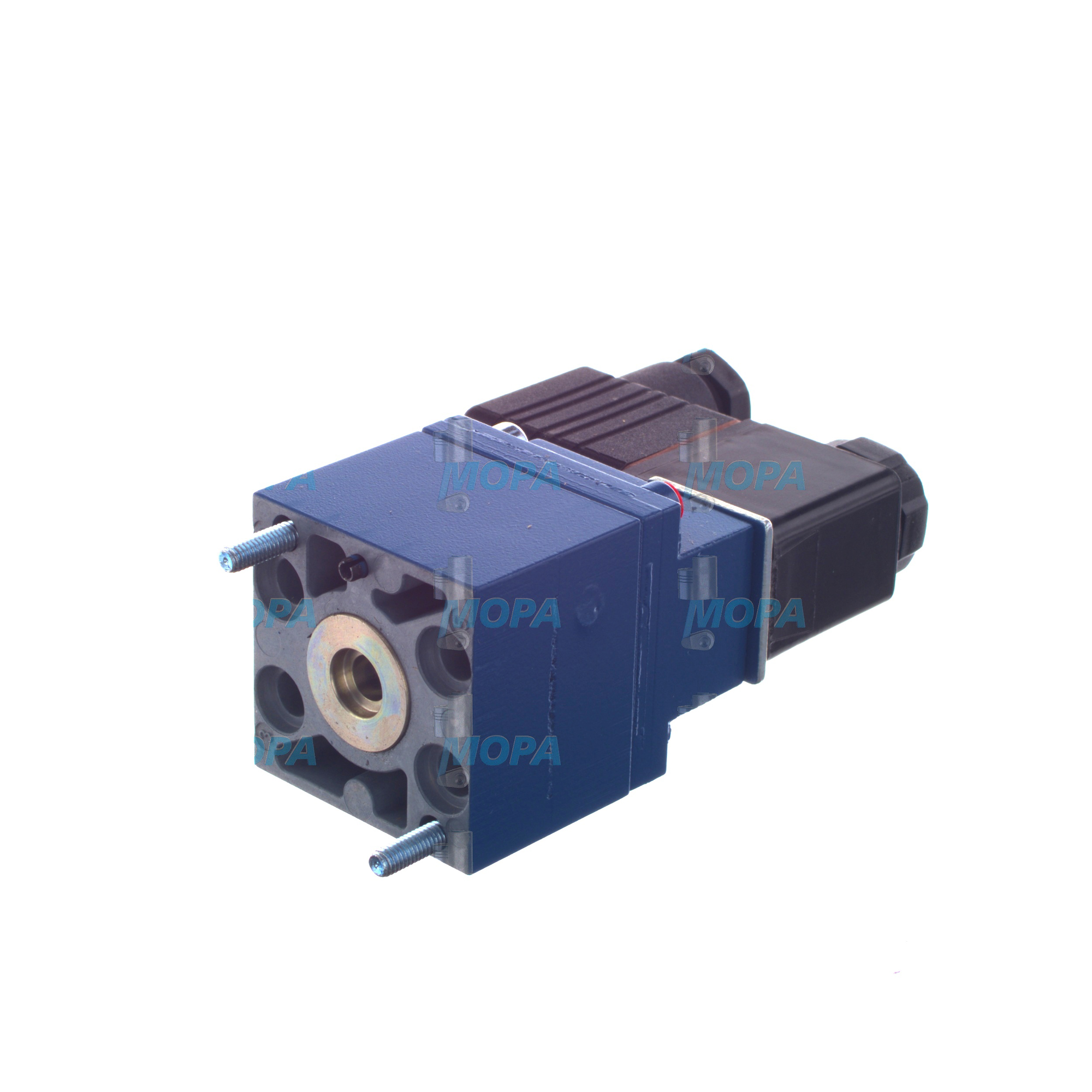

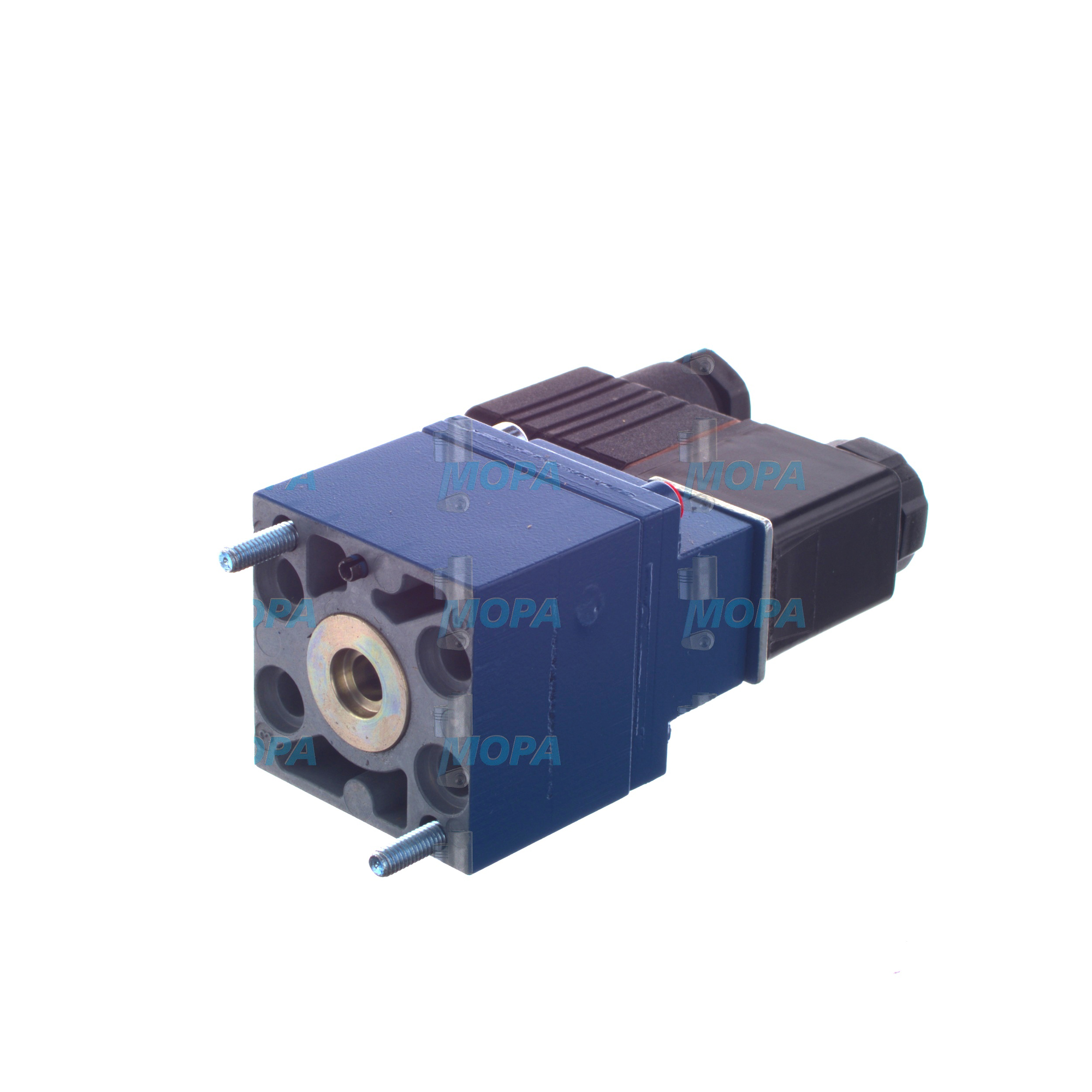

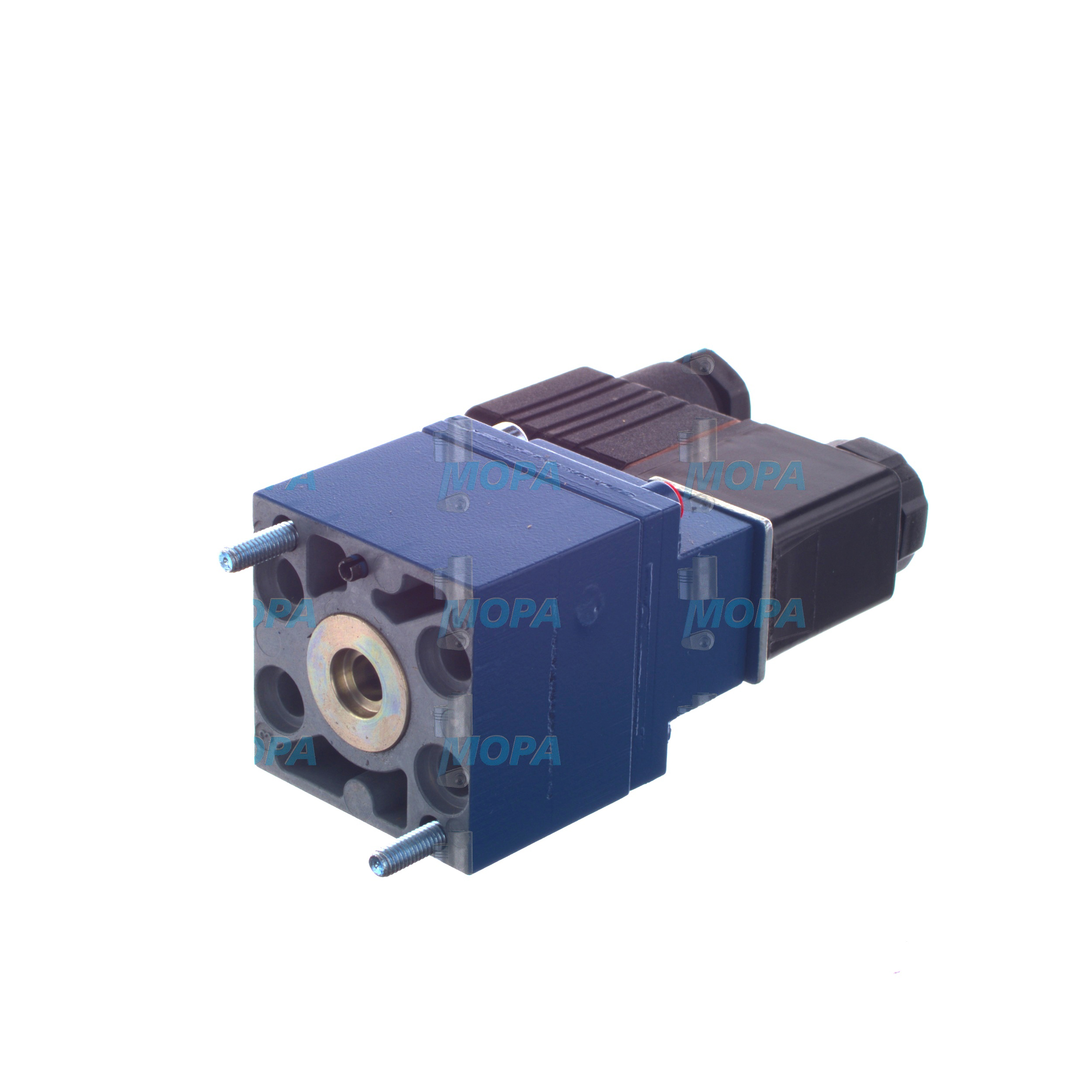

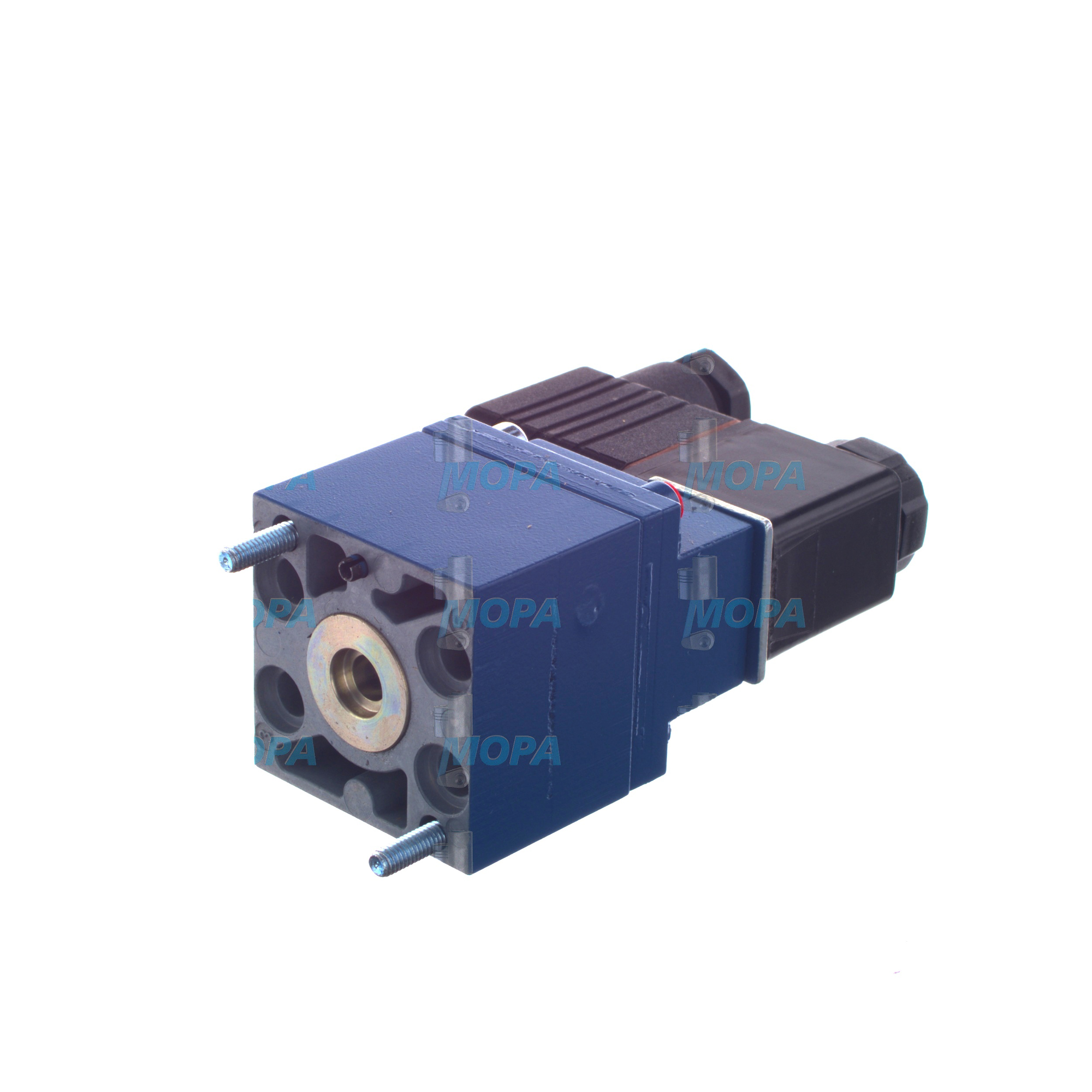

3/2-WAY SOLENOID VALVE – Valves for Marine and Diesel Engines

Valves are precision components that control the flow, pressure, and direction of media such as air, fuel, oil, and coolant. In engines, they perform critical tasks—from gas exchange in the cylinders to start-air distribution, fuel shut-off, lubrication, and thermal regulation. This article category covers