8V396TE54 marine diesel engine: performance profile and applications

The 8V396TE54 is a proven V8 marine diesel engine renowned for dependable output, compact dimensions, and long service life in demanding duty profiles. While it belongs to MTU’s established 396 series, decision‑makers typically choose the 8V396TE54 for its specific balance of power density, fuel efficiency, and serviceability that suits a wide spectrum of propulsion and generator set roles at sea and on shore.

Built for continuous operation and fast load acceptance, the 8V396TE54 combines a rugged base engine with optimized turbocharging and charge‑air cooling. For fleet owners and plant operators seeking predictable lifecycle costs, this model delivers a reliable foundation for technical availability, whether installed as a propulsion prime mover or as a highly responsive genset driver.

8V396TE54 technical characteristics and performance

As a V8 configuration within the MTU 396 platform, the 8V396TE54 is a four‑stroke, turbocharged and charge‑air‑cooled diesel engine engineered for consistent output under variable load. Typical attributes of this class include direct fuel injection with a precision governor, a pressurized lube system with high‑capacity filtration, and a resilient cooling circuit designed for marine heat‑exchanger or keel‑cooling layouts. A stiff crankcase and robust rotating assembly help maintain alignment and minimize vibration, extending overhaul intervals in commercial duty.

Relevant technical data for the 8V396TE54 in common marine ratings typically include:

Architecture: V8, 4‑stroke, turbocharged with charge‑air cooling.

Bore/Stroke (family values): approximately 165 mm x 185 mm.

Total displacement: roughly 31–32 liters for the 8‑cylinder variant in the 396 family.

Rated speed ranges: commonly 1,500–1,800 rpm depending on propulsion or generator rating.

Power class: typically in the high‑hundreds of kilowatts (approx. 700–1,000 kW), subject to duty rating and build list.

Fuel system: mechanically governed direct injection with high‑precision pump and injector components.

Cooling: freshwater jacket cooling with heat exchanger or keel cooler, charge‑air cooler integrated with the turbocharging system.

This technical foundation explains why the 8V396TE54 is valued in workboat propulsion, fast response auxiliary drives, and generator sets where stable frequency and rapid load pick‑up are essential. The engine’s compact V8 form factor simplifies integration in tight engine rooms and allows service access around key components such as turbochargers, charge‑air coolers, fuel pumps, and filtration modules.

- · V8, four‑stroke, turbocharged and charge‑air cooled.

- · Approx. 31–32 L displacement within the MTU 396 family.

- · Typical ratings around 1,500–1,800 rpm for marine duty.

- · Power class in the 700–1,000 kW range, depending on rating.

- · Strong power‑to‑weight ratio for compact engine rooms.

- · Fast load acceptance for propulsion and genset applications.

- · Service‑friendly design with excellent component accessibility.

Applications of the 8V396TE54 marine engine

The 8V396TE54 MTU marine engine supports a broad operational footprint:

Propulsion: coastal cargo vessels, ferries and passenger ships, patrol and pilot boats, offshore support vessels, dredgers, and harbor craft where dependable thrust, maneuverability, and economical operation are priorities.

Power generation: marine hotel‑load gensets on passenger vessels, platform and rig power, emergency and standby systems, and land‑based prime‑power or standby roles in industrial and utility environments. In these settings, the 8V396TE54 diesel engine is appreciated for its steady frequency control and efficient specific fuel consumption across partial loads.

Because of its proven design and availability of 8V396TE54 OEM parts, operators can maintain consistent performance curves and predictable service intervals, making this engine type a practical choice for fleets seeking long-term asset stability.

