TBD441

TBD441 marine diesel engine: performance profile and sourcing insights

The TBD441 is a proven medium‑speed diesel engine that has powered countless vessels and stationary installations for decades. While it belongs to the 441 series developed by MWM & Deutz, the focus for operators has always been the robust, serviceable design of the TBD441 itself: a turbocharged and charge‑air‑cooled workhorse built for reliable output under continuous load. For purchasers, shipowners, and technical decision‑makers, the TBD441 offers a balanced combination of power density, fuel efficiency, and maintainability that keeps assets productive on demanding duty cycles.

TBD441 technical characteristics and engineering highlights

As a marine and industrial prime mover, the TBD441 is typically supplied in V‑configuration variants designed for propulsion and auxiliary generation. Depending on the build and classification, common configurations include multi‑cylinder V‑arrangements engineered for dependable continuous operation. The engine’s architecture emphasizes a rigid crankcase, high‑strength crankshaft and connecting rods, and efficient thermal management via turbocharging and intercooling. Fuel systems are configured for marine distillates (MDO/MGO), with injection equipment tailored to stable combustion and clean exhaust profiles within the constraints of legacy platforms.

Key performance ranges for the TBD441 diesel engine include:

• Cylinder configurations: V‑type multi‑cylinder variants suited to propulsion and genset duty

• Output classes: approximately 1,000–3,000 kW for propulsion, and roughly 1.0–2.5 MWe in generator applications (application‑ and tuning‑dependent)

• Speed ranges: typically in the 900–1,500 rpm band for medium‑speed operation, with propeller law optimization for marine drivetrains

• Displacement: large‑bore, long‑stroke geometry delivering strong low‑end torque and steady continuous rating

The result is a TBD441 marine engine that is valued for steady torque across the mid‑rpm range, straightforward service access, and parts commonality across the 441 series family. Operators appreciate how the TBD441 integrates with mechanical or hybridized control systems and how it tolerates long operating hours between major overhauls when maintained to specification.

- · Medium‑speed diesel design for continuous duty.

- · Turbocharged with charge‑air cooling for higher efficiency.

- · Proven V‑configuration with durable bottom‑end components.

- · Power range suitable for propulsion and auxiliary generation.

- · Designed for marine distillate fuels and stable combustion.

- · Strong parts ecosystem and service know‑how worldwide.

- · TBD441 OEM parts availability supports predictable lifecycle costs.

Applications of the MWM & Deutz TBD441 marine engine

The TBD441 is widely deployed across blue‑water and near‑shore fleets as well as land‑based power systems. In maritime operations, its balance of torque and fuel economy makes it a fit for controllable‑pitch or fixed‑pitch propulsion lines and for auxiliary generator sets that power hotel loads, cargo handling, and mission equipment.

TBD441 use cases in vessels and stations

• Cargo vessels and feeders: propulsion and auxiliary power with reliable loading response for harbor maneuvers and sea passages.

• Passenger ferries and RoPax: steady electrical generation and propulsion where schedule adherence depends on a dependable medium‑speed platform.

• Offshore supply, tug, and workboats: high torque at practical rpm for bollard pull, DP operations, and deck equipment.

• Dredgers and specialized craft: constant‑load profiles where the TBD441 diesel engine maintains efficiency under prolonged operation.

• Stationary power plants: baseload or prime‑power generator sets in remote sites, ports, or industrial facilities, often configured as 50/60 Hz packages.

Why is the TBD441 particularly common and valued? The answer lies in its engineering moderation: it avoids extremes in peak cylinder pressure and specific output, favoring component longevity and predictable overhaul intervals. The design integrates well with standard marine gearboxes, resilient mountings, and class society requirements. Parts logistics are mature, and technical documentation is well understood in shipyards and power service companies. For operators seeking a dependable platform with manageable lifecycle costs, the TBD441 by MWM & Deutz remains a practical choice.

From an SEO perspective for procurement teams, the search terms “TBD441 marine engine,” “TBD441 diesel engine,” and “TBD441 OEM parts” frequently align with projects involving life extension, repowering, or fleet standardization—scenarios in which the 441 series offers proven compatibility and performance headroom.

