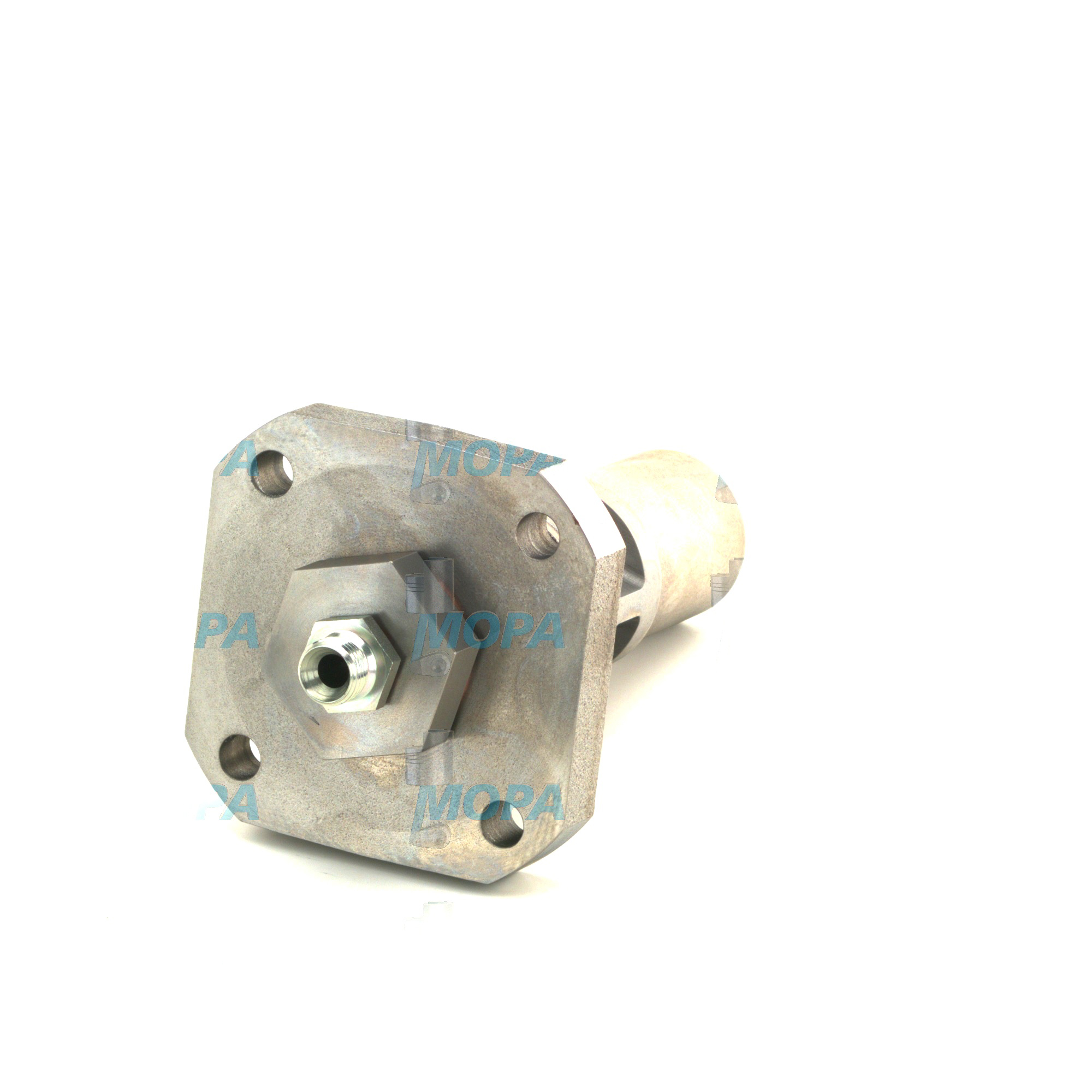

2/2-WAY SOLENOID VALVE Valves for Marine, Diesel, and Gas Engines

Valves are precision components that regulate, direct, and shut off the flow of liquids and gases throughout an engine. In propulsion and power generation, they control everything from combustion air and fuel delivery to lubrication, cooling, and starting air. By managing pressure, flow rate, and timing, valves protect core engine components, stabilize operating conditions, and contribute directly to efficiency, emissions control, and safety. Within this broad category, electromechanical devices such as the 2/2-WAY SOLENOID VALVE play a decisive role in on/off control and fail-safe functions across marine engine and diesel engine systems.

Valves in engines: flow control and 2/2-WAY SOLENOID VALVE applications

Engine installations rely on a mix of valve types—mechanical intake/exhaust valves for gas exchange, non-return check valves to prevent backflow, pressure-control valves to stabilize circuits, and solenoid-actuated shut-off valves to switch media reliably. A 2/2-WAY SOLENOID VALVE has two ports and two switching states. It is commonly configured as normally closed (energize to open) or normally open (energize to close) and is actuated by a coil and plunger mechanism. In a marine engine, this compact device provides rapid, repeatable switching in fuel supply, pilot oil, lube bypass, cooling water bypass, and starting-air pilot lines. In a diesel engine, it is widely used for emergency fuel shut-off, automatic priming control, and auxiliary system interlocks.

