F6L912 air‑cooled diesel engine for demanding marine and stationary duty

The F6L912 is a six‑cylinder, air‑cooled diesel built for hard, continuous service where uptime and fuel efficiency matter most. Part of the Deutz 912 lineage, the focus here is the F6L912 itself: a robust inline‑six that earned its reputation through mechanical simplicity, clean combustion, and dependable power delivery across a wide speed range. Whether driving a marine genset, powering hydraulic equipment on deck, or running a land‑based pump or compressor, the F6L912 combines compact dimensions with exceptional durability.

Known among shipowners and plant operators for its straightforward serviceability, the F6L912 relies on proven direct‑injection technology and a mechanically governed fuel system that thrives in harsh environments. The air‑cooled design eliminates the vulnerability of raw‑water circuits and heat exchangers in marine applications, making the engine a practical choice for vessels operating in silty, icy, or debris‑laden waters.

F6L912 technical profile and performance

The F6L912 Deutz diesel engine is an inline six with air cooling, direct injection, and naturally aspirated breathing (typical configurations). It delivers steady torque at low to mid speeds and maintains efficiency under continuous loads—ideal for auxiliary power generation and propulsion on smaller workboats. Typical factory ratings vary by build and emissions calibration, but the following data reflects common specifications seen in fielded units:

Key technical data (typical)

• Configuration: Inline‑6, air‑cooled, 4‑stroke, direct injection

• Displacement: approx. 5.7 L (bore x stroke around 100 x 120 mm)

• Power output: roughly 60–95 kW (80–128 hp) depending on rating

• Rated speed: common settings from 1500 to 2300 rpm

• Fuel system: mechanical in‑line injection with mechanical governor

• Aspiration: naturally aspirated (most F6L912 builds)

• Lubrication: full‑flow oil filtration, gear‑driven pump

• Cooling: finned cylinder barrels and heads with high‑capacity air flow

In marine contexts, the F6L912 Deutz marine engine is frequently configured for continuous duty at 1500 or 1800 rpm for gensets, providing stable frequency output, long service intervals, and predictable fuel burn. As a propulsion prime mover in modest displacement craft, its flat torque curve supports maneuvering and bollard‑pull tasks with confidence. In stationary roles, the F6L912 diesel engine powers compressors, irrigation pumps, fire pumps, and industrial generators—applications that reward the model’s endurance under steady‑state loads.

- · Six cylinders for smooth operation and low vibration.

- · Air‑cooled design removes raw‑water failure risks at sea.

- · Mechanical simplicity; easy field service and diagnostics.

- · Strong low‑end torque for auxiliary and propulsion duties.

- · Proven fuel efficiency in continuous‑duty operation.

- · Compact footprint for tight engine rooms and skid units.

- · Widely supported F6L912 OEM parts and service expertise.

Where the F6L912 excels: marine and stationary applications

The F6L912 is valued by operators because it blends rugged construction with consistent output and predictable lifecycle costs. In shipping, typical deployments include:

• Cargo vessels: auxiliary gensets, hydraulic power packs, deck machinery drives.

• Passenger ships and ferries: emergency and harbor gensets, bilge/fire pumps.

• Offshore and workboats: winches, capstans, pumps, and compact propulsion on smaller units.

• Fishing vessels: reliable ship service power and refrigeration compressors.

On land, the same attributes make the F6L912 a reliable prime mover for power plants (island or standby), agricultural irrigation systems, construction compressors, and municipal emergency sets. Operators prize the engine’s resilience against cooling‑system contamination and its ability to maintain rated output in dusty, saline, or thermally challenging environments. For procurement teams, the availability of F6L912 OEM parts simplifies lifecycle planning and reduces unplanned downtime risks.

Why operators choose the F6L912 Deutz marine engine

Unlike liquid‑cooled alternatives, the F6L912 minimizes failure points related to heat exchangers, raw‑water pumps, and seawater corrosion. Its mechanical fuel system tolerates variable fuel quality better than many electronically controlled designs, and the air‑cooled architecture accelerates warm‑up while stabilizing operating temperatures. The net result is a workhorse that delivers dependable power at a competitive specific fuel consumption in continuous duty.

For fleets standardizing on the Deutz 912 platform, the F6L912 streamlines crew training and spare‑parts holdings, enabling efficient maintenance across mixed assets. The model’s long global track record translates into predictable service routines and an established supply chain for the F6L912 OEM parts needed to keep engines on spec.

