F4L912 diesel engine: robust power for marine and industrial duties

The F4L912 stands out as a compact, air-cooled four‑cylinder diesel built for dependable power in tough environments. While it belongs to the renowned Deutz 912 series, the focus here is squarely on the F4L912 itself—its technical strengths, proven reliability, and suitability for marine auxiliaries and stationary applications where uptime and efficiency matter most.

With straightforward mechanical fuel injection, direct air cooling, and a rugged crankcase design, the F4L912 delivers consistent output with minimal system complexity. Purchasers and technical decision‑makers value its balance of fuel economy, ease of service, and the ability to run reliably in hot, dusty, or saline atmospheres where liquid‑cooled engines require more supporting infrastructure.

Technical profile of the Deutz F4L912 diesel engine

The F4L912 is a naturally aspirated, in‑line four‑cylinder diesel engine with direct injection and a proven air‑cooling concept. Typical continuous ratings fall in the 40–70 kW range depending on configuration and duty cycle, with rated speeds commonly between 1500 and 2500 rpm for marine and industrial variants. A robust mechanical governor supports steady frequency control in generator sets and stable shaft speeds for hydraulic power packs or pumps.

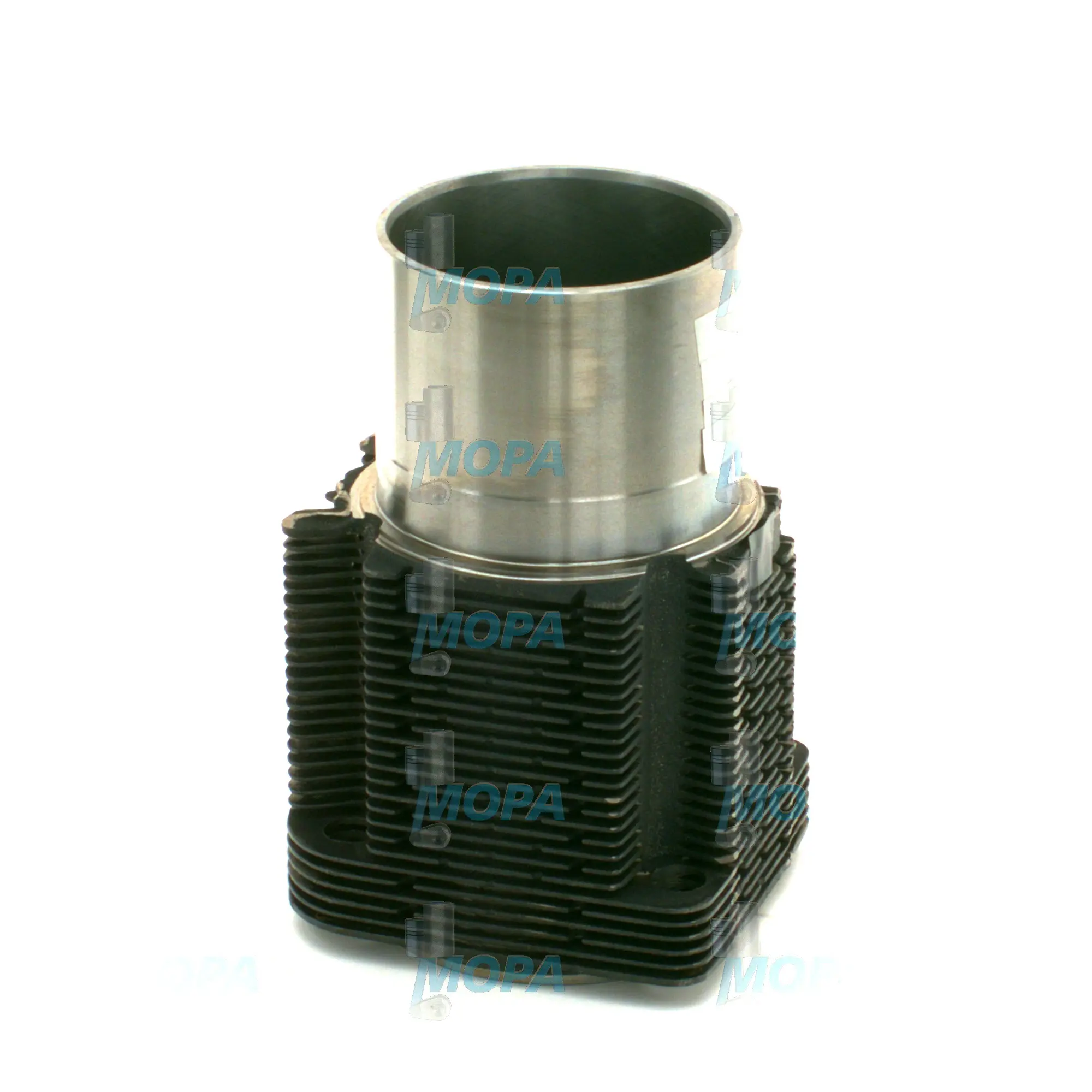

Engine architecture highlights include a finned cylinder/barrel design, an efficient axial cooling fan, and a durably engineered crankshaft and bearings designed for long service intervals. Typical bore and stroke dimensions within the 912 family yield an approximate displacement of 3.7–3.8 liters for the F4L912, producing a torque curve well‑suited to auxiliary drives and gensets. In practice, operators often report stable fuel use across mid‑load ranges and predictable cold‑start behavior with the correct starting aids and fuel settings. Exact figures vary by build code and rating, but the core advantages remain consistent: simplicity, durability, and reliable output.

- · Four‑cylinder, air‑cooled, direct‑injection diesel

- · Approx. 3.7–3.8 L displacement, naturally aspirated

- · Typical 40–70 kW continuous power at 1500–2500 rpm

- · Mechanical injection and governor for stable control

- · Compact footprint and low auxiliary system complexity

- · Strong low‑to‑mid‑range torque for auxiliary duties

- · Field‑proven for marine gensets, pumps, and hydraulics

- · Designed for harsh ambient conditions

