F6L413FR marine and industrial diesel engine

The F6L413FR is a proven six‑cylinder diesel engine that stands out for its robust air‑cooled design and dependable performance in demanding marine and stationary applications. Part of the well‑known Deutz 413 family, it inherits the series’ hallmark durability while the F6L413FR designation points to a configuration tailored for maritime duties and constant‑speed operation. For buyers and technical decision‑makers who value reliability, straightforward maintenance, and global serviceability, the F6L413FR offers a compelling balance of power density and lifecycle economy.

F6L413FR technical profile and performance data

The F6L413FR is an inline six‑cylinder, four‑stroke diesel engine with direct injection. Its air‑cooled architecture eliminates seawater heat‑exchangers and associated corrosion risks, making it particularly attractive for vessels and offshore equipment exposed to harsh environments. Depending on build and governing, typical continuous marine output for the Deutz F6L413FR diesel engine spans roughly 120–170 kW, with intermittent ratings higher where permissible. Common speed settings cover 1500 rpm (50 Hz generator sets), 1800 rpm (60 Hz generator sets), and up to around 2100–2300 rpm for propulsion or auxiliary drives. Displacement is in the ~10‑liter class, delivering a strong torque curve suitable for reliable load acceptance in onboard power and propulsion duty.

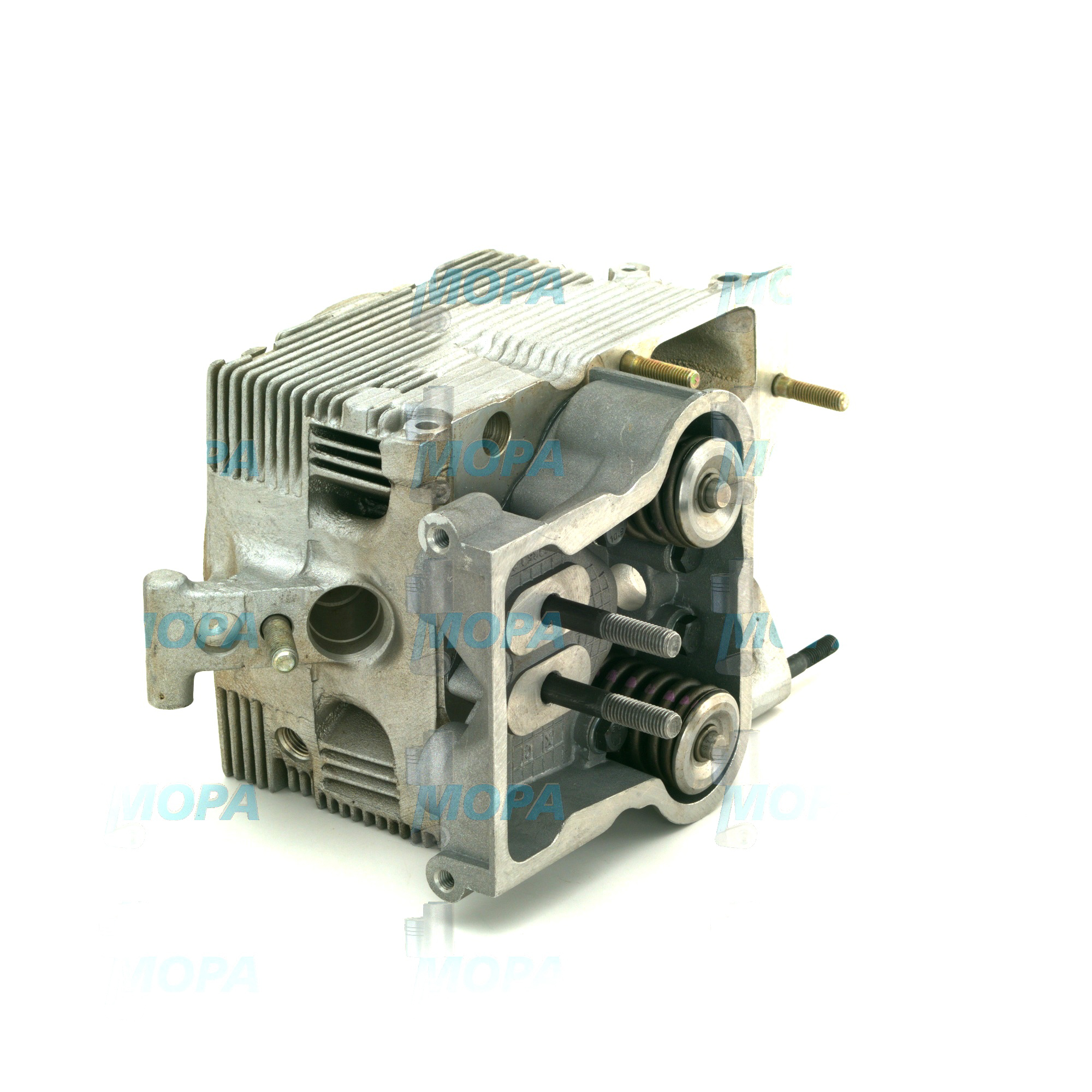

Fuel is metered by a mechanical inline injection pump, valued for its ruggedness and ease of service at sea. The individual finned cylinder barrels and heads are a hallmark of the 413 series, promoting even heat dissipation and simplified cylinder‑wise maintenance. Specific fuel consumption for correctly set engines is typically in the ~205–220 g/kWh range, influenced by duty cycle, ambient conditions, and governor calibration. Lubrication is by a full‑flow system with efficient oil cooling; filtration is arranged for long service intervals when using approved oils and scheduled maintenance practices.