OEM spare parts suitable for F6L912: maximize performance, reliability, and service life

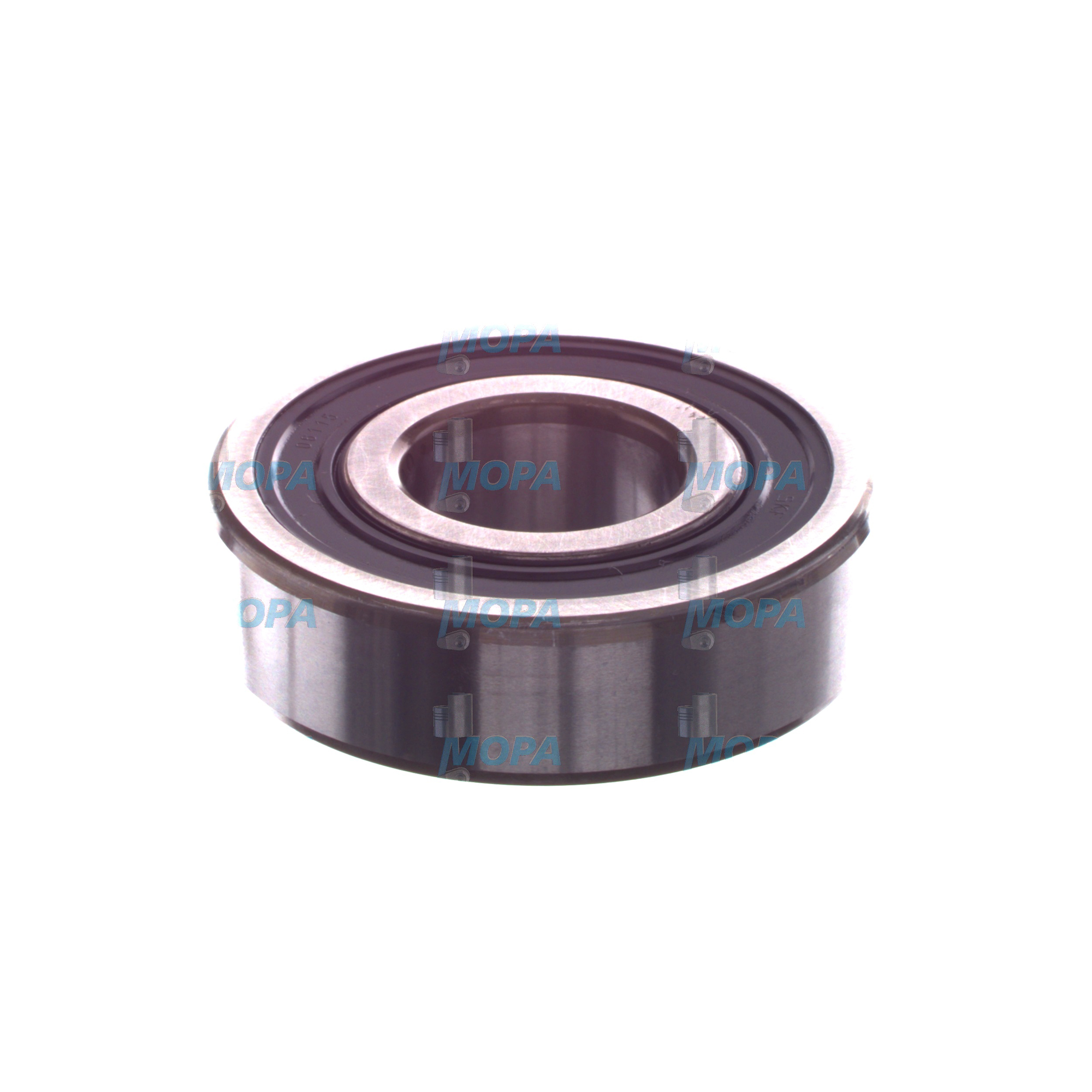

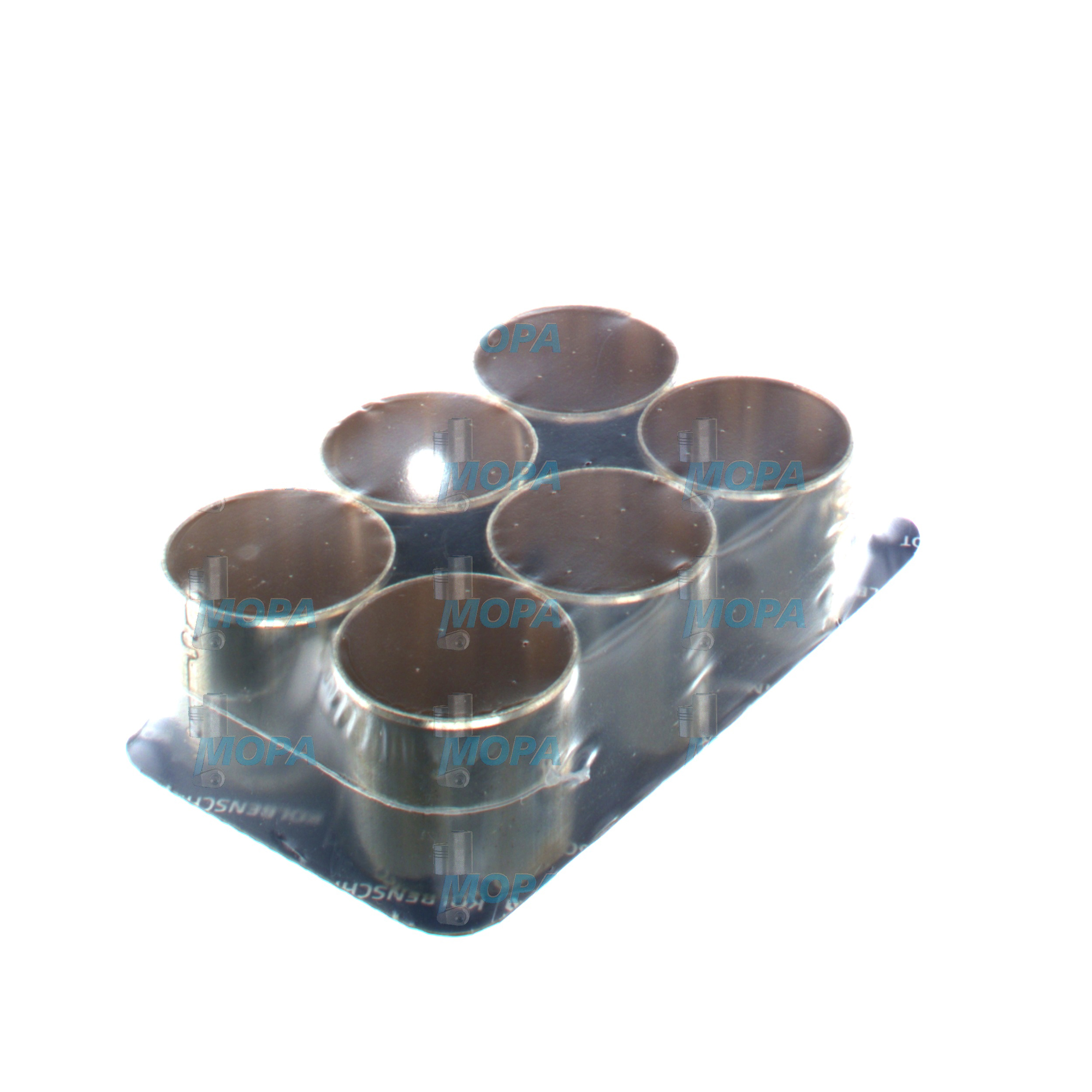

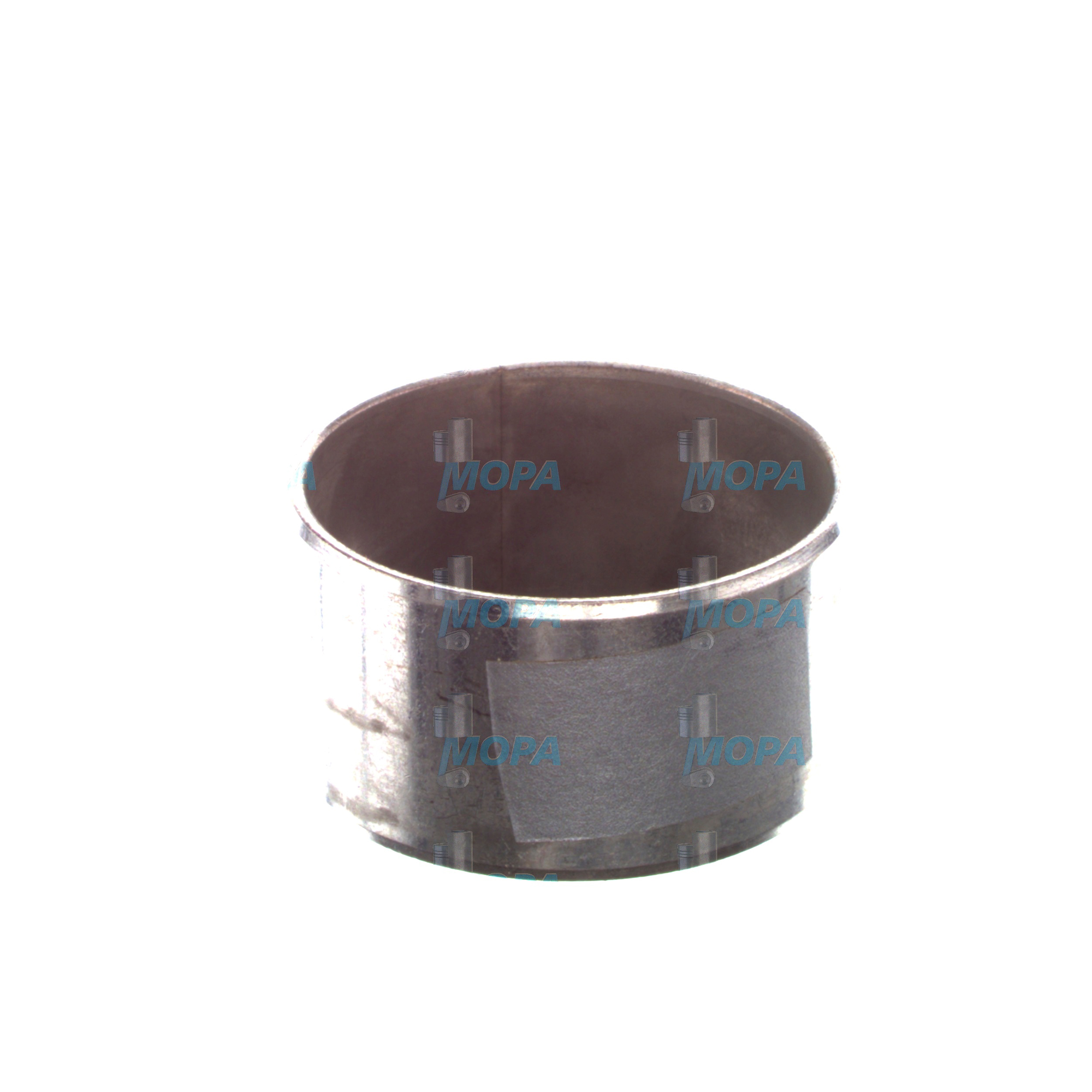

To fully realize the engineering intent of the F6L912, components must match the engine’s dimensional tolerances, materials, and calibration settings. OEM spare parts suitable for F6L912 safeguard combustion quality, oil control, thermal stability, and timing precision across long operating intervals. Precision‑matched pistons and rings preserve compression, correctly honed cylinder barrels manage heat transfer, and validated injection components sustain atomization and timing—preventing power loss and reducing fuel penalties.