Marine and stationary applications for the F4L912 marine engine

As a marine auxiliary, the F4L912 is commonly specified for generator sets on cargo vessels, coastal workboats, fishing vessels, and passenger ships. Its air‑cooled concept eliminates the need for seawater coolers and reduces vulnerability to scaling or fouling, which is especially useful in warm, sediment‑rich waters. In offshore vessels and support craft, the F4L912 marine engine is often paired with hydraulic power units driving winches, capstans, cranes, or hatch covers, where dependable torque at controlled RPM is essential.

In stationary roles, the F4L912 diesel engine drives irrigation and fire pumps, compressors, and small power plants—tasks where continuous-duty reliability and low service complexity are decisive. Many operators standardize on the F4L912 Deutz diesel engine due to its long record of service, ease of maintenance, and global service familiarity.

Why the F4L912 is valued across fleets and facilities:

Its design prioritizes uptime. The air‑cooling system reduces ancillary equipment counts, there are no coolant leaks to manage, and the mechanical fuel system is straightforward to troubleshoot. The engine’s robust castings and wear components support long overhaul intervals when operated on the correct duty cycle and maintained with the right service parts. The result is predictable lifecycle cost and minimal downtime—key selection criteria for shipowners and plant operators alike.

OEM spare parts suitable for F4L912: performance, reliability, and service life

Using OEM spare parts suitable for F4L912 preserves the engine’s designed combustion quality, thermal behavior, and mechanical clearances. Precision‑matched pistons and liners, correctly profiled injection nozzles, and specification‑accurate valve train components keep efficiency and exhaust temperatures within intended limits. This directly supports dependable starts, steady load acceptance, and longer intervals between top‑end service events.

When it comes to repair planning, OEM spare parts suitable for F4L912 help standardize maintenance outcomes across a fleet. Consistent tolerances and materials result in predictable service procedures, shorter dock times, and better parts interchangeability—even across engines of different build years. For operators of the F4L912 marine engine in continuous duty, that consistency translates into reliable power availability and optimized total cost of ownership.

