PRESSURE CONTROL VALVE

PRESSURE CONTROL VALVE – Valves for Marine and Diesel Engines

Valves are precision components that manage the flow and pressure of gases and liquids inside an engine. From fuel injection and lubrication to cooling, air start, and exhaust, every major subsystem relies on correctly specified valves to hold pressure, meter flow, and respond predictably under load. In heavy-duty applications—such as a marine engine on continuous duty or a high-output diesel engine in standby power—valves protect core components, stabilize operating parameters, and keep emissions and efficiency within specification. Within this category, the PRESSURE CONTROL VALVE plays a pivotal role by regulating pressure in fuel rails, lubrication galleries, and auxiliary circuits to match dynamic engine demand.

Whether installed in large-bore two-stroke propulsion units or medium-speed generator sets, valves must combine robust materials, tight tolerances, and precise calibration. The result is reliable sealing, rapid actuation, and stable pressure control across a broad operating envelope, even as temperatures, viscosities, and loads fluctuate.

Technical function of Valves and the PRESSURE CONTROL VALVE in engine systems

In an engine, “valve” encompasses several designs—poppet, spool, needle, check, relief, and thermostatic—each serving a distinct function. A PRESSURE CONTROL VALVE in a diesel engine typically uses a spring-biased poppet or a proportional solenoid-operated spool to modulate return flow and maintain a defined setpoint in the rail or circuit. The engine control unit (ECU) trims the valve duty cycle to match instantaneous fuel or oil demand, holding pressure steady during transients such as load acceptance, maneuvering, or start/stop events.

On marine engine common-rail systems, a PRESSURE CONTROL VALVE may stabilize rail pressure within narrow tolerances despite injector opening events that momentarily depress the rail. In lubrication systems, relief and pressure-regulating valves prevent overpressure during cold starts and maintain target pressure (often in the 3–7 bar range) once oil reaches operating temperature. Cooling circuits use thermostatic and bypass valves to control temperature gradients, reducing thermal stress and improving efficiency. Air systems depend on non-return and safety valves to isolate start air receivers and protect against backflow or overpressure, commonly in the 20–30 bar range.

How a PRESSURE CONTROL VALVE stabilizes fuel-rail pressure in a diesel engine

Fuel delivery benefits directly from precise pressure regulation. When the pump output exceeds injector demand, the PRESSURE CONTROL VALVE meters excess fuel back to the tank or low-pressure side, keeping the rail within the ECU’s target window. This stabilizes injection timing, droplet size, and combustion quality, directly impacting power density, fuel efficiency, and emissions. The same principle applies to gas engines with regulated gas admission: steady differential pressure across the metering device ensures repeatable combustion and avoids knock.

Valves protecting lubrication and cooling performance on a marine engine

In the lube circuit, pressure-regulating and safety valves protect bearings, cam followers, and turbocharger journals from both starvation and pressure spikes. Bypass valves route oil around clogged filters to prevent catastrophic pressure loss, while check valves preserve prime during shutdown. In the cooling loop, temperature-stable valve operation accelerates warm-up, maintains optimal jacket-water temperature, and prevents localized boiling under high load—key to component longevity.

- · Accurate pressure control across transient and steady-state operation.

- · Robust sealing surfaces for high-temperature and high-pressure media.

- · Fast response to ECU commands in electronically actuated designs.

- · Materials and coatings that resist corrosion, cavitation, and wear.

- · Stable performance with varying viscosity and temperature.

- · Integrated safety features to prevent overpressure events.

Importance for engine operation and service life

Valves are mission-critical for reliability. If a PRESSURE CONTROL VALVE drifts out of calibration or its sealing surfaces erode, several issues can arise: unstable rail pressure causes rough running, elevated emissions, and injector wear; low lube oil pressure accelerates bearing damage and turbocharger failures; relief valves stuck closed can blow seals or rupture filters; check valves leaking back lead to hard starts; and cooling valve malfunctions induce thermal shock, head gasket failures, or liner scuffing. For marine operators, these risks translate into unplanned downtime, higher fuel consumption, and elevated maintenance costs—often far exceeding the cost of timely valve replacement.