OEM spare parts suitable for TBD441: performance, reliability, service life

Operational reliability depends heavily on the precision and material integrity of components exposed to thermal and mechanical stress. OEM spare parts suitable for TBD441 are engineered to fit the engine’s original design intent, maintaining combustion geometry, clearances, and tolerances that directly influence fuel efficiency, emissions stability, and vibration behavior. When components such as injectors, turbocharger cartridges, cylinder liners, pistons, bearings, and valve train parts conform to the correct specifications, operators preserve baseline performance while minimizing unplanned downtime.

Why does this matter for lifecycle economics? Using OEM spare parts suitable for TBD441 helps secure consistent condition monitoring values (e.g., lube oil analysis, exhaust temps, and vibration signatures), which enables longer, predictable maintenance intervals. It also supports repeatable overhaul outcomes across sister vessels or multi‑unit power plants, simplifying spares planning and technician training. In short, it sustains the asset’s productivity profile over many service years.

MOPA is a reliable partner for OEM spare parts suitable for TBD441, supplying critical components and consumables with application support. From identification of correct part codes to logistics and documentation, MOPA helps procurement teams keep engines on spec and on schedule.

Conclusion: TBD441 value and secure parts supply

The TBD441 combines dependable medium‑speed performance with practical maintainability, making it a favored choice for propulsion and auxiliary power in diverse marine and stationary settings. Its balanced engineering and wide service base translate into predictable operations and controlled lifecycle costs.

To protect performance and service life, OEM spare parts suitable for TBD441 are essential, and MOPA provides a dependable supply and technical support for these components. For operators planning overhauls or fleet standardization, aligning the TBD441 with the right parts strategy is a proven path to reliable, efficient operation.

