, case depth, and surface finish reduce scuffing.

- · Budget: Longer service intervals and fewer unplanned stoppages reduce lifecycle cost.

- · Service life: Optimized materials and fits limit recession and cam/follower wear.

- · Fit and function: Exact tolerances for stem height, lash, and retainer/keeper angles.

- · Compliance: Helps maintain emissions and fuel efficiency targets.

Specifically, selecting a VALVE CAP OEM parts match ensures cap thickness and hardness align with rocker geometry, guide protrusion, and installed spring height—small deviations here cascade into timing errors and accelerated wear. On high-output diesel and gas engines, those tolerances directly affect mean effective pressure and thermal loading.

MOPA: fast, secure supply of OEM parts for VALVE CAP and valve train components

MOPA is an experienced, reliable partner for OEM spare parts for valve train components. We source and trade VALVE CAP options for diesel engine and marine engine platforms alongside matched valves, guides, seats, tappets, rockers, springs, retainers, and cam components. Our focus is speed, quality, and security—rapid quotations, traceable documentation, and controlled logistics that keep vessels and power plants running.

With MOPA, purchasers and technical managers gain access to application-verified selections, cross-references by engine model, and expert support on lash targets, stem tip heights, and cap material compatibility. From single-line items to complete top-end kits, we deliver OEM parts for diesel and gas engines efficiently and with confidence in their technical performance.

Selection tips for VALVE CAP OEM parts in heavy-duty engines

- · Verify cap thickness against target lash and stem tip height.

- · Match hardness and coating to follower type (roller vs. flat tappet).

- · Confirm retainer/keeper angle (e.g., 7°/10°) and spring installed height.

- · Check cap diameter and chamfers for correct rocker sweep pattern.

- · Inspect lubrication paths and ensure proper oiling to the contact zone.

Conclusion

Valve train components, including the VALVE CAP, are fundamental to precise timing, clean combustion, and long engine life in diesel, gas, and marine engine applications. The right VALVE CAP OEM parts pairing secures correct lash, minimizes wear, and protects the entire top end. Partnering with MOPA simplifies sourcing and ensures you receive high-quality, application-matched components that keep critical equipment operating at peak performance.