VALVE GUIDE in Valve Train Components for High-Performance Engines

Valve train components form the precise mechanical system that opens and closes the combustion chamber at exactly the right moment. This category includes the camshaft, lifters/tappets, pushrods, rocker arms, valve springs, retainers, valve seats, and the essential VALVE GUIDE. Together, these parts ensure that intake and exhaust valves move with exact timing, remain perfectly aligned, and seal reliably against their seats. In diesel and gas engines—especially in demanding marine engine applications—robust, correctly matched valve train components are indispensable for power density, fuel efficiency, emissions control, and long service life.

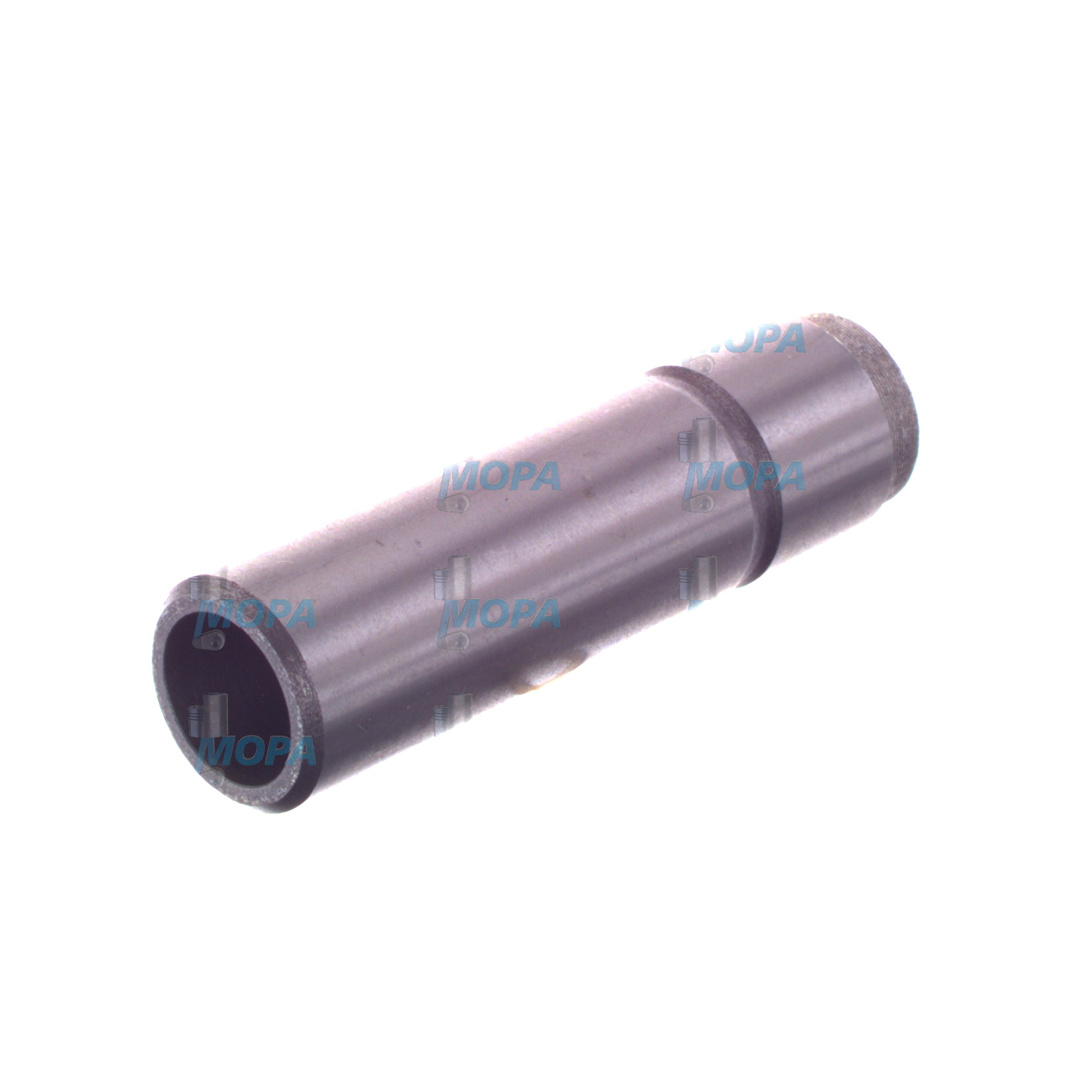

A VALVE GUIDE provides the radial support that keeps the valve stem centered, controlling lateral movement and ensuring the valve face meets the seat concentrically. When combined with correctly matched springs, rockers, and followers, the entire system maintains timing accuracy across a wide temperature and load range. Because these components work under high thermal and mechanical stress, procurement decisions for ships, power plants, and industrial installations must prioritize dimensional accuracy, metallurgical quality, and proven compatibility.