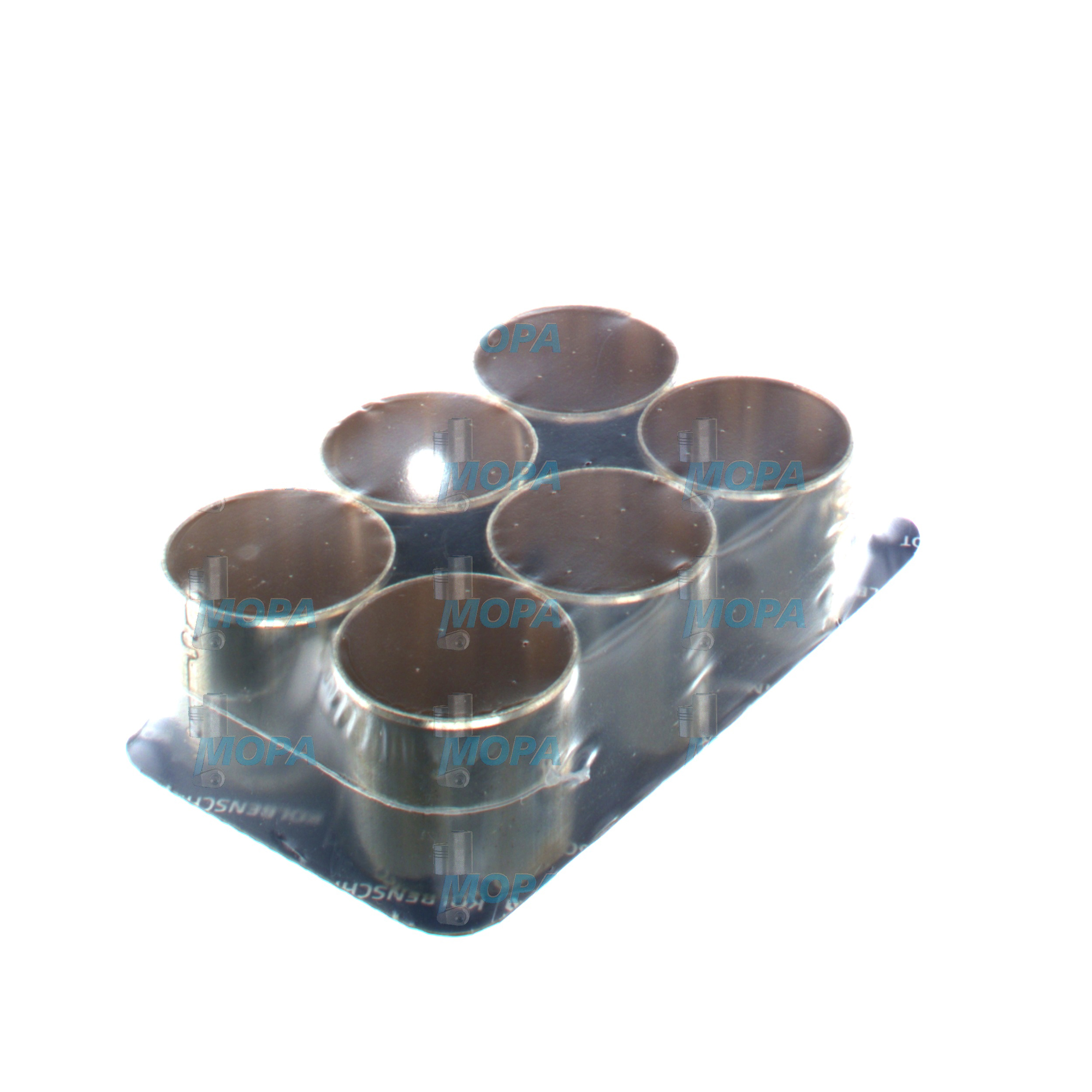

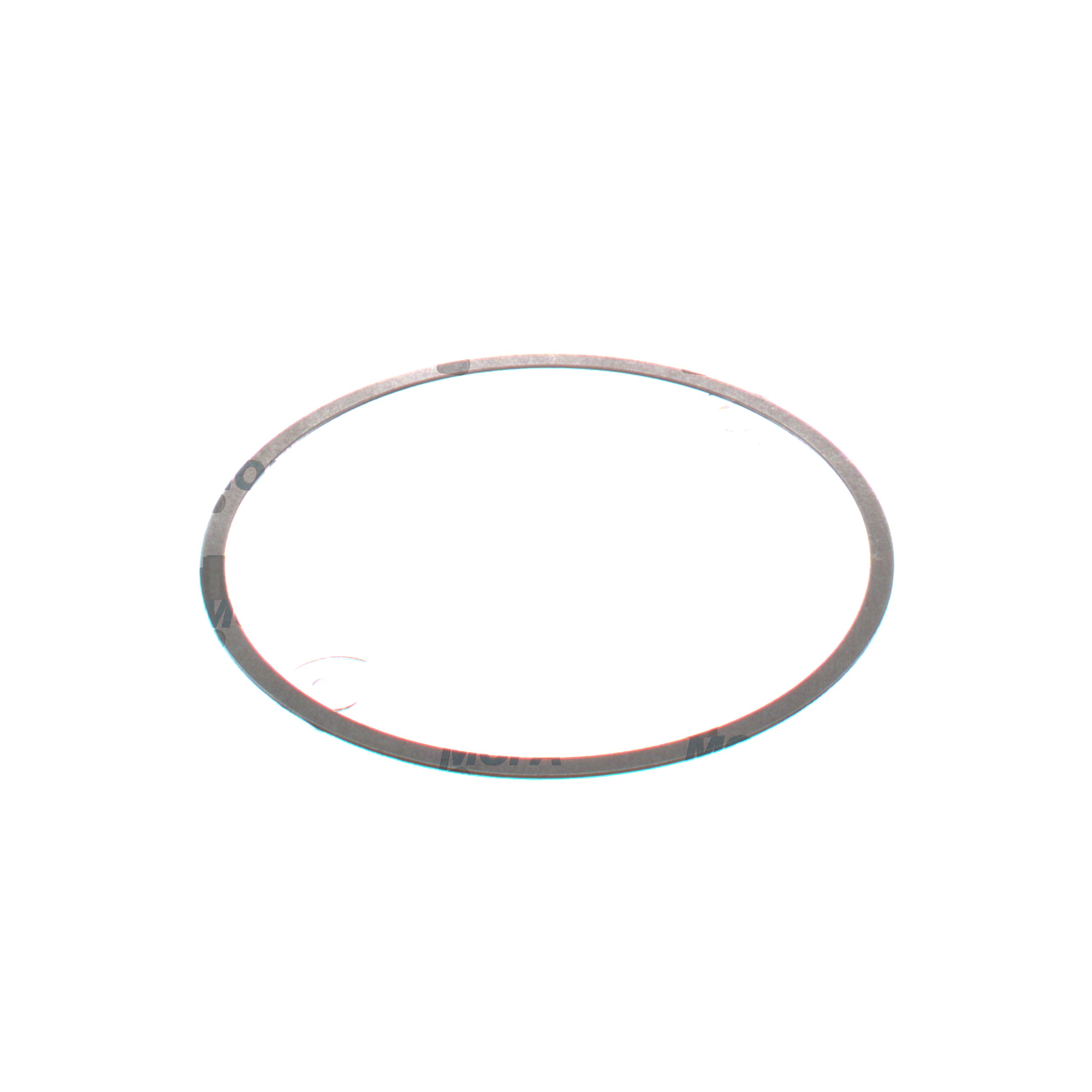

MOPA is a reliable partner for OEM spare parts suitable for F4L912. From F4L912 OEM parts such as pistons, cylinder barrels, and rings to injection elements, filters, gaskets, oil pumps, and cooling fan components, MOPA supports planned maintenance as well as urgent repair needs with technically compliant parts that align with Deutz specifications for the 912 series.

How F4L912 OEM parts sustain uptime

Fitting OEM spare parts suitable for F4L912 helps safeguard output, emissions stability, and long‑term durability—especially under marine loads where salt exposure, vibration, and variable duty cycles are the norm. Properly calibrated fuel system parts maintain injection timing and atomization, while correct metallurgy in wear components reduces scuffing, blow‑by, and unplanned tear‑downs. By keeping the engine within design tolerances, operators maintain consistent fuel consumption and power density across overhaul cycles.

Conclusion: F4L912 benefits with assured parts support

The F4L912 combines compact design, air‑cooled simplicity, and proven mechanical reliability—attributes that make it a frequent choice for marine auxiliaries, deck equipment, and stationary power. For decision‑makers, it offers dependable performance with straightforward service routines.

MOPA supplies OEM spare parts suitable for F4L912, supporting performance, reliability, and service life across the full operating envelope. With the right components and a disciplined maintenance plan, the F4L912 Deutz diesel engine remains a sound investment for fleets and facilities worldwide.