RBV8M545 marine engine – V8 power from the 545 series

The RBV8M545 is a proven V8 diesel engine that delivers dependable power and robust efficiency for maritime and stationary duty. Originating from the 545 series by MWM & Deutz, this medium-speed platform is valued for its long service life, strong torque curve, and straightforward maintenance concept. While the series context matters for identification, the spotlight here is squarely on the RBV8M545 itself—an engine type known among shipowners and plant operators for reliable output in propulsion and generator set applications.

RBV8M545 marine engine: design and operating concept

The RBV8M545 is a four-stroke, turbocharged V8 diesel engine with charge‑air cooling. Its compact V-configuration combines a durable cast-iron crankcase with a forged crankshaft and replaceable cylinder liners, achieving high structural rigidity and stable bearing loads under continuous operation. A gear-driven camshaft, mechanical fuel injection (commonly via inline pump or individual pump elements), and an efficient charge‑air cooler align the engine for consistent combustion quality across a wide load range.

In typical marine setups, the RBV8M545 integrates with jacket-water and seawater heat exchangers in a two-circuit cooling arrangement (HT/LT). This approach stabilizes thermal conditions at varying sea temperatures, protecting components and preserving clearances. Lubrication is secured via a high-capacity, gear-driven oil pump and full-flow filtration, with bypass filtration frequently included for extended oil cleanliness. The result is a diesel engine that is straightforward to service onboard and resistant to the kind of cyclic stresses seen in maneuvering, harbor work, or variable genset loading.

RBV8M545 technical characteristics and performance data

Depending on configuration and rating, the RBV8M545 typically operates in the medium-speed band, often between 900 and 1,500 rpm. Power output spans a broad range to suit propulsion or auxiliary roles, commonly from the mid-hundreds up to around one megawatt class. Total displacement for the V8 layout is usually in the 30–40 liter class, with two valves per cylinder being typical for the platform. The torque-rich character supports direct mechanical propulsion with reduction gearboxes as well as stable, low-vibration generator drive for 50/60 Hz onboard power.

Fuel system settings and turbocharger matching are decisive for the final rating, allowing operators to select duty profiles that prioritize longevity or peak output. In well-maintained condition, the RBV8M545 achieves fuel consumption in the low 200 g/kWh class under ISO reference conditions—appropriate for a mature, medium-speed marine engine. Common fuel types include marine diesel oil (MDO) and marine gas oil (MGO), with filtration and centrifuge systems recommended for cleanliness and injector protection.

- · V8, four-stroke, turbocharged with charge‑air cooling

- · Medium-speed operation for propulsion and gensets

- · Robust crankcase and replaceable cylinder liners

- · Mechanical fuel injection for predictable response

- · Strong low‑end torque and stable speed control

- · Flexible ratings to match vessel or plant demands

- · Service-friendly design for onboard maintenance

RBV8M545 applications in shipping and stationary power

Because the RBV8M545 balances output, fuel efficiency, and maintainability, it is widely used in workboats, coastal cargo vessels, passenger ferries, offshore support vessels, and fishing fleets. As a propulsion engine, the strong torque at modest rpm supports responsive acceleration and economical cruising. As a genset prime mover, the stable governor behavior delivers clean frequency control and low harmonic distortion when paired with appropriate alternators.

In stationary environments, the RBV8M545 is equally at home in continuous or standby power plants, emergency generator systems, and industrial drive packages for pumps or compressors. Operators value the engine’s predictable parts lifecycle, straightforward overhauls, and the broad technical knowledge base that exists for the 545 series. For fleet managers and purchasing teams, this translates into high availability, manageable lifecycle cost, and easy integration with existing service routines and spares inventories.

OEM spare parts suitable for RBV8M545: performance, reliability, service life

Using OEM spare parts suitable for RBV8M545 is essential to preserve combustion efficiency, emissions stability, and mechanical integrity over long operating hours. Tolerances in components such as pistons, ring sets, liners, injector nozzles, and bearings are calibrated to the RBV8M545’s geometry and load paths. When these parts match the engine’s design intent, operators see fewer unscheduled stoppages, better fuel economy, and consistent start-up behavior after maintenance.

