TCG2020-V12 gas engine for high-efficiency power generation

The TCG2020-V12 is a proven 12-cylinder V-configuration gas engine engineered for demanding continuous duty and combined heat and power applications. Positioned within the 2020 GAS series by MWM & Deutz, this model stands out for its robust performance, high electrical efficiency, and flexible fuel capability. While the series context is notable, the focus here is on what makes the TCG2020-V12 an optimal choice for operators who prioritize dependable output, low emissions, and lifecycle economy.

In real-world deployments, the TCG2020-V12 delivers consistent power in baseload, peaking, and CHP setups. Its lean-burn combustion, advanced turbocharging, and precise engine management enable stable operation across a broad load range, with excellent thermal integration options for heat recovery. Whether configured for natural gas or special gases such as biogas and landfill gas, the engine maintains strong efficiency and reliability metrics that help reduce total cost of ownership.

TCG2020-V12 technical characteristics and performance

The TCG2020-V12 is a turbocharged, intercooled, spark-ignited gas engine designed for grid-parallel and island operation. As a V12, it balances compact installation footprints with high specific output. Typical generator-set configurations offer approximately 1.0–1.2 MW electrical output (application- and gas-quality-dependent). Standard operating speeds are 1,500 rpm for 50 Hz grids and 1,800 rpm for 60 Hz, facilitating straightforward integration with synchronous alternators. The engine’s total displacement is in the ~24–30 L class depending on variant, with optimized compression ratio and Miller-cycle-inspired timing to enhance knock resistance and efficiency.

Electrical efficiency commonly reaches the mid-40% range in well-tuned installations, while CHP layouts—recovering jacket water and exhaust heat—can achieve total system efficiencies above 90%. A modern engine management system (e.g., plant-level controls integrating ignition timing, air-fuel ratio, and knock detection) keeps operation stable despite gas composition fluctuations. Emissions performance is typically aligned with stringent regional norms, supported by lean-burn calibration and optional oxidation or three-way aftertreatment where required.

- · 12-cylinder V-configuration with lean-burn combustion.

- · Approx. 1.0–1.2 MW electrical output in typical genset packages.

- · 1,500/1,800 rpm for 50/60 Hz applications.

- · High electrical efficiency; strong CHP suitability.

- · Fuel-flexible: natural gas, biogas, landfill/sewage gas.

- · Robust turbocharging and efficient charge-air cooling.

- · Digital controls for grid code compliance and stability.

- · Designed for long service intervals and predictable OPEX.

Applications of the TCG2020-V12 in power generation and marine

The TCG2020-V12 by MWM & Deutz is widely deployed in decentralized power plants, industrial self-generation, district heating networks, and municipal utilities. In CHP mode, it supports factories, data centers, hospitals, and campuses that require high availability and thermal utilization. Operators in the waste-to-energy sector value its ability to handle varying methane content and trace compounds (with appropriate gas treatment), maintaining stable output and emissions compliance.

Beyond stationary use, the engine can serve selected marine auxiliary roles where gaseous fuels are available, such as harbor power or onboard utility generation on vessels equipped for LNG or compressed natural gas. In this context, the TCG2020-V12 marine engine configuration is appreciated for lower specific emissions and acoustic performance compared with conventional solutions. Many shipowners consider the TCG2020-V12 a capable diesel engine alternative when pursuing gas-fueled strategies, especially in emission-controlled zones and ports.

Why it is valued in the field: high uptime, dependable part-load behavior, and a mature supply chain. The engine’s balance of efficiency and durability underpins predictable lifecycle costs, while its control system supports remote monitoring, performance trending, and fast response to grid events.

For procurement and technical teams comparing options, the TCG2020-V12 OEM parts ecosystem and service methodologies are well-established, facilitating streamlined maintenance planning and minimizing unplanned downtime.