OEM spare parts suitable for 8V396TE54: why they matter

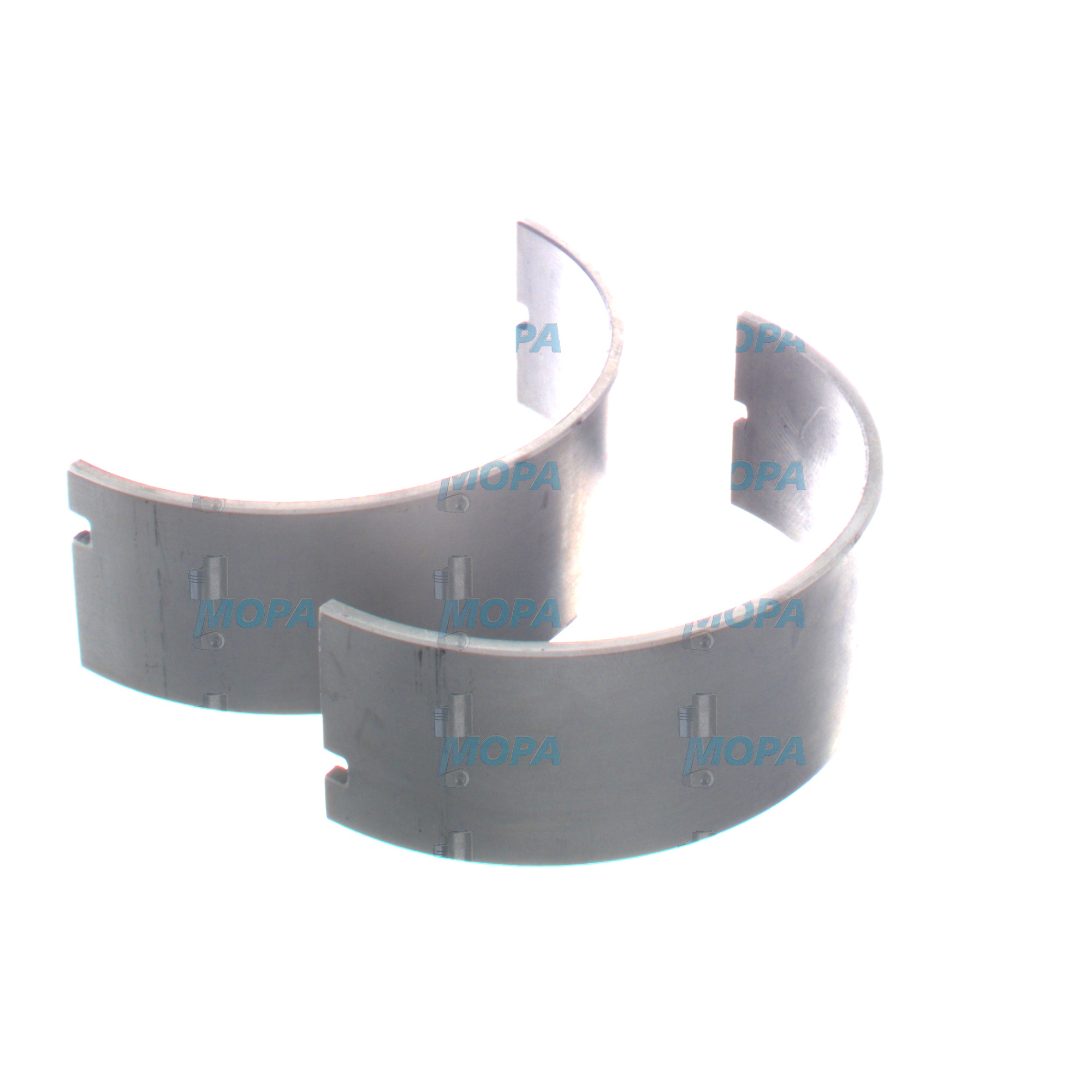

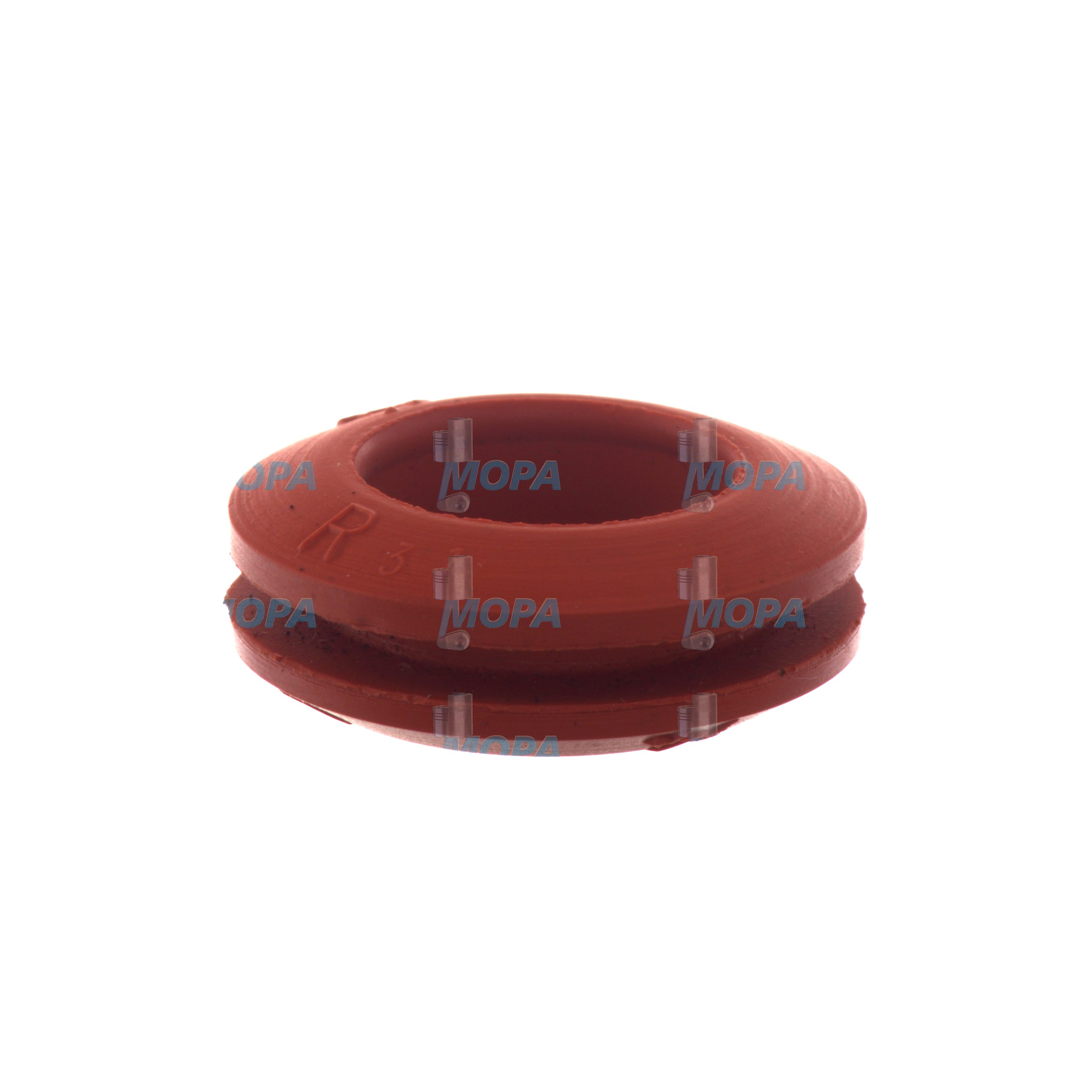

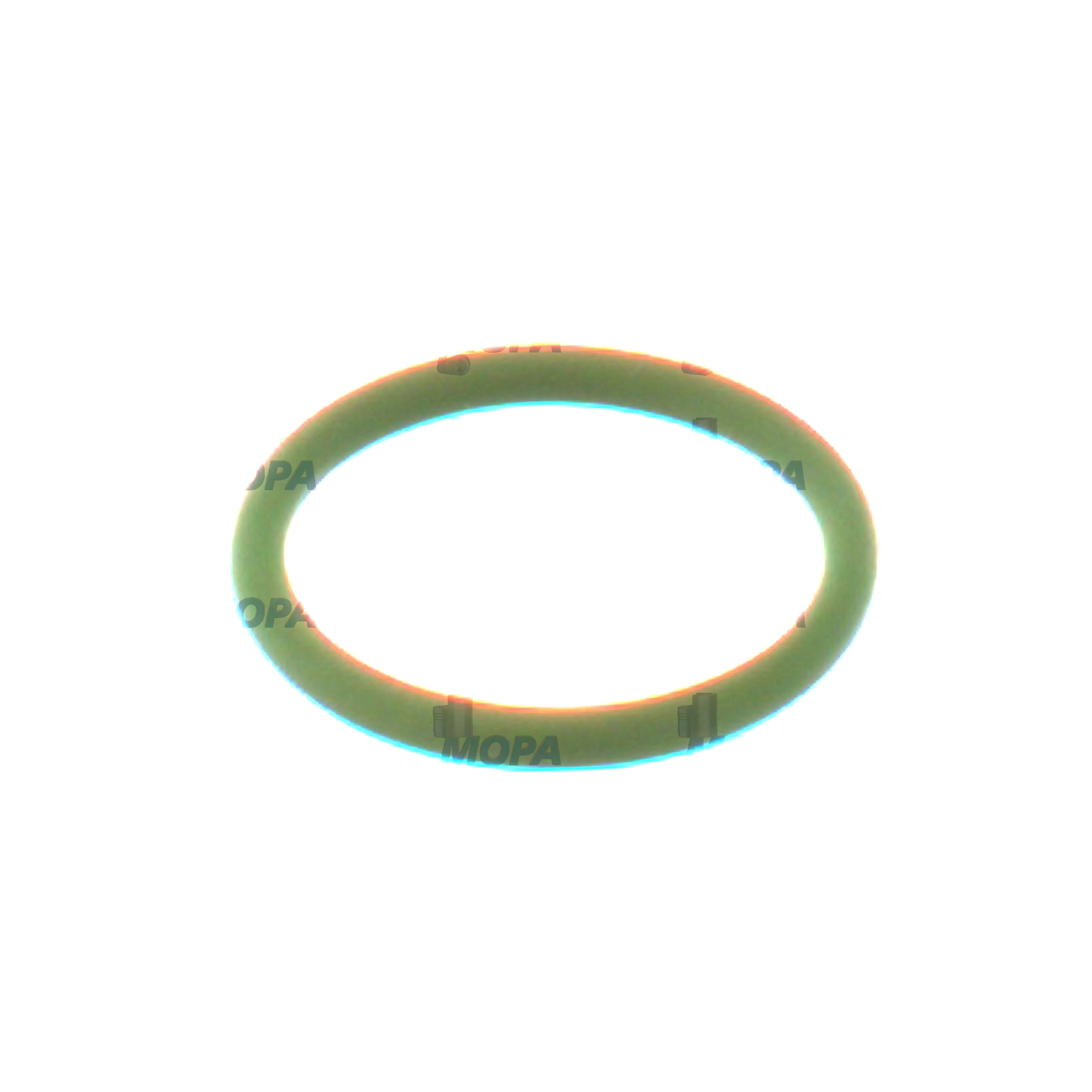

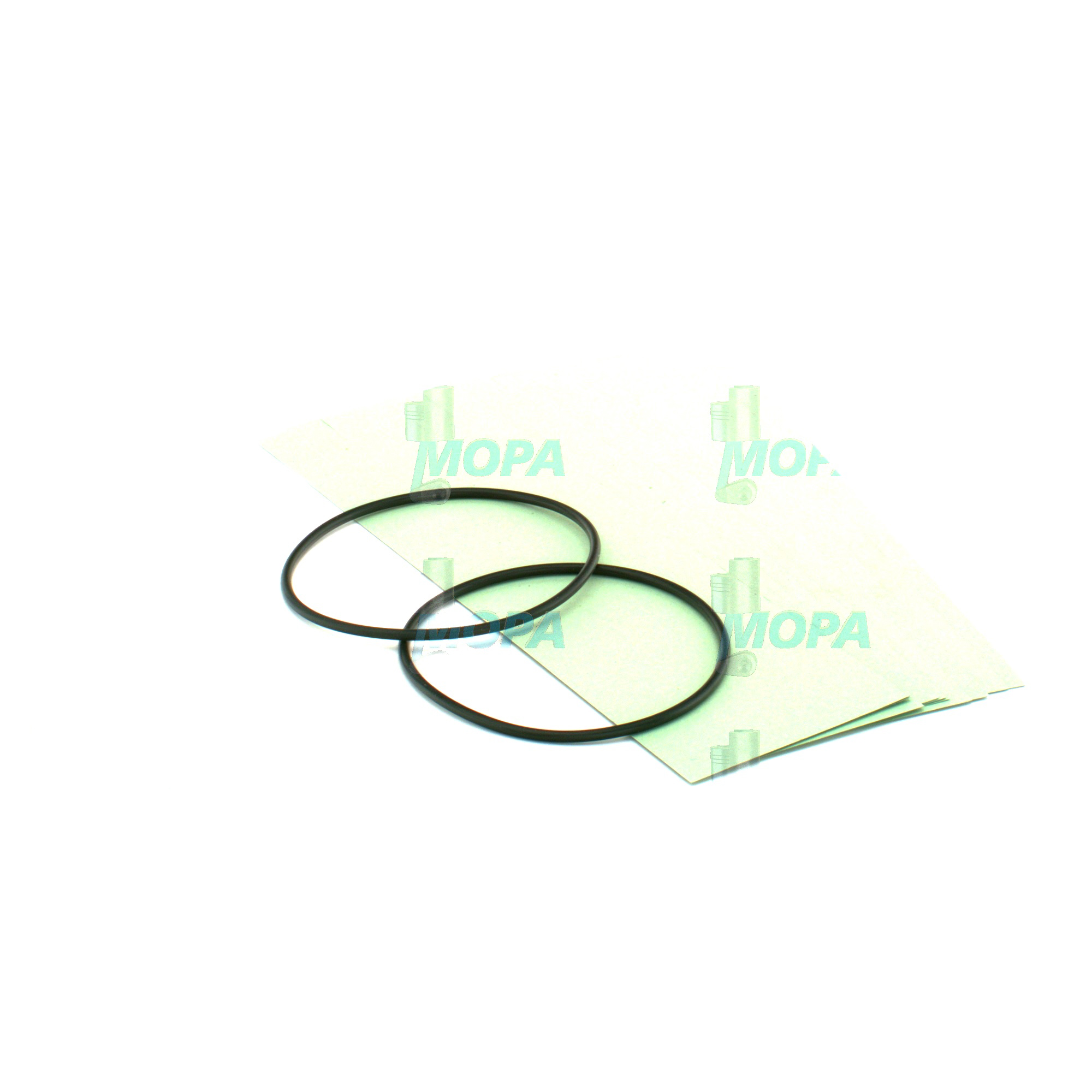

To sustain output, fuel economy, and uptime, it is essential to specify OEM spare parts suitable for 8V396TE54. Precision‑matched pistons, liners, bearings, fuel injection components, turbocharger cartridges, gaskets, and filtration elements are engineered to the dimensional tolerances and material specifications that the engine’s design depends on. This fit accuracy preserves