12V331TC81 MTU marine engine: performance, applications, and OEM parts

The 12V331TC81 sets a benchmark in its class for robust propulsion and auxiliary power. Belonging to the MTU 331 series, this 12‑cylinder V‑configuration diesel engine is widely recognized by shipowners and operators for its dependable service in demanding maritime and stationary environments. While the MTU and 331 series context is valuable, the focus here is the 12V331TC81 itself—its architecture, operating characteristics, and why decision‑makers continue to specify the 12V331TC81 for long‑term, heavy‑duty use.

12V331TC81 technical characteristics and MTU diesel engine applications

The 12V331TC81 is a four‑stroke, turbocharged compression‑ignition engine engineered for consistent output and high torque across a practical operating band. With 12 cylinders arranged in a compact V, the engine delivers a strong power‑to‑size ratio suited to hulls and machinery rooms where footprint and service access are critical. Typical duty settings place the 12V331TC81 in the medium‑speed range around 1,000–1,500 rpm (application‑dependent), enabling efficient propulsion and steady auxiliary performance.

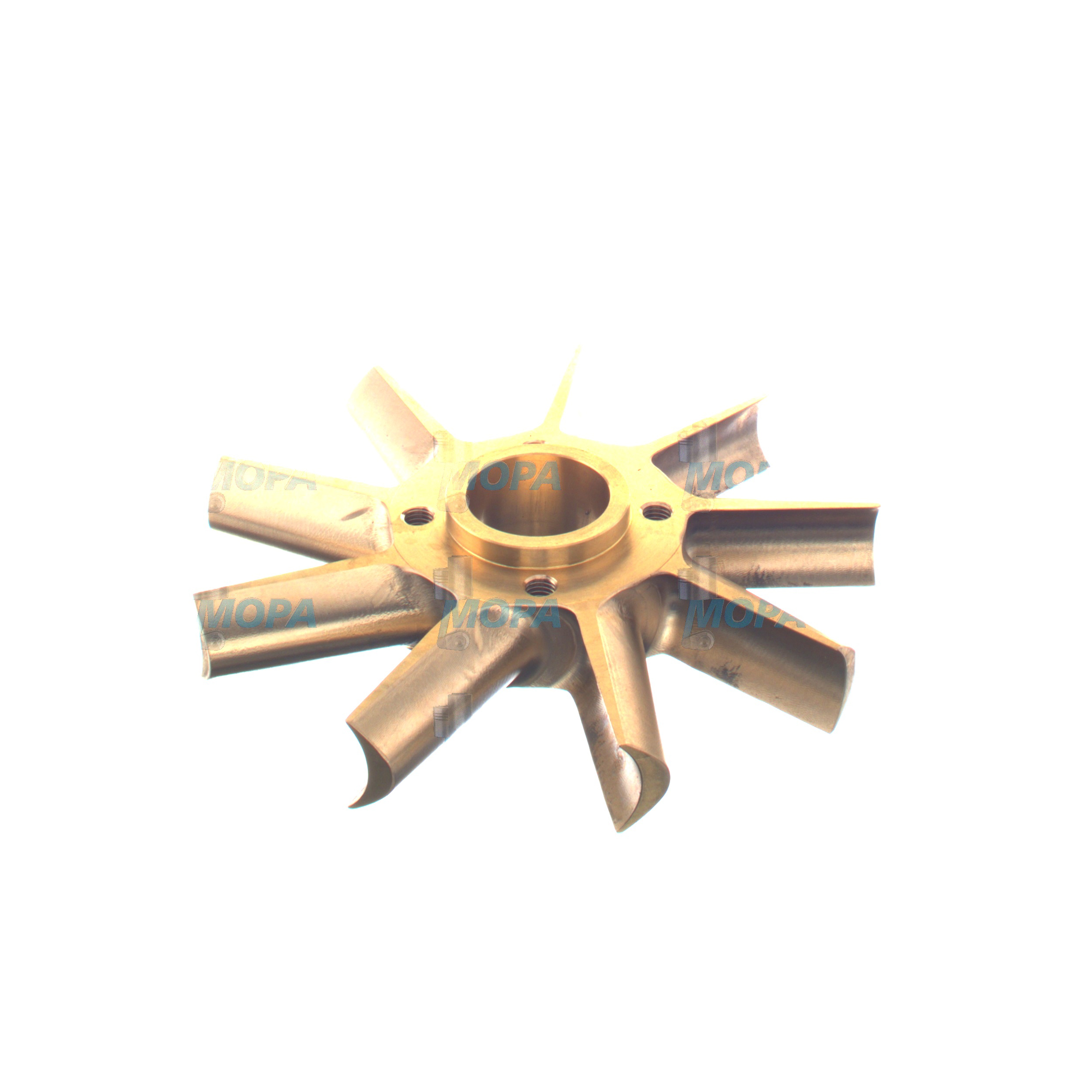

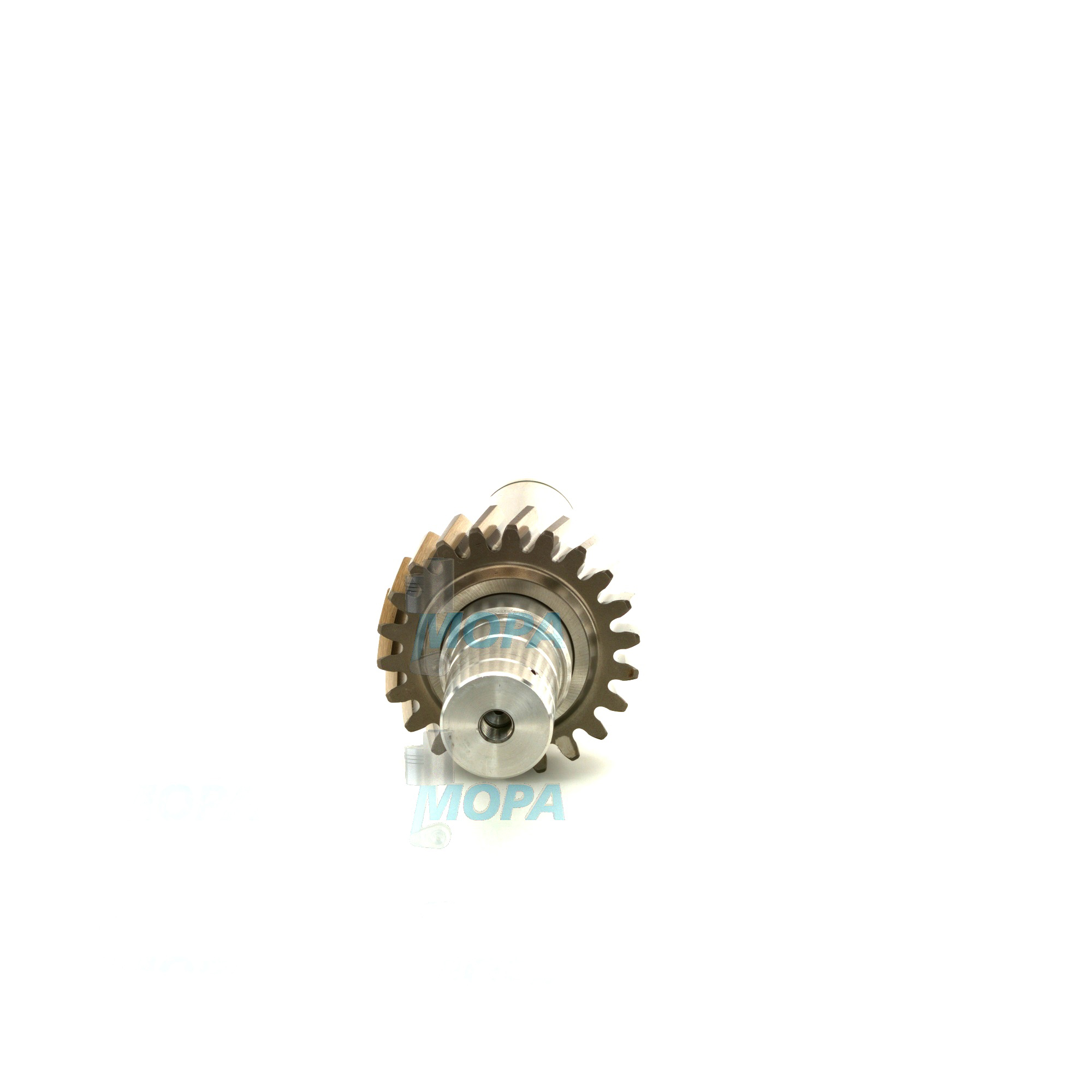

Core design features include a heavy‑duty crankcase, replaceable wet liners, and individual cylinder heads that simplify overhaul planning. Turbocharging and efficient charge‑air management support clean combustion, stable load