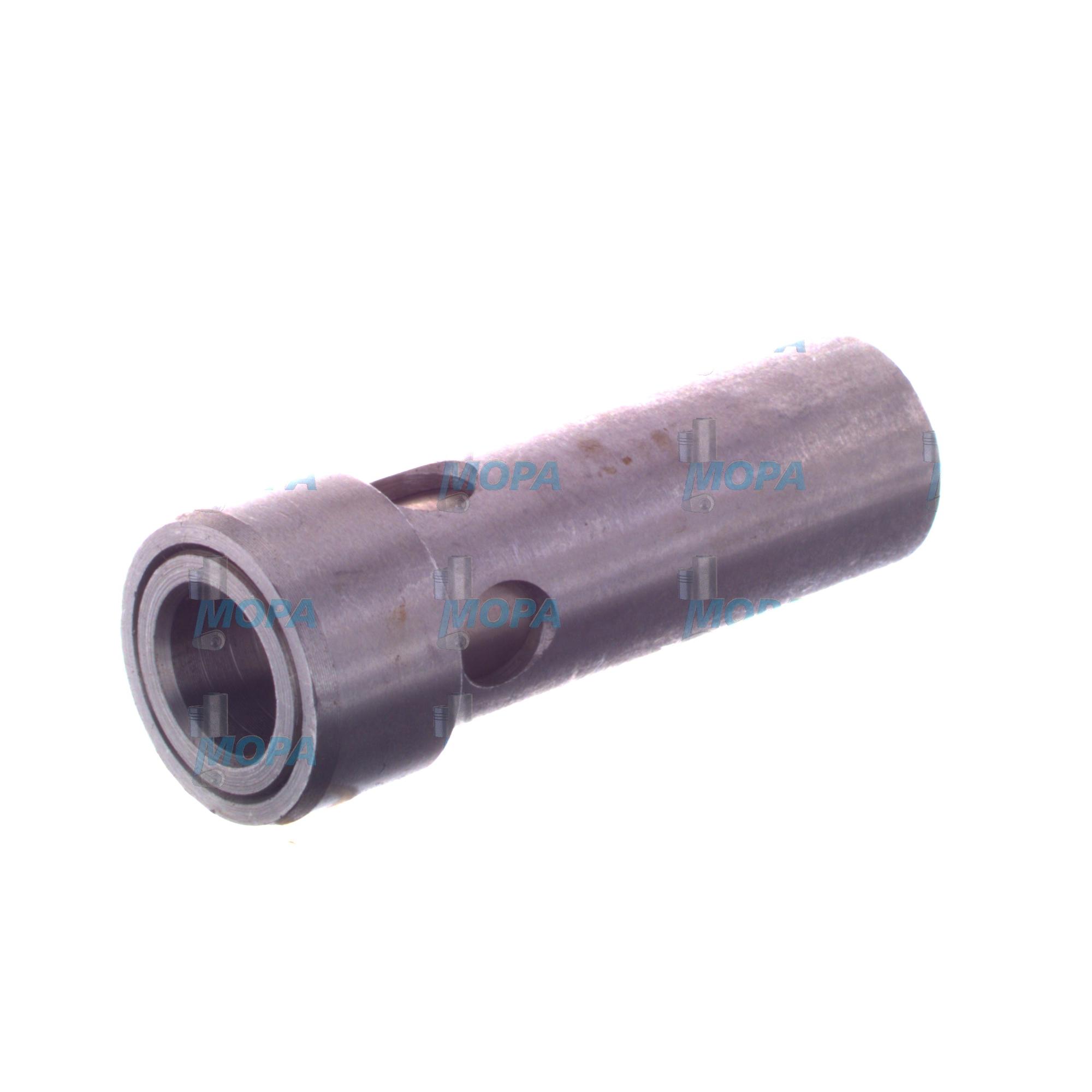

PRESSURE MAINTAINING VALVE – Valves for dependable engine fluid control

Valves are precision control components that regulate flow, pressure, and direction of media such as fuel, lubricating oil, cooling water, and starting air. In marine and stationary power applications, valves are fundamental to engine integrity, efficiency, and safety. Within this category, the PRESSURE MAINTAINING VALVE is a key device that stabilizes minimum system pressure, keeps circuits primed, and prevents harmful pressure fluctuations. For buyers and technical decision-makers, selecting robust valves is a direct lever to extend engine life and reduce lifecycle costs.

In large diesel and gas engines—especially in marine engine installations with complex auxiliary systems—valves coordinate the interaction between pumps, filters, heat exchangers, injectors, and bearings. The PRESSURE MAINTAINING VALVE differs from a relief valve: instead of venting pressure above a maximum limit, it ensures a defined minimum backpressure. This provides stable operating conditions for lubrication and fuel systems, protects components from starvation, and supports consistent performance from cold start to full load.