Using OEM spare parts suitable for F6L912 helps maintain consistent vibration levels and bearing loads, preserving crankshaft and camshaft alignment while protecting ancillary equipment such as alternators, hydraulic pumps, and clutches. For marine service in particular, correct sealing elements, fasteners, and elastomers resist chemical exposure and temperature cycling, cutting the risk of unplanned stoppages.

MOPA is a reliable partner for OEM spare parts suitable for F6L912. From fuel‑system elements, cylinder‑head components, and valve‑train parts to gaskets, filters, and sensors, MOPA supports procurement with technical clarity, traceable sourcing, and responsive logistics—so maintenance windows are met and class surveys proceed without delay.

- · OEM spare parts suitable for F6L912 maintain factory performance.

- · Tight tolerances protect fuel efficiency and emissions levels.

- · Correct materials improve thermal and wear resistance.

- · Reliable fit reduces installation time and rework.

- · MOPA ensures timely availability and expert part selection.

Conclusion: F6L912 value and assured spare‑parts supply

The F6L912 stands out for air‑cooled simplicity, dependable torque, and proven durability in both marine and stationary roles. Its balance of power density and serviceability makes it a preferred choice for operators who demand reliable, efficient output in challenging conditions.

MOPA supports owners and procurement teams with OEM spare parts suitable for F6L912, enabling consistent performance and long service life across the Deutz 912 fleet. Talk to MOPA to secure the components that keep every F6L912 operating to specification.