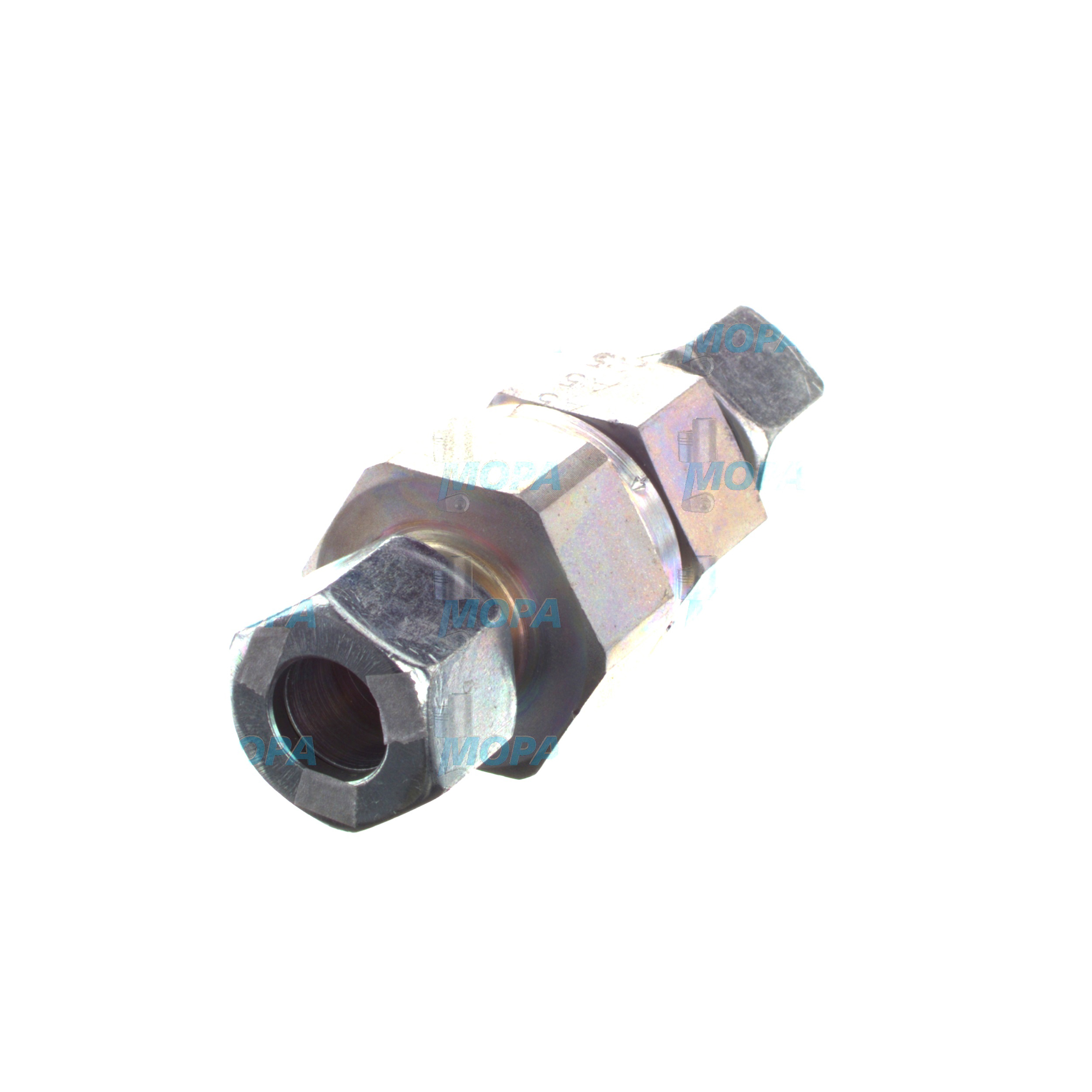

NON-RETURN VALVE Valves for Marine, Diesel and Gas Engines

Valves are precision components that direct, meter, and protect the flows that keep engines running. In large marine engines and high-output diesel and gas engines, the category includes intake and exhaust poppet valves, safety and relief valves, pressure-control valves, and the critical NON-RETURN VALVE (check valve) variants used throughout fuel, lubrication, cooling water, and starting air systems. Together, these devices safeguard combustion quality, preserve lubrication films, stabilize temperatures, and maintain system integrity under varying loads and dynamic conditions.

Within this category, the NON-RETURN VALVE plays a special role: it enforces one-way flow. Whether preventing backflow from a common rail, holding prime in a lube oil line, or isolating a starting air distributor, a correctly specified NON-RETURN VALVE helps the engine start reliably, run efficiently, and stop safely. For shipowners and technical buyers, understanding how valves interact with the wider system is essential to maximizing availability and minimizing lifecycle costs.

