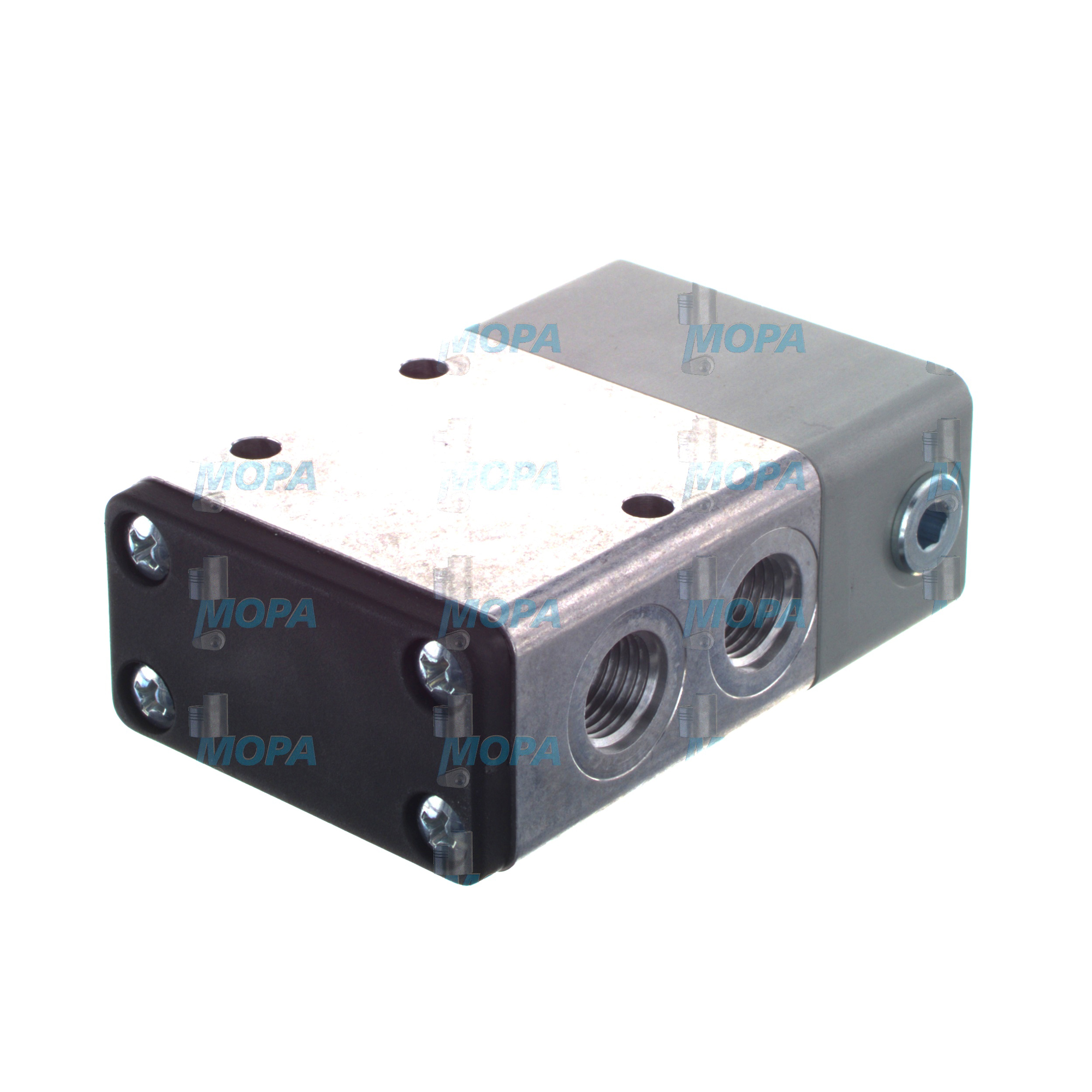

3/2-WAY VALVE – Valves for Diesel and Marine Engines

Valves are critical engine components that control, direct, and isolate the flow of liquids and gases. In marine engines, stationary power plants, and high-performance diesel engines, valves ensure the right medium reaches the right place at the right time—whether that’s fuel to injectors, air to start systems, coolant through bypass circuits, or lube oil across filtration loops. As a subcategory within engine controls, the 3/2-WAY VALVE plays a decisive role by switching between two circuit states across three ports, enabling safe, repeatable control of actuators and process streams. Without robust, precisely matched valves, no engine can achieve stable performance, low emissions, or dependable uptime.

Technical function of Valves and the role of the 3/2-WAY VALVE in diesel and marine engine systems

Engine valves span multiple designs—poppet, spool, ball, butterfly, needle, and relief—each selected for specific pressure, temperature, media, and response-time requirements. In engine applications, they control the routing of fuel (HFO/MGO/MDO), air (combustion air or start air), lube oil (supply, scavenge, filtration), and coolant (jacket water and charge-air cooling). The 3/2-WAY VALVE is especially common wherever an actuator or circuit needs to toggle between supply and exhaust, or between two sources. In a marine engine, for example, a pneumatic 3/2-WAY VALVE can switch start air to a cylinder actuator and then vent it; in a diesel engine fuel system, a 3/2-WAY VALVE can facilitate changeover or isolate a circuit for maintenance. When specified as OEM parts, a 3/2-WAY VALVE is matched to the engine maker’s pressure envelopes, flow coefficients (Cv/Kv), seal compounds, and actuation forces, ensuring consistent behavior under vibration and thermal cycling.

