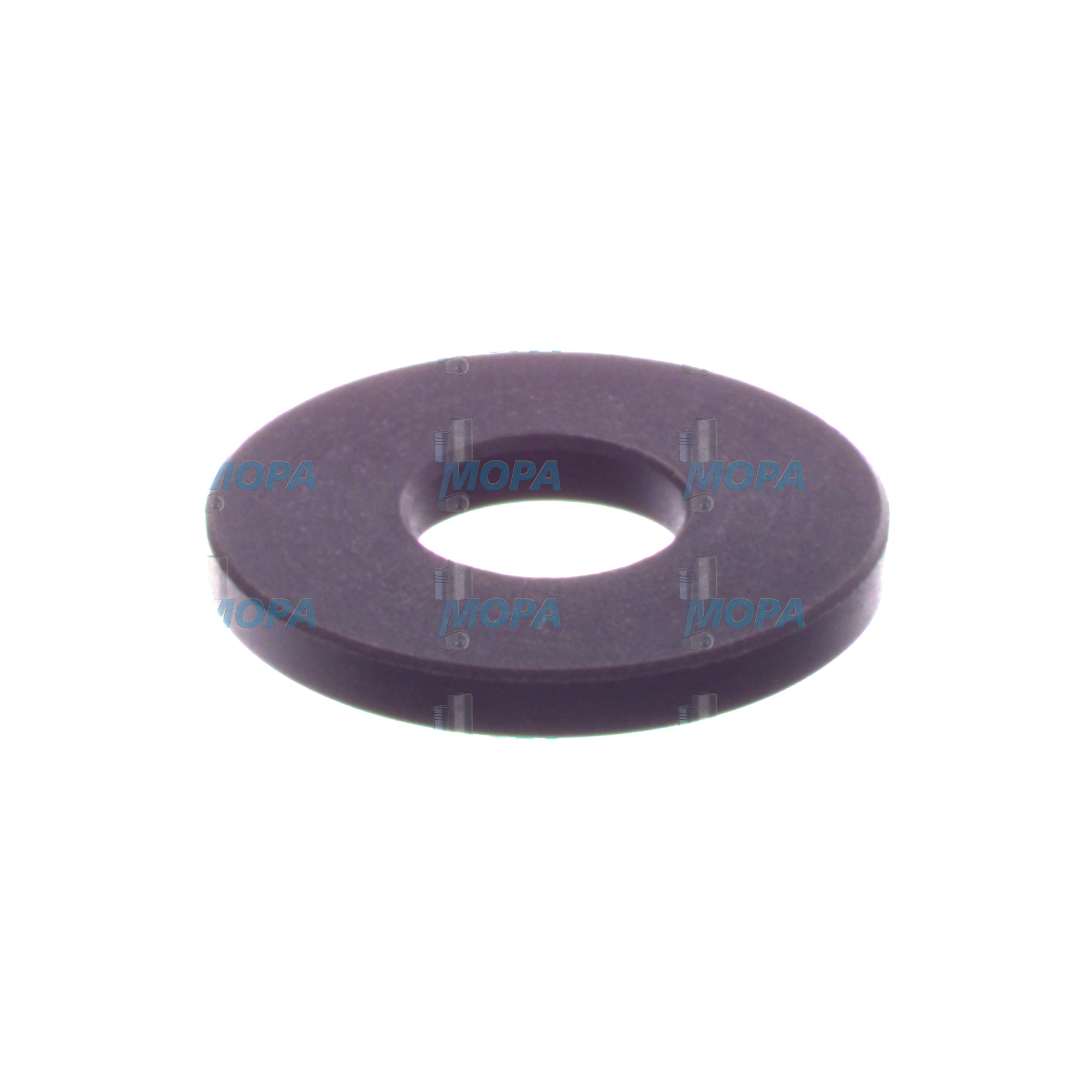

INSULATING WASHER and Engine Washers for Marine and Diesel Applications

Washers are small but critical components that ensure secure, reliable connections throughout an engine. In rotating equipment and heavy-duty powertrains, the right washer manages clamping force, distributes load, prevents leakage, and—when required—isolates electrical circuits. From mounting brackets and fuel systems to alternators and control modules, high-quality washers support stable torque, minimize wear, and protect the engine against mechanical and electrical risks over thousands of operating hours.

Within this category, the INSULATING WASHER plays a particularly important role. It provides electrical separation between conductive parts to prevent stray currents, sensor faults, and galvanic corrosion—especially vital in a marine engine environment. Alongside insulating variants, other washer types such as flat, spring, sealing, and shim washers contribute to vibration resistance, accurate alignment, and sealing integrity across diesel engine and gas engine platforms.

