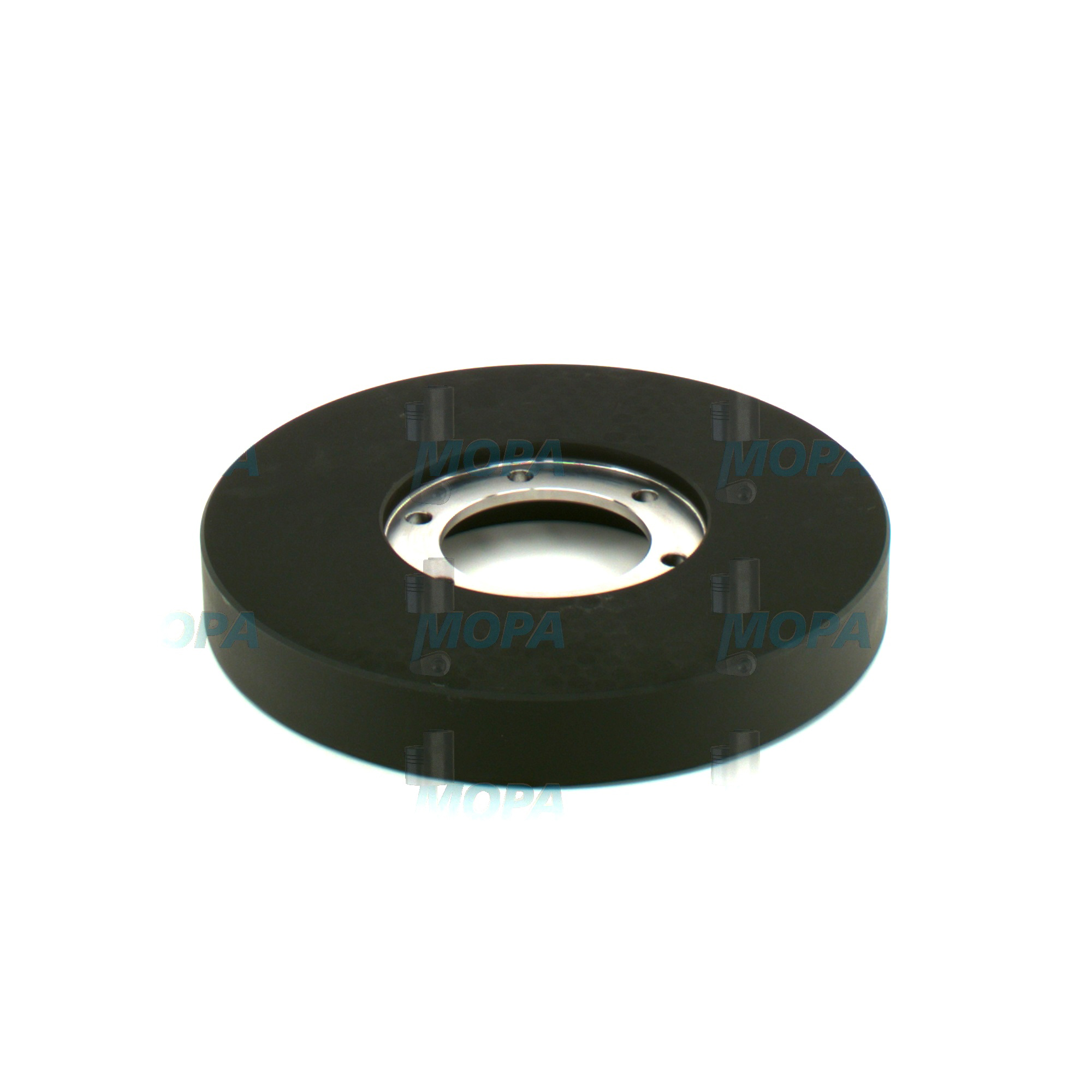

VIBRATION DAMPER – Vibration dampers for diesel and marine engines

Vibration dampers are precision-engineered components that control torsional oscillations in rotating assemblies. In engines, they protect the crankshaft, gear train, and auxiliary drives from destructive vibration loads that arise from cyclic combustion forces. Whether installed on a high-output diesel engine, a gas engine in power generation, or a propulsion-grade marine engine, a VIBRATION DAMPER is a key element for smooth operation, higher efficiency, and long component life. As a category, vibration dampers include viscous, elastomeric, and hybrid designs tuned to the specific firing orders and torsional characteristics of each engine type.