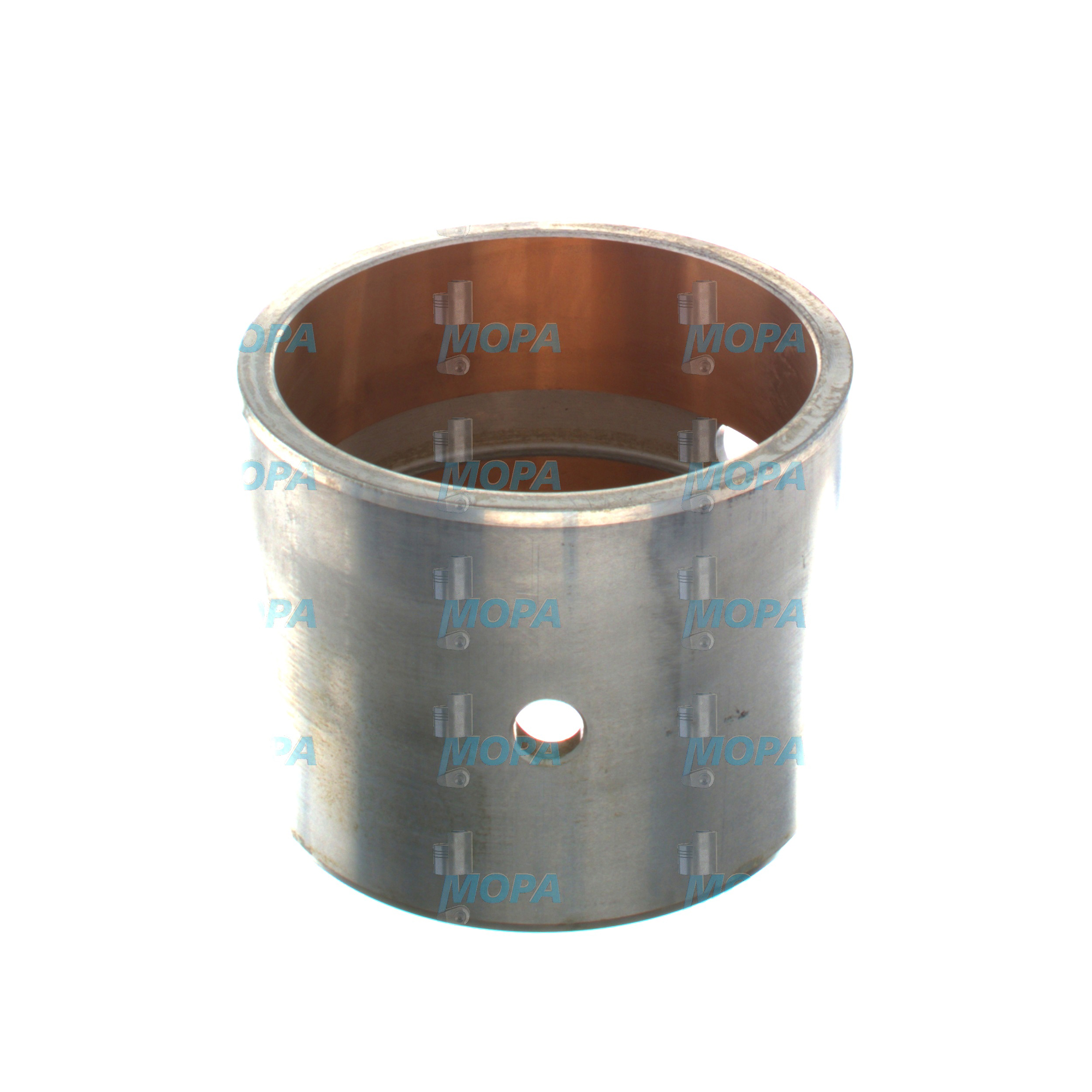

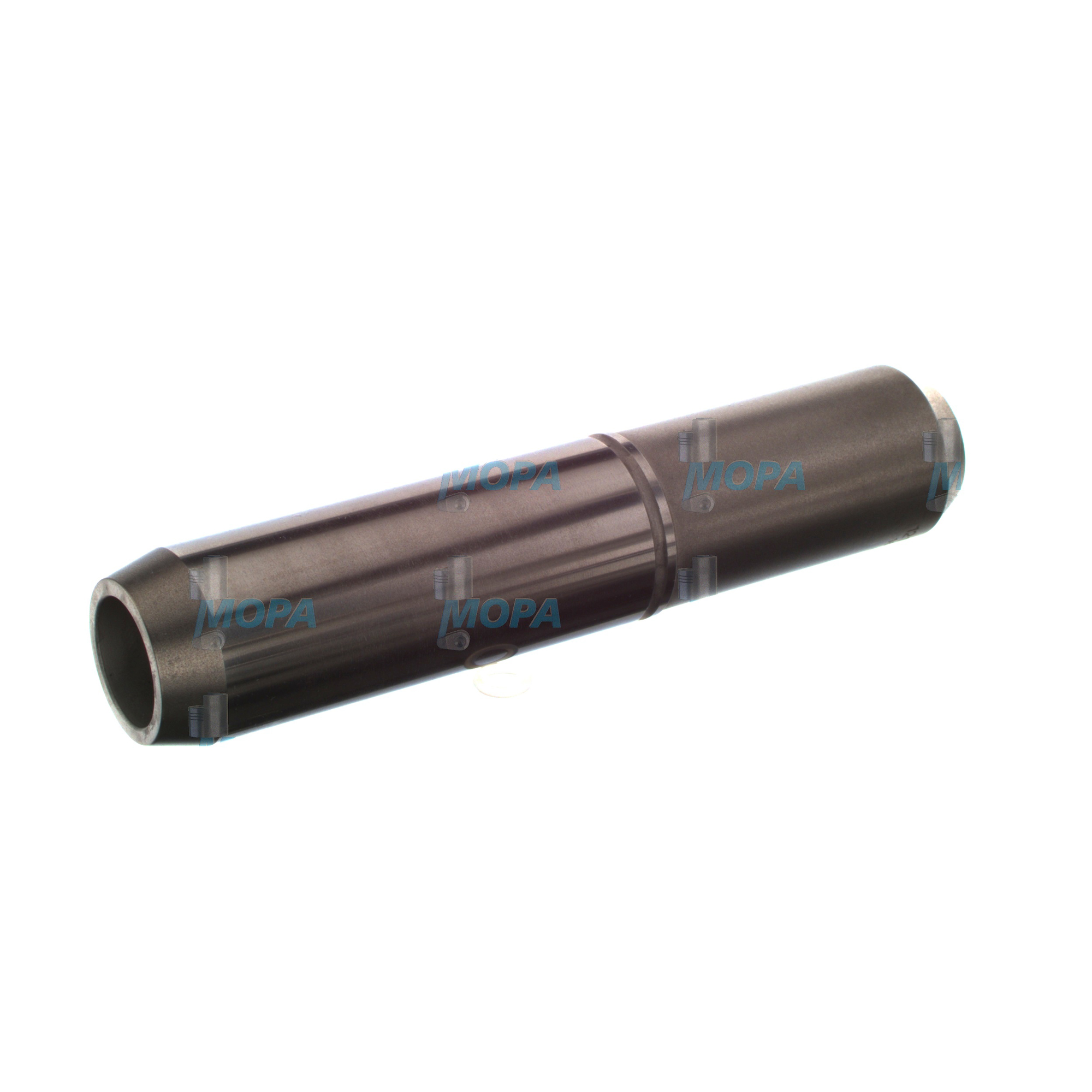

Small End Bush with Comparison Number 12171247Discover the small end bush with comparison number 12171247, an essential OEM replacement part for your engine applications. This product is specifically designed and suitable for use in various areas. With an optimal fit, the small end bush is ideally compatible with MWM & Deutz engines of the series 441 and the engine types TBD441. Rely on dependable performance and quality in your engine operation.

TORIC SEAL with the comparison number 604931000324 suitable for MWM & Deutz engines

Quality Half-rings suitable for MWM & Deutz EnginesDiscover the half-rings with the comparison number 12170669, specifically designed to provide top-notch performance. This product is an OEM replacement part, suitable for the MWM & Deutz series 440 and 441 due to its excellent fit. Rely on the quality of these half-rings to ensure the efficiency of your engines in marine and stationary applications.

Excellent Hexagon Bolt Suitable for Your EnginesDiscover the Hexagon bolt with the comparison number 628/48/60/05033994, an essential OEM replacement part that provides optimal performance for your applications. This product has been precisely tailored to meet the requirements and fits perfectly for the series 331, 493, 1163, 440, and 441, as well as the specific engine types 12V331TC92, 12V493, 20V1163TB93, TBD440-6, and TBD441. Expect maximum efficiency and reliability in your Deutz engines.Compact and Practical: Hexagon Bolt for Every UseOur Hexagon bolt weighs only 0.025 kg and has dimensions of 2.8 cm in length and width, as well as 1.8 cm in height. These compact measurements ensure that the product is easy to handle. As an OEM replacement part, it stands in quality, allowing you to choose the right product for your applications. Trust in a replacement part that is perfectly suited for Deutz engines.