the full spectrum of engine valves, including shut-off, control, safety, and pilot valves. Within this mix, the 3/2-WAY SOLENOID VALVE is a compact, electrically actuated device that enables safe, rapid switching in pneumatic or hydraulic circuits. For fleet managers and technical buyers, the right selection and timely replacement of valves is fundamental to performance, uptime, and compliance.

Technical function of Valves and the 3/2-WAY SOLENOID VALVE in diesel and marine engines

Valves maintain the required operating conditions across engine subsystems. Intake and exhaust valves govern gas exchange; pressure control valves stabilize fuel and lube oil supply; thermostatic valves regulate jacket water temperature; safety relief devices protect against overpressure in crankcase, cooling, and fuel circuits. Their job is to meter flow with minimal losses, isolate lines when needed, and react predictably to changing load and ambient conditions.

The 3/2-WAY SOLENOID VALVE is central to many control loops. With three ports (pressure, outlet, exhaust) and two positions, it directs supply to an actuator or vents it. Energizing the coil shifts a plunger or spool, switching the flow path; de-energizing returns it via spring force to a fail-safe state. In a marine engine start-air system, a 3/2-WAY SOLENOID VALVE feeds air to the distributor during start and vents the line on stop. In a diesel engine, it pilots fuel shut-off actuators, governor oil circuits, turbo bypass devices, or cylinder cut-out mechanisms—delivering fast response and clear fail-safe behavior for safety-critical functions.