Technical function of VIBRATION DAMPER in diesel and marine engine applications

Every cylinder firing event creates torque ripple that twists the crankshaft slightly back and forth. At specific speeds, these oscillations can align with the system’s natural frequencies and amplify into harmful resonance. A VIBRATION DAMPER counters this effect by introducing a controlled phase lag and energy dissipation, cutting the peak torsional amplitudes before they stress critical parts. In a typical viscous design, an inertia ring shears through silicone fluid inside a sealed housing; in an elastomeric design, a bonded rubber element flexes to absorb energy. Both types are tuned to the engine’s dominant orders and operating range, making them essential on medium- and high-horsepower diesel engines and on long-stroke marine engines where torsional loads are substantial.

Correctly sized and maintained, the damper stabilizes the crankshaft speed, improves timing consistency, reduces belt slip on the front-end drive, and mitigates gear rattle in the camshaft and auxiliary gear trains. By smoothing the rotational irregularities, the VIBRATION DAMPER also supports better fuel economy and lower noise and vibration harshness (NVH), which is especially important in propulsion lines and gensets where coupling loads and alignment tolerances are tight. For service teams and buyers managing fleets, choosing VIBRATION DAMPER OEM parts ensures that damping coefficients, inertia, and balance quality match the engine maker’s specifications.

- · Reduces torsional peaks at critical engine orders.

- · Protects crankshafts, bearings, and gear trains.

- · Stabilizes accessory drives and belt systems.

- · Tuned to diesel engine and marine engine duty cycles.

- · Available as viscous or elastomeric concepts.

- · Improves NVH and lowers coupling loads.

- · Delivered with precise balance and match-fit dimensions.

Importance of VIBRATION DAMPER for reliability and service life

The health of the vibration damper directly influences engine reliability. As damping performance degrades over time—through fluid aging, seal leakage, elastomer hardening, or bonded joint fatigue—the crankshaft sees higher torsional stress. Consequences can include fretting on keyways and hubs, micro-cracking at fillets, accelerated main and thrust bearing wear, gear tooth pitting, accessory belt failures, and excessive load on flexible couplings or alternator shafts. Engines may exhibit increased noise, resonance bands at certain RPMs, and higher fuel consumption due to timing scatter.

Routine inspection is therefore critical. Many marine engine makers recommend dimensional checks, visual inspection for leakage, and periodic replacement in the 20,000–30,000 operating-hour range, or per condition monitoring results. Any signs of oil contamination around the front pulley, melted or cracked elastomer, loose inertia rings, or unusual vibration at steady RPM are typical triggers for immediate evaluation and replacement. Keeping the VIBRATION DAMPER in proper condition preserves the engine’s torsional safety margins and extends component life across the entire rotating assembly.

Advantages of OEM spare parts suitable for Vibration dampers

Selecting OEM spare parts suitable for vibration dampers delivers measurable gains in performance, reliability, budget control, and service life:

Performance and efficiency

OEM damper specifications follow the exact damping curves, inertia values, and balance grades defined for the target engine model. This precision preserves torsional tuning across the whole operating range, from idle to continuous power and transient load steps, ensuring stable operation in both propulsion and generator modes.

Reliability and lifecycle

Material quality (housing steels, elastomers, and silicone fluids), bonding processes, and sealing systems are validated to withstand high thermal cycles and oil mist environments common in engine rooms. Traceable production and testing ensure consistent damping performance across service intervals, maintaining resonance margins and protecting expensive drivetrain components.

Budget and downtime

Accurate fit and supplied balance minimize installation time and reduce the risk of misalignment or rework. By controlling torsional loads as designed, OEM spare parts suitable for VIBRATION DAMPER reduce secondary failures—such as gearbox or coupling damage—that can cause costly unplanned downtime.

MOPA as your partner for VIBRATION DAMPER OEM parts

MOPA supplies purchasers, shipowners, and technical decision-makers with OEM parts for diesel and gas engines—fast, reliably, and with strict quality control. Our team sources VIBRATION DAMPER OEM parts aligned to the exact engine variant and class requirements, supports documentation needs, and ensures secure handling and delivery to keep assets operating on schedule. From single units to fleet-wide spare strategies, MOPA combines technical expertise with a responsive supply chain.

Conclusion: VIBRATION DAMPER in focus

A properly specified and maintained vibration damper is indispensable for controlling torsional stress, safeguarding the crankshaft, and stabilizing auxiliary drives. Choosing OEM spare parts suitable for Vibration dampers preserves the intended damping characteristics, supports efficient operation, and reduces lifecycle cost across diesel and marine engine applications.