ELEMENT with the comparison number 605209000023 suitable for MWM & Deutz engines

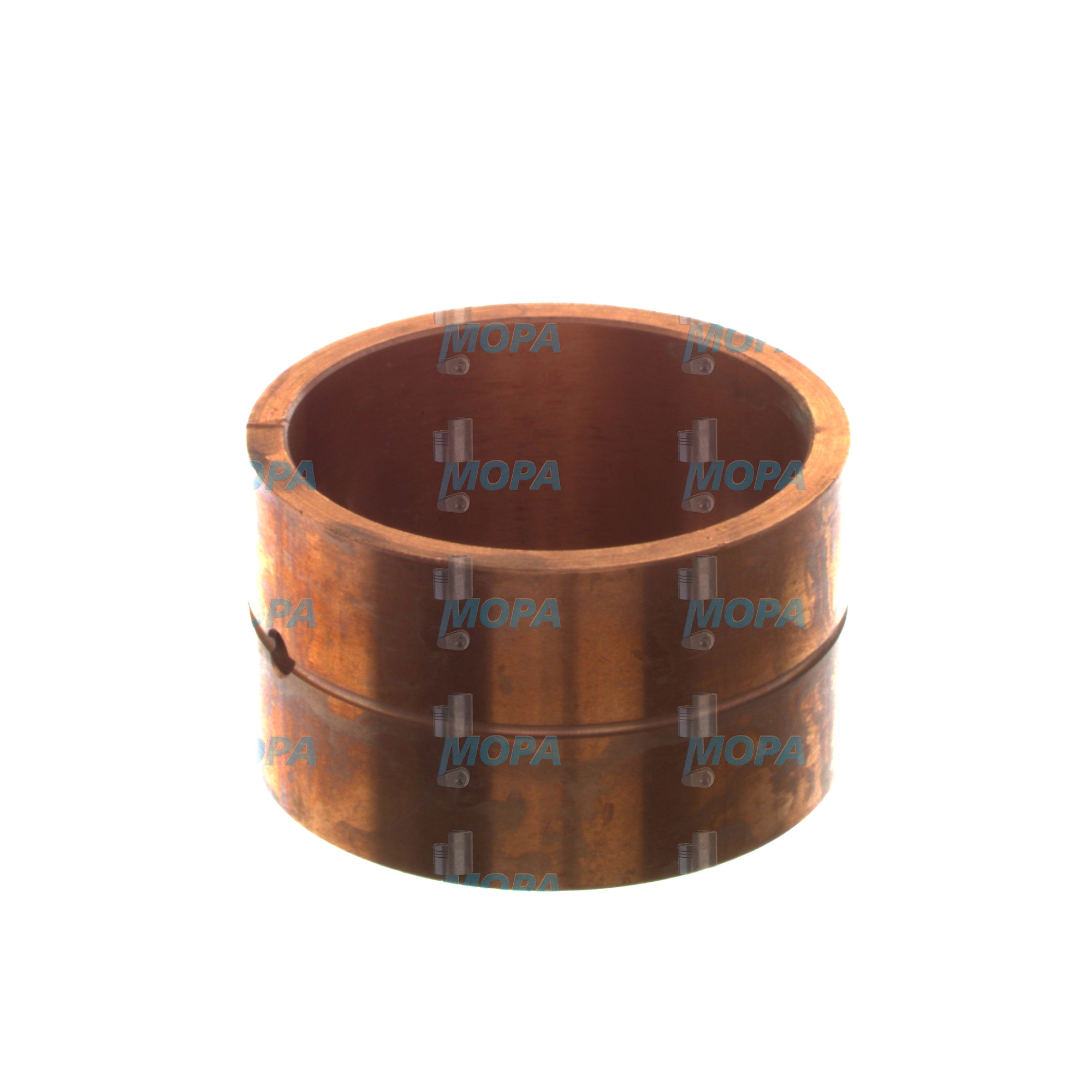

Efficient Big End Bearing Shell for High-Quality EnginesDiscover the top-quality big end bearing shell with the comparison number 12174231 – an essential engine drive component for your applications. This OEM replacement part ensures that your machines operate efficiently by establishing a stable connection between the connecting rod and the crankshaft. Weighing only 2.28 kg, it is both compact and robust, specially suited for demanding applications in marine and stationary technology.Compatible with MWM & Deutz EnginesThe big end bearing shell 12174231 is compatible with MWM & Deutz engines, particularly the series 440 and 441 as well as the engine types TBD440-6 and TBD441. This combination of quality and precision is crucial for the performance of your machines. With this product, you can be confident that your engine runs smoothly and meets performance requirements even under the highest loads.