acceptance, and fuel economy under continuous operation. Mechanical governing is common in legacy installations, while modernized packages may interface with electronic monitoring for condition‑based insights. Lubrication, cooling, and fuel systems are gear‑driven for reliability, and the modular layout helps minimize downtime during planned maintenance.

Where the 12V331TC81 excels is in real‑world use. As an MTU marine engine, it is regularly deployed for propulsion on workboats, cargo vessels, inland barges, and passenger ferries, where predictable torque and responsive load pickup matter during maneuvers. In offshore vessels and harbor craft, the 12V331TC81 diesel engine provides dependable bollard pull characteristics and resilience under cyclic loading. Stationary roles are equally common: shipboard auxiliary gensets, shoreside power generation, and industrial drives for pumps or compressors all benefit from the engine’s steady‑state efficiency and serviceable design.

Output ratings for the 12V331TC81 vary by configuration (propulsion vs. generator set, continuous vs. intermittent duty), making it essential to match the specific rating to the vessel profile or site load. Regardless of duty, the platform’s reputation is built on durability, parts availability, and long‑term operating economy. This consistency explains why the 12V331TC81 MTU marine engine remains in active fleets and is frequently selected for refits where proven hardware and predictable lifecycle costs are decisive.

Key characteristics and advantages of the 12V331TC81

· 12‑cylinder V configuration; four‑stroke, turbocharged diesel engine.

· Medium‑speed operating band around 1,000–1,500 rpm (duty‑specific).

· High continuous torque for propulsion and auxiliary drives.

· Individual cylinder heads and wet liners for streamlined overhauls.

· Stable load acceptance; efficient charge‑air management.

· Proven in cargo vessels, ferries, offshore units, and stationary gensets.

· Broad ecosystem of 12V331TC81 OEM parts to support lifecycle performance.

Why operators value the 12V331TC81 MTU marine engine

Operators appreciate the 12V331TC81 for its balance of reliability, maintainability, and fuel efficiency. The engine’s conservative mechanical design withstands harsh marine environments, including frequent docking cycles, variable sea states, and high ambient temperatures. Integration with common marine gearboxes is straightforward, while the compact V layout eases installation in constrained machinery spaces. For stationary power, the engine’s steady‑state efficiency and predictable service intervals make it a practical choice for base‑load and standby configurations.

When fleets standardize on the 12V331TC81, they also gain logistical advantages: trained crews, repeatable maintenance routines, and streamlined stocking of critical consumables and rotating components. The result is fewer unplanned stoppages and a clearer total cost of ownership profile over multiyear horizons.