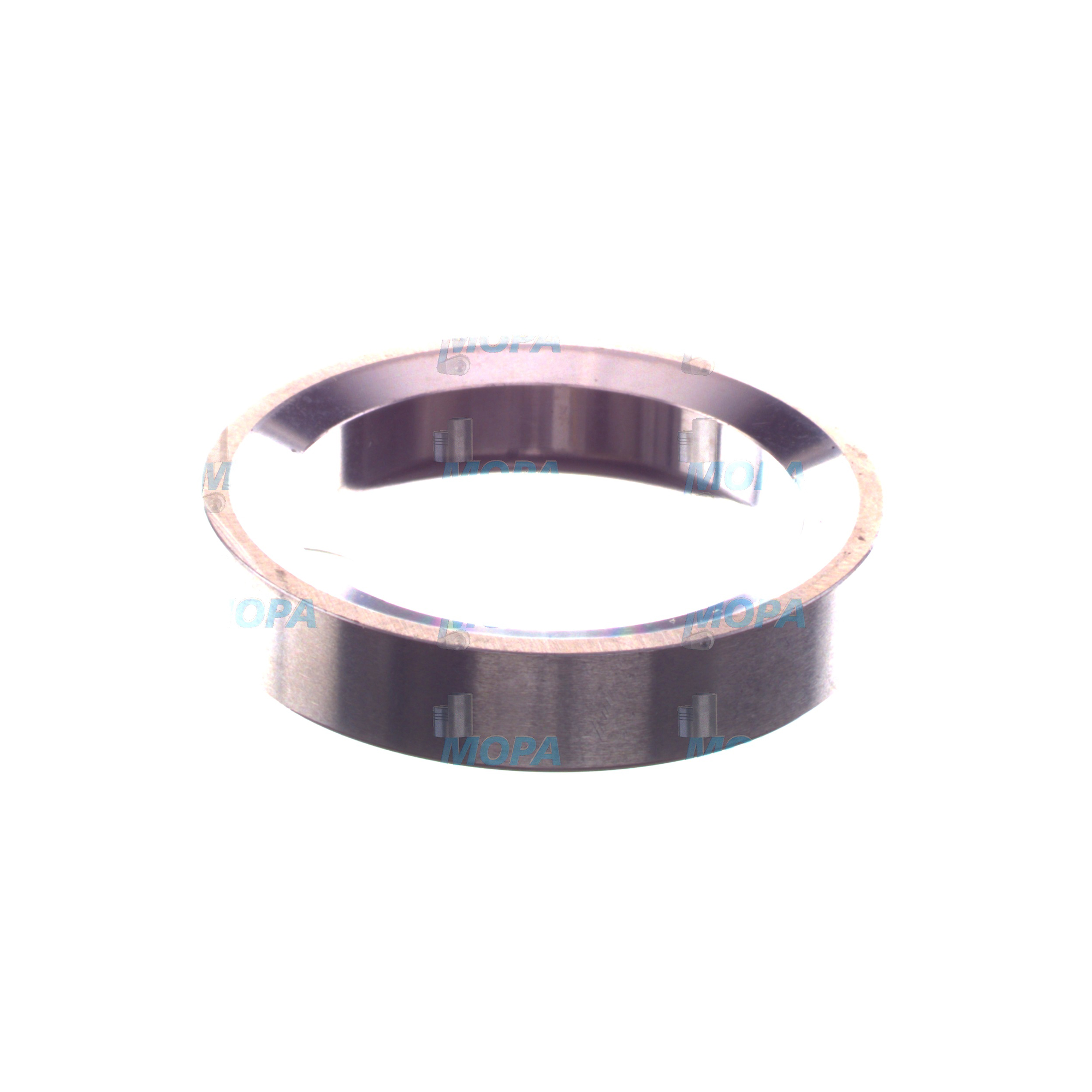

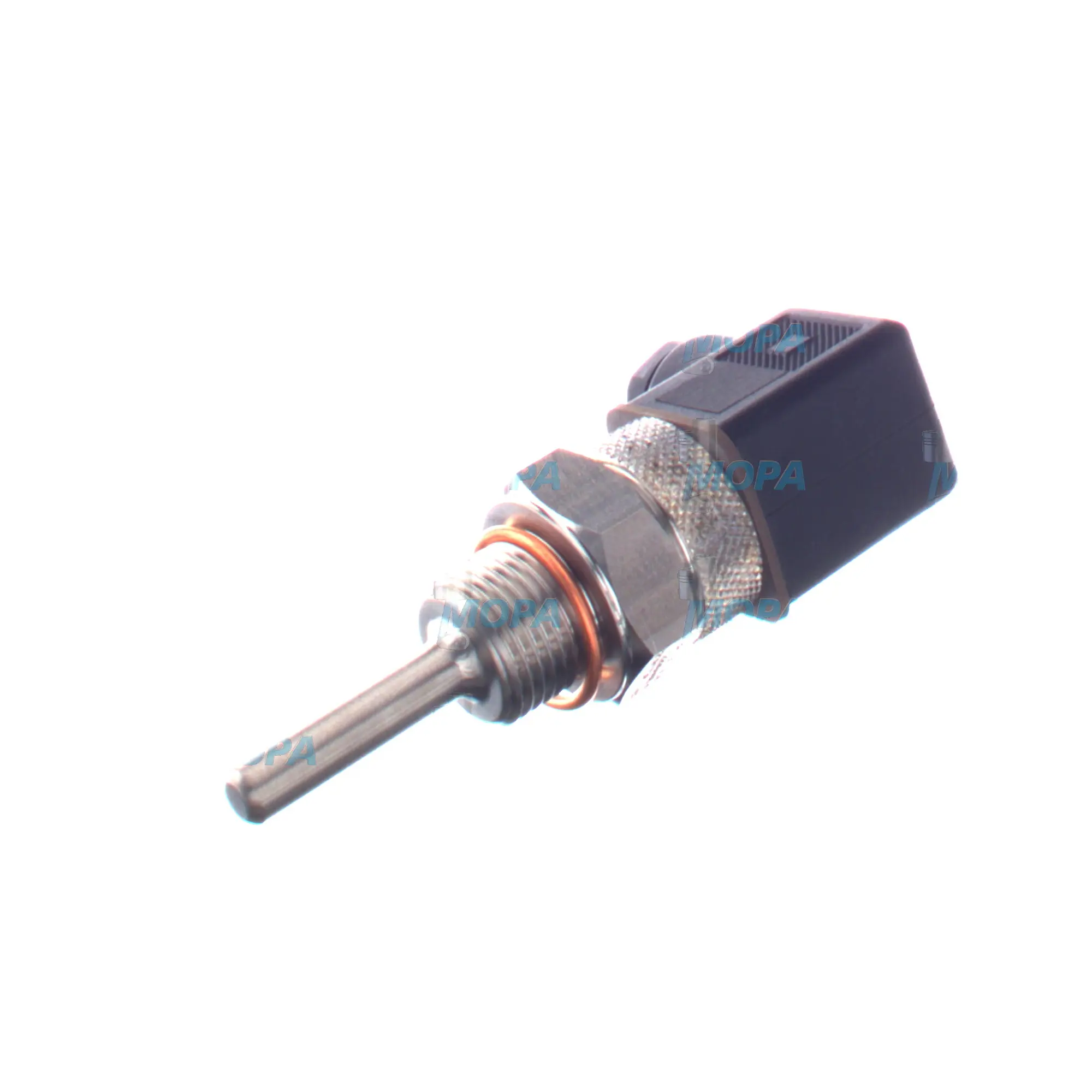

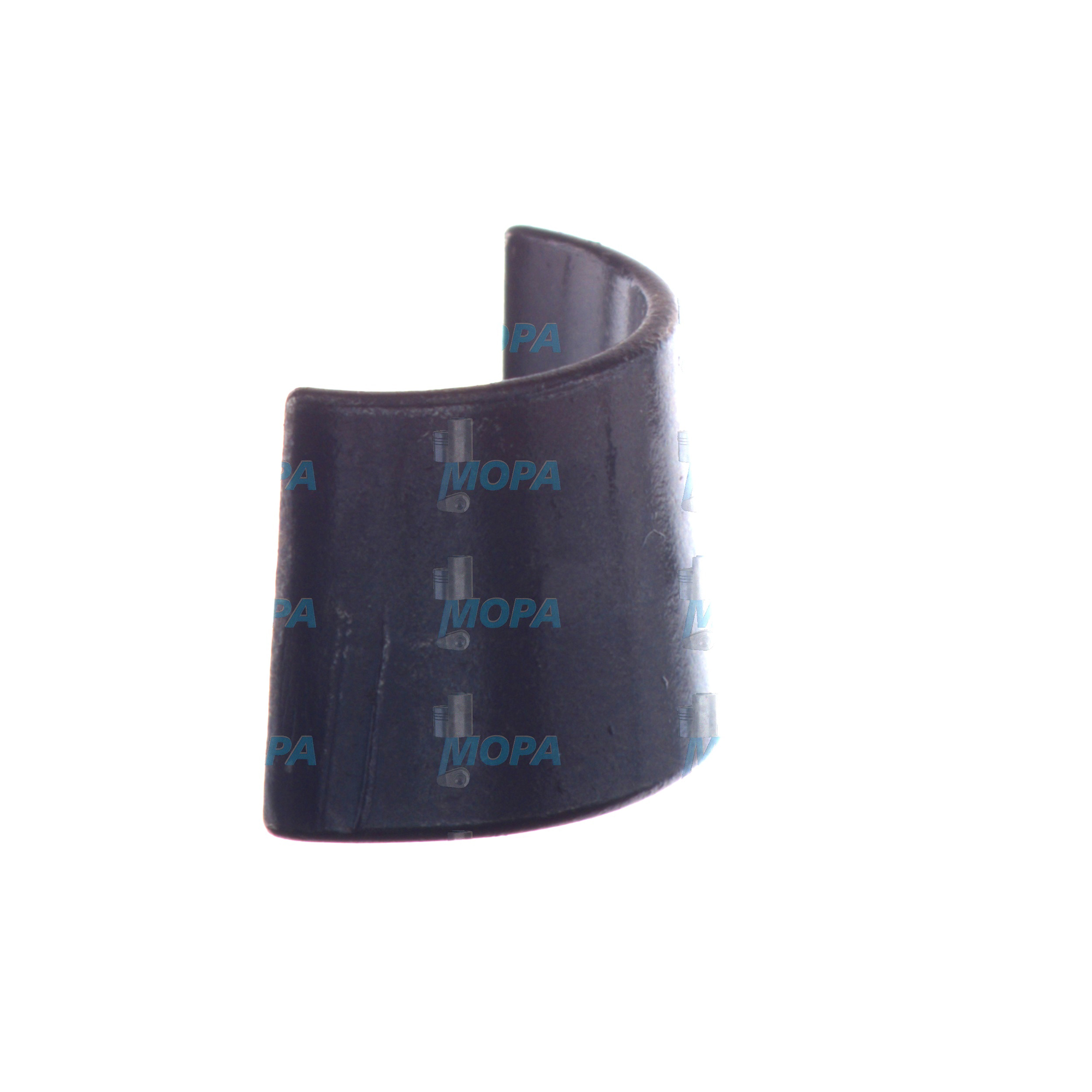

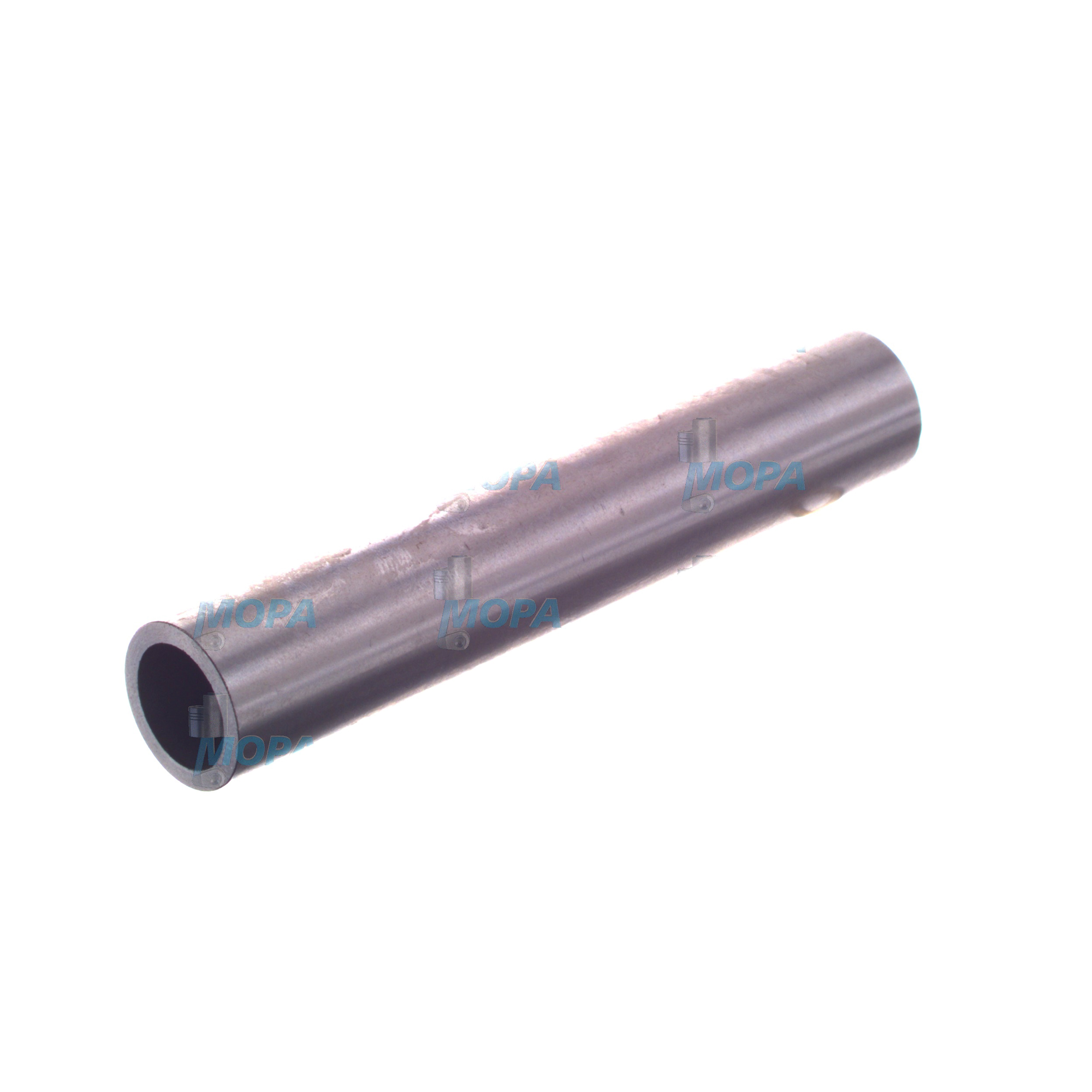

OEM spare parts suitable for TCG2020-V12: performance, reliability, service life

Protecting the performance envelope of a gas engine requires consistent component quality and precise fit. OEM spare parts suitable for TCG2020-V12 are engineered to the same tolerances and materials specifications as the components used in the engine’s production build. That means combustion-critical items—such as ignition components, pistons and rings, cylinder heads, turbocharger cartridges, valves, and sensors—maintain the calibrated relationships that drive efficiency, emissions stability, and longevity.