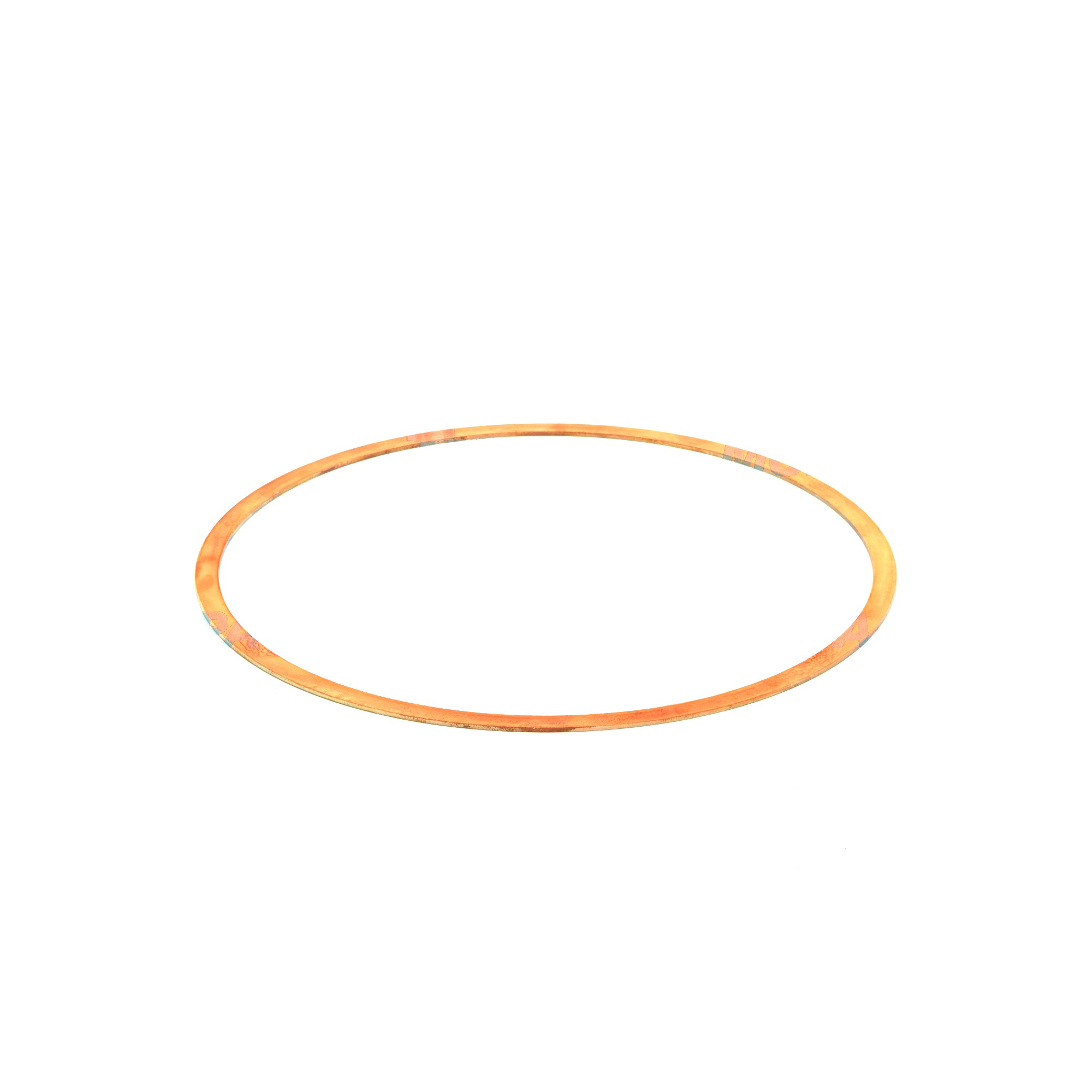

Truly Reliable Toric Seal for Your MachinesThe product with the comparison number 604931240474 is an essential toric seal specifically designed for diesel and gas engines. This OEM spare part offers you the assurance of a perfect fit, ensuring the flawless functionality of your systems. The toric seal has a lightweight of only 0.005 kg and compact dimensions of 5.4 cm in length, 5.4 cm in width, and 0.4 cm in height, making it an ideal choice for tight spaces in your applications.Suitable for Deutz Engines and SeriesOur gaskets, including this toric seal, are specifically intended for models designed to be compatible with Deutz. In particular, this toric seal is suitable for the series 441 and the specific engine types TBD441, highlighting its relevance for maintenance and repair needs. This makes it the ideal OEM spare part that not only provides functionality but also supports the longevity of Deutz engines.

Sealing ring with high sealing propertyExperience the quality of the sealing ring with the comparison number 606901280309. This product is an essential OEM spare part, specifically designed for reliable sealing in engines. As part of the gaskets, this sealing ring offers optimal sealing properties that have proven themselves in many applications.

