VALVE COLLET and Valve Train Components for Marine and Diesel Engines

Valve train components form the mechanical backbone that times and actuates the breathing of an engine. From camshaft and lifters to pushrods, rocker arms, valves, retainers, springs, guides, and the precision-fit VALVE COLLET, this assembly governs air exchange, combustion stability, and emissions. In heavy-duty applications such as a marine engine or high-load industrial diesel engine, the valve train operates under continuous thermal and mechanical stress, making robust design and correct parts selection essential for efficiency, uptime, and safety.

Within this category, each part must transmit motion with minimal loss while maintaining tight clearances and seat pressure over thousands of operating hours. The result is reliable valve opening and closing, consistent compression, and controlled combustion—outcomes directly linked to fuel economy, power density, and compliance with operational standards.

Technical function of valve train components and the role of VALVE COLLET in a diesel engine

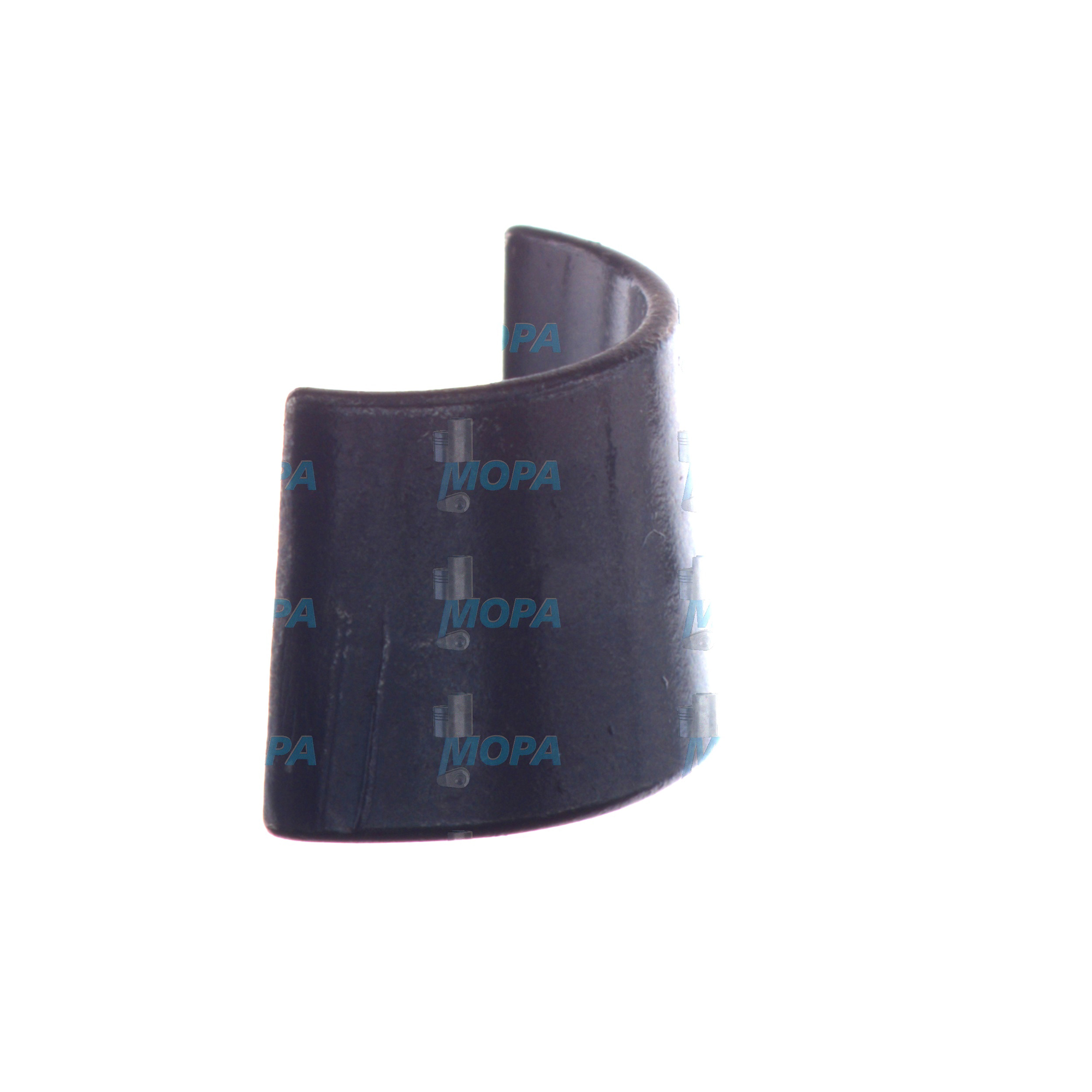

The valve train converts the camshaft profile into linear valve movement. In a typical diesel engine, the cam lobe lifts a lifter/tappet, sends motion through a pushrod to a rocker arm, and depresses the valve stem to open the port. A valve spring then closes the valve and ensures positive seating. The retainer sits atop the spring, while the VALVE COLLET (also called a keeper) locks the retainer to the valve stem via a precision groove. This small, tapered pair is critical: it clamps the valve, defines installed height, preserves spring preload, and prevents the stem from slipping under high loads and speed.

