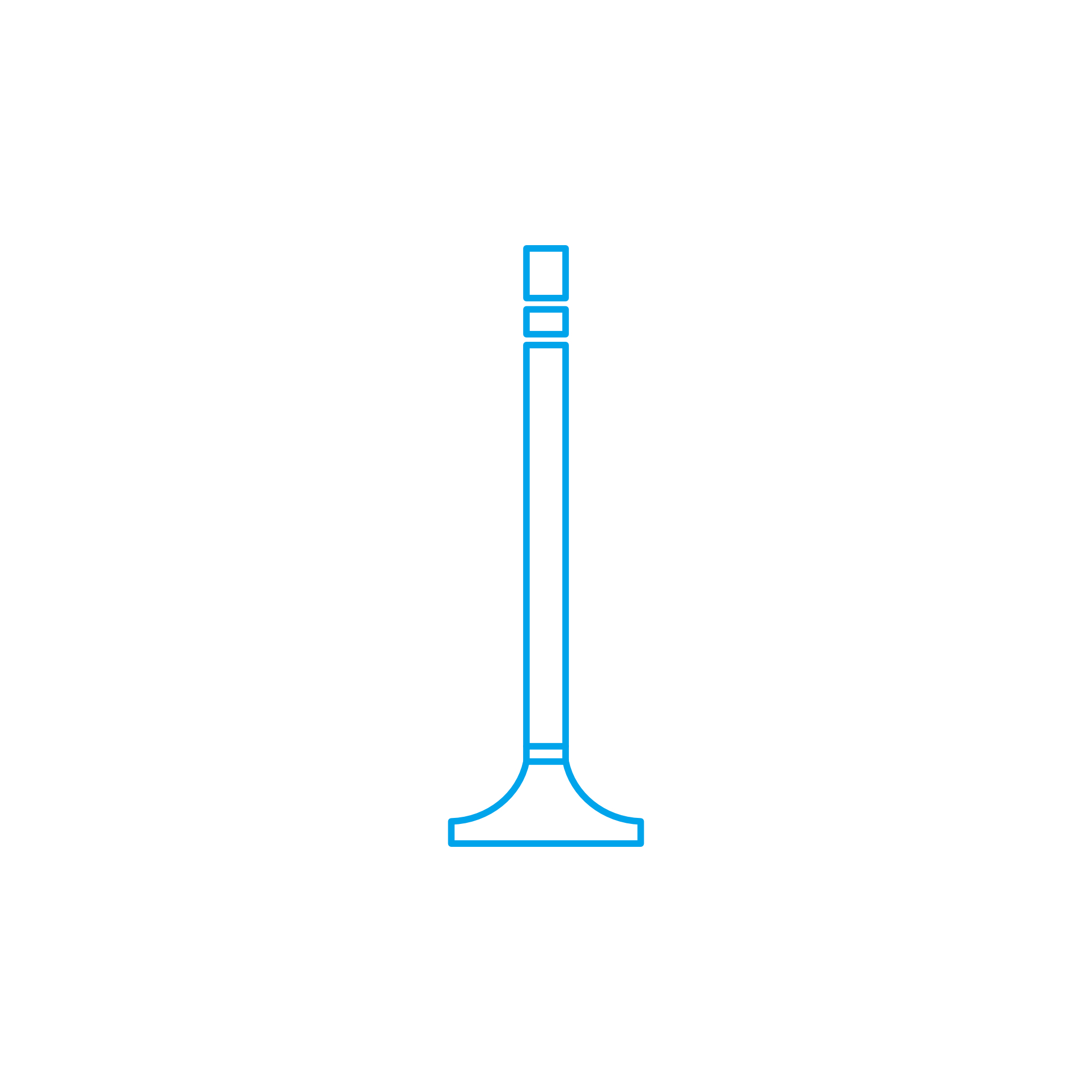

RELAY VALVE Valves for High-Performance Marine and Diesel Engines

Valves are precision components that control, meter, or isolate the flow of air, fuel, oil, coolant, and exhaust gases within an engine and its auxiliary systems. From intake and exhaust valves in the cylinder head to control, check, relief, and shut-off units in lubrication, fuel, and starting-air circuits, the category “Valves” defines how reliably a powerplant breathes, cools, lubricates, and protects itself. In marine engine and diesel engine installations, valves directly influence start-up behavior, load response, emissions, safety interlocks, and long-term service life. Within this portfolio, the RELAY VALVE is a key control element that amplifies a small pilot signal into a large flow action, enabling fast, consistent actuation elsewhere in the system.

Technical function of Valves in a diesel engine: from gas exchange to RELAY VALVE control

In four-stroke engines, intake and exhaust valves govern gas exchange with millisecond precision. Their timing and lift define volumetric efficiency, combustion quality, and exhaust temperature. Seat hardfacing, stem coatings, and optimized guide clearances ensure the valve can withstand high thermal and mechanical loads, while correct spring forces and rocker geometry protect against valve float at peak rpm. In two-stroke crosshead designs, exhaust valve actuation often relies on hydraulic or pneumatic control modules, again making dependable valve function central to cylinder performance.

