D2840LE marine diesel engine for demanding propulsion and power generation

The D2840LE stands out as a robust V10 platform renowned for dependable power delivery, long service life, and consistent efficiency across marine and stationary duties. While it belongs to the MAN D D2840 series, the engineering focus and practical advantages of the D2840LE itself make it a preferred choice for operators who require a compact high-output configuration without compromising reliability.

As a high-speed four-stroke diesel, the D2840LE combines strong torque characteristics with efficient fuel consumption, enabling precise load response for propulsion and generator applications. Its balance of output, durability, and maintainability has made the D2840LE a fixture on commercial vessels and in industrial installations where uptime is mission-critical.

Technical profile of the D2840LE MAN D marine diesel engine

The D2840LE is a 10-cylinder, 90-degree V-configuration diesel engine engineered for marine propulsion and auxiliary power as well as stationary power generation. Typical configurations are turbocharged and charge‑air cooled, designed to sustain continuous duty under variable sea states and ambient conditions.

Key technical characteristics commonly associated with the D2840LE include:

- · V10, four-stroke, direct-injection layout for compact power density

- · Turbocharged with charge-air cooling to stabilize intake temperatures

- · Displacement in the ~18–20 L class, optimized for mid- to high-speed duty

- · Typical speed range 1,500–2,100 rpm depending on rating and application

- · Power outputs commonly spanning roughly 300–735 kW (continuous to intermittent ratings)

- · Closed-circuit freshwater cooling with heat exchanger or keel cooling options

- · Robust lubrication system with high-capacity oil filtration for extended service intervals

- · Mechanical governor configurations widespread, with options for electronic control on some variants

This combination delivers excellent load acceptance and steady-state efficiency, making the D2840LE diesel engine a strong candidate where predictable lifecycle costs and straightforward maintenance are priorities. The engine’s architecture supports both direct propulsion (gearbox-coupled to fixed or controllable-pitch propellers) and generator-drive applications where frequency stability is crucial.

D2840LE applications in shipping and stationary operations

Because of its torque curve and proven hardware, the D2840LE MAN D marine engine is frequently selected for:

- · Coastal cargo vessels and small bulkers requiring reliable continuous power

- · Passenger ferries and workboats where fast throttle response improves maneuverability

- · Offshore support vessels, crew transfer vessels, and patrol craft demanding dependable acceleration

- · Fishing vessels operating long hours with fluctuating loads

- · Marine gensets (harbor power, hotel loads, DP systems)

- · Stationary generator sets for industrial sites and remote power plants

- · Firefighting pumps, dredging equipment, and auxiliary machinery

Operators value the D2840LE for its balance of compact size and output, supported by widely available D2840LE OEM parts and established service know-how. In propulsion roles, the engine’s steady fuel mapping helps maintain predictable consumption per nautical mile. In generator duties, its rotational stability and governor response aid frequency control under step-load conditions.

Why the D2840LE is trusted: performance, efficiency, and serviceability

For shipowners and technical managers, the D2840LE combines high specific output with a service-friendly design. Cylinder-bank accessibility, conventional fuel-injection hardware, and standardized wear components simplify overhauls and planned maintenance. The engine’s cooling and lubrication circuits are engineered for thermal stability, supporting long oil life and consistent bearing protection during continuous operation.

The following points summarize why procurement teams and superintendents frequently shortlist the D2840LE MAN D diesel engine:

- · Proven V10 platform with strong parts availability

- · Predictable lifecycle costs across typical duty cycles

- · Good power-to-weight ratio for space-limited engine rooms

- · Stable frequency control in genset configurations

- · Tuned for marine loads and harsh operating environments

- · Supported by D2840LE OEM parts and technical documentation

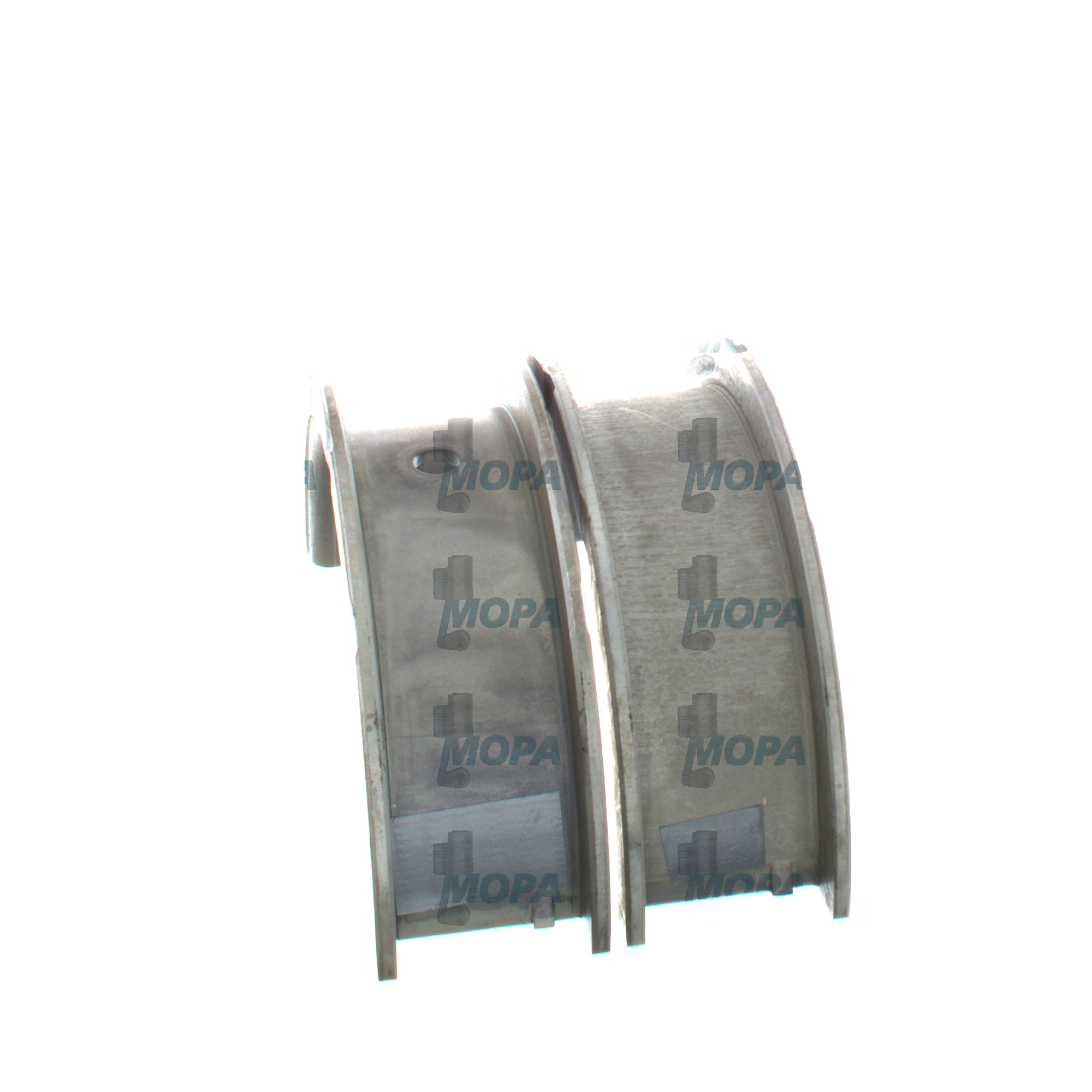

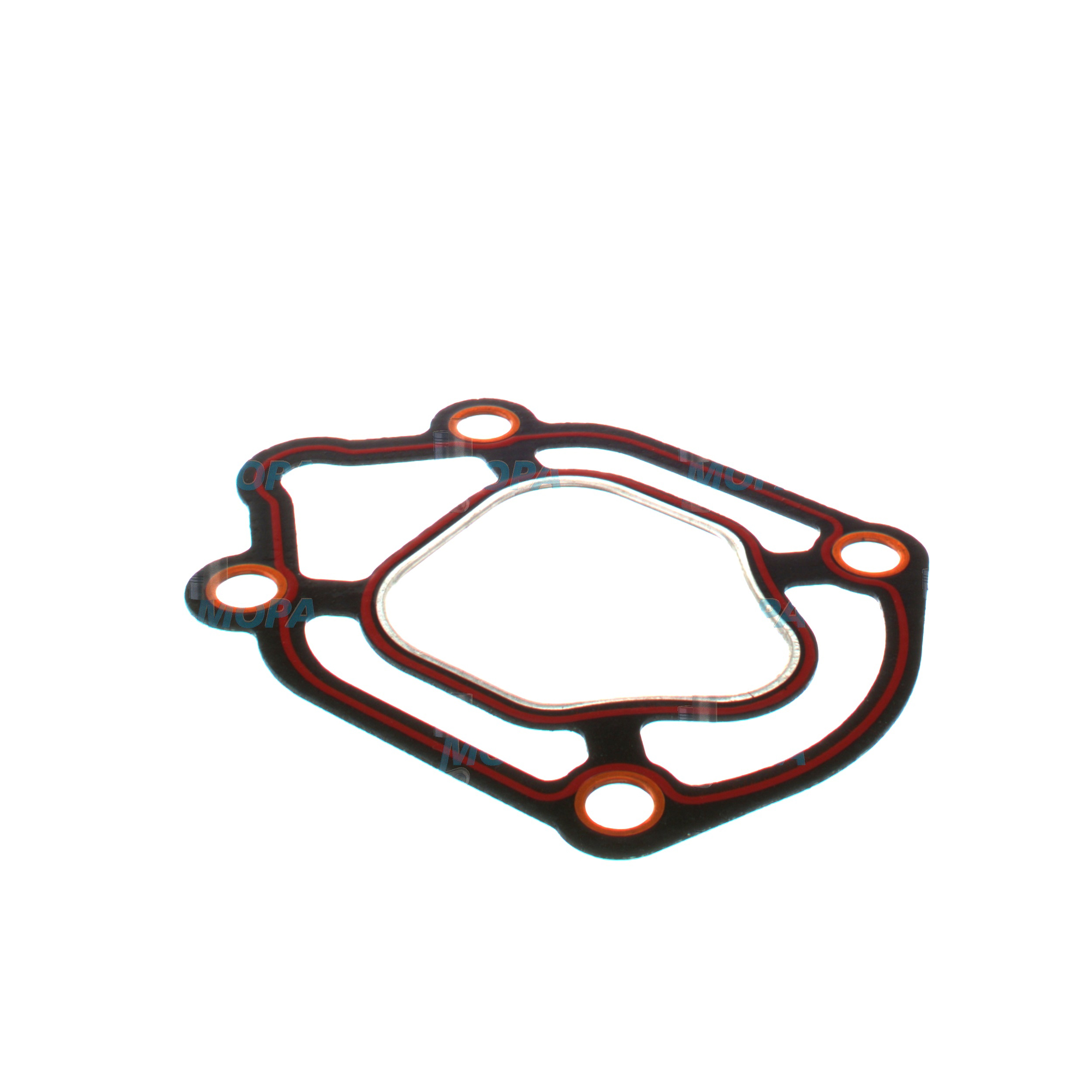

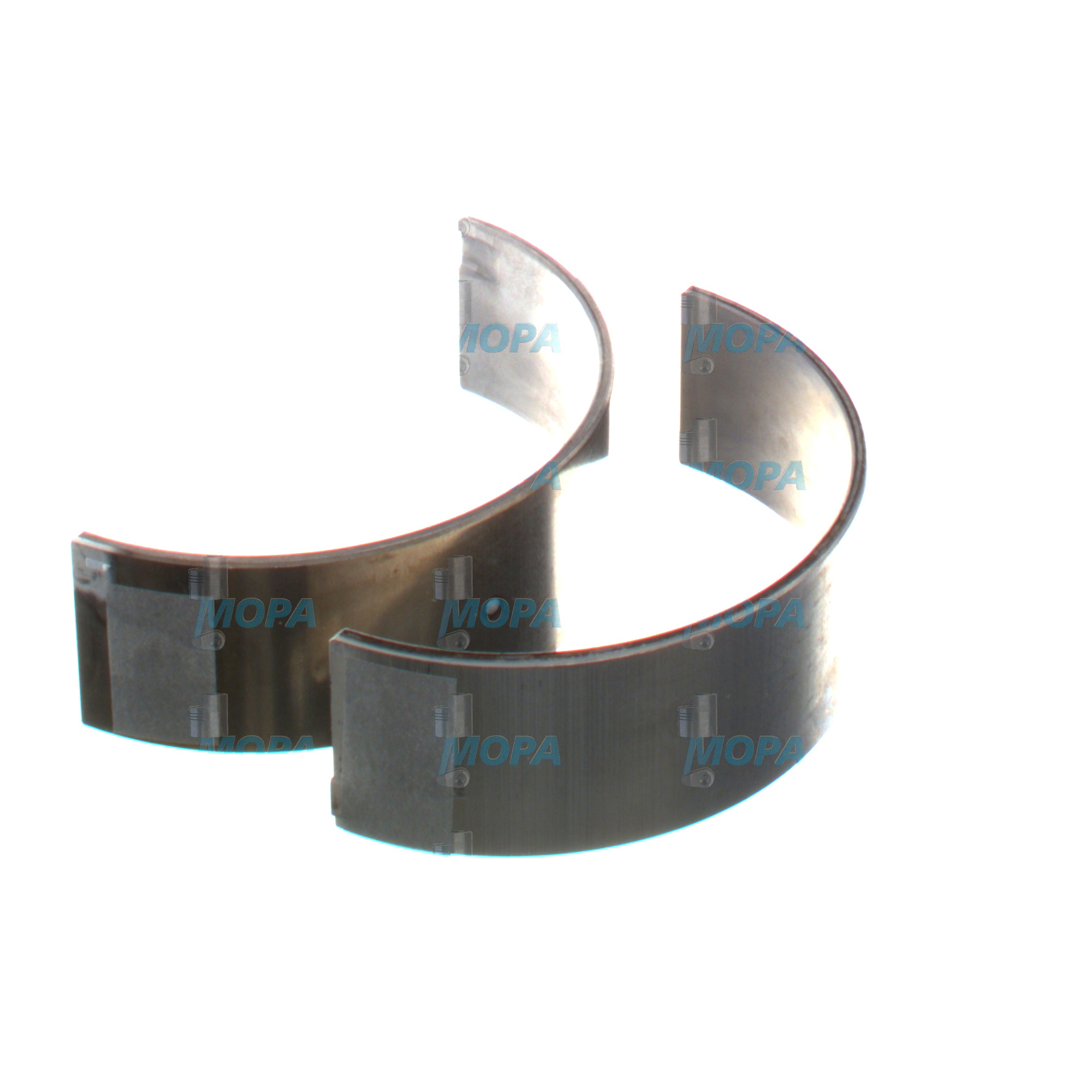

OEM spare parts suitable for D2840LE: reliability, longevity, and compliance

Maintaining peak performance and safeguarding service life starts with using OEM spare parts suitable for D2840LE. Dimensional accuracy, material specifications, and validated production processes directly influence combustion quality, heat rejection, and mechanical durability. From pistons, liners, and rings to bearings, injectors, high-pressure pumps, turbochargers, water pumps, oil pumps, charge‑air cooler cores, gaskets, and sensors, each component must match the engine’s design intent to preserve output, fuel economy, and emissions compliance.

Key advantages delivered by OEM spare parts suitable for D2840LE include:

