TCG2032-V16 high-efficiency gas engine for demanding power applications

The TCG2032-V16 stands out as a high-output, lean-burn gas engine designed for continuous duty where efficiency, uptime, and fuel flexibility are critical. Positioned within the 2032 GAS series from MWM & Deutz, this V16 platform is engineered for reliable base-load power, combined heat and power (CHP), and robust industrial duty. While the series context matters, the focus here is the TCG2032-V16 itself: a powerhouse that delivers strong electrical output in the multi-megawatt class with low emissions and a proven service concept tailored to long operating cycles.

Customers select the TCG2032-V16 for its balance of fuel efficiency, load response, and lifecycle cost. The engine’s lean-burn combustion, optimized turbocharging, and advanced engine management contribute to high electrical efficiency while maintaining low NOx, making it suitable for both utility-grade installations and industrial self-generation. Whether running on pipeline natural gas or other treated gaseous fuels, the TCG2032-V16 offers consistent performance across diverse duty profiles.

TCG2032-V16 technical characteristics and performance

At its core, the TCG2032-V16 is a 16-cylinder, turbocharged, aftercooled gas engine engineered for high-efficiency power generation. Typical generator set configurations target 50 Hz (1500 rpm) and 60 Hz (1800 rpm) operation, enabling integration into international grids and islanded systems alike. Depending on configuration, the TCG2032-V16 delivers electrical output in the upper multi-megawatt range—commonly around 4–4.5 MW—while maintaining strong part-load efficiency. Thermal recovery options support CHP, boosting total system efficiency significantly for sites that can utilize process heat or district heating.

Key data and operating ranges for the TCG2032-V16

The engine’s design emphasizes durability and serviceability: a rigid crankcase architecture, optimized V16 firing order, and precise air–fuel control maintain stable operation over long run hours. Electronic engine management ensures knock control, cylinder balancing, and emissions stability across fluctuating fuel qualities. For grid-parallel and island mode, the TCG2032-V16 provides fast load acceptance and stable frequency control, supporting critical loads in industrial and infrastructure environments.

· V16 lean-burn gas configuration with high power density

· Electrical output commonly around 4–4.5 MW, depending on setup

· 1500/1800 rpm generator drive for 50/60 Hz markets

· Designed for continuous duty, base load, and CHP projects

· Low NOx and stable emissions with advanced engine management

· Robust turbocharging and effective charge-air cooling

· Strong part-load efficiency and reliable load-step behavior

· Engineered for long service intervals and high availability

· Compatible with digital monitoring, predictive maintenance, and remote support

· Suitable for pipeline natural gas and selected treated gaseous fuels

Applications of the TCG2032-V16 in power generation and marine contexts

Why is the TCG2032-V16 so widely appreciated? It combines high electrical efficiency with consistent uptime and a proven maintenance concept—key decision factors for owners targeting predictable cost of electricity (LCOE) and tight emissions compliance. In stationary applications, the engine is frequently deployed in utility-scale CHP plants, industrial cogeneration, district energy schemes, process industry sites (chemicals, paper, food), commercial campuses, and data-center backup/prime power concepts where fuel availability and heat recovery help maximize project economics.

In marine and offshore environments, the TCG2032-V16 can be configured as an auxiliary power solution or as part of gas-based propulsion/energy systems where gaseous fuels are available, such as LNG-fueled ferries, inland vessels, harbor craft, and offshore platforms. Its stable frequency control and fast load acceptance support hotel loads, DP systems, and mission-critical auxiliaries. The combination of efficiency and low emissions helps operators meet tightening maritime environmental requirements. For search visibility and specification clarity: TCG2032-V16 MWM & Deutz, TCG2032-V16 marine engine solutions, and TCG2032-V16 OEM parts are common decision keywords for procurement and engineering teams evaluating lifecycle performance.

