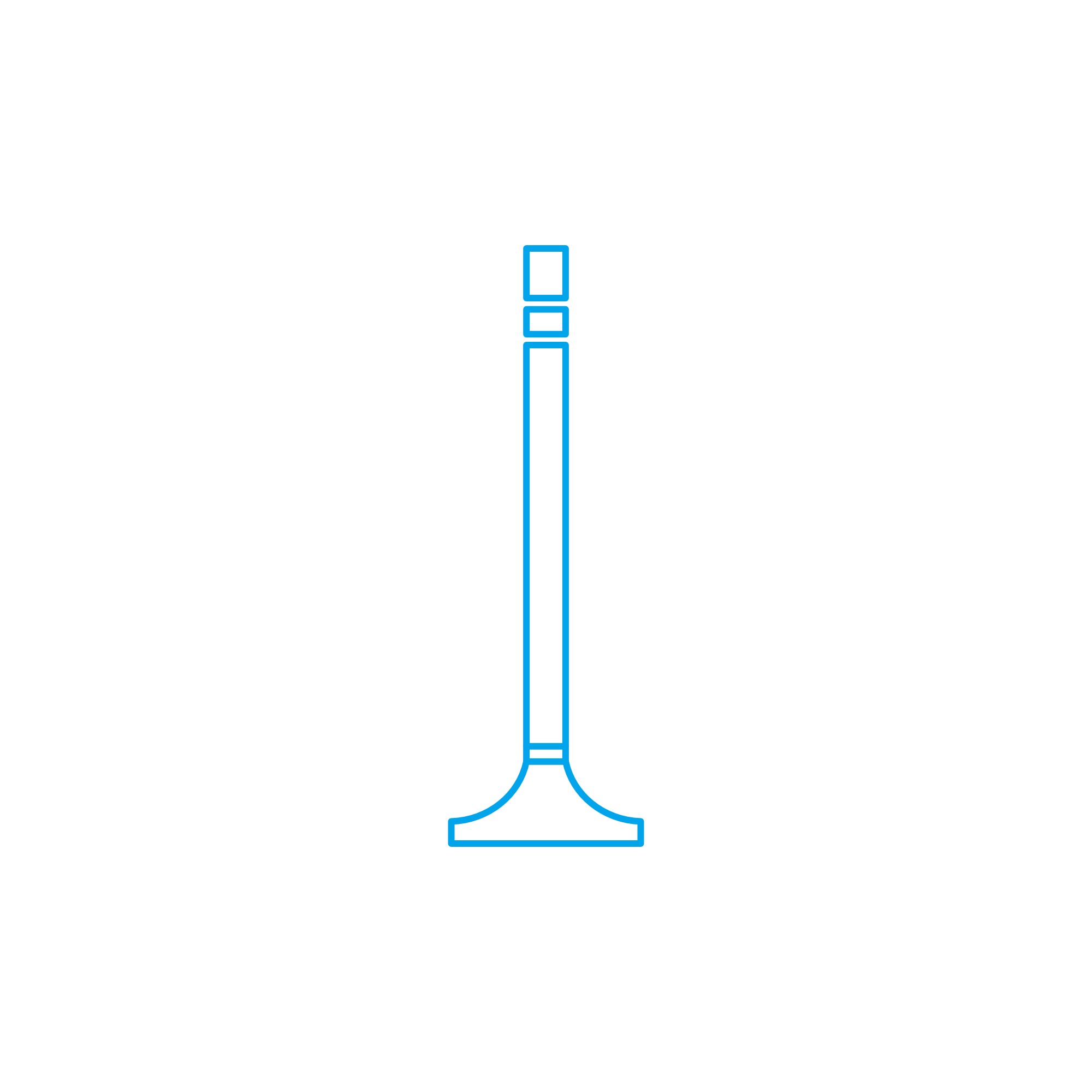

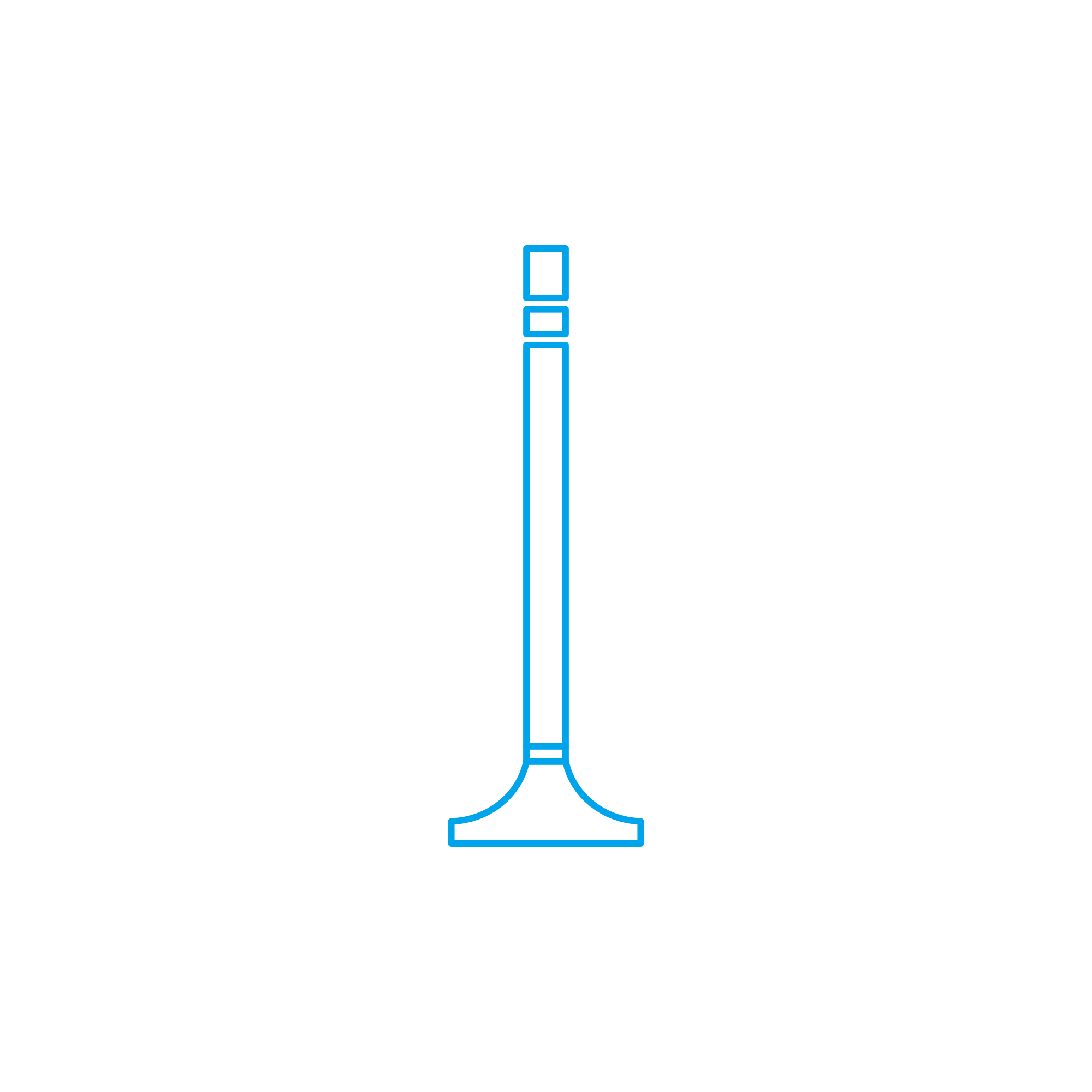

SAFETY VALVE focus within Valves for diesel and gas engines

Valves are precision-engineered components that control, meter, and protect the flows of air, fuel, exhaust gas, cooling water, and lubrication oil inside engines and their auxiliary systems. Within this broad category, the SAFETY VALVE plays a central role in overpressure protection, but intake and exhaust valves, check valves, control valves, and relief devices all work together to keep marine and stationary powerplants operating at peak performance. For shipowners, operators, and technical buyers, selecting the right valves—and maintaining their condition—directly influences uptime, fuel efficiency, and lifecycle costs.

In combustion engines, valves are the gatekeepers of thermodynamic efficiency and operational safety. Intake and exhaust valves orchestrate precise gas exchange in the cylinder head; fuel system valves ensure accurate injection and return flows; and fluid-system valves maintain stable cooling and lubrication conditions. A correctly specified and maintained SAFETY VALVE in a marine engine or diesel engine prevents damaging pressure spikes in receivers, jackets, and piping, safeguarding both machinery and personnel.

Technical function of Valves in diesel and marine engines, including the SAFETY VALVE

Engine valves fulfill distinct functions depending on their location and duty. Cylinder head intake and exhaust valves regulate the timing, lift, and duration of airflow, directly affecting volumetric efficiency, peak firing pressure, and combustion quality. Their stems run in guides for alignment, while hardened seats and stellite-faceted faces provide hot-gas resistance and sealing integrity. Actuation occurs via camshafts, rocker arms, or hydraulic/electro-hydraulic systems, with springs ensuring rapid closure to prevent blowback and compression loss.