- · Consistent tolerances that maintain compression and injection timing

- · Correct metallurgy and surface treatments for extended wear resistance

- · Validated fit-up that reduces installation time and rework risk

- · Stable performance over long maintenance cycles

- · Documentation and traceability that support audits and class requirements

For technical decision-makers, these factors translate into higher availability, fewer unplanned stoppages, and more predictable overhaul scheduling. Using OEM spare parts suitable for D2840LE also helps sustain the engine’s baseline efficiency, protecting specific fuel oil consumption and keeping exhaust parameters within intended thresholds.

MOPA is a reliable partner for OEM spare parts suitable for D2840LE. Procurement teams benefit from expert parts identification, cross-referencing by engine number and build list, and rapid logistics to minimize vessel downtime. Whether you require complete top-end kits, fuel-system components, or rotating equipment for the D2840LE MAN D marine engine, MOPA streamlines sourcing and supports fleet standardization.

Service insights for the D2840LE MAN D diesel engine

Effective maintenance planning is essential to extract the full value of the D2840LE. Many operators align oil and filter changes with fuel-in-rotation cycles (often within 250–500 operating hours, depending on fuel quality and duty). Periodic condition monitoring—oil analysis, borescope inspections, injector and turbocharger checks—helps anticipate top-end work and keep the engine within target performance. Ensuring clean charge air, correct cooling mixture, and accurate governor settings protects bearings, valves, and turbo machinery across long service intervals.

Conclusion: the D2840LE advantage with dependable parts availability

The D2840LE delivers a compelling mix of power density, reliability, and serviceability for marine propulsion and stationary generation. Its proven V10 platform, efficient turbocharged design, and stable operation make it a smart choice for fleets focused on predictable lifecycle performance.

To keep the D2840LE operating at its best, rely on OEM spare parts suitable for D2840LE. MOPA supports purchasers and shipowners with fast, knowledgeable supply of OEM spare parts suitable for D2840LE, helping you sustain uptime and performance across your vessels and installations.