Technical function of washers in a diesel engine

Washers serve as engineered interfaces between fasteners and the components they clamp. A properly selected flat washer spreads the load over a larger surface area, protecting softer materials and maintaining joint integrity under dynamic loads. Spring and lock washers help preserve preload in bolted joints subject to vibration, thermal cycling, and pulsation—conditions common in ship propulsion and auxiliary generator sets. Sealing washers provide fluid-tight connections at fuel lines, oil galleries, and coolant circuits, preventing micro-leaks that can escalate into performance losses or safety risks.

The INSULATING WASHER for marine engine assemblies adds a crucial electrical function. Positioned under terminals, sensor mounts, or control cabinet interfaces, it blocks unintended current paths and helps maintain signal integrity. In a diesel engine, the INSULATING WASHER also reduces the risk of galvanic coupling between dissimilar metals exposed to moisture and salt, protecting both the fastener and the connected component. Materials commonly used include phenolic, fiber, nylon, PTFE, and high-performance polymers, chosen for dielectric strength, temperature resistance, and chemical compatibility. When sourced as INSULATING WASHER OEM parts, dimensional accuracy and material consistency support repeatable torque-tension relationships and stable electrical isolation.

- · Distributes clamping force to prevent embedment and joint relaxation.

- · Maintains preload under vibration and thermal cycling.

- · Provides fluid sealing at critical oil, fuel, and coolant interfaces.

- · Ensures electrical isolation with an INSULATING WASHER in marine engine systems.

- · Minimizes galvanic corrosion between dissimilar metals.

- · Supports accurate alignment and spacing with shim washers.

- · Enables repeatable, reliable torque application across service intervals.

Importance for engine operation and service life

Washers directly influence reliability and uptime. If a washer is worn, incorrectly specified, or damaged, joint preload can drop, leading to loosening, fretting, and increased vibration. On fluid systems, degraded sealing washers may cause weeping at banjo fittings, injector lines, or oil passages—issues that reduce efficiency and raise contamination risks. Electrical disturbances are especially costly: without a correctly specified INSULATING WASHER in diesel engine instrumentation or alternator connections, stray currents may trigger false readings, cause hot spots, or accelerate corrosion, ultimately impacting performance and safety.

In high-hour operations, minor deviations in washer thickness, hardness, or surface finish can accumulate into measurable torque loss and uneven clamping. Over time, this can distort flanges, stress gaskets, and shorten the service life of adjacent components. For shipowners and power plant operators, maintaining the correct washer type and specification is a cost-effective way to protect major assets and avoid unplanned stoppages.

Advantages of OEM spare parts suitable for washers

OEM spare parts suitable for washers are engineered to the engine maker’s specifications and validation processes. This ensures that geometry, material composition, and surface finish achieve the designed torque-tension performance and long-term stability. In practice, that means fewer retorque events, better sealing reliability, and consistent electrical isolation when using an INSULATING WASHER OEM parts set.

From a lifecycle perspective, precise fit and proven materials reduce rework, prevent collateral damage, and support predictable maintenance planning. For purchasing teams, this is not only a technical decision but a budget-conscious one: the right washer specification helps avoid downstream costs tied to leaks, premature component wear, or electrical troubleshooting.

Why choose OEM spare parts suitable for the INSULATING WASHER and other washers

- · Consistent dimensions for repeatable torque and preload.

- · Material traceability aligned with engine requirements.

- · Reliable dielectric properties for INSULATING WASHER OEM parts.

- · Chemical and temperature resistance suited to fuel, oil, and coolant exposure.

- · Reduced downtime through fit-first-time replacements.

- · Optimized total cost of ownership by preventing leaks and loosening.

MOPA as a partner for INSULATING WASHER and washer OEM parts

MOPA is an experienced and reliable partner for OEM spare parts suitable for washers, including the INSULATING WASHER for marine engine and diesel engine applications. We focus on speed, quality, and security across the entire parts supply chain, helping operators keep fleets running with confidence. Our team supports multi-brand diesel and gas engines, providing rapid quotations, efficient logistics, and comprehensive documentation to streamline procurement and compliance.

With MOPA, purchasers and technical decision-makers gain a single point of contact for washer assortments—flat, spring, sealing, shim, and insulating—matched to engine-specific requirements. We help you select the correct thickness, outer and inner diameters, material grade, and dielectric rating where necessary, ensuring that every washer contributes to stable performance and long service life.

Application highlights using INSULATING WASHER OEM parts

- · Alternator and starter terminals requiring electrical isolation.

- · Sensor brackets and control modules sensitive to stray currents.

- · Battery connections and grounding points in marine environments.

- · Corrosion-prone interfaces between dissimilar metals exposed to salt spray.

Conclusion

Washers are foundational to engine reliability, from maintaining clamp load and sealing integrity to ensuring clean electrical interfaces with an INSULATING WASHER in marine and diesel engine systems. Selecting OEM spare parts suitable for washers secures consistent performance, protects budgets, and extends service life across the entire powertrain.

MOPA delivers the speed, quality, and security you need to source washer OEM parts with confidence—keeping your engines efficient, safe, and ready for demanding operations.