From a functional standpoint, the coil produces a magnetic field that moves the armature, lifting or seating the valve seal. Flow is either allowed or blocked, creating a precise on/off response with millisecond-level actuation times. Correct sizing (Cv/Kv), body material (brass, stainless steel), seal selection (NBR, FKM, EPDM), and coil specifications (voltage, power, insulation class) ensure compatibility with the medium, temperature, and pressure profile. Deployed as 2/2-WAY SOLENOID VALVE OEM parts, these units integrate seamlessly with engine controls, remote shutdown systems, and safety circuits.

How a 2/2-WAY SOLENOID VALVE supports marine engine and diesel engine systems

In fuel systems, a 2/2-WAY SOLENOID VALVE marine engine assembly provides positive shut-off to prevent dribble and backflow when the engine stops, reducing risk of leakage into the crankcase and ensuring cleaner restarts. In lube and cooling circuits, it switches bypass lines or isolates sub-circuits during maintenance. In starting-air lines, it acts as a pilot valve to command larger actuators. For dual-fuel or gas engines, it contributes to purge, pilot, and safety shut-off logic. Thanks to its simple two-port design, it offers high reliability with minimal pressure drop when open and tight sealing when closed.

- · Fast actuation for precise on/off control

- · Tight shut-off to protect downstream components

- · Broad media compatibility (fuel, oil, water, air)

- · Configurable as normally closed or normally open

- · Coil options to match shipboard and plant voltages

- · Durable materials for marine and industrial environments

- · Integrates with engine safety and control systems

Why valves are critical for engine reliability and service life

Healthy valves keep operating parameters within specification. A leaking shut-off valve can cause fuel dilution, uncontrolled flow, air ingress, or pressure loss, which in turn accelerates wear on pumps, injectors, and bearings. Sticking or slow-acting solenoids may prevent timely shutdown, trigger alarms, or cause hard starting. Mechanical valve train wear (seat, guide, stem) leads to poor compression and higher exhaust temperatures, elevating thermal stress and emissions. Conversely, well-maintained valves stabilize temperatures, ensure target flow and pressure, and protect major components—extending overhaul intervals and avoiding unplanned stops.

Common failure modes include coil burnout from overvoltage or heat, plunger contamination by particulates, seal hardening due to incompatible media, and corrosion in aggressive atmospheres. Preventive measures—proper filtration, correct voltage selection, heat management, and timely renewal with fit-for-purpose components—mitigate these risks and safeguard uptime.

Advantages of OEM spare parts suitable for valves and 2/2-WAY SOLENOID VALVE assemblies

Choosing OEM spare parts suitable for valves ensures dimensional fidelity, material consistency, and performance that matches the engine builder’s specifications. For a 2/2-WAY SOLENOID VALVE diesel engine installation, that means the coil, armature, spring, body, and seals deliver the response time, flow capacity, and sealing class that the control logic expects—without the need for re-tuning. Traceable materials and qualified manufacturing contribute to predictable service life and stable mean time between failures, supporting planned maintenance budgets and fleet-wide standardization.

From a cost perspective, correctly specified OEM parts reduce installation time, minimize rework, and cut the risk of collateral damage caused by leakage or delayed actuation. Engineers also benefit from consistent coil power ratings, insulation classes, and connector standards, simplifying spares management on board and across multiple vessels or plants.

Key reasons to select OEM parts for valves

- · Exact fit and function align with engine specifications

- · Proven materials and seal compounds for the intended media

- · Stable response times and leakage performance

- · Lower life-cycle cost through predictable service intervals

- · Simplified compliance with class and safety requirements

- · Streamlined inventory and crew training across fleets

MOPA as your partner for OEM valve parts and 2/2-WAY SOLENOID VALVE sourcing

MOPA is an experienced, reliable partner for OEM spare parts Valves. We focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines—covering fuel, lube, cooling, air, and safety systems. Our experts cross-reference drawings and part numbers, advise on media and temperature compatibility, and propose optimized kitting for overhauls. With global availability and rigorous inbound quality checks, MOPA helps you keep critical systems operational while maintaining procurement transparency and documentation integrity.

Whether you need a 2/2-WAY SOLENOID VALVE OEM parts package for a marine engine shut-off circuit or a comprehensive valve kit for your diesel engine maintenance, MOPA streamlines sourcing and delivery to meet tight schedules and technical requirements.

Conclusion: dependable valves and OEM parts for efficient operation

Valves—mechanical and solenoid—are fundamental to safe, efficient engine operation, from fuel shut-off to cooling control. Selecting properly specified OEM spare parts suitable for Valves, including the 2/2-WAY SOLENOID VALVE, preserves performance and reduces operational risk.

With MOPA as your partner, you gain fast, secure access to quality OEM solutions that support reliable marine engine and diesel engine performance across your fleet or plant.