STARTING AIR VALVE and Valves for reliable diesel and gas engine operation

Valves are precision components that control the timing, direction, and pressure of working fluids in engines. In large diesel and gas units—especially marine propulsion and power generation sets—Valves regulate air intake, exhaust evacuation, fuel admission, cooling, and critical safety functions. Within this category, the STARTING AIR VALVE plays a special role: it enables the initial rotation of heavy-duty crankshafts by admitting high-pressure air to the cylinders, making reliable starts possible even under harsh conditions. Robust, dimensionally accurate Valves are therefore indispensable for performance, efficiency, and safety across the entire engine lifecycle.

Technical function of Valves and the STARTING AIR VALVE in a marine engine

In an internal combustion engine, Valves orchestrate the gas exchange and protective functions that keep the machine running within design limits. Intake Valves meter fresh air (or air-fuel mix in certain concepts) into the cylinder. Exhaust Valves evacuate combustion gases and protect the turbocharger from excessive temperature and pressure. Additional Valves manage lubrication flow, cooling circuits, fuel cutoff, and safety relief. Each type must seal reliably, withstand thermal cycling, and operate with minimal friction and wear.

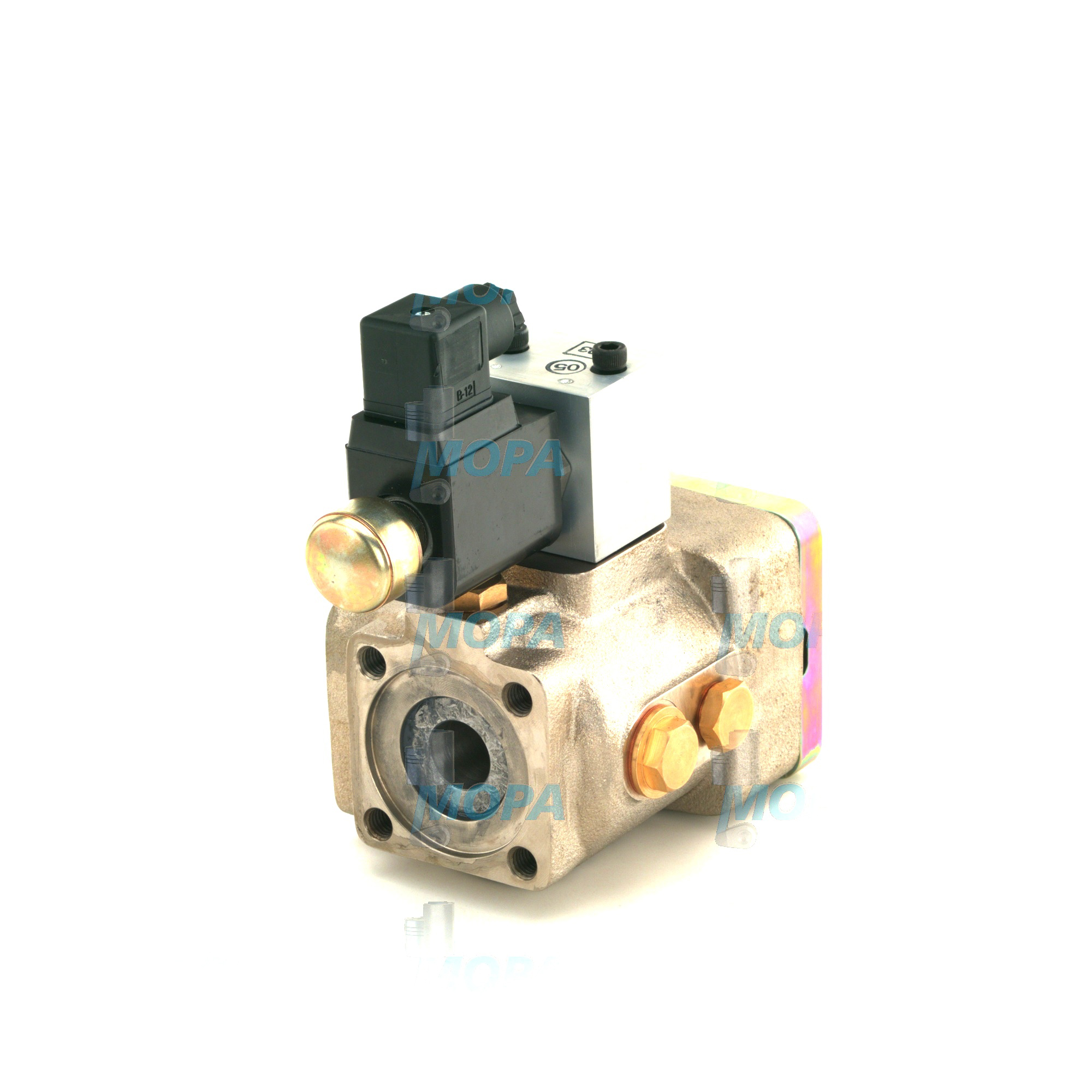

The STARTING AIR VALVE is purpose-built for large diesel engine and gas engine starting systems. In a marine engine, compressed air—typically 20–30 bar—feeds a distributor that sequences admission to each cylinder near top dead center. The STARTING AIR VALVE on the cylinder head opens at the precise crank angle, admitting air that drives the piston downward and turns the crankshaft until self-sustaining combustion is established. A pilot-air control and interlocks ensure that the valve only opens when the turning gear is disengaged and conditions are safe. When correctly maintained, the STARTING AIR VALVE reduces starting time, lowers electrical loads, and prevents unburned fuel accumulation during repeated start attempts.