Technical Function: Valve Train Components and the Role of the VALVE GUIDE in a Diesel Engine

The valve train converts camshaft rotation into linear motion at the valve. In a typical diesel engine, the cam lobe profile defines lift, duration, and timing. Tappets or rollers transfer this motion to pushrods and rocker arms, which press the valve stem downward. The valve spring then restores the valve to the closed position. Throughout this cycle, the VALVE GUIDE keeps the valve stem stable, ensuring the valve face lands squarely on the seat, maintaining gas-tight sealing and consistent heat transfer.

The VALVE GUIDE also acts as a critical thermal bridge. Hot exhaust valves dissipate a substantial portion of their heat through the stem into the guide and cylinder head. Materials such as high-phosphor bronze or alloyed cast iron are chosen for wear resistance, thermal conductivity, and compatibility with modern stem coatings. Correct stem-to-guide clearance—engineered to micrometer-scale tolerances—balances lubrication, heat transfer, and friction. Too tight, and the valve can seize during thermal expansion; too loose, and blow-by, unstable seating, and oil consumption increase.

In a marine engine, the cumulative precision of the valve train directly influences torque stability, turbocharger performance, and exhaust gas temperature distribution. Cam followers with hardened surfaces, nitrided rocker shafts, and correctly tensioned valve springs prevent valve float at high RPM and heavy load. Meanwhile, a dimensionally correct VALVE GUIDE for a marine engine or VALVE GUIDE OEM parts matched to the cylinder head material preserve alignment across thermal cycles, minimizing fretting, scuffing, and valve seat erosion.

- · Precise valve guidance for concentric seating and tight sealing.

- · Optimized stem-to-guide clearance for lubrication and heat transfer.

- · Durable materials (bronze, alloy cast iron) for high-load, high-heat duty.

- · Stable timing through rigid tappets, pushrods, and rocker geometry.

- · Controlled spring dynamics to prevent valve float and impact wear.

- · Reduced emissions via reliable valve sealing and combustion control.

- · Extended component life through proper surface finishes and coatings.

Importance for Engine Operation: Why Valve Train Components and the VALVE GUIDE Matter

Reliability starts with clean, repeatable valve events. If the VALVE GUIDE wears beyond limits, the valve can tilt on closure, leading to seat leakage, hot spotting, and ultimately burned valves. Misalignment also accelerates wear on the stem, rocker tip, and seat inserts, raising maintenance costs and downtime. Excessive clearance can draw oil into the combustion chamber, increasing deposits on the valve head and turbocharger turbine, impairing efficiency and raising emissions.

In heavy-duty diesel and gas engines, even small deviations in valve lift or seating pressure erode performance. Timing drift due to worn followers or rockers reduces volumetric efficiency, weakens combustion, and elevates specific fuel consumption. In worst cases, failed components can cause piston-to-valve contact—catastrophic for any engine. Keeping the VALVE GUIDE, valve springs, and contact surfaces within specification is therefore critical to safeguarding power output, fuel economy, and safety at sea or in power generation.

Advantages of OEM Spare Parts Suitable for Valve Train Components

Selecting OEM spare parts suitable for valve train components—such as a VALVE GUIDE for a diesel engine—delivers consistent fit, geometry, and metallurgy aligned with the cylinder head design and cam profile. Repeatable tolerances shorten installation time and reduce the risk of rework. Surface treatments and heat treatments are matched to the expected duty cycle, minimizing scuffing and corrosion under high sulfur or high temperature exhaust conditions.

Performance, Reliability, and Budget Benefits with VALVE GUIDE OEM Parts

By using VALVE GUIDE OEM parts and complementary valve train components, operators realize measurable gains:

- · Stable timing and sealing for sustained efficiency and power.

- · Lower oil consumption and cleaner exhaust paths.

- · Reduced risk of unplanned stops thanks to validated materials and fits.

- · Faster overhauls with parts that install cleanly to spec.

- · Better lifecycle cost through slower wear and extended service intervals.

- · Consistent performance across diesel and gas applications, including marine engine duty.

For fleet managers and plant operators, these factors translate into fewer maintenance interventions, predictable parts planning, and safer operation—without compromising on performance targets or emissions compliance.

MOPA: Your Partner for OEM Spare Parts Valve Train Components

MOPA is an experienced and reliable partner for OEM spare parts valve train components, including the VALVE GUIDE, valves, seats, springs, and associated hardware. We focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines. Rapid sourcing, technically verified cross-references, and full traceability support efficient procurement and audit-ready documentation. Our team helps you identify the correct configuration—material pairing, clearances, and spring rates—to match specific engine types and operating profiles, from auxiliary gensets to main propulsion.

With streamlined logistics and dedicated export handling, MOPA reduces downtime risks for shipowners and power producers. Whether you need a single VALVE GUIDE set or a complete overhaul kit, we deliver dependable availability and technical clarity.

Conclusion: VALVE GUIDE and Valve Train Components in Focus

Valve train components—anchored by a correctly specified VALVE GUIDE—are central to engine efficiency, durability, and safe operation. Precision alignment, robust materials, and proper dynamics protect performance under the harshest duty cycles. Choosing OEM spare parts suitable for valve train components safeguards fit, reliability, and lifecycle cost, ensuring your diesel or gas engine delivers as intended over the long term.