Regular condition monitoring—tracking pressure trends, response times, and leak-off rates—combined with preventive replacement intervals helps keep engines within design parameters. Choosing components with the correct calibration, flow coefficients, and material specs is fundamental to avoiding recurrence.

Advantages of OEM spare parts suitable for Valves

Using OEM spare parts suitable for Valves—especially for a PRESSURE CONTROL VALVE in a marine engine or diesel engine—ensures fit-for-purpose performance. These components are built to the same dimensional tolerances, spring rates, and magnetics (for solenoids) specified by the engine platform. Material selections for seats, guides, and seals (e.g., hardened steels, Stellite overlays, FKM/PTFE compounds) match the thermal and chemical environment of fuel, oil, or gas. Flow calibration and leak-down characteristics align with ECU maps and service documentation, so engines return to baseline performance after overhaul.

The result is predictable behavior, streamlined installation, and consistent life-cycle cost control. Traceable OEM parts help maintain compliance, simplify troubleshooting, and reduce the risk of cascading failures caused by pressure instability. For fleets, standardizing on OEM spare parts suitable for Valves supports consistent maintenance planning and inventory efficiency across vessel classes and power plants.

MOPA: fast, secure supply of OEM spare parts for Valves

MOPA is a reliable partner for sourcing OEM parts for diesel and gas engines, with deep expertise in Valves and the PRESSURE CONTROL VALVE across multiple engine families. Customers benefit from short lead times, rigorous quality control, and secure logistics from quotation to delivery. MOPA supports purchasers and technical teams with component cross-references, documentation, and application advice, ensuring that the selected OEM spare parts suitable for Valves align with the required pressure ranges, materials, and control strategies. For marine engine operators and power-generation sites, this combination of speed, quality, and security minimizes downtime and safeguards engine performance.

Conclusion

Valves are essential to stable, efficient engine operation, and the PRESSURE CONTROL VALVE is central to precise pressure management in fuel, lube, and auxiliary systems. Selecting OEM spare parts suitable for Valves restores design-level performance, extends service life, and protects budgets by reducing unplanned stops. With MOPA as a partner, operators secure the right OEM parts quickly and confidently for diesel and gas engines in demanding duty cycles.