Across auxiliary systems, control and check valves stabilize flows and prevent reverse currents in lube oil circuits, fuel conditioning skids, charge-air coolers, and cooling-water loops. Here, material selection (e.g., duplex or austenitic steels), surface finishes, and precision clearances counter cavitation, erosion, and corrosion.

The SAFETY VALVE is the last line of defense against overpressure. In a diesel engine air receiver, jacket water line, or lube system manifold, it is calibrated to lift at a defined set pressure, venting safely and reseating reliably to prevent media loss. A SAFETY VALVE marine engine configuration typically features anti-chatter geometry, high-temperature elastomers or metal-to-metal seats, and certified set-point accuracy to maintain system integrity. In combustion spaces, specialized crankcase relief devices with flame arrestors rapidly discharge pressure from a primary explosion while minimizing the risk of secondary ignition.

When sourced as SAFETY VALVE OEM parts, the defined lift characteristics, spring constants, nozzle areas, and blowdown values align with the engine maker’s specifications. This ensures stable relief behavior under pulsating loads common in two-stroke and four-stroke applications and secures consistent protection across service intervals.

Key characteristics and advantages of Valves

· Precise flow control under high thermal and mechanical loads.

· Reliable sealing to maintain compression and prevent leaks.

· Optimized materials and coatings for wear, heat, and corrosion resistance.

· Fast, repeatable response in dynamic engine conditions.

· Calibrated set points for each SAFETY VALVE diesel engine application.

· Low pressure drop to support fuel economy and performance.

· Robust geometry against cavitation and vibration-induced fatigue.

· Compatibility with OEM parts for dimensional fit and function.

Importance of Valves for reliability and service life

Valves determine whether an engine delivers design performance over its service life. Worn intake or exhaust valves reduce compression, degrade combustion, and elevate exhaust temperatures, risking hot corrosion, turbocharger imbalance, and component cracking. Sticking or leaking control valves in lube or cooling circuits can starve bearings or cause thermal stress, leading to unplanned stoppages. If a SAFETY VALVE drifts from its set point, the system may either lift prematurely—causing energy losses and contamination—or fail to open at the critical moment, exposing the installation to severe overpressure events.

Typical failure modes include seat recession, face burning, guide wear, stem galling, spring fatigue, and debris-induced leakage. In marine duty, salt-laden atmospheres and cyclic loading add to the challenge. Rigorous specification, condition monitoring, and timely replacement with precisely matched components are essential to preserve reliability, efficiency, and compliance with class requirements.

Advantages of OEM spare parts suitable for Valves

OEM spare parts suitable for valves ensure that dimensions, materials, and functional parameters match the engine builder’s design—down to seat angles, stem tolerances, spring rates, and surface treatments. This precision is vital for gas exchange efficiency, stable set pressures on each SAFETY VALVE, and predictable maintenance intervals.

Choosing OEM spare parts suitable for valves supports performance, reliability, budget, and service life in several ways:

· Consistent fit that shortens installation time and reduces rework.

· Certified metallurgy and heat treatment for long wear life.

· Verified sealing geometry to maintain compression and low emissions.

· Accurate SAFETY VALVE lift/seat behavior for dependable protection.

· Lower total cost of ownership through longer intervals and fewer breakdowns.

· Traceable production and testing for quality assurance and audit readiness.

· Harmonized spares across fleets, simplifying inventory and logistics.

MOPA as your partner for OEM spare parts Valves and SAFETY VALVE components

MOPA is an experienced, reliable partner for OEM spare parts Valves, supporting operators of diesel and gas engines across marine and power generation. Customers value our speed in sourcing critical items, our focus on quality throughout the supply chain, and the security we bring to global trade of OEM parts. From intake and exhaust valves to a calibrated SAFETY VALVE marine engine package, we help you maintain fleet readiness with efficient logistics, technical documentation, and responsive service.

Our team understands the nuances of valve specifications—materials, coatings, lift curves, and set pressures—and aligns deliveries with your planned maintenance windows to minimize downtime. With MOPA, you receive consistent, traceable parts and timely deliveries that keep engines operating at design performance.

Conclusion

Valves are fundamental to engine performance, protection, and efficiency, and the SAFETY VALVE is crucial to preventing overpressure incidents in diesel and marine applications. By selecting OEM spare parts suitable for valves, operators safeguard reliability, control budgets, and extend service life while preserving the engine’s intended performance profile.