Toric Seal for Optimal Function of Your EnginesOur toric seal is an essential product for the maintenance of your engines. It is suitable for a variety of Deutz engines, including models 816, CG170, and 628. The optimal fit and durability of these OEM spare parts ensure a perfect seat and prevent leaks. Each dimension has been carefully crafted: with a length and width of 5.9 cm and a height of 0.6 cm, the toric seal is ideal for use in various engine models.

Robust OEM Replacement Part: Hexagon BoltDiscover the hexagon bolt with the reference number 628/48/2/05033999, a significant OEM replacement part specifically designed for use in high-performance engines. This product is applicable in marine and stationary installations and is characterized by precision and reliability. The hexagon bolt ensures that all components work together optimally.Suitable Solutions for Deutz EnginesThe hexagon bolt is compatible with Deutz engines of model series 331, 493, 1163, 440, and 441. With the reference number 628/48/2/05033999, this product offers an ideal fit. Additionally, it fits the engine types 12V331TC92, 12V493, 20V1163TB93, TBD440-6, and TBD441. Weighing only 0.025 kg and with compact dimensions of 2.8 cm in length and width and 1.8 cm in height, handling and installation are significantly eased.

Excellent Replacement Part: Toric SealDiscover the toric seal as a top-quality product specifically designed to fit Deutz engines of series 440, 441, and 444. With the comparison number 604931040186, this is an OEM replacement part that meets high standards of quality and durability. Our OEM replacement parts are designed to support the optimal performance of your engines at all times.

Quality of the Plug-in Element in DetailDiscover the plug-in element with the comparison number 606901720301, an essential product for anyone working with MWM & Deutz engines. This OEM replacement part ensures optimal performance of your machines and significantly contributes to efficiency. Rely on the high standards associated with a product from the manufacturer.Perfect Fit for MWM & Deutz EnginesThe plug-in element is suitable for the renowned series of MWM & Deutz and has been specifically developed for use in engines of type TBD441. Weighing 3.375 kg, it meets high demands for stability and durability. Want to ensure that your engine runs reliably? Then this product is the right choice.

Valve Guide – Your Solution for Efficient EnginesDiscover the valve guide, a decisive OEM replacement part with the comparison number 12170625. This product is essential for the smooth operation of the valve train and ensures excellent performance in every application. Our valve guide has been specifically designed for use in diesel and gas engines, providing long-lasting reliability.Suitable for MWM & Deutz Engines: Optimal FitThe valve guide with the comparison number 12170625 is suitable for MWM & Deutz engines, particularly designed for the series 441. Its thoughtful design and precise dimensions—weighing only 0.25 kg with dimensions of 12.5 cm in length and width, and 2.6 cm in height—allow for easy integration into existing engine systems. Don’t waste time and rely on our top-notch OEM replacement parts.

Precise Product: Toric seal with comparison number 604931240503Discover our reliable toric seal, which offers excellent properties for diesel and gas engines. With the comparison number 604931240503, this OEM replacement part is your optimal partner for preventive maintenance. The toric seal is characterized by outstanding quality in its construction and is ideal if you are looking for a product designed for durability.Compatibility with Deutz Engine TypesThis toric seal is suitable for Deutz engines, including the series compatible with TBD441, TBD604-BV8, TBD616-V12, and TBD620-V16. It is tested quality for engines that must operate reliably. With dimensions of 5.8 cm x 5.8 cm and a height of 0.6 cm, this product is easy to install. For those who rely on their machines, its nature as an OEM replacement part ensures that you receive only the best for your Deutz engines.

Precise Product Description of the Rectangular Ring Our Rectangular Ring with the comparison number 605031512301 is an indispensable OEM replacement part specifically designed for use in engines. This product description covers all essential features of this piston ring. With a fit that you expect from top-quality OEM replacement parts, this Rectangular Ring is an ideal choice for your business.Compatible with MWM & Deutz Engines This Rectangular Ring is optimally compatible with MWM & Deutz engines. It expands the usability of the engine range series 441 and engine type TBD441. By using this product in your engines, you ensure maximum efficiency in marine and stationary applications.