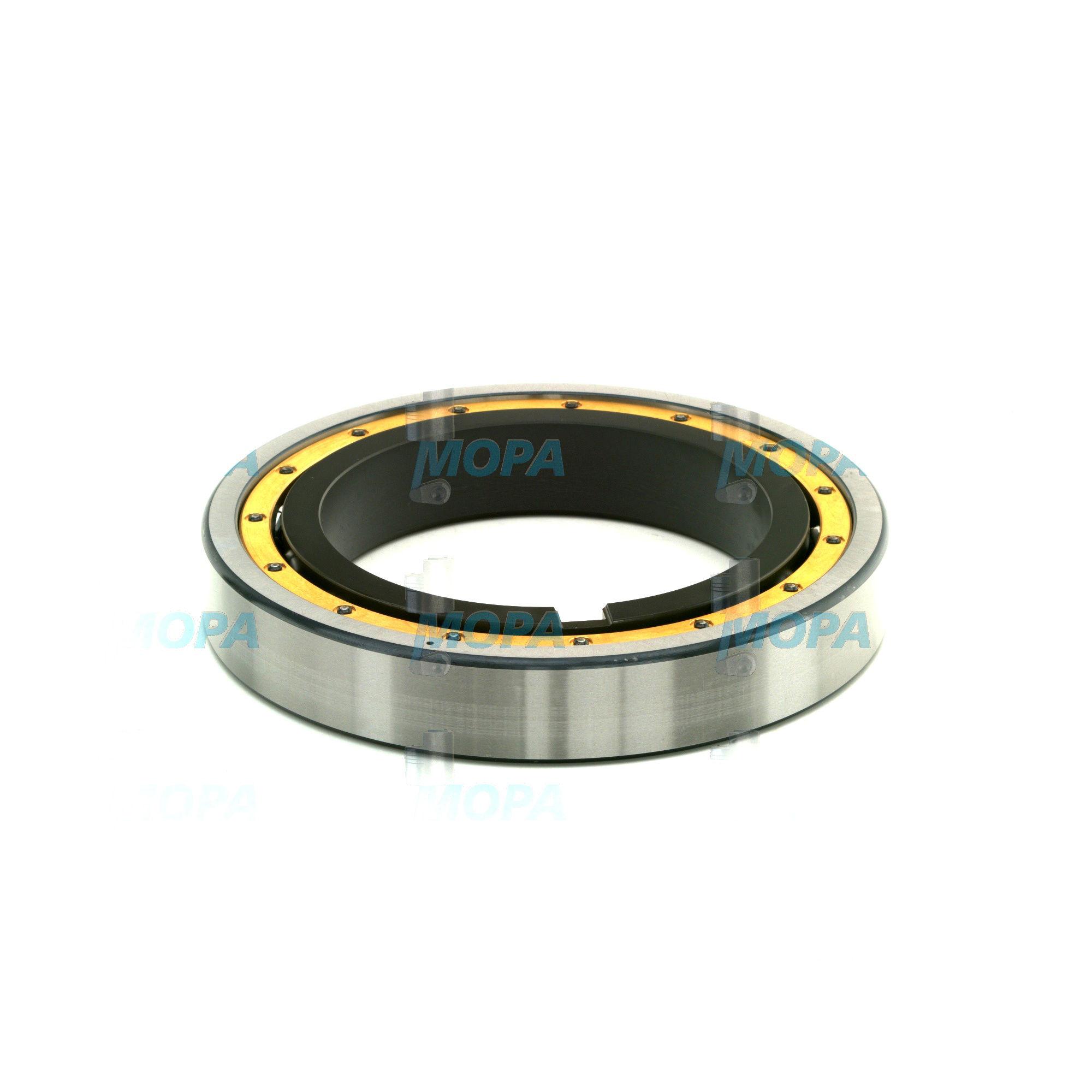

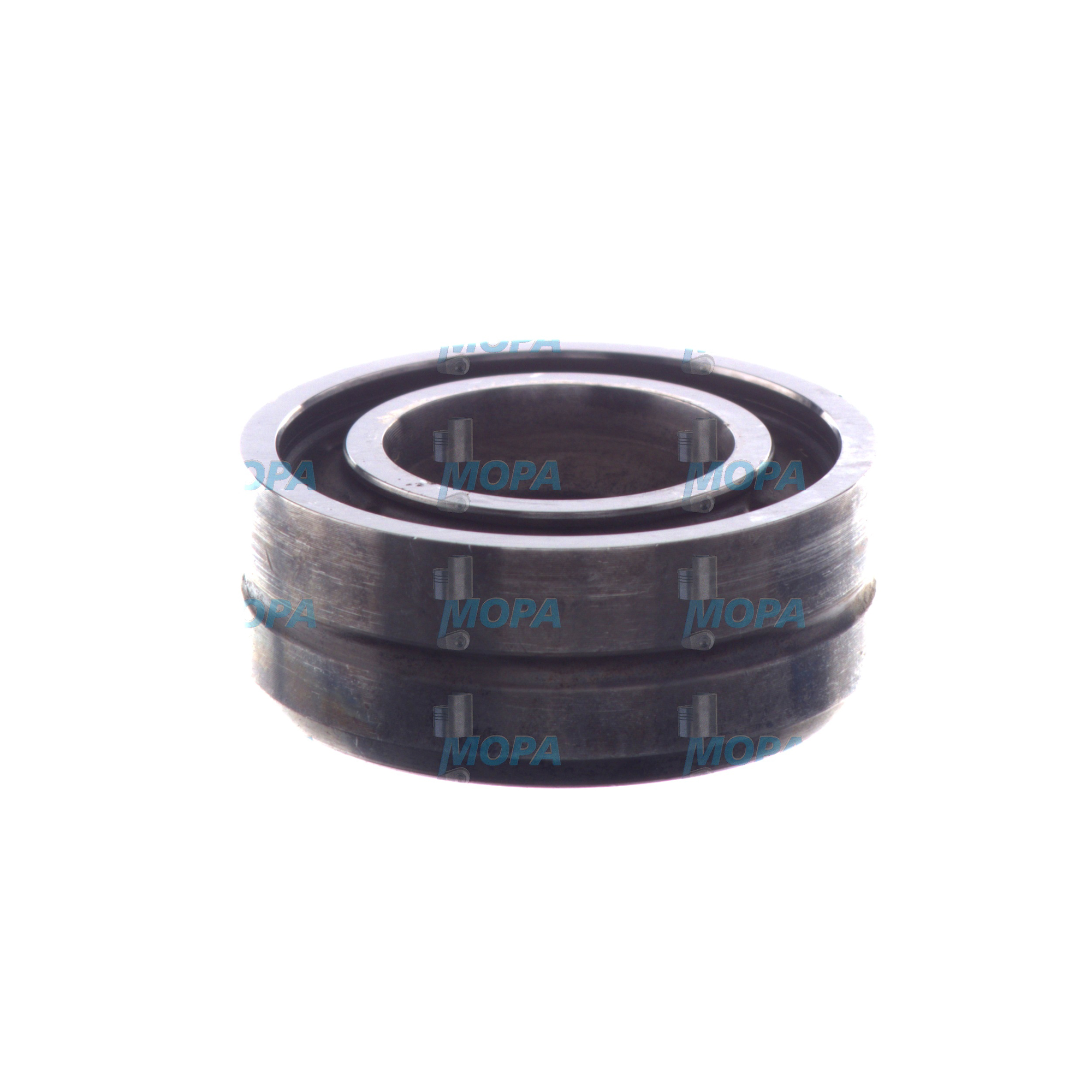

OEM spare parts suitable for 12V331TC81: maximize performance and uptime

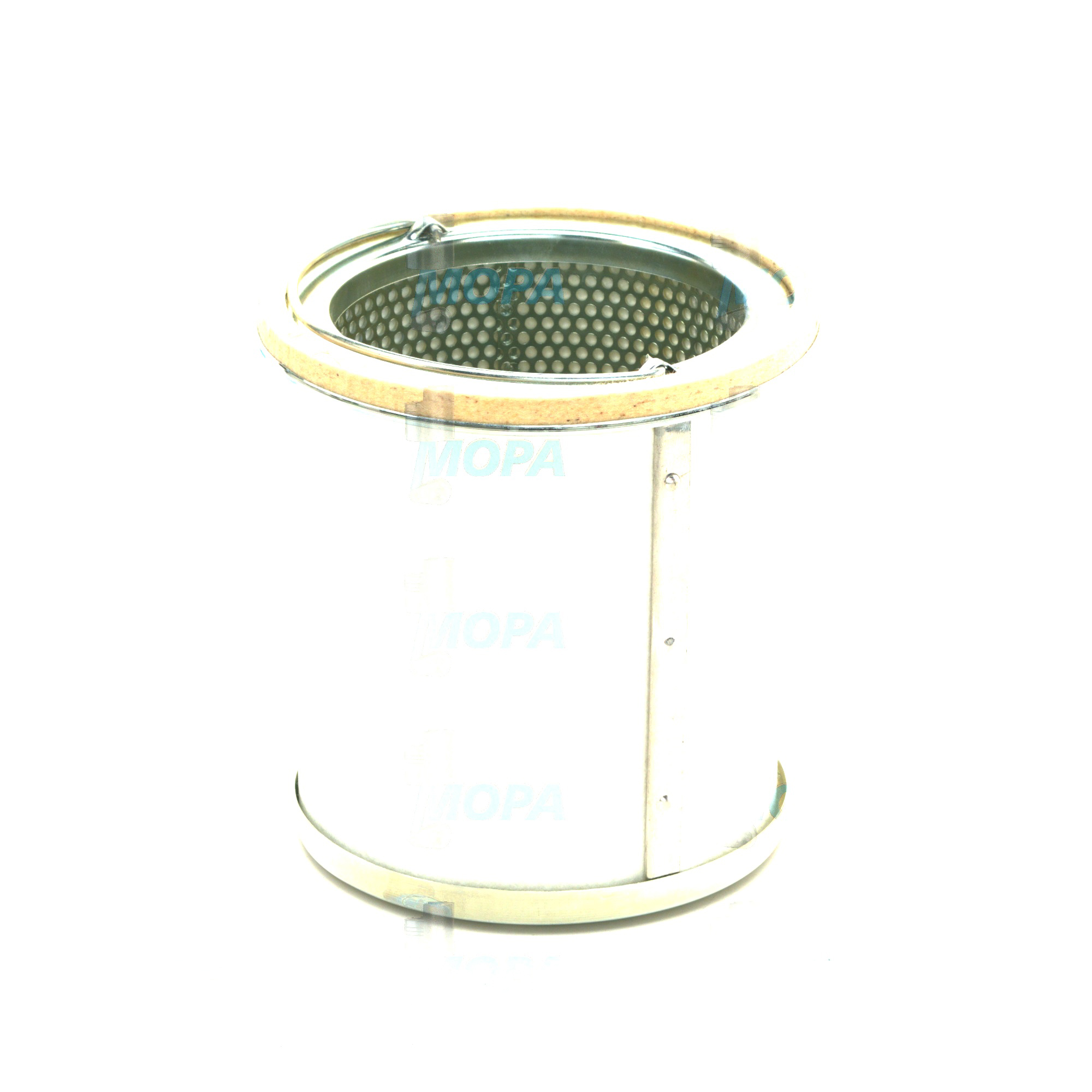

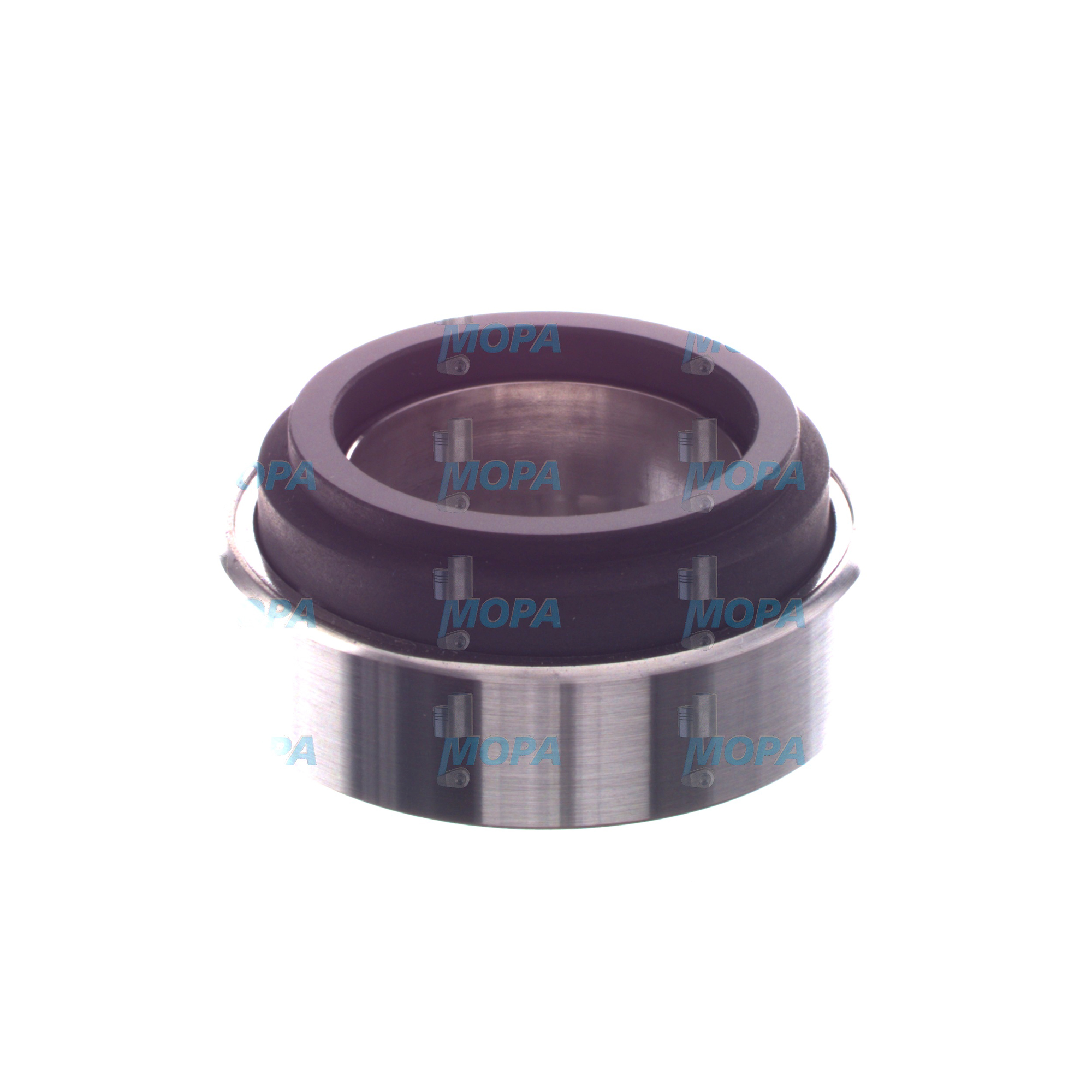

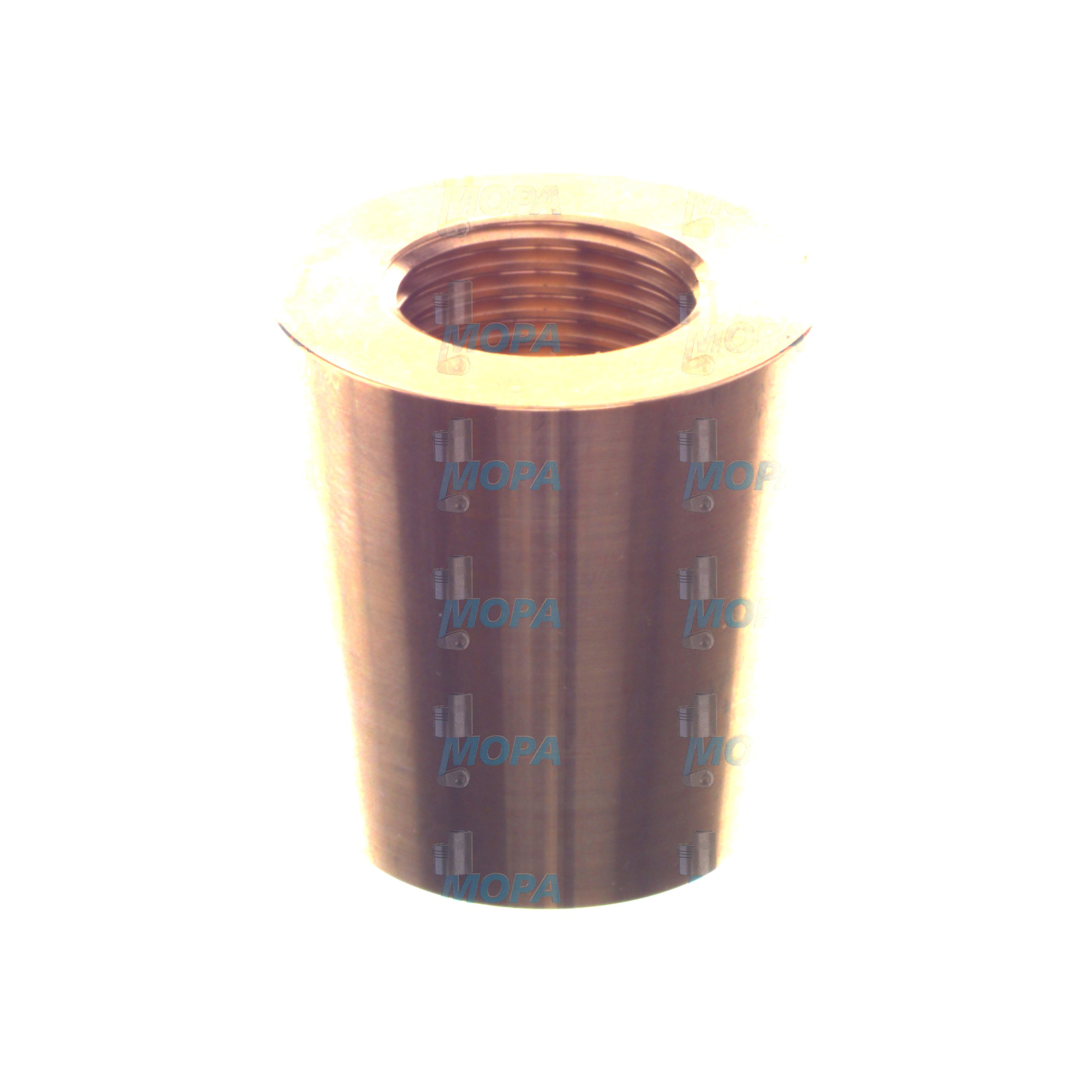

For dependable operation, OEM spare parts suitable for 12V331TC81 are essential. Precision‑matched components preserve clearances, surface finishes, and material compatibilities established by the engine’s design. This alignment safeguards core performance metrics—combustion efficiency, oil control, vibration