Beyond the cylinder head, numerous valves orchestrate auxiliary flows: pressure-relief valves protect lube oil circuits, non-return valves prevent backflow in fuel lines, thermostatic or solenoid valves stabilize cooling-water temperature, and control valves trim turbocharger bypass or starting air distribution. Here the RELAY VALVE in a marine engine or diesel engine converts a low-energy pilot command into rapid, high-capacity flow switching. For example, a small pneumatic or hydraulic signal triggers the RELAY VALVE to open a larger line, accelerating the actuation of starting-air distributors, fuel shutoff, or exhaust valve servo systems. As a result, response time, repeatability, and overall safety logic improve—especially under high demand when line lengths and volumes are significant.

Engineers select valves by flow coefficient (Cv), pressure class, media compatibility, and temperature range. In demanding marine environments, bodies and internals in stainless steel or nickel alloys resist corrosion, while elastomers such as FKM or HNBR ensure long sealing life. For RELAY VALVE OEM parts, stable pilot-to-outlet ratio, low hysteresis, and tight internal leakage limits are vital to maintain predictable actuation across load steps and ambient conditions.

Key characteristics and advantages of Valves at a glance

· Precise flow control under high temperature and pressure.

· Fast response and consistent timing, critical for engine performance.

· Robust materials and coatings for corrosion and wear resistance.

· Tight sealing and low leakage for efficiency and safety.

· Defined Cv and pilot ratios for predictable system behavior.

· Easy service access and clear interchangeability by part number.

· Documented testing and traceability for compliance and audits.

Why Valves, including the RELAY VALVE, are critical for reliable operation

The health of valves determines whether an engine reaches and holds its rated power with stable emissions and fuel consumption. Worn intake or exhaust valves can cause blow-by, hot spots, and seat recession, degrading cylinder performance and damaging turbocharger components via uncontrolled temperature spikes. In lubrication and fuel systems, leaking check or relief valves reduce pressure stability, raising wear rates on bearings and injectors. A drifting or sticking RELAY VALVE in a diesel engine can delay starting-air delivery, slow emergency shutdown, or destabilize hydraulic servo functions—issues that directly impact vessel safety and availability.

Common failure indicators include delayed pressure build-up, unexplained leak-down, irregular idle, hard starting, and abnormal exhaust temperatures. Regular inspection of sealing surfaces, pilot passages, springs, and diaphragms, combined with timely replacement of worn components, preserves the designed control logic and extends overhaul intervals. Because many protective functions depend on crisp, repeatable valve behavior, maintaining correct calibration and response time is just as important as maintaining static pressure ratings.

Advantages of OEM spare parts suitable for Valves and RELAY VALVE assemblies

Spec-compliant OEM spare parts keep the original flow geometry, pilot ratios, and sealing characteristics intact, so engines behave exactly as designed after maintenance. Dimensional accuracy ensures correct fit and prevents misalignment that would accelerate stem, seat, or guide wear. Metallurgy and surface treatments match the intended duty cycle, resisting corrosion, erosion, and deposit formation in marine service. For a RELAY VALVE in OEM parts quality, precisely defined spring rates, diaphragms, and spool tolerances secure rapid switching and low leakage over many cycles.

From a budget perspective, correct performance out of the box reduces diagnostic time, avoids iterative adjustments, and minimizes collateral damage from off-spec actuation. Stable valve behavior supports fuel efficiency, lower emissions, and predictable maintenance windows—crucial for fleet planning and lifecycle cost control. Documentation and traceability further simplify class and audit requirements across global operations.

MOPA: your partner for OEM spare parts for Valves and RELAY VALVE components

MOPA supports shipowners, power plants, and service companies with fast, secure sourcing of OEM parts for diesel and gas engines. Our team cross-references part numbers, matches technical specifications, and supplies valves—from intake/exhaust valves to control, check, and RELAY VALVE units—precisely aligned with engine maker data. We emphasize speed through responsive quotations and optimized logistics, quality through vetted suppliers and inspection routines, and security through reliable packaging, clear documentation, and consistent delivery performance worldwide.

Whether you need a RELAY VALVE for a marine engine starting-air system or complete valve kits for an overhaul, MOPA streamlines procurement and helps protect uptime. Our inventory reach and technical expertise reduce lead times and ensure the parts meet the operational demands of harsh marine and industrial environments.

Conclusion

Valves are the control points of any engine, and the RELAY VALVE plays a decisive role in fast, reliable actuation across pneumatic and hydraulic systems. Selecting and maintaining spec-accurate components safeguards performance, efficiency, and safety. With OEM spare parts suitable for valves and RELAY VALVE assemblies—and with MOPA as a dedicated partner—you keep engines operating predictably, cost-effectively, and ready for service.