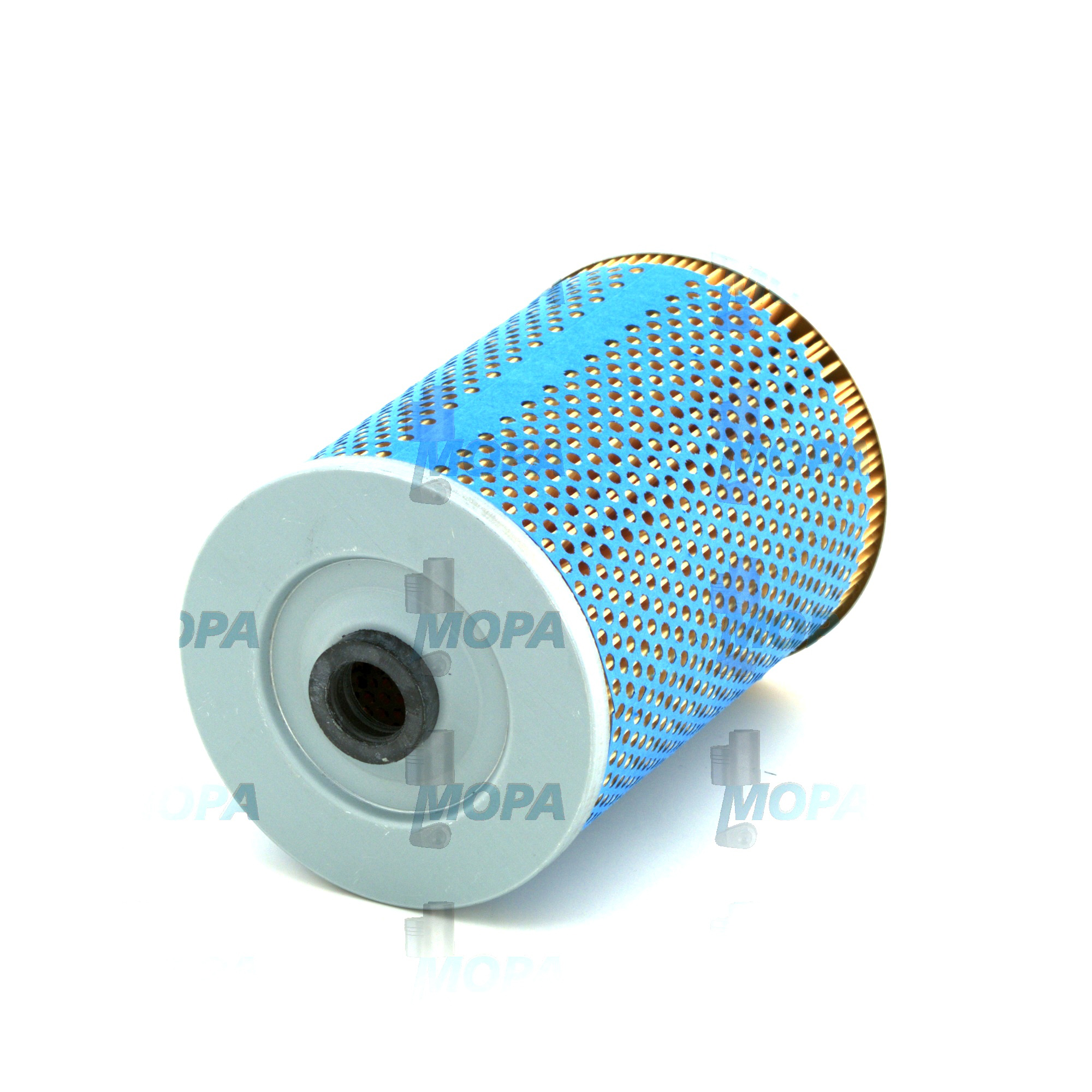

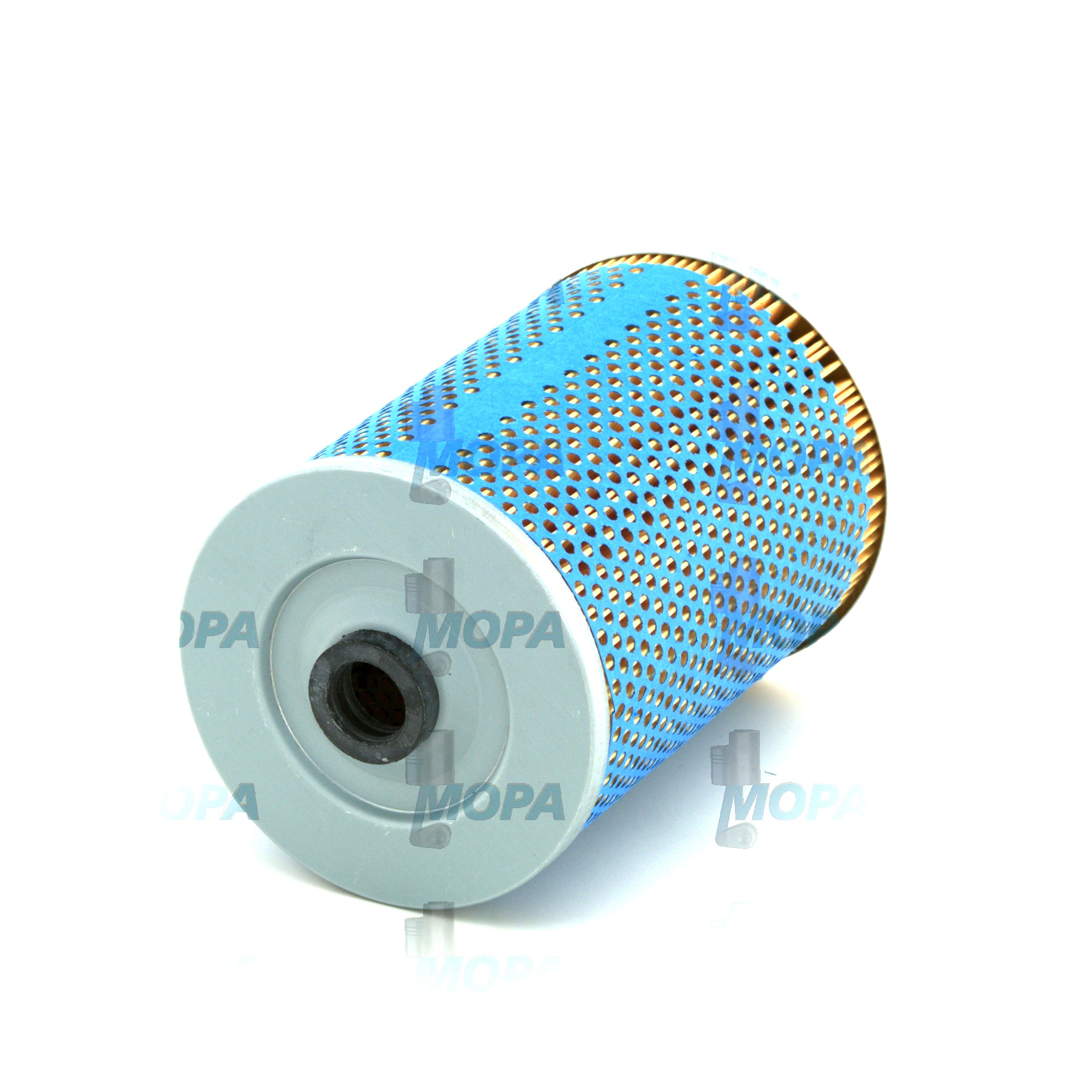

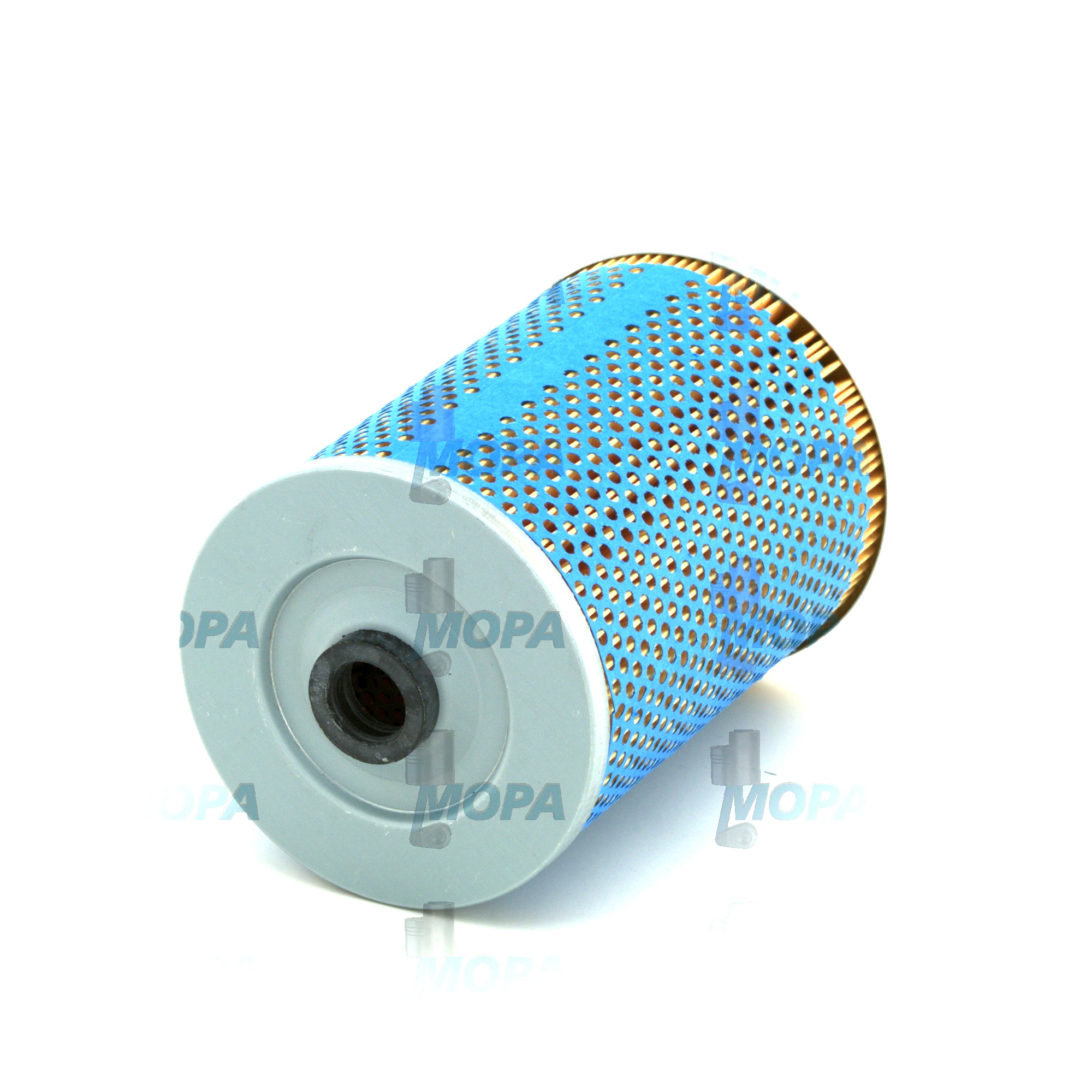

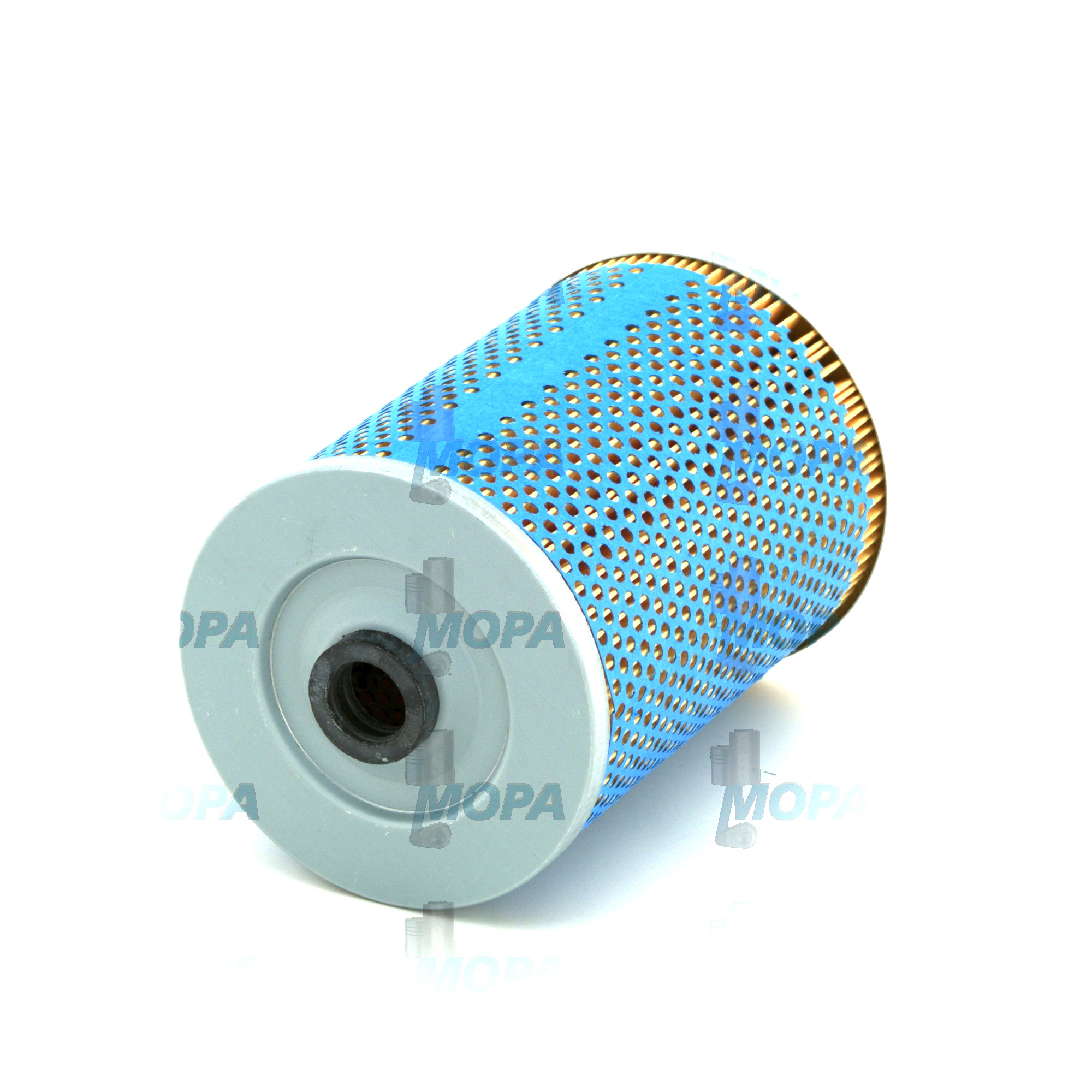

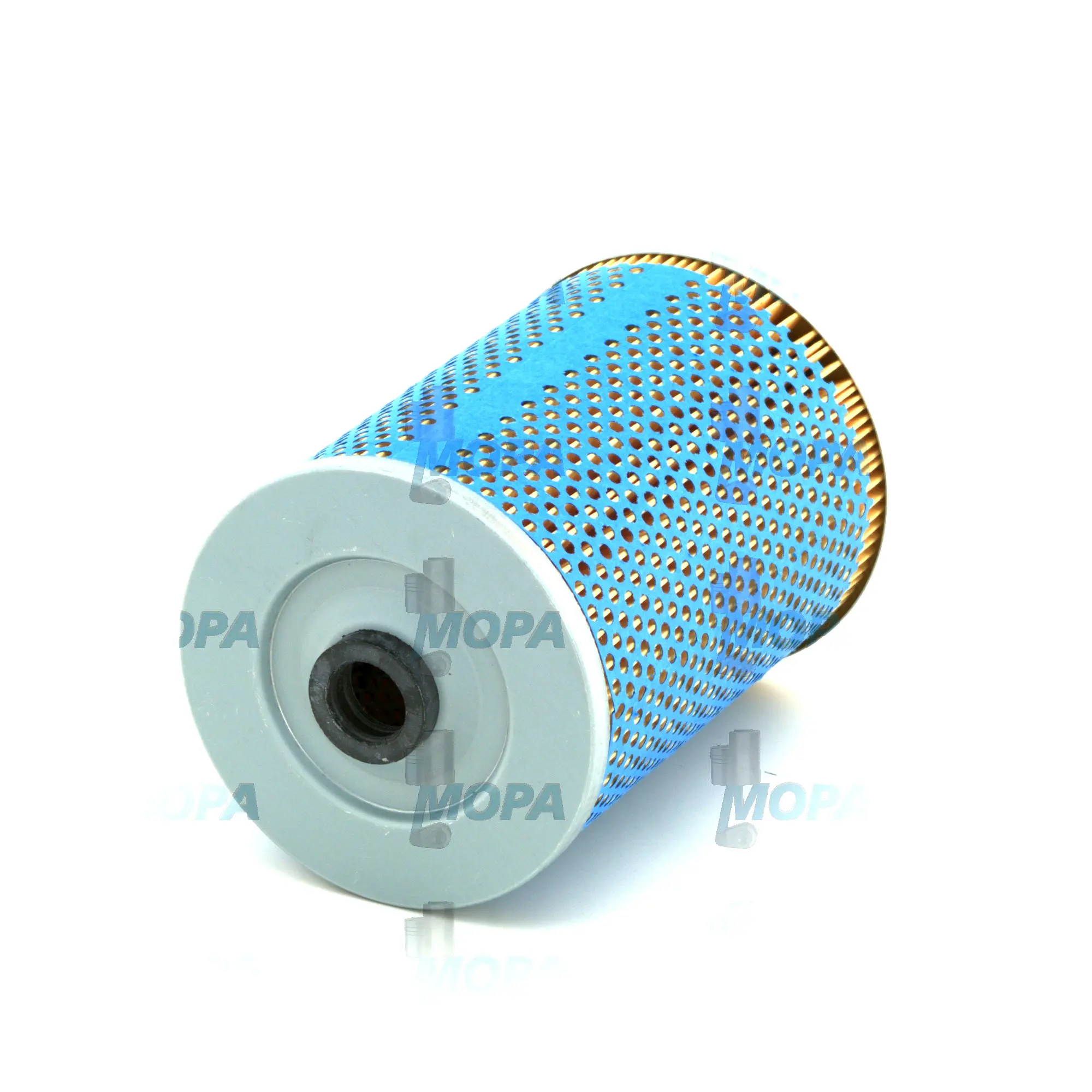

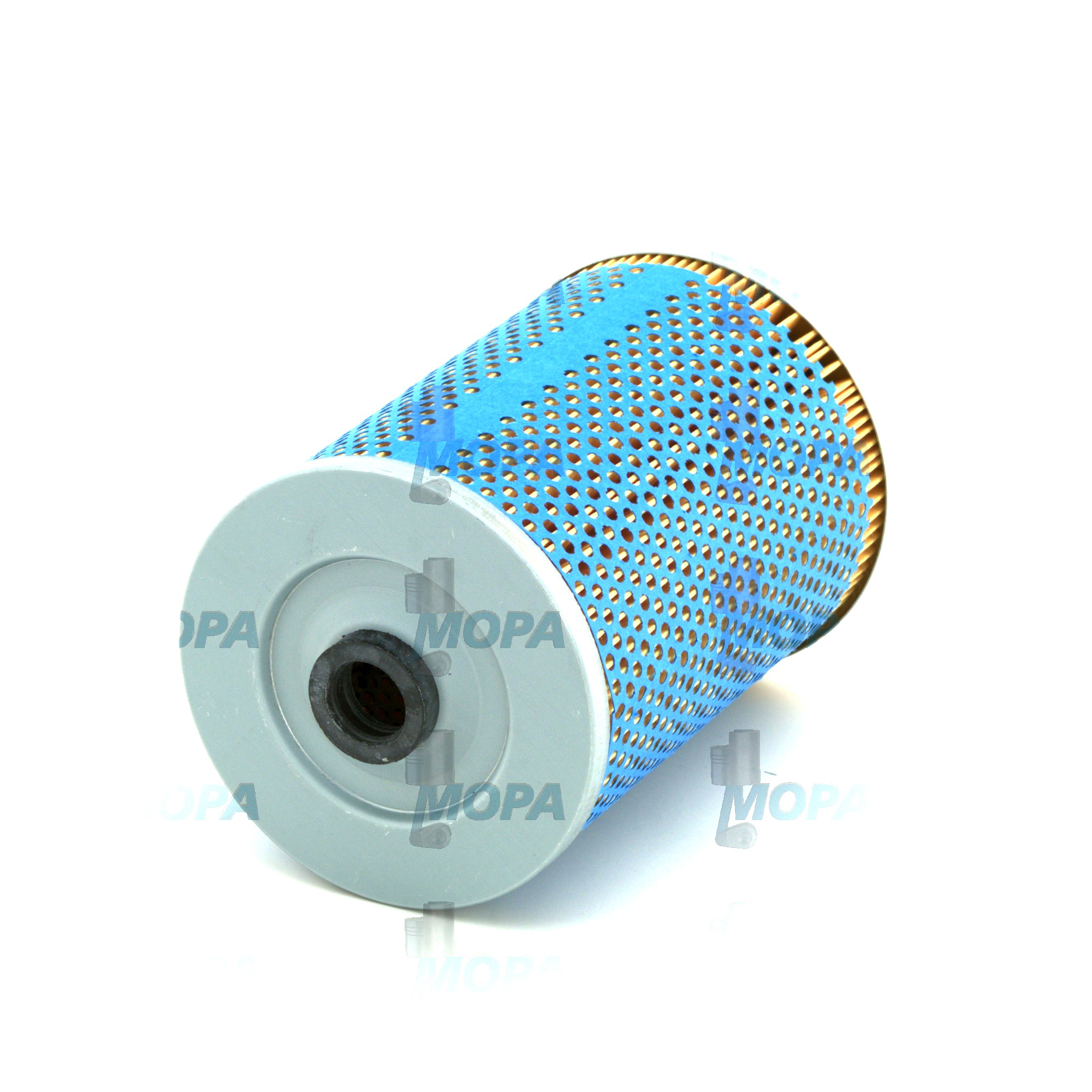

Typical RBV8M545 OEM parts categories include cylinder head components, valve train items, complete liner-piston-rod kits, main and big-end bearings, oil and cooling