Functionally, valves convert control signals (electrical, pneumatic, or hydraulic) into precise flow changes. Solenoid-operated valves offer fast response for safety and shutdown functions; pilot-operated designs minimize power draw at high pressures; manually actuated valves provide simple and secure isolation. Material selection—such as stainless or duplex bodies, PTFE or FKM seats, and corrosion-resistant springs—prevents sticking, cavitation damage, and leakage. Tightness class, hysteresis, and actuation speed define how well an engine can hold pressure, maintain stable temperatures, and meet emissions targets over time. A correctly sized 3/2-WAY VALVE diesel engine assembly will minimize pressure drop, avoid chattering in pulsating flows, and keep actuators responsive in cold-start or heavy-sea conditions.

Key characteristics and advantages of Valves

· Precise flow control across fuel, air, lube oil, and coolant circuits.

· Fast, repeatable actuation for start, changeover, and shutdown logic.

· Materials and seals matched to media, temperature, and pressure.

· Low leakage rates that stabilize pressures and reduce losses.

· Cavitation- and corrosion-resistant designs for long service life.

· Compact footprints and standard interfaces for easy integration.

· Compliance with class and safety requirements in marine service.

· Traceable build and testing data for confidence in performance.

How valves drive performance, efficiency, and safety

Stable pressure and flow are prerequisites for clean combustion and efficient heat rejection. Valves influence injector supply quality, turbocharger bypass behavior, charge-air cooling balance, and lube-oil cleanliness. Safety-wise, fast-acting valves support emergency shutdown systems and fire-safety functions, while check and relief valves protect against backflow and overpressure. In air-start systems, a 3/2-WAY VALVE marine engine configuration determines how reliably cylinders receive and vent start air—directly affecting start success rates and crankcase load. Precision and durability in these components translate into fewer unplanned stops and lower fuel and maintenance costs.

Importance of Valves for reliability and service life

Because valves sit at the intersections of critical circuits, their condition directly impacts uptime. Wear, seat erosion, elastomer hardening, or particulate contamination can cause leakage or sticking. A leaking fuel changeover valve increases consumption and raises fire risk; a stuck cooling bypass valve can trigger thermal stress, liner scuffing, or turbocharger temperature alarms; a slow or non-seating 3/2-WAY VALVE in an air system can cause start failures and extended cranking. Electrical coil burnouts, stem galling, and spring fatigue are typical failure modes that increase downtime. Regular inspection intervals, proper filtration, and spec-correct replacements restore designed clearances, response times, and tightness—preserving efficiency and extending the engine’s service life.

Advantages of OEM spare parts suitable for Valves

Using OEM spare parts suitable for Valves ensures that materials, tolerances, and functional parameters match the engine maker’s drawings and test plans. Flow coefficients, seal profiles, and actuation forces remain within the calibrated window, keeping emissions and performance consistent. Traceability documentation and batch-level testing add confidence, especially in classed vessels and critical power applications. Over the lifecycle, accurate fit and predictable reliability reduce troubleshooting time, spares holdings, and the risk of cascading failures in adjacent systems. For a 3/2-WAY VALVE OEM parts selection, you get the correct porting, response characteristics, and coil specifications for your control voltage—minimizing integration risks and commissioning time.

Examples of system gains with OEM-specified 3/2-WAY VALVE assemblies

In diesel engine fuel trains, OEM-matched 3/2-WAY VALVE modules provide clean switching during low-sulfur fuel changeover, avoiding thermal shock and coking. In air-start manifolds, properly rated 3/2 units ensure reliable engagement and complete venting, preventing valve overlap that can waste start air. In coolant systems, 3/2 bypass valves maintain setpoint temperature and reduce thermal cycling of cylinder heads—helping preserve liner roundness and gasket integrity.

MOPA as your partner for OEM spare parts Valves

MOPA is an experienced, reliable partner for OEM spare parts Valves across diesel and gas engines. We combine technical expertise with fast response, ensuring you receive spec-correct components—such as a 3/2-WAY VALVE marine engine package or a 3/2-WAY VALVE diesel engine assembly—rapidly and securely. Our global network streamlines sourcing, our quality processes verify conformity and traceability, and our logistics options reduce downtime for shipowners and power operators. With MOPA, purchasers and technical teams gain a dependable channel for OEM parts, from consultation and identification through to delivery and documentation.

Conclusion

Valves are essential for precise control, safety, and efficiency in modern engines, and the 3/2-WAY VALVE is a core building block in many pneumatic, hydraulic, and fuel-routing functions. Choosing OEM spare parts suitable for Valves safeguards performance, reliability, and service life while protecting budgets through fewer interruptions and faster maintenance.