combustion quality, protects the cranktrain and valvetrain, and stabilizes operating temperatures and oil cleanliness over long running hours.

By using OEM spare parts suitable for 8V396TE54, operators can keep the engine within its designed performance envelope—from start‑up behavior and transient response to emissions stability and vibration levels. This directly supports predictable overhaul planning, minimizes unplanned downtime, and protects total cost of ownership across multi‑year maintenance cycles.

- · Consistent performance and fuel efficiency over time.

- · Optimal clearances and materials for critical wear parts.

- · Stable load acceptance and frequency control in genset duty.

- · Reduced risk of premature component fatigue.

- · Streamlined maintenance with parts that fit first time.

MOPA is a reliable partner for OEM spare parts suitable for 8V396TE54, supplying components selected for dimensional accuracy and durability. From injectors and pumps to cooling modules, seals, and sensors, MOPA supports planned maintenance, rapid repairs, and overhaul projects so that fleets and facilities can keep the 8V396TE54 MTU marine engine operating at its intended performance level.

Conclusion: 8V396TE54 value and assured parts supply

The 8V396TE54 combines compact V8 architecture, dependable power delivery, and service‑ready design to meet the needs of propulsion and power generation across maritime and stationary environments. Its balance of responsiveness and durability makes it a preferred choice for operators seeking reliable output and manageable lifecycle costs.

With MOPA as a trusted source for OEM spare parts suitable for 8V396TE54, purchasers and technical teams can maintain performance, reliability, and service life across the engine’s operational horizons.