Because the VALVE COLLET must withstand cyclic loads, shock, and vibration, its metallurgy (typically high-strength, case-hardened steel), taper accuracy, and groove geometry are decisive. In a marine engine running long duty cycles, any mismatch in taper angle between retainer and collet or excessive stem groove wear can trigger fretting, loss of preload, valve float, or in extreme cases, a dropped valve. Correctly matched VALVE COLLET OEM parts ensure the intended clamp force, maintain valve spring seat pressure, and safeguard the combustion chamber from intrusion events.

- · Positive valve control at high temperature and load

- · Stable valve seating pressure and compression

- · Accurate transfer of cam lift and timing

- · Reduced wear via correct materials and surface treatments

- · Safety margin against valve float and stem pull-through

- · Service-friendly assembly with matched VALVE COLLET OEM parts

VALVE COLLET for marine engine duty and OEM parts precision

Geometry and surface finish define the reliability of the collet-retainer interface. The taper must mate perfectly with the retainer; the groove radius and flank angle must match the valve stem; and surface hardness must resist brinelling and micro-movement. VALVE COLLET OEM parts for a diesel engine are produced to tight dimensional tolerances, with controlled case depth and shot-peened or nitrided finishes where required. This precision prevents micro-slip that leads to fretting, maintains spring installed height across overhauls, and protects the stem groove from notch-induced fatigue. In fleets with mixed engine types, adherence to the specified taper and groove standard is essential to keep component interchangeability and predictable valve dynamics.

Importance of valve train components for reliable engine operation

Well-maintained valve train components are central to engine reliability and service life. If spring preload drifts or retainers and collets lose clamping force, valve motion becomes erratic. Outcomes include valve lash instability, reduced compression, hot gas leakage, higher exhaust temperatures, and accelerated seat and guide wear. At speed, inadequate preload causes valve float, which can culminate in piston-to-valve contact, bent pushrods, broken rockers, or cam lobe scuffing—events that risk major downtime and costly repairs on board.

Common degradation mechanisms include thermal fatigue in springs, abrasive wear in guides, pitting on cam lobes from lubrication issues, and fretting at the retainer–VALVE COLLET interface. Routine inspections such as measuring installed height, checking spring force at height, dye penetrant testing of retainers, and gauging valve stem grooves help detect early warning signs. Keeping the valve train in specification preserves combustion stability, reduces fuel consumption, and supports emissions performance across the entire TBO.

Advantages of OEM spare parts suitable for Valve train components

Using OEM spare parts suitable for valve train components delivers measurable benefits in performance, reliability, budget, and service life. These parts are built to the manufacturer’s specification, ensuring the correct taper angles, groove profiles, spring rates, and heat treatments that maintain designed preload and timing characteristics. For a VALVE COLLET, this means predictable clamp force, consistent installed height, and protection against micro-movement. For springs, retainers, lifters, and rockers, it means dimensional stability and durability under high-cycle fatigue.

- · Exact dimensional fit for drop-in assembly

- · Consistent metallurgy and heat treatment

- · Proven performance in marine and stationary duty cycles

- · Full traceability and documentation for compliance

- · Lower lifecycle cost via reduced unplanned downtime

- · Reliable compatibility across diesel and gas engine platforms

Beyond direct performance, correctly specified OEM spare parts help control total cost of ownership: fewer reworks, shorter maintenance windows, and reduced risk of secondary damage. In practice, that translates to better schedule adherence for shipowners and cleaner technical audits for asset managers.

MOPA – experienced partner for VALVE COLLET and valve train components

MOPA is a reliable partner for OEM spare parts covering the full scope of valve train components, from the smallest VALVE COLLET to complete spring–retainer kits. We focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines: fast response, quality-controlled sourcing, and secure, transparent logistics. Our team supports purchasers and superintendents with technical cross-references, kitting for overhauls, and documentation that streamlines compliance and onboard receiving. With MOPA, you gain a dependable supply line that helps keep engines running to plan.

Conclusion: VALVE COLLET and valve train components in focus

Valve train components—especially the precisely matched VALVE COLLET and retainer—are fundamental to engine efficiency, safety, and service life. Specifying OEM spare parts suitable for valve train components preserves design intent, stabilizes performance across duty cycles, and protects maintenance budgets through dependable reliability.