Using OEM spare parts suitable for TCG2020-V12 helps preserve knock margins, air-fuel ratio control, and thermal balance across cylinders. This is especially important for engines operating on variable fuels like biogas, where component wear or sensor drift can quickly erode efficiency. Consistent parts quality supports stable spark timing, clean combustion, and targeted exhaust temperatures, all of which contribute to extended service life and predictable overhaul intervals.

- · Maintains designed efficiency and emissions stability.

- · Ensures precise fit and calibration across critical systems.

- · Reduces unplanned downtime and protects overhaul schedules.

- · Supports reliable operation on variable-gas applications.

- · Aligns with OEM maintenance strategies and updates.

MOPA is a reliable partner for OEM spare parts suitable for TCG2020-V12. With a focused portfolio and technical know-how, MOPA supports purchasers, shipowners, and plant operators in sourcing the correct components—ignition systems, filtration, gaskets, fuel-mixing elements, and more—so that the engine continues to meet performance targets. Whether your priority is baseload reliability, CHP efficiency, or readiness for marine auxiliary duties, OEM spare parts suitable for TCG2020-V12 from MOPA help keep your asset competitive.

Conclusion: TCG2020-V12 benefits and reliable parts supply

The TCG2020-V12 combines robust mechanical design with high efficiency and flexible fuel compatibility, making it a strong choice for CHP plants, industrial self-generation, waste-to-energy projects, and selected marine auxiliary roles. Its controlled combustion, mature controls, and proven V12 architecture deliver dependable output and attractive lifecycle economics.

To safeguard these advantages, OEM spare parts suitable for TCG2020-V12 are essential. MOPA supports continuous, efficient operation by supplying OEM spare parts suitable for TCG2020-V12 with the quality and precision that technical decision-makers expect.