12V4000 marine engine by MTU – technical overview and OEM parts

The 12V4000 is a 12‑cylinder V‑configuration high‑speed diesel engine that has become a benchmark for reliable power in demanding marine and stationary applications. As part of the MTU 4000 series, it combines robust mechanical design with modern electronics and fuel systems, enabling strong performance across a broad range of duty profiles. While MTU and the 4000 series provide the wider platform, the focus here is the capabilities that make the 12V4000 a preferred choice for operators who need dependable propulsion or prime power with efficient lifecycle economics.

With advanced common rail fuel injection, optimized turbocharging, and precise electronic control, the 12V4000 diesel engine delivers responsive torque, clean combustion, and competitive fuel consumption. Its modular architecture supports serviceability and configuration flexibility, so shipyards and owners can tailor the package to propulsion, auxiliary, or power‑generation roles without sacrificing maintainability.

MTU 12V4000 diesel engine: technical characteristics

The MTU 12V4000 uses a compact 12‑cylinder V layout engineered for high specific output and consistent thermal management. Typical variants feature electronically controlled common rail injection at high pressures for fine‑grained fuel metering, along with turbocharging and charge‑air cooling to sustain power density in warm ambient and high‑load environments. Electronic engine management coordinates fuel, air, and speed control to stabilize operation over transient loads common in marine propulsion and genset applications.

Depending on the exact variant and rating, the 12V4000 marine engine operates in the mid‑ to high‑speed band, commonly around 1,500 to 2,100 rpm for propulsion, and 1,500/1,800 rpm for 50/60 Hz generator sets. Power ratings span a broad range to match duty cycles—from continuous and heavy‑duty for commercial vessels and power plants to higher intermittent ratings for fast craft—providing flexibility for designers and operators. Select versions are configured to meet current emissions requirements, including IMO II and IMO III with aftertreatment, as well as regional standards in inland and coastal markets.

Why the platform is widely adopted comes down to a proven balance of output, efficiency, and uptime. The engine’s block, rotating assembly, and valve train are designed for durability under high cyclic loads, while the fuel and air systems maintain clean combustion to support long intervals between overhauls. In practice, operators value the 12V4000 for its predictable lifecycle costs and strong service network coverage.

- · 12‑cylinder V configuration with high power density

- · Common rail injection for precise fuel control

- · Turbocharged and charge‑air cooled for sustained performance

- · Typical operating speeds: ~1,500–2,100 rpm (variant‑dependent)

- · Broad rating range for propulsion and genset duty

- · Electronic engine management for load response and efficiency

- · Emissions compliance options, including IMO II/III (variant‑dependent)

- · Modular design for streamlined maintenance

Applications of the 12V4000 marine engine and stationary power

The 12V4000 MTU marine engine is commonly specified for commercial vessels that need dependable thrust and long service intervals. Typical applications include cargo vessels, Ro‑Ro and passenger ferries, offshore support vessels, tugs, workboats, patrol and governmental craft, and larger yachts. In these roles, its torque characteristics support efficient acceleration, while steady‑state fuel economy reduces operating costs over long routes or extended on‑station periods.

In auxiliary and stationary applications, the 12V4000 diesel engine serves as a prime mover for generator sets in shipboard power plants and land‑based facilities. Electrical outputs are configured to match 50/60 Hz grids, making the platform suitable for base‑load and standby power in harbors, terminals, industrial plants, data centers, and critical infrastructure. The engine’s electronic control and robust mechanical systems deliver stable frequency and voltage when coupled to properly sized alternators, an essential attribute for sensitive loads and mission‑critical operations.

Across both propulsion and power generation, the engine’s adaptability is a key differentiator. Package options include different cooling concepts, intake and exhaust arrangements, and accessory configurations to fit constrained engine rooms or standardized genset containers. For operators, this means the 12V4000 can be integrated without extensive redesign, yet still provide the output headroom needed for future operating demands. When sourcing service and 12V4000 OEM parts, global availability further strengthens lifecycle planning and minimizes downtime.

