OIL PRESSURE VALVE in Valves for Marine and Diesel Engines

Valves are precision control components that manage flows of gases, liquids, and pressure within an engine. In large marine engine and high-output diesel engine applications, valves coordinate air intake and exhaust, meter fuel delivery, regulate lubrication, and protect critical circuits from overload. From intake and exhaust poppet valves to safety relief and check valves, the category “Valves” encompasses the parts that make controlled combustion, efficient lubrication, and safe operation possible. Within this family, the OIL PRESSURE VALVE plays a decisive role by stabilizing the lubrication system—directly influencing performance, efficiency, and component life.

Technical function of Valves and the OIL PRESSURE VALVE in a diesel engine

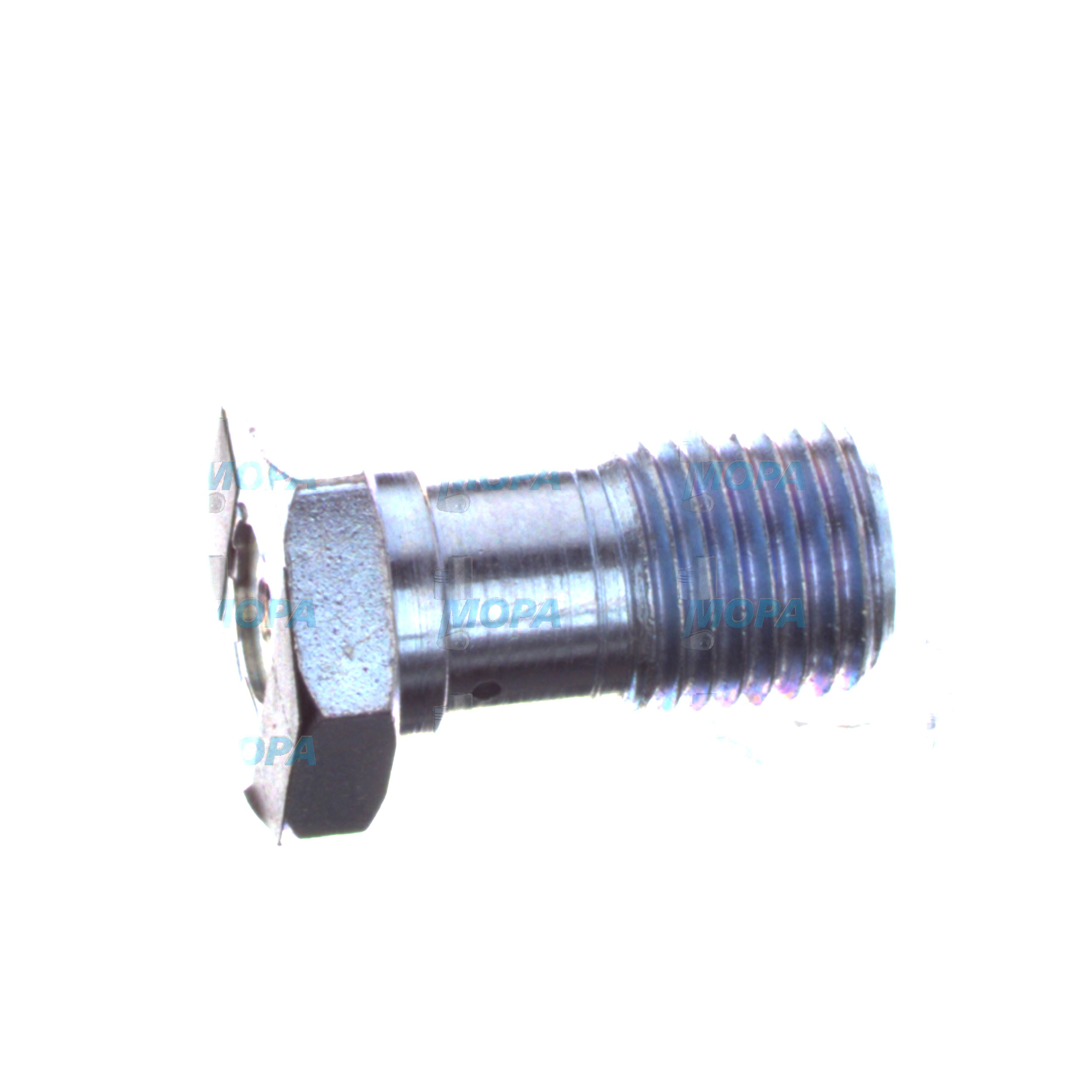

Across an engine, valves execute several distinct jobs. Intake and exhaust valves time the breathing cycle; fuel valves and injectors deliver metered fuel; control, check, and relief valves distribute and protect auxiliary systems. The OIL PRESSURE VALVE, often implemented as a spring-loaded relief or a proportional control valve, governs oil pressure in the lubrication circuit. In a diesel engine, oil pressure must remain within a narrow window: high enough to maintain hydrodynamic film on bearings and cam lobes, but not so high that seals, coolers, or filters are overstressed.