Design features vary by maker but often include hardened or stellite-faced seats, nitrided or chrome-plated stems, corrosion-resistant housings, and finely lapped sealing faces to ensure tight shutoff. Non-return and flame-arresting elements in the starting air line protect the manifold from backflow and potential ignition. In OEM parts configurations, the STARTING AIR VALVE is engineered to match the port geometry, pilot pressure, and timing of the engine, ensuring clean starts and minimal air consumption.

- · Precise flow control for intake, exhaust, and starting air.

- · High-temperature alloys and surface hardening for long service life.

- · Tight sealing to maintain compression and system pressure.

- · Optimized stem/guide pairing for low friction and stable clearance.

- · STARTING AIR VALVE timing matched to diesel engine sequences.

- · Proven compatibility with marine engine safety interlocks.

Why Valves—especially the STARTING AIR VALVE—are critical for reliability and uptime

Valves directly influence power output, fuel economy, and emissions by governing air mass flow, scavenging, and residual gas fraction. Leakage across intake or exhaust Valves reduces compression and increases fuel consumption, while poor heat rejection at the exhaust side accelerates seat and guide wear, elevates exhaust temperatures, and stresses the turbocharger. In gas engines, improper sealing can destabilize combustion, increasing knock risk and maintenance demand.

The STARTING AIR VALVE is pivotal for dependable vessel operations. If it sticks, leaks, or opens late, the engine may crank slowly, fail to start, or require repeated cycles that waste compressed air and time. Worn sealing faces can allow combustion gases to travel backward into the starting manifold—a serious safety hazard that marine regulations address through non-return devices and explosion relief valves. Keeping the STARTING AIR VALVE in prime condition safeguards both the starting sequence and the air system infrastructure, reducing unplanned downtime and protecting crew and assets.

Advantages of OEM spare parts suitable for Valves and STARTING AIR VALVE OEM parts

Choosing OEM spare parts suitable for Valves ensures that materials, tolerances, and surface finishes match the engine maker’s specifications. This is vital for maintaining compression, flow coefficients, and start timing. For a STARTING AIR VALVE, correct pilot pressure thresholds, spring rates, and lift profiles are essential to synchronize with the air distributor and reduce air consumption per start.

Performance, reliability, budget, and service life

With OEM spare parts suitable for Valves you benefit from a controlled bill of materials, repeatable heat treatment, and verified dimensions that preserve engine performance and extend component longevity. Precision-ground stems and matched guides reduce wear and oil carryover. Seat hardfacing maintains sealing at high temperature. For STARTING AIR VALVE OEM parts, tested sealing faces and calibrated actuation deliver consistent opening behavior, faster light-off, and reduced stress on compressors and receivers. The result is lower total cost of ownership through predictable maintenance intervals, less rework during overhauls, and fewer starting failures that can disrupt schedules and charters.

- · Dimensional fidelity preserves sealing and timing.

- · Metallurgy and hardfacing resist high-cycle fatigue.

- · Traceability and documentation support class compliance.

- · Drop-in fit reduces installation time and risk.

- · STARTING AIR VALVE actuation calibrated for OEM distributor logic.

- · Stable performance across diesel engine and gas engine duty profiles.

MOPA as your partner for OEM Valves and STARTING AIR VALVE supply

MOPA is an experienced and reliable partner for OEM spare parts Valves, including STARTING AIR VALVE assemblies, seats, guides, springs, and related hardware. We focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines used in marine propulsion, offshore, and power generation. Our network provides short lead times, consistent stock availability for common engine types, and rigorous inbound quality checks. Customers benefit from clear documentation, batch traceability, and a supply chain designed for time-critical dockings and voyage repairs. Whether you need a single STARTING AIR VALVE for a marine engine or a complete valve set for a scheduled overhaul, MOPA streamlines procurement and reduces operational risk.

Conclusion on Valves and STARTING AIR VALVE selection

Valves are core to engine health, efficiency, and safety, with the STARTING AIR VALVE enabling dependable starts in demanding applications. Selecting OEM spare parts suitable for Valves preserves performance, extends service life, and protects budgets through predictable, reliable operation. MOPA supports you with fast, secure access to the right OEM parts so your diesel and gas engines start cleanly and run at their best.