pumps, seals and gasket sets, charge‑air cooler elements, turbocharger service kits, governors or governor components, and filtration elements. Selecting OEM spare parts suitable for RBV8M545 maintains correct clearances, surface finishes, and materials (for example, ring metallurgy and coating systems, or bearing overlay compositions) that are crucial for long service life under marine loading cycles.

MOPA is a reliable partner for OEM spare parts suitable for RBV8M545. The scope covers critical wear components and overhaul kits as well as ancillary items to keep the RBV8M545 diesel engine operating at specification, whether installed in a vessel propulsion line or a stationary power unit. With MOPA, procurement teams benefit from technical support, traceable sourcing, and delivery solutions tailored to dock schedules and planned maintenance windows.

Why operators choose the RBV8M545 diesel engine

The RBV8M545 is appreciated because it combines a time-tested mechanical core with adaptable ratings and broad application coverage. For buyers seeking a dependable RBV8M545 MWM & Deutz marine engine, the platform offers robust torque, manageable fuel consumption, and an accessible maintenance concept. When paired with OEM spare parts suitable for RBV8M545, operators can extend overhaul intervals, protect major components, and sustain output across diverse duty profiles. For search relevance and procurement clarity, terms like “RBV8M545 OEM parts,” “RBV8M545 marine engine,” and “RBV8M545 MWM & Deutz diesel engine” help identify the exact engine type and support ecosystem.

Conclusion: RBV8M545 value and parts supply

The RBV8M545 delivers dependable V8 performance, proven medium‑speed efficiency, and a maintenance-friendly design for both marine and stationary applications. Its strengths—torque, durability, and flexible ratings—make it a practical choice for shipowners and plant operators.

MOPA supports long, reliable operation with OEM spare parts suitable for RBV8M545, ensuring fit, performance, and consistent service life across the complete maintenance cycle.