OEM spare parts suitable for 12V4000: performance and reliability

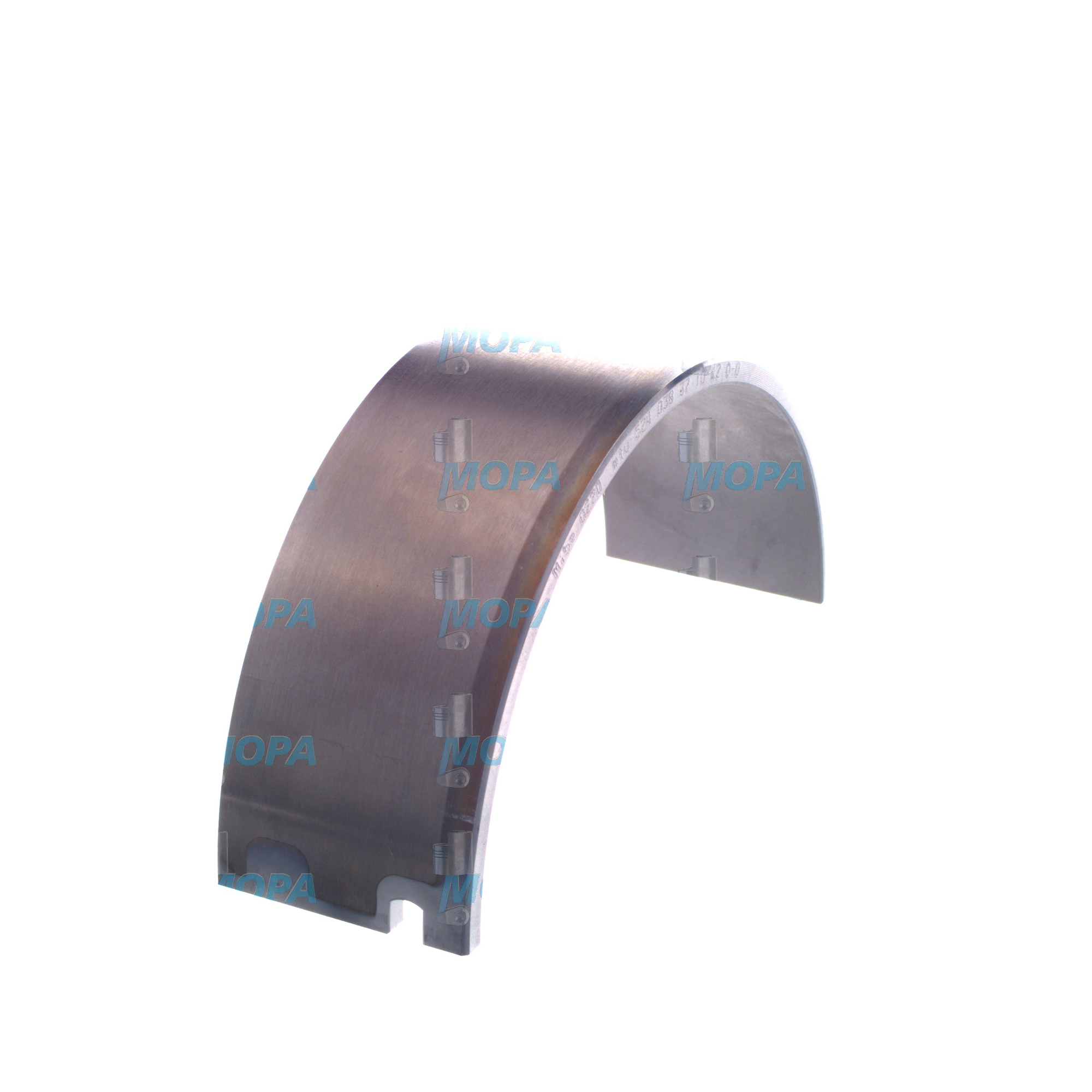

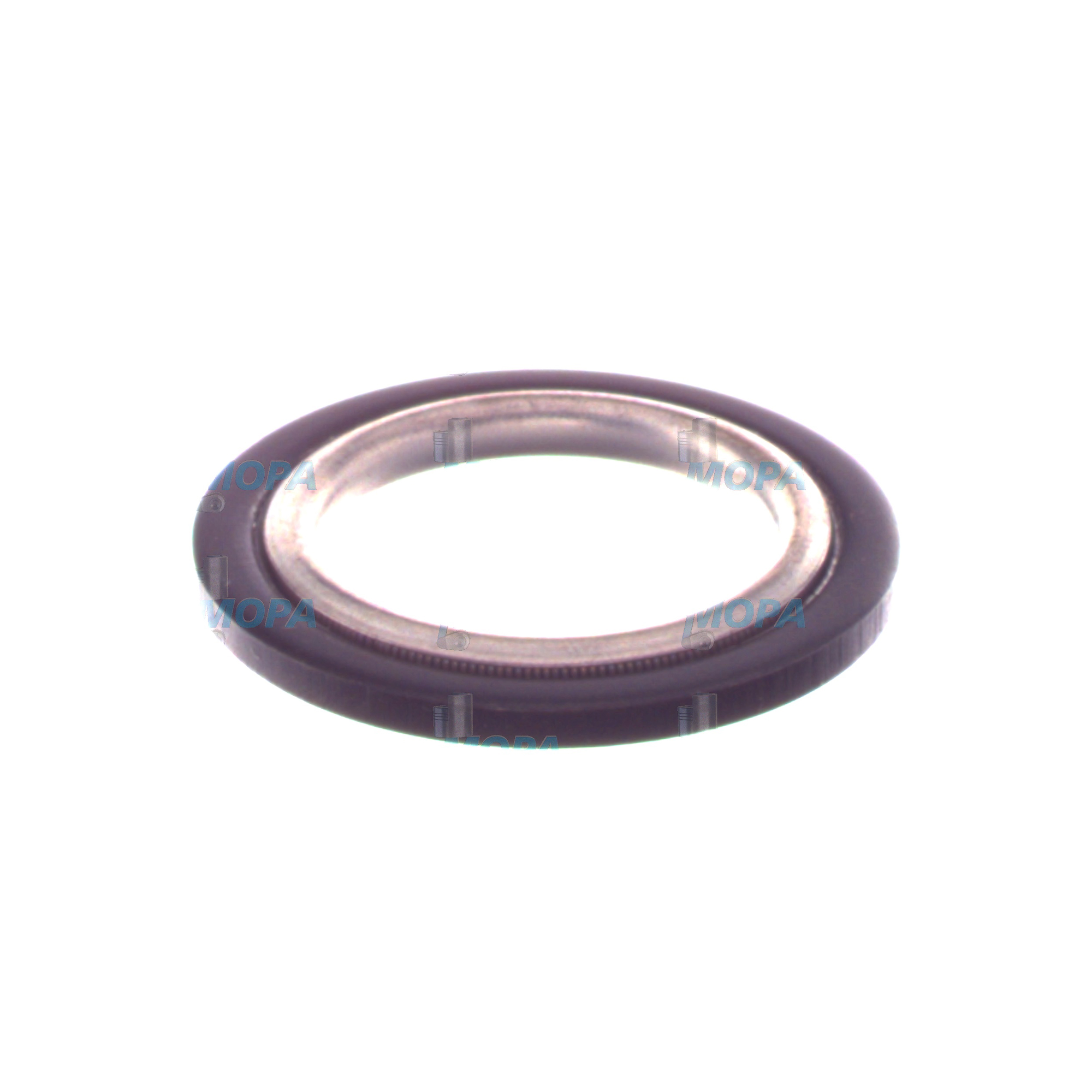

To preserve the engineered performance of the platform, it is essential to use OEM spare parts suitable for 12V4000. Precision components—injectors, pumps, filters, sensors, pistons, liners, bearings, and gaskets—must match the engine’s design tolerances and material specifications. Correct spray patterns, sealing surfaces, and wear characteristics are critical to maintaining combustion efficiency, emissions conformity, and the intended time‑between‑overhaul. Substituting components that do not meet these requirements can disrupt fuel atomization, raise thermal stress, and accelerate wear across the valve train and rotating assembly.

With OEM spare parts suitable for 12V4000, operators retain the calibration integrity of the fuel and air systems, ensuring stable start behavior, load acceptance, and power output under variable conditions. This is especially important in marine environments where salt, vibration, and thermal cycling challenge every subsystem. Consistent parts quality supports predictable maintenance planning, protects key assets like turbochargers and aftercoolers, and helps keep emissions compliance on track across inspection cycles.

MOPA is a reliable partner for OEM spare parts suitable for 12V4000. As a specialist supplier, MOPA supports procurement with technical clarity, traceable sourcing, and responsive logistics—helping shipowners, operators, and power‑plant managers secure the right parts on time. From scheduled overhauls to corrective maintenance, sourcing through MOPA streamlines inventory planning and shortens downtime, ensuring the 12V4000 MTU fleet remains ready for service.

Why choose OEM parts for the 12V4000 diesel engine

- · Maintains design clearances and material specs

- · Preserves fuel‑system calibration and emissions conformity

- · Supports reliable load steps and steady output

- · Enables predictable maintenance intervals

- · Reduces risk of secondary damage and downtime

- · Backed by MOPA’s professional sourcing and logistics

Conclusion: 12V4000 value and parts support

The 12V4000 stands out for its combination of power density, fuel efficiency, and application flexibility across marine propulsion and stationary power. Its engineering and service ecosystem make it a dependable choice for operators who prioritize uptime and lifecycle cost control.

To sustain these advantages over the long term, rely on OEM spare parts suitable for 12V4000. MOPA supplies and supports the parts you need to keep the 12V4000 operating at its intended performance, reliability, and service life.