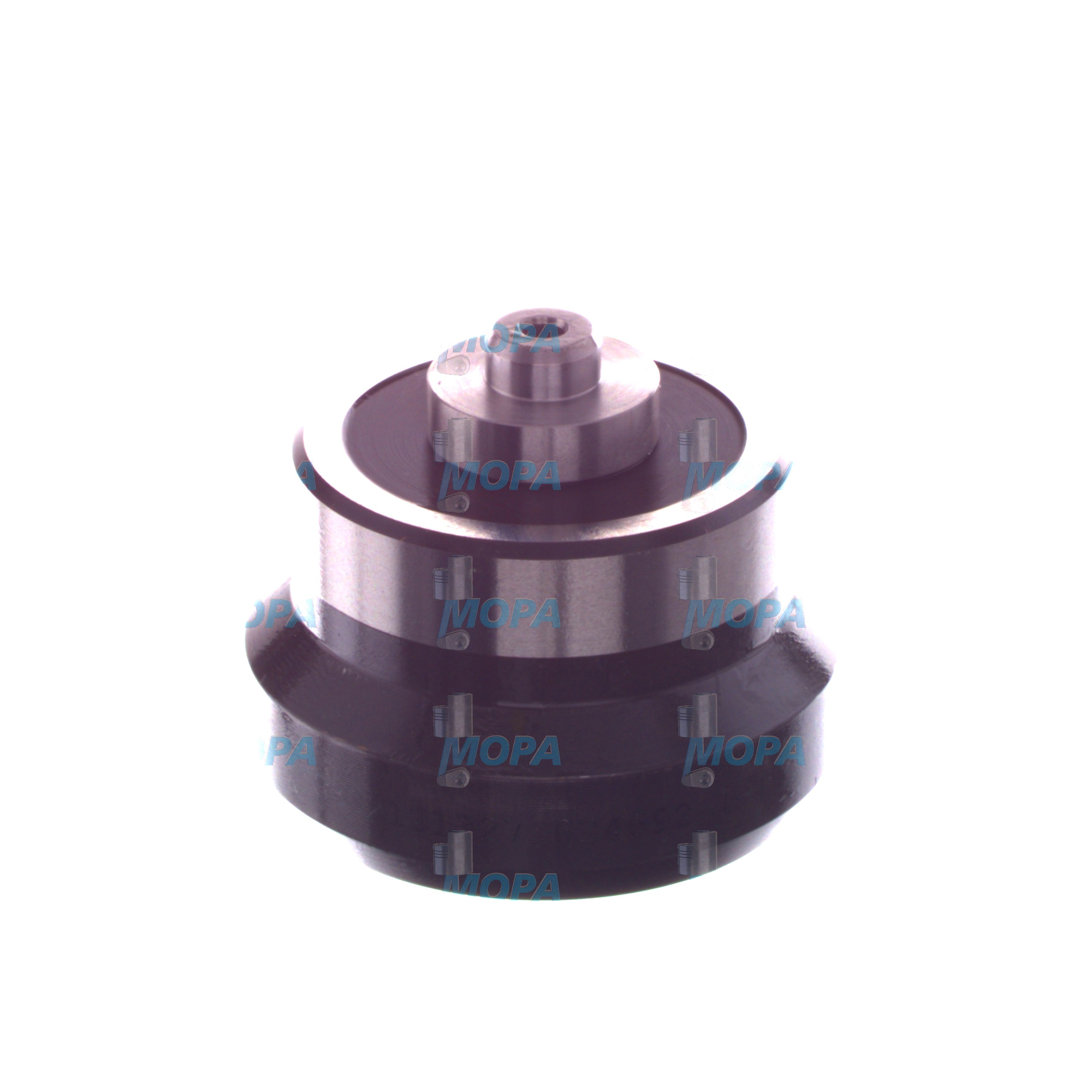

Optimal Engine Performance with the Pressure Control Valve 02122702 Discover our pressure control valve with the comparison number 02122702, an essential OEM spare part for the efficient operation of your engines. This product is indispensable for professional applications in marine and stationary technology. Our pressure control valve is exactly what you need to maximize the performance of your machines.

Efficient Pressure Control Valve with Comparison Number 833743Discover the pressure control valve, comparison number 833743, perfectly suited for demanding applications. This product belongs to the category of valves and offers optimal performance and safety in your area of use. Weighing just 0.014 kg, it is lightweight and practical, allowing for easy installation and maintenance.Quality and Performance with Suitable OEM Replacement PartsThe pressure control valve is an OEM replacement part that meets high standards of manufacturability. With the comparison number 833743, this product ensures a precise fit and functionality. Rely on OEM replacement parts suitable for Volvo/Volvo Penta engines to optimize the efficiency of your systems. This investment in robust parts pays off.

Pressure control valve suitable for MWM & DeutzDiscover the OEM replacement part pressure control valve with comparison number 01318385. This precise component is suitable for MWM & Deutz engines. The use of durable materials makes it an ideal choice for long-lasting applications.

Pressure Control Valve – Comparison Number 2418552185Discover our high-quality pressure control valve (comparison number: 2418552185), specifically designed to ensure optimal performance in engines. This pressure control valve is suitable for MWM & Deutz engines and is a reliable component for your applications in marine and stationary fields. Trust in the precise craftsmanship of a powerful product.