Why is the F6L413FR so widely adopted? Beyond power‑to‑weight and proven metallurgy, its air‑cooled concept reduces system complexity—no raw‑water pumps, no plate coolers, and fewer fouling points—cutting downtime and consumables. The engine’s mechanical simplicity supports rapid troubleshooting and predictable parts planning. As a Deutz F6L413FR marine engine, it aligns well with workboats and auxiliaries where availability matters more than cutting‑edge electronics, and where crews appreciate straightforward service procedures.

- · 6‑cylinder inline, air‑cooled diesel

- · Approx. 10‑liter displacement class

- · Typical marine continuous output ~120–170 kW

- · Common speed settings: 1500, 1800, 2100–2300 rpm

- · Direct injection with mechanical governing

- · Strong load acceptance for gensets and propulsion

- · Simplified cooling concept—no seawater heat‑exchanger

- · Proven Deutz 413 platform with global serviceability

Applications of the Deutz F6L413FR diesel engine

In maritime settings, the F6L413FR is frequently specified for auxiliary generator sets on cargo vessels, inland barges, tugs, offshore support vessels, and passenger ferries. Its steady‑state efficiency at 1500/1800 rpm makes it a reliable prime mover for 50/60 Hz shipboard power, with ample reserve to handle transient loads from bow thrusters, winches, and hotel services. For propulsion on smaller workboats and utility craft, the F6L413FR offers a predictable torque profile that pairs well with mechanical gearboxes.

Beyond shipboard use, the engine is found in stationary roles such as port‑side power, emergency fire pumps, and remote micro‑power plants where cooling water quality is a concern. The combination of air‑cooling and mechanical injection makes the F6L413FR resilient to varying ambient conditions, supporting regulated operation from cold climates to tropical heat.

Why operators value the F6L413FR marine engine

Operators appreciate the Deutz F6L413FR marine engine for its uptime and maintainability. The platform’s modular cylinders and robust bottom end support long service life with predictable overhaul planning. Air‑cooling simplifies installation and reduces auxiliary equipment counts, while parts inventories are streamlined across fleets using the Deutz F6L413FR diesel engine. For purchasers, the total‑cost proposition is reinforced by consistent performance, straightforward diagnostics, and ready access to F6L413FR OEM parts through established supply channels.

OEM spare parts suitable for F6L413FR: performance, reliability, service life

To sustain the engine’s output, efficiency, and longevity, OEM spare parts suitable for F6L413FR are essential. Precision‑matched components—injectors, pumps, pistons, cylinder heads, gaskets, and valve train elements—ensure correct clearances, material specifications, and heat resistance needed by an air‑cooled design. Using OEM spare parts suitable for F6L413FR preserves combustion quality and thermal balance across cylinders, protecting against hotspots, detuning, and premature wear that can arise from mismatched components.

Equally important, OEM spare parts suitable for F6L413FR maintain calibration integrity. Fuel injection timing, nozzle spray patterns, and governor response depend on tightly controlled tolerances. Correct filters and seals protect lubrication and air systems from contamination that accelerates scuffing or fin fouling. For engines driving constant‑speed generators, component consistency directly supports stable frequency and voltage under step loads.

- · Dimensional accuracy safeguards compression and sealing.

- · Verified metallurgy tolerates cyclic thermal loads.

- · Calibrated injection parts sustain efficient combustion.

- · Proper cooling‑air flow is preserved by correct shrouds and tins.

- · Planned maintenance intervals remain predictable.

- · System reliability and uptime improve across the duty cycle.

MOPA is a reliable partner for OEM spare parts suitable for F6L413FR, providing responsive sourcing, technical clarification on supersessions, and delivery options aligned with dock schedules. With MOPA, purchasers and superintendents can consolidate procurement for the Deutz F6L413FR marine engine and related 413‑series units, ensuring that the right items arrive on time and fit first time. From cylinder kits to governor components, MOPA supports the full lifecycle of your installation with OEM spare parts suitable for F6L413FR.

Conclusion: F6L413FR value and secure parts supply

The F6L413FR offers a proven mix of durability, straightforward maintenance, and dependable power for marine and stationary duties, built on the respected Deutz 413 platform. Its air‑cooled design, strong torque, and mechanical simplicity make it a favorite for operators who prioritize uptime.

To keep this performance consistent over time, rely on MOPA for OEM spare parts suitable for F6L413FR. With precise components and knowledgeable support, MOPA helps ensure your F6L413FR continues to deliver reliable service in every operating condition.