Technical function of valves and the role of a NON-RETURN VALVE in a marine engine

Valves in engines perform three core functions: control, protection, and isolation. Intake and exhaust valves time the gas exchange and strongly influence power density and thermal efficiency. Relief and control valves stabilize pressures to protect coolers, filters, and pumps. The NON-RETURN VALVE—often spring-loaded poppet, plate, or ball design—prevents reverse flow that would otherwise cause pressure loss, contamination, or mechanical shock.

In a marine engine fuel system, a NON-RETURN VALVE diesel engine application maintains residual pressure between pump strokes and prevents rail pressure collapse during rapid load changes. In lubrication circuits, check valves keep oil columns intact after shutdown, yielding faster oil pressure build-up on the next start and protecting bearings. Cooling water NON-RETURN VALVE marine engine duties include preventing back-siphoning and water hammer when pumps cycle. In starting air lines, cylinder head check valves isolate each unit, stopping blowback and protecting the manifold. Across these duties, correct cracking pressure, tight reseal at low differential pressure, and fast closing dynamics are decisive for stability and safety.

Precision-engineered NON-RETURN VALVE OEM parts also reduce pulsation-induced vibration and cavitation at pump outlets, which improves pump longevity and lowers noise. Material and seat geometry (e.g., hardened stainless seat with Stellite facing, elastomer selection matched to fuel or oil chemistry) determine leakage rates, erosion resistance, and the consistency of closing behavior over thousands of cycles.

- · One-way flow control in fuel, oil, water, and air systems.

- · Defined cracking pressure and rapid reseal for stable operation.

- · Wear-resistant seats and guides for long service intervals.

- · Low leakage rates to preserve efficiency and cleanliness.

- · Compatibility with diesel, gas, and marine environments.

- · Protects pumps, filters, coolers, and manifolds from reverse-flow damage.

Why valves are critical for engine reliability and service life

Even minor valve degradation propagates quickly through an engine. Leakage across a NON-RETURN VALVE allows backflow that can aerate fuel or oil, collapse pressure at injectors, delay lubrication on start, or trigger coolant migration when pumps stop. The consequences range from hard starting and unstable idle to bearing distress, injector nozzle erosion, higher specific fuel consumption, and thermal cycling of components.

For gas exchange valves, poor seating raises exhaust temperatures and turbocharger inlet thermal load, accelerating hot-side wear. For safety and relief valves, drift in set pressure can expose coolers and filters to damaging overpressure or insufficient protection. In starting air systems, a leaking check valve risks pressure spikes, contamination of the manifold, and dangerous blowback during maintenance.

Early indicators include slow pressure build, pressure decay after shutdown, higher differential pressure across filters, elevated EGTs on single cylinders, or unusual pump noise. Routine testing—crack-pressure verification, leak-back measurement, seat inspection, and spring rate checks—keeps small issues from becoming critical failures. Keeping valves within specification is one of the most cost-effective actions to extend engine life and preserve uptime.

Advantages of OEM spare parts suitable for valves and NON-RETURN VALVE OEM parts

Selecting OEM spare parts suitable for valves ensures dimensional accuracy, metallurgy, and surface treatments align with the engine maker’s performance envelope. For a NON-RETURN VALVE OEM parts package, this translates into tightly controlled crack pressure, consistent closing time, and stable leakage rates over the intended service interval. Springs retain force characteristics at temperature, seats resist indentation and erosion, and elastomers remain compatible with today’s low-sulfur fuels, biofuel blends, and synthetic lubricants.

Beyond performance, OEM spare parts support reliability and budget control: predictable durability reduces unplanned off-hire, while drop-in fit shortens maintenance windows. Correct materials and coatings (nitriding, Stellite, DLC on stems and guides) limit wear in abrasive or corrosive environments. Documentation and traceability streamline class compliance and simplify procurement across fleets.

How OEM choices support performance, efficiency, and safety

With OEM valves, injection timing and pressure stability improve combustion efficiency. Lubrication integrity shortens dry-running time on startup and lowers bearing temperatures. In cooling circuits, accurate check-valve behavior mitigates water hammer, protecting piping and cooler plates. For starting air, certified seating and closure dynamics reduce risk during isolation and maintenance.

MOPA: fast, secure supply of NON-RETURN VALVE OEM parts and valves

MOPA is an experienced partner for sourcing OEM spare parts Valves across diesel and gas engine platforms. We combine speed, quality, and transactional security to support planned overhauls and urgent repairs alike. From fuel system NON-RETURN VALVE marine engine items to intake/exhaust valve components, our team matches specifications, cross-references part numbers, and ensures compatibility with your build list.

Procurement through MOPA means responsive quotations, proven logistics for port-to-vessel deliveries, and full traceability. We help purchasers and superintendents consolidate orders, reduce lead times, and minimize risk with reliable OEM supply for engines operating worldwide.

Conclusion

Valves—especially the NON-RETURN VALVE—are pivotal to stable pressures, clean flows, and safe operation in marine, diesel, and gas engines. Their condition directly affects performance, fuel economy, and component life. Choosing OEM spare parts suitable for valves secures consistent function, lowers total cost of ownership, and supports dependable engine availability across your fleet.