behavior, and thermal stability—across full and partial loads. Typical high‑impact parts include pistons and rings, cylinder liners, main and rod bearings, fuel injection equipment, turbocharger components, cooling and lube system pumps, sealing sets, filters, and sensors.

Using OEM spare parts suitable for 12V331TC81 helps maintain consistent outputs and smooth transients, which is crucial for propulsion and for generator applications where frequency stability under step loads is critical. It also supports extended service life by reducing premature wear, preventing imbalance in rotating assemblies, and minimizing the risk of cascading failures after a single component deviation. Importantly, parts traceability and documentation aid compliance with maintenance schedules and class requirements on board.

MOPA is a reliable partner for OEM spare parts suitable for 12V331TC81. Procurement teams benefit from responsive sourcing, complete documentation, and kitting options tailored to minor, intermediate, and major overhauls. With global logistics capabilities, MOPA helps ensure that time‑critical components reach shipyards, ports, or power plants on schedule, reducing laytime and safeguarding operational commitments.

What to prioritize when sourcing OEM spare parts suitable for 12V331TC81

· Match parts to the exact engine designation and serial scope.

· Align components with duty rating (propulsion, auxiliary, or stationary).

· Plan kits around measured wear (liners, pistons, bearings, injector nozzles).

· Replace sealing sets and fastening hardware during every major opening.

· Refresh cooling, lube, and fuel filtration to protect high‑value assemblies.

· Coordinate delivery windows with dry‑dock or port calls to minimize downtime.

Conclusion: 12V331TC81 MTU diesel engine and OEM parts supply

The 12V331TC81 stands out as a durable, efficient MTU diesel engine for marine propulsion and stationary power, valued for its torque characteristics, maintainable design, and long service life. Keeping the engine at peak performance is best achieved with OEM spare parts suitable for 12V331TC81 to preserve reliability and efficiency across operating profiles. MOPA supports operators with a dependable supply of OEM spare parts suitable for 12V331TC81, helping fleets and facilities stay on schedule with confidence.