Technical function of valves and the PRESSURE MAINTAINING VALVE in marine and diesel engines

Valves in engines control timing, direction, and pressure to achieve reliable combustion and safe operation. A PRESSURE MAINTAINING VALVE is typically a direct-acting, spring-loaded poppet or spool design with a calibrated setpoint. When line pressure drops toward the setpoint, the valve modulates flow to maintain a minimum backpressure in the circuit. In a marine engine’s lube oil return or bypass line, this prevents drain-back after shutdown and keeps filters and galleries filled, ensuring immediate oil delivery at the next start. In a diesel engine fuel line, it stabilizes rail or gallery pressure for consistent injection, which supports clean combustion, steady idle, and rapid load acceptance.

Design details matter. Seat geometry and surface finish reduce leakage; matched spring rates limit hysteresis so the valve closes smoothly without oscillation. Adequate flow capacity (Cv) maintains pressure while minimizing pump work, supporting overall efficiency. Materials are chosen for media compatibility and longevity: stainless or duplex steels for corrosion resistance, nitrided steels for wear surfaces, and elastomers such as FKM or HNBR for temperature and fuel resilience. In many systems, the PRESSURE MAINTAINING VALVE works alongside non-return, shut-off, and thermostatic valves to orchestrate pressure control and thermal management. Typical setpoints may range from 1.5–3 bar for lubrication circuits and 4–6 bar for fuel recirculation (values depend on engine maker and duty profile). When supplied as OEM parts, the valve’s calibration and build standard align with engine-specific requirements, reducing the risk of misadjusted pressures.

Key characteristics of valves and the PRESSURE MAINTAINING VALVE

- · Stabilizes minimum system pressure at a defined setpoint.

- · Prevents drain-back and cavitation during shutdown and start-up.

- · Protects filters, seals, bearings, and pumps from pressure shock.

- · Supports consistent injection and atomization in a diesel engine.

- · Helps maintain turbocharger lubrication at all operating states.

- · Low pressure loss and high Cv reduce parasitic pump power.

- · Corrosion- and temperature-resistant construction for marine service.

- · Calibrated springs and refined seat finishes for repeatable behavior.

Why valves and a PRESSURE MAINTAINING VALVE are critical for engine reliability

The health of an engine depends on stable pressure in lubrication and fuel circuits. If a PRESSURE MAINTAINING VALVE drifts out of calibration or wears, several issues can arise:

Low oil pressure on start can delay the formation of the hydrodynamic film in main and rod bearings, accelerating wear on crankshaft journals and cam lobes. Air ingress or drain-back may cause pump cavitation, noisy starts, and rapid bearing distress. In the fuel system, unstable backpressure results in variable injection quantities, poor atomization, increased smoke, and higher specific fuel consumption. Excessive pressure can rupture hoses, damage filter elements, or stress seals, while insufficient pressure can starve turbocharger bearings, risking premature failure.

For marine engine operators, these faults translate into higher maintenance hours, unplanned downtime, and potential safety incidents such as loss of propulsion or blackout events. Keeping valves—including the PRESSURE MAINTAINING VALVE—within specification is therefore essential to safeguard service life, maintain compliance targets, and protect vessel schedules.

Advantages of OEM spare parts suitable for valves and the PRESSURE MAINTAINING VALVE

Using OEM spare parts suitable for valves delivers measurable benefits in performance and risk control. Precision machining and validated spring characteristics keep the setpoint accurate throughout the service interval. Correct elastomer compounds ensure compatibility with today’s low-sulfur marine fuels, biofuel blends, and high-alkaline lube oils. Tight tolerances on seat flatness and surface finish minimize leakage and reduce chattering, which extends component life and keeps pump energy demand low.

Drop-in dimensional accuracy speeds turnaround during dockings and scheduled maintenance, while documented calibration supports predictable reliability across engines in a fleet. With OEM spare parts for the PRESSURE MAINTAINING VALVE, operators can maintain consistent minimum pressure, reduce the likelihood of secondary damage, and protect the overall efficiency of pumps, filters, and injectors. Over time, fewer reworks, shorter troubleshooting sessions, and stable fuel and lube consumption translate into tangible budget benefits.

MOPA – OEM parts partner for PRESSURE MAINTAINING VALVE and valves

MOPA is an experienced and reliable partner for OEM spare parts in the Valves category, including the PRESSURE MAINTAINING VALVE for diesel and gas engines. We focus on speed with short lead times and efficient logistics, quality through vetted sourcing and technical documentation, and security in every transaction. Our team supports precise part identification using engine serials and cross references, provides pre-calibrated options where available, and can bundle valve kits with gaskets and ancillary items to reduce downtime.

Whether you operate a marine engine on a deep-sea vessel or a power-generation diesel engine on land, MOPA helps keep fluid systems stable and engines protected. From single PRESSURE MAINTAINING VALVE replacements to fleet-wide standardization on OEM parts, we streamline procurement and support consistent technical outcomes.

Conclusion on valves and the PRESSURE MAINTAINING VALVE

Valves are indispensable to engine health, and the PRESSURE MAINTAINING VALVE is central to stable lubrication and fuel pressures that underpin reliable performance. Selecting OEM spare parts suitable for this component preserves calibration, reduces risk, and supports cost-efficient operation across marine and industrial engines.

MOPA supplies the speed, quality, and security needed to source the right valve components with confidence—helping you protect assets and optimize uptime.