Cylinder Head Gasket 12172375 – Ideal for Your NeedsDiscover the cylinder head gasket with the comparison number 12172375, perfectly suitable for the renowned manufacturers MWM & Deutz. This product is precisely designed for engines of the series 440 and 441, ensuring optimal sealing for your engine performance. This component is specifically compatible with MWM & Deutz engines and meets the highest quality standards through the use of OEM replacement parts.Product Features of the Gasket in DetailThe cylinder head gasket weighs only 0.083 kg and has the perfect dimensions of 27.6 cm in length and width and a height of 0.8 cm. These specific measurements and the lightweight design make it an extremely practical component that is easy to handle and integrates particularly well into various MWM & Deutz engines. Rely on our OEM replacement parts to ensure the quality and durability you need.

Introduction to the Big End Bolt: Component with PrecisionThe Big end bolt with reference number 644003530014 is an indispensable component, suitable for MWM & Deutz engines. As a quality-assured OEM spare part, it ensures a reliable and long-lasting connection within your engines in marine and stationary applications. Thanks to its optimal design, it fits perfectly into the series 440 and 441 as well as the specific engine types TBD440-6 and TBD441.Precise Design Suitable for MWM & Deutz EnginesThis Big end bolt is characterized by its first-class processing, making it the perfect product for mechanics and companies working with MWM & Deutz engines. Weighing 0.552 kg and having compact dimensions of 15.9 cm x 15.9 cm x 3.6 cm, this OEM spare part can be used under demanding conditions. The short delivery time of our products is specifically tailored to your requirements.

Quality of the Cylinder Liner 66-6440Discover the cylinder liner with the comparison number 66-6440. This product belongs to the group of crankcase parts and is an essential component that optimizes the performance of your engines. Use OEM replacement parts to ensure access to reliable components at any time.Suitable for MWM & Deutz EnginesThe cylinder liner 66-6440 is suitable for MWM & Deutz engines and compatible with model series 440 and 441, as well as engine types TBD440, TBD440-6, and TBD441. Weighing 50 kg, it demonstrates its durability, contributing to optimal functionality in various applications.

Premium Piston Pin – Comparison Number 12152379 Discover the piston pin, a top-quality product that perfectly meets your needs. With the comparison number 12152379, this piston pin significantly influences the performance of your engines. It belongs to the category of engine drive components and helps to enhance the efficiency of your engines.Technical Specification and Suitable Application The piston pin is compatible with MWM & Deutz engines, particularly suitable for the series 440 and 441. It also fits optimally with the engine types TBD440-6 and TBD441. Weighing in at a solid 9.2 kg, this replacement part brings the necessary robustness and stability required for marine and stationary applications.

Premium Gaskets for Precise FitDiscover our top-quality sealing ring replacement part with the comparison number 606901200149, an essential product that is perfectly suitable for MWM & Deutz engines. Through careful selection according to market standards, this OEM replacement part offers you optimal functionality that you can rely on.

Toric Seal: Suitable for Deutz Engines Discover our reliable product, the toric seal with the reference number 604931042186, which is specifically designed for Deutz engines of the series 440 and 441. This toric seal is an essential component to ensure the tightness of your engines and create optimal operating conditions. As an OEM replacement part, this product stands out for its highest quality and contributes to the efficiency of your engine, especially for the engine types TBD440, TBD440-6, and TBD441.

Bearing Bushing: Your Reliable OEM Replacement PartDiscover the bearing bushing, suitable for MWM & Deutz engines, with the comparison number 644004320104. This crucial product ensures your machines operate reliably, both in marine and stationary applications. It is manufactured to meet the specific requirements of engines from series 441 and upholds the highest quality standards, making it a valuable investment for your company.

Toric seal suitable for Deutz engines – Quality that convincesThe reference number 604931040724 stands for an efficient toric seal designed for a variety of Deutz engines. Our OEM spare parts are characterized by precise fitting and durability. With a diameter of 8 cm and a height of 0.4 cm, this product ensures optimal sealing of the systems in which it is used. Rely on compatibility that is designed for performance.

Piston Pin Comparison Number 644003110034 for EnginesDiscover the powerful piston pin with the comparison number 644003110034, a fundamental OEM replacement part specifically designed to meet the highest requirements in engine technology. The optimal fit of the piston pin enhances functionality when used for MWM & Deutz engines.