For engineering and procurement, specifications matter. A 3/2-WAY SOLENOID VALVE OEM parts portfolio typically includes normally closed or normally open variants; coil voltages of 24 VDC, 110 VAC, and 230 VAC; IP65–IP67 protection; response times in the 10–50 ms range; brass or stainless-steel bodies; and seal sets (NBR/FKM/EPDM) matched to media such as air, light oil, or fuel vapor. Typical pneumatic working pressures are up to 10–16 bar, with manifold or threaded mounting for compact installations. Correct material pairing and seal chemistry prevent swelling, leakage, and premature wear in the engine room’s heat, vibration, and salt-laden atmosphere.

Beyond solenoid devices, engine systems employ a wide array of valves: pressure-reducing valves for stable injector feed, thermostatic mixing valves that keep jacket water in the optimal range, and relief valves that prevent damage to coolers and filters. Together with the 3/2-WAY SOLENOID VALVE in a diesel engine or marine engine control circuit, they ensure smooth starts, clean combustion, and safe shutdowns.

- · Precise flow and pressure control across fuel, air, lube, and coolant.

- · Fast, fail-safe actuation via a 3/2-WAY SOLENOID VALVE in start/stop circuits.

- · Materials and seals engineered for harsh marine engine environments.

- · Coil voltages and IP ratings suited to diesel engine rooms.

- · Dimensional consistency for straightforward replacement and commissioning.

Importance of Valves for engine reliability and service life

Reliable valves keep engines operating within design limits. Tight shut-off prevents backflow and fuel dilution; accurate pressure control protects pumps and injectors; stable temperature regulation reduces thermal stress on liners, heads, and turbochargers. If a valve leaks, sticks, or drifts out of calibration, the impact is immediate: hard starting, sluggish load acceptance, rising exhaust temperatures, increased specific fuel oil consumption, contaminated lubricants, or nuisance trips from safety interlocks. A sticking 3/2-WAY SOLENOID VALVE can delay start-air release, while a weak return spring may compromise emergency stop response—both unacceptable in marine operations.

Common failure modes include seat erosion from particulates, elastomer hardening from heat, corrosion from humidity and salt, and coil burnout from voltage spikes. Preventive strategies are robust filtration, regular functional tests, correct supply voltage, and timely replacement with parts that match design tolerances and media compatibility. This approach lengthens service intervals, supports predictable dry-dock planning, and reduces unplanned downtime.

Advantages of OEM spare parts suitable for Valves and 3/2-WAY SOLENOID VALVE assemblies

Choosing OEM spare parts for valves secures the dimensional accuracy, metallurgy, and actuation characteristics the engine system was built around. For a 3/2-WAY SOLENOID VALVE, that means consistent response times, defined fail-safe positions, and coil specifications aligned with the control system. For pressure and thermostatic valves, it ensures calibrated springs and wax elements that deliver the right setpoints over thousands of cycles.

The operational benefits are measurable: stable performance at varying loads, improved fuel efficiency through tighter control, and adherence to safety and emissions requirements. From a budget perspective, OEM-compliant fit and materials reduce installation time, avoid rework, and minimize collateral wear, lowering total cost of ownership across the vessel or plant.

Procurement teams also gain process advantages: traceable documentation, standardized part numbering across fleets, and predictable lead times that simplify inventory planning. In short, OEM spare parts suitable for valves protect reliability, budget, and the long-term service life of diesel and gas engines.

MOPA – your partner for OEM spare parts Valves, including 3/2-WAY SOLENOID VALVE

MOPA is an experienced, reliable partner for sourcing OEM spare parts for valves. The focus is speed, quality, and security in the trade of OEM parts for diesel and gas engines: rapid quotation, short lead times from stock, and dependable logistics to ports and plants worldwide. Whether you need a 3/2-WAY SOLENOID VALVE for a marine engine start-air circuit or pilot valves for a diesel engine fuel shut-off system, MOPA aligns specifications with your application and compliance requirements.

Technical buyers value MOPA’s support in part identification, media compatibility, and cross-referencing within OEM catalogs. From intake and exhaust valve components to relief, thermostatic, and solenoid valves—including complete 3/2-WAY SOLENOID VALVE OEM parts—MOPA streamlines procurement while maintaining the performance baseline your engines depend on.

Conclusion

Valves are indispensable to engine performance, efficiency, and safety, and the 3/2-WAY SOLENOID VALVE is a pivotal control element in start, stop, and protection circuits. Using OEM spare parts suitable for valves preserves reliability, controls lifecycle costs, and extends service life in marine and land-based diesel and gas applications.