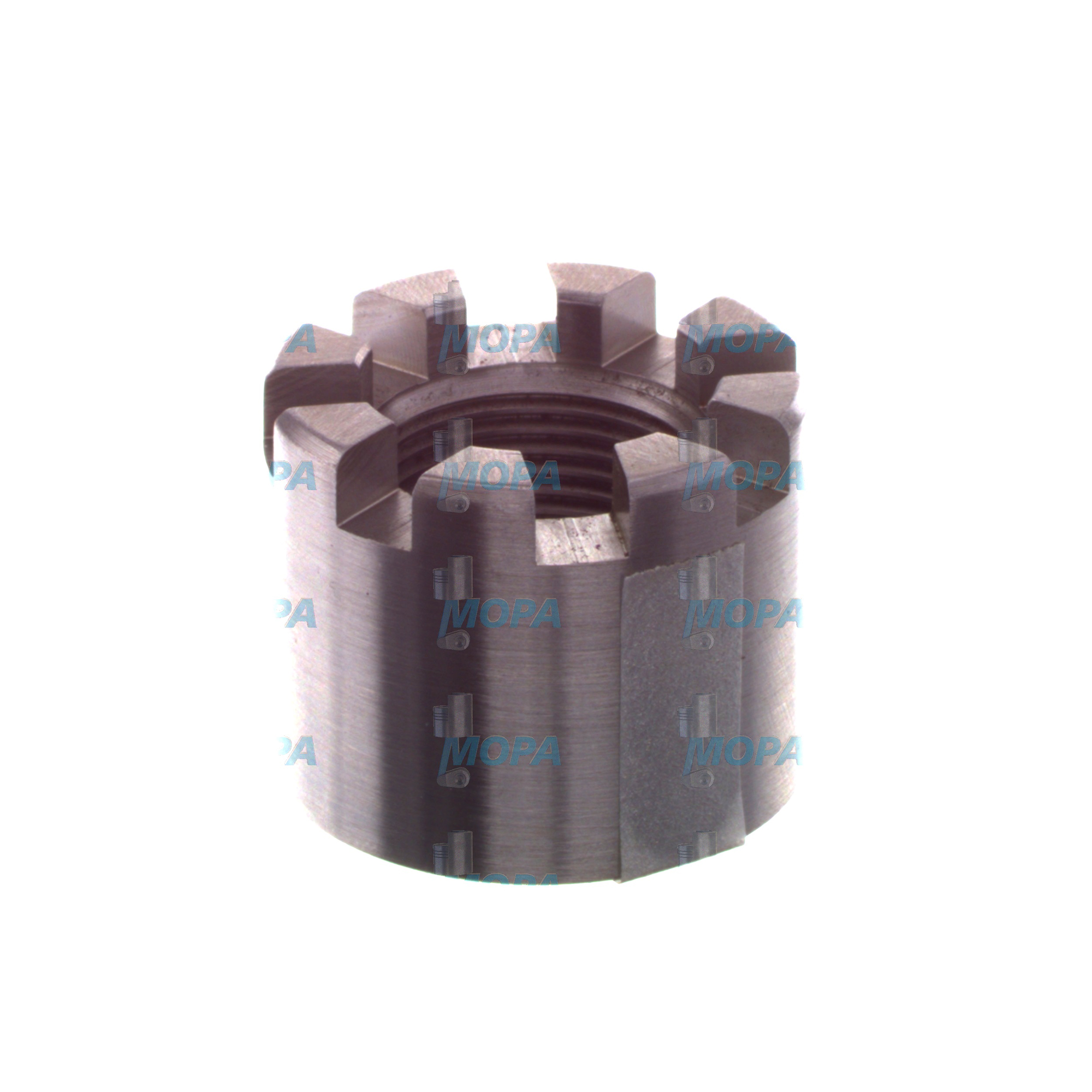

OEM spare parts suitable for TCG2032-V16 — performance, reliability, and service life

Long-term engine performance depends on precision components. OEM spare parts suitable for TCG2032-V16 are engineered to fit exact tolerances, maintain designed combustion characteristics, and preserve emissions stability. From ignition systems, pistons, liners, bearings, valves, and turbocharger components to gas mixers, sensors, and control elements, each part is dimensioned to match the engine’s thermal and mechanical loads. This dimensional accuracy, material quality, and compatibility directly influence cylinder balancing, knock margins, oil consumption, and maintenance intervals.

Using OEM spare parts suitable for TCG2032-V16 also supports repeatable overhauls and predictive maintenance strategies. When parts behave as designed, condition-based monitoring—vibration, exhaust temperature spreads, ignition energy, and lambda—yields reliable trends, allowing planned interventions instead of disruptive corrective stops. For operators running CHP, this stability protects heat offtake contracts and grid commitments. For marine operators, it translates into dependable auxiliary power and operational continuity across varied load profiles.

Partnering with a knowledgeable supplier simplifies the entire lifecycle. MOPA is a reliable partner for OEM spare parts suitable for TCG2032-V16, providing application support, rapid availability, and documentation alignment that helps your teams execute overhauls on schedule. With access to the right components and technical insight, owners sustain high availability, protect fuel efficiency, and uphold emissions compliance throughout the engine’s service life.

Conclusion — TCG2032-V16 value in operation and parts support

The TCG2032-V16 delivers multi-megawatt output, low emissions, and high efficiency in a compact V16 platform, making it a strong choice for CHP plants, industrial power, and suitable marine auxiliary roles. Its engineering focus on durability and control stability underpins predictable operating costs and uptime. For continued performance, OEM spare parts suitable for TCG2032-V16 are essential—and MOPA supplies OEM spare parts suitable for TCG2032-V16 with the technical support and availability that operators expect.