When cold oil or sudden rpm changes drive pressure above a calibrated threshold, the OIL PRESSURE VALVE opens a bypass route—diverting flow back to the sump or to a low-pressure side. As the oil warms and viscosity decreases, the valve modulates back toward nominal, maintaining a steady setpoint. In a marine engine with long oil galleries and large bearing surfaces, this regulation stabilizes flow to main and rod bearings, turbocharger bearings, and rocker gear, helping to prevent metal-to-metal contact and thermal hotspots. In many designs, the valve also prioritizes pressure to critical circuits during start-up, reducing scuffing and wear.

Engineering details matter. Seat geometry and surface finish minimize leakage. Spring rate and preload define opening pressure and hysteresis. Clearances around the spool or poppet control response time and damping, preventing oscillation (chatter) under pulsating pump output. The result is smooth, predictable lubrication behavior—especially important when the engine transitions rapidly between idle and load, or operates continuously at high power for extended periods.

- · Precise pressure control protects bearings and turbochargers.

- · Stable lubrication improves efficiency and reduces friction losses.

- · Correct valve dynamics prevent pressure spikes and cavitation.

- · Heat- and wear-resistant materials extend service intervals.

- · Tight tolerances ensure repeatable opening and closing behavior.

- · Calibrated settings match engine-family requirements.

OIL PRESSURE VALVE function in a marine engine lubrication system

In marine propulsion and genset duty, long steady-state runs amplify small imbalances. An OIL PRESSURE VALVE that is precisely matched to pump capacity, oil grade, and bearing clearances keeps the film thickness consistent, supports cleaner filter differential pressures, and helps sustain emissions compliance by reducing blow-by-inducing wear. For fleets, the result is more predictable maintenance cycles and lower total cost of ownership.

Why Valves are critical to engine reliability and service life

Valves—especially the OIL PRESSURE VALVE—are guardians of engine reliability. If intake or exhaust valves lose seal integrity, cylinder efficiency drops, temperatures rise, and turbocharger load fluctuates. If a lubrication control valve drifts out of tolerance, the consequences can be severe: low oil pressure accelerates bearing wear and risk of seizure; excessive pressure can deform filter elements, stress coolers, and create leaks at seals. Erratic valve modulation can also cause foaming, aeration, or localized starvation in the upper galleries. Over time, these issues manifest as increased noise, higher oil consumption, metallic debris in filters, and ultimately unplanned downtime. Keeping valves in calibrated condition is therefore central to long service life and predictable operation.

Advantages of OEM spare parts suitable for Valves and OIL PRESSURE VALVE OEM parts

Specifying OEM spare parts suitable for valves pays off from day one. These parts are produced to the same engineering drawings and process controls as the components the engine platform was designed around. That means correct metallurgy, heat treatment, coating, and dimensional fidelity—elements that determine how a valve seals, how a spring relaxes over time, and how a spool resists varnish or particulate-induced sticking. For the OIL PRESSURE VALVE in particular, the opening pressure, flow curve, leakage rate, and response time are calibrated to the pump map and bearing clearances of your marine or diesel engine.

Choosing OEM valves and OIL PRESSURE VALVE OEM parts supports:

- · Performance: Maintains designed oil pressure and breathing dynamics.

- · Reliability: Proven materials and test protocols reduce failure risk.

- · Budget control: Longer service intervals and fewer breakdowns cut lifecycle cost.

- · Service life: Proper lubrication and sealing slow wear across moving parts.

- · Compliance: Consistent combustion and lubrication help sustain emissions targets.

- · Drop-in fit: Tolerances match housings, guides, and seats without rework.

MOPA — your partner for OEM Valves and OIL PRESSURE VALVE supply

MOPA is an experienced, reliable partner for sourcing OEM spare parts suitable for valves, including the OIL PRESSURE VALVE for diesel and gas engines. We focus on speed, quality, and security throughout the procurement process: fast quotations, quick dispatch from vetted supply channels, and full traceability for peace of mind. Whether you manage a single vessel or an international fleet, MOPA helps minimize downtime with responsive logistics and knowledgeable technical support.

Our team understands engine families across marine, power generation, and industrial segments. We match valve specifications to engine serials and build lists, coordinate documentation, and package to protect precision surfaces during transport. The result is efficient transactions, dependable parts availability, and stable engine operation after installation.

Conclusion: Valves and OIL PRESSURE VALVE benefits

Valves are fundamental to every engine’s breathing, lubrication, and safety functions, and the OIL PRESSURE VALVE is central to protecting the lubrication circuit in both diesel engine and marine engine platforms. By choosing OEM spare parts suitable for valves, you safeguard performance, extend service life, and control operating costs. Partner with MOPA to secure the right OIL PRESSURE VALVE OEM parts quickly and confidently.