First-Class Pressure Control Valve: Reliable PerformanceDiscover our Pressure Control Valve with the comparison number 02323549, specifically designed to be compatible with MWM & Deutz engines. This OEM spare part offers excellent performance in your diesel and gas engines.Optimal Quality through OEM Spare PartsOur products meet the highest standards of manufacturers and provide a reliable solution for your engines. With the comparison number 02323549, you receive a Pressure Control Valve that is compatible with MWM & Deutz engines – ensuring remarkable functionality and efficiency.

Pressure Control Valve – Development for Professional EnginesThe Pressure Control Valve with the comparison number 01265573 is a unique OEM replacement part that plays an essential role in the interplay of numerous components. Weighing only 0.08 kg, it offers easy handling and installation.

PRESSURE CONTROL VALVE with the comparison number 02121328 suitable for MWM & Deutz engines

Top Product: Pressure control valve with comparison number 0481007002Our Pressure control valve with the comparison number 0481007002 is an exceptional OEM spare part that is ideal for optimizing the performance of MWM & Deutz engines. This technical product provides you with the reliability and precision you need in demanding applications.Suitable for MWM & Deutz: Increase EfficiencyThis precise and reliable Pressure control valve is perfectly suited to keep your engines running efficiently. It is an OEM spare part designed specifically for MWM & Deutz and is characterized by easy integration into existing systems. Weighing 0.3 kg, you benefit from a clever design that significantly optimizes the installation and handling experience.

Pressure control valve with comparison number 12850224 for your enginesDiscover our OEM replacement part, the pressure control valve with the comparison number 12850224. This product is precisely designed for Deutz engines and ensures precision in your drive system. Weighing only 0.016 kg, it combines performance and robustness to meet high demands.Optimal functionality suitable for Deutz enginesThe functional design of the pressure control valve enables reliable pressure regulation, contributing to the overall performance of your engines. This OEM replacement part is specifically designed for Deutz engines and is ideal for applications in marine and stationary fields.

PRESSURE CONTROL VALVE with the comparison number 85400009856 suitable for MAN D engines

Efficient Pressure Control Valve for EnginesDiscover our Pressure control valve with the comparison number 1418522055, which is essential for the operation of your Deutz engines. This OEM spare part combines reliability and high-level performance, making it the ideal choice for marine and stationary applications. With a weight of just 0.018 kg, it offers easy handling without compromising on quality.Optimal Use – Suitable for DeutzThe Pressure control valve, suitable for Deutz, is competently designed to enhance the efficiency and durability of your engines. Our OEM spare parts stand for consistent quality and longevity, which pays off in daily use. Rely on this product to increase the functionality and lifespan of your Deutz engine.

Pressure Control Valve – Efficient Solution for Your Engines Discover our versatile pressure control valve, which is marked with the reference number 01319328 and specifically tailored to your needs. This OEM spare part delivers the performance you expect from a product designed for easy installation while optimizing the maintenance of your engines. Weighing only 0.04 kg, this item is intuitively usable.

Pressure control valve with comparison number 02121875 for optimal performanceExperience the efficiency of the pressure control valve with comparison number 02121875, designed specifically to maximize the performance of engines. This product is an essential OEM spare part, suitable for MWM & Deutz engines and part of our selected category of valves. Benefit from its perfect fit and functionality, which significantly contribute to the performance of the machines.

Precise Functionality of the Pressure Control ValveDiscover our Pressure control valve, specifically designed to deliver optimal performance in a wide range of engine applications. This product is distinguished by the reference number 04066374 and belongs to the category of valves. Precision and reliability make this OEM replacement part the ideal choice for all your engine needs.Suitable for MWM & Deutz EnginesOur products are suitable for MWM & Deutz engines. Through targeted development, you save time and costs, as the compatibility of your Pressure control valve is ensured. Rely on our OEM replacement parts that offer optimal performance and durability – exactly what you need for your machines.

Efficient Pressure Control Valve for Excellent PerformanceThe pressure control valve with the comparison number 9411617010 is a promising OEM spare part that has been specifically designed to support engines suitable for MWM & Deutz. Through its functionality, this spare part ensures optimal pressure regulation, which is essential for the efficiency and smooth operation of your engines.

Flexible Pressure Control Valve for Your ApplicationDiscover our pressure control valve, an important OEM spare part, marked with the comparison number 1418512220. It ensures the reliable function of your engines and is suitable for Deutz engines. This product belongs to the product category "Valves," which ensures efficient performance in a variety of machines.Optimal Functionality for Deutz EnginesOur pressure control valve plays a central role in heating and fuel supply, thereby contributing to the efficiency of your engine operation. With its precise design, it ensures a reliable flow. Additionally, this OEM spare part is a cost-effective choice for any machine operator. Suitable for Deutz engines, you can trust that it enhances the performance and lifespan of your equipment.

Efficient Pressure Control Valve - Comparison Number 5411800415Discover our pressure control valve with the comparison number 5411800415, which integrates perfectly into your MTU engines. This component belongs to the category of valves and ensures that your engines can operate efficiently and reliably. Weighing 0.274 kg, it is an essential part of your applications.

PRESSURE CONTROL VALVE with the comparison number 604528600002 suitable for MWM & Deutz engines

Pressure Control Valve: Small Component, Big ImpactDiscover our Pressure Control Valve with the comparison number 12157194, a comprehensive product that offers precise compatibility with suitable for MWM & Deutz engines. This OEM replacement part belongs to the category of Valves and impresses with innovative technology. Weighing 0.35 kg, the Pressure Control Valve is designed to optimally support the performance of your machines.Precision for EnginesOur Pressure Control Valve is tailor-made and suitable for MWM & Deutz, making it a perfect choice for high-resolution applications. As OEM replacement parts, we meet high standards to ensure your equipment operates efficiently. The Pressure Control Valve ensures smooth operation of your engines. Rely on strict quality controls and years of experience in the industry.

Reliable Pressure Control Valve with Comparison Number 1418522212Experience the reliable pressure control valve with the comparison number 1418522212. This OEM replacement part stands out for its outstanding quality and functionality. Suitable for Deutz engines, it meets all requirements in marine and stationary applications as well as in locomotives. Ensure the performance your engines need with a product you can trust.Robust Features for Optimal OperationWeighing 17 kg, this pressure control valve is a heavyweight among OEM replacement parts. Compatible with various Deutz engines, it offers support for smooth operation and optimal efficiency of your machines. Uncompromising workmanship and precise construction make this product the first choice for professionals.

Pressure Control Valve – Comparison Number 01265825Discover our pressure control valve with the comparison number 01265825, which is essential for your engines. This product has been meticulously developed to function as a reliable component suitable for MWM & Deutz engines. Weighing in at just 0.09 kg, it offers excellent handling and easy installation.

PRESSURE CONTROL VALVE with the comparison number 81111330015 suitable for MAN D engines

Pressure control valve suitable for MWM & Deutz engines Discover the pressure control valve with the comparison number 12019928, a top-quality OEM replacement part designed for the demanding requirements of stationary and marine engine assembly. This product belongs to the valves category and demonstrates our commitment to excellent solutions in engine technology.Efficient product for your engines The pressure control valve is specifically designed to be suitable for MWM & Deutz engines, offering optimal performance characteristics. Weighing only 0.001 kg, this OEM replacement part provides excellent toughness and reliability that you need for the smooth operation of your engines.

Efficient Pressure Control Valve for Reliable EnginesOur pressure control valve with the comparison number 358/117B/427 is the ideal choice for anyone looking to rely on dependable and durable OEM spare parts. This product belongs to the group of valves and has been designed to support streamlined and precise functions in your engines. The pressure control valve ensures optimal pressure regulation and thus significantly contributes to the efficiency of your engines.Features of a Pressure Control Valve Suitable for MWM & DeutzThe pressure control valve is compatible with MWM & Deutz engines and specifically tuned to the series 358. Weighing only 0.216 kg and with compact dimensions of 4.1 cm in length and 3.4 cm in height, it is easy to install. The robust construction